Guillotine shears – sheet length 3150 mm

| MODEL | MAXIMUM LENGTH OF SHEET, MM | MAXIMUM SHEET THICKNESS, MM | MAXIMUM LENGTH OF CUT STRIP AT STOP, MM | KNIFE STROKES PER MIN | DIMENSIONS, mm | WEIGHT, KG |

| NA3225 | 3150 | 32 | 1000 | 3.5 | 5185x3700x2950 | 33950 |

| NA3224 | 3150 | 25 | 1000 | 3.5 | 5155x3630x2850 | 31200 |

| NA3223 | 3150 | 20 | 1000 | 3.5 | 5100x3550x2760 | 27850 |

| NA3222 | 3150 | 16 | 1000 | 10 | 4920x3360x2400 | 24000 |

| NA3221 | 3150 | 12 | 1000 | 12 | 4615x2075x2190 | 15800 |

| NA3218 | 3150 | 6,3 | 630 | 20 | 4220x1680x1720 | 7200 |

| NG3418-01 | 3200 | 6 | 500 | 8 | 4100x1580x1960 | 5050 |

Technical characteristics of a manual guillotine for metal

The segment of manual guillotines for working with metal is mainly represented by saber-type units. Their design is based on a small panel or platform that holds the base, and the actual cutting is performed by a movable knife. As already noted, manual guillotine shears can handle sheets up to 2 mm thick. As a rule, in the case of stainless steel this figure is 1.5-1.7 mm. However, aluminum sheets can be cut with such a tool even with a thickness exceeding 2 mm. True, the cutting length is still noticeably inferior to full-fledged machines - in standard families the maximum reaches 1300 mm. On the other hand, such models benefit from their compact size and low weight, which rarely exceeds 100 kg. Accordingly, the manual guillotine can be transported around the work site to different points during installation operations, which simplifies the production and construction process.

Guillotine shears – sheet length 2000 mm

| MODEL | MAXIMUM LENGTH OF SHEET, MM | MAXIMUM SHEET THICKNESS, MM | MAXIMUM LENGTH OF CUT STRIP AT STOP, MM | KNIFE STROKES PER MIN | DIMENSIONS, mm | WEIGHT, KG |

| NG-20M | 2000 | 20 | 1000 | 6 | 2870x2250x2350 | 9300 |

| H478 | 2000 | 18 | 1000 | 20 | 3150x2275x2350 | 11 000 |

| NA3122 | 2000 | 16 | 500 | 60 | 3325x1950x2375 | 8000 |

| NG-16 | 2000 | 16 | 500 | 3145x1920x2225 | 6900 | |

| NG-13 | 2000 | 13 | 500 | 3100x2000x2250 | 5600 | |

| NA3121 | 2000 | 12 | 500 | 40 | 3390x2300x2345 | 7500 |

| H3118 | 2000 | 6,3 | 900 | 55 | 3160x1930x2175 | 5100 |

| NK3418 | 2000 | 6,3 | 700 | 25 | 2780x2050x1510 | 4250 |

| NK3416 | 2000 | 4 | 700 | 25 | 2610x2050x1510 | 2870 |

| H3116 | 2000 | 4 | 450 | 40 | 2850x2050x1850 | 4500 |

| ND-3314G | 1600 | 2,5 | 700 | 34 | 2300x1570x1470 | 2000 |

| NG1250 | 1250 | 1 | 1550x1240x1070 | 380 |

Engine characteristics

The operational capabilities of a guillotine machine are directly determined by the potential of the power plant, which provides the function of the knives. To begin with, you should divide the machines into models operating from a network of 220 and 380 V. Power is the main indicator of the unit’s performance and is usually 3-4 kW. This potential makes it possible to confidently handle thick sheets at high frequencies. By the way, the torque at which hydraulic guillotine shears operate can be 1200-1500 rpm. Here it is important to note the dependence of the electric motor on the design. So, the wider the cutting capabilities, the higher the power potential of the drive should be.

Design

Each model of guillotine shears includes the following components:

- all-welded frame. Performs the function of a stable base to which all other nodes are attached;

- Desktop. Intended for placing sheet blanks;

- pressure beam. Provides strong fixation of the processed material;

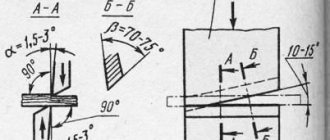

- knife beam. It has a vertical feed type. The cutting angle is set according to the sheet thickness;

- drive unit. Can be hydraulic or crank-lever.

Types of guillotines for metal cutting

Conventionally, the group of guillotine cutters can be divided into three segments. The first will include the most powerful electrical machines that operate on a drive mechanism and include a full-fledged motor in the device. These are the most powerful guillotine shears, with which you can cut metal sheets in production flow mode. Next comes the intermediate category of cutters, whose representatives do not have an electric drive, but also have a massive active element in the form of a cutter and a bed, the presence of which unites such models with the first class of planes.

If we are not talking about complex operations that are planned to be performed in large volumes, then it makes sense to use compact and low-maintenance cutters. These are manual guillotine shears, the design of which is maximally optimized for quick work with small workpieces. With this tool you can cut a small metal sheet to the desired size, spending a little effort on it.

