Types of cutting discs

metal disc from Vulcan

Among the many consumables for grinders, the most common are metal cutting discs. They are somewhat cheaper than their stone or concrete counterparts and are usually painted blue. The difference lies in the type of abrasive material: coarse chips or crushed diamond. To polish metal, special nozzles coated with fabric are used.

Consumables vary in size, thickness, coding and price. All this data is indicated on the front surface of the cutting disc.

Typical disk sizes for angle grinders

All interchangeable wheels have standardized sizes, so for any model of grinder you can choose a suitable size disk, even if it is “non-original” (from another company). The table below shows the typical dimensions of cutting discs in terms of thickness, diameter of the circle and seat:

| Circle diameter, mm | Thickness, mm | Mounting socket, mm |

| 115 | 1,0; 1,6; 2,0; 2,5; 3,0; 3,2 | 22,00; 22,23 |

| 125 | 0,8; 1,0; 1,25; 1,6; 2,0; 2,5; 3,0; 3,2 | 13,20; 22,23 |

| 150 | 0,8; 1,0; 1,25; 1,6; 2,0; 2,5; 3,0; 3,2 | 13,20; 22,23 |

| 180 | 1,0; 1,25; 1,6; 2,0; 2,5; 3,0; 3,2; 4,0 | 22,23; 32,00 |

| 230 | 1,6; 2,0; 2,5; 3,0; 3,2; 4,0 | 22,23; 32,00 |

The larger the diameter of the circle and its thickness, the thicker the products it can cut. Please note that the diameter of the disc should not exceed the permissible size for a particular grinder model. Thus, a 230 mm disc cannot be placed on an angle grinder with a maximum allowable wheel size of 125 mm. Such actions will force you to remove the protection, which is a violation of safety regulations, and will lead to an increase in the linear speed of the cutting edge, which is why the disk can simply fly apart during operation and injure the operator.

The diameter of the seat in most grinders is 22.23 mm, 13.20 mm is less common, and the diameter of 32.00 is relevant only for large disks. Pay attention also to the linear speed of rotation of the disk. For example, if the disc’s marking indicates a speed of 13,000 rpm, this means that your grinder must also produce such revolutions in order to work with it.

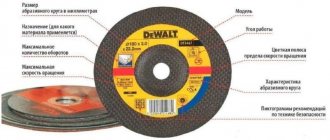

You can understand what material the nozzle can work with and what its typical dimensions are by looking at its markings on the front side. If you came to the store and picked up the disc, you can see the following:

We would like to note that sometimes the buyer may encounter non-standard nozzle sizes, and this may apply to both diameter and thickness. This often happens when purchasing “no-name” disks of unknown manufacture. We still recommend buying branded discs, since unknown ones are erased faster, and in the end you have to pay more.

Selection by size

The outer and inner diameters of the circle are indicated on the main surface of the consumable. There are 9 standard external sizes from 125 to 500. The indicator is selected taking into account the class of the angle grinder. It is strictly forbidden to work with a larger circle. Only for large professional tools can you purchase consumables of any diameter.

The inner or bore diameter must match the size of the drive shaft. Most shafts are produced with a diameter of 22 mm, so 22.2 mm is an almost universal mounting diameter. Both sizes must fit the instrument model!

Selection by thickness

It's much easier to cut with a thin circle. Indeed, when cutting into metal, a thick cutting disc experiences powerful resistance; more effort will be required to overcome it.

The cut with a thin disk is more accurate, and the work goes faster. The working surface heats up less, so it lasts longer. Thin circles are considered to be up to 1.2 mm thick, compared to the standard 2.4-2.5 mm with a diameter of 125 mm. The thickness of the disc is directly proportional to the diameter!

This option is suitable for small grinders with batteries or low power, allowing you to save energy.

There is an opinion: the thinner the consumable, the more fragile it is. This is nothing more than a myth. Any cutting disc is reinforced from the inside with non-woven fabric, so the safety of work depends on compliance with the rules, and not on the thickness of the consumable.

Thickness of cutting wheels

Wheels with a large thickness are more often used for sharpening/grinding, and with a fine thickness (i.e. thin) - for making cuts/cuts. However, the minimum thickness of the disk will not be less than 0.8 millimeters, and the maximum will not exceed 4 millimeters. When choosing disks by thickness, you must be guided by the following categories:

- To achieve an effective result when cutting, you will have to put in less effort and spend less time if the equipment has a small thickness;

- In cases where a thick circle is used, doing quality work will require more time and more effort.

However, some experts still prefer discs with greater thickness, justifying their choice by the fact that they have increased strength and are less susceptible to destruction. However, practice shows the opposite: cutting metal with a thin disk is much safer, but before starting work it should be selected properly. Safety is justified by increased elasticity, with the possibility of their unhindered bending in the absence of irreparable deformation, which nozzles with large thickness cannot boast of.

Encoding

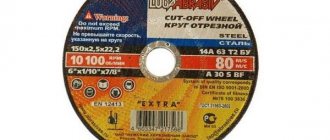

The circle specification is encoded in four characters, Latin letters and numbers:

- the first letter indicates the material of the abrasive chips: AS - white electrocorundum, it is suitable for working on stainless steel, because the alloy contains practically no chlorine, sulfur and iron, which increase the cutting temperature; A - electrocorundum; C - silicon carbide - such circles are used to cut tiles and stone, but not metal;

- number - indicates the number of abrasive grains per unit area. The higher the number, the smaller the particle size. For cutting steel, larger grains are