Our offer

LLC SO "PRESSMASH" produces guillotine shears equipped with a hydraulic drive and CNC. The presence of software control allows you to quickly calculate the following parameters for each sheet:

- gap between blades;

- the angle at which the knife edge should be positioned;

- length of strip to be cut.

The calculation is made based on the entered data: sheet thickness and type of material. The hydraulic drive ensures rigid fixation of the workpiece with a pressure beam along its entire length, thereby guaranteeing high cutting accuracy. All guillotine shears of SO "PRESSMASH" LLC are equipped with steel blades. At the request of the customer it is possible to equip with additional devices.

To buy or find out the price of equipment, contact us by phone, request a call back or send an email to our email address. To receive a commercial offer, fill out the appropriate form on the website. You can first consult with our specialists by leaving them a message in the online chat.

Main characteristics of guillotine shears

Performance characteristics are the main criterion for choosing guillotine shears. One of the main parameters is the force with which the equipment and, in particular, the knife acts on the workpiece. Thus, the average value for power load for machine-made models is about 5-7 kg/mm2. Next, the width and thickness with which the guillotine shears work is taken into account. The characteristics of the machine equipment allow cutting sheets with a thickness of 0.5 to 3 mm. For hand tools, this figure rarely exceeds 2 mm. The width of the cut also matters in the work process. Depending on the model, this value can vary on average from 1000 to 1500 mm. The frequency of operations affects the overall productivity of the guillotine and is usually around 60 cuts per minute.

Design features of scissors

The most ordinary guillotine necessarily consists of a strong frame on which there is a feed table, as well as a graduated stop. In addition, the lower blade is attached to it.

A movable beam on which the upper blade is located is specially fixed to the frame.

The primitive machine is also equipped with a clamping device and a depth limiter that controls the supply of metal.

Quite common are units that are additionally equipped with a return tray designed to collect finished material.

In the photo below you can see the simplest manual guillotine device.

Electric machines are additionally equipped with a beam, which serves as the main mount for the engine. In addition, it houses a gearbox connected in a special way to the shaft.

Also, such units have crank devices and a brake drum. In this case, both the upper and lower knives are placed on a special traverse.

Hydraulic guillotines, in turn, are equipped with a hydraulic drive, which allows cutting metal of almost any thickness.

Such devices are capable of transmitting high-power force to metal, despite the fact that human physical participation in their operation is minimized.

If it is necessary to make straight cuts, use scissors, which are usually mounted on a durable frame.

Their movable knife can move only in one direction and plane, and in any case the angle of inclination remains unchanged.

IMPORTANT TO KNOW: How to make a pendulum saw for metal with your own hands?

If necessary, knives are sharpened, which can be either single-sided or double-sided.

It is recommended to use guillotines for cutting metal that are equipped with a special mechanism that is capable of firmly fixing the sheet workpiece.

Professional devices are often equipped with locking mechanisms that are electrically or hydraulically driven.

The characteristics of guillotines mainly depend on their functionality, despite the fact that the operating pattern is always the same.

Consumables and components

In addition to guillotine equipment, manufacturers offer processing tool kits, personal protective equipment and control equipment. From the point of view of performing the main cutting operation, it is important to have high-quality diamond needle files on hand, which are most often used for metalworking operations with metal, as well as tiles and glass. These devices will help if the main work is performed by mechanical guillotine scissors, which do not allow obtaining a neat cut. In other words, needle files will make the edge better and smoother. Also, to adjust guillotine machines, sets of appropriate keys should be provided. Typically, an all-metal bench square is used for this purpose. As for personal protective equipment, the operator of an electrical machine must be equipped with it. The basic set includes: gloves, a filtering half mask, goggles and noise protection headphones.

Reviews about manufacturers

The guillotine equipment segment is not as widespread as more technological and at the same time expensive devices for high-precision metal cutting. However, there is a choice. In particular, on the domestic market these products are represented by the brands Stalex, Anchor, MetalMaster, etc. The Stalex brand produces machines of good build quality that can handle hard grades of steel. This is largely due to the use of high-quality high-carbon cutters in the design of the machines. In addition, the welded design increases the reliability of the installation as a whole, therefore, the repair of Stalex guillotine shears is also delayed. As the users themselves note, after a long period of operation, only the sheet clamping mechanism and the system for limiting the depth of material supply will have to be restored. As for the models from and MetalMaster, they are mainly represented by manual reciprocating cutters with a simple design and convenient control mechanism. The only problem with operating such tools is the shortage of replacement knives, which is what equipment owners most often complain about.

Types of guillotines

For cutting thin material, manual guillotines are usually used.

In turn, if it is necessary to cut material with a large thickness, electric or hydraulic shears are used, which have a solid housing and increased strength characteristics.

The simplest types of devices include manual guillotines, which are equipped with a lever mechanism. In turn, hydraulically driven guillotines have a more complex device.

They have a capital body and a massive structure of complex configuration.

The main characteristics of their work are distinguished by the high accuracy of the resulting cut.

Also, mainly in production, electric and electromechanical guillotines are used, which have optimal reliability characteristics and are capable of providing high-quality cutting of material.

In addition, in industrial enterprises you can find knives with pneumatic drive. The operation of all types of guillotines is similar in principle.

In the photo below you can see a pneumatic guillotine, which is capable of providing high precision cutting of parts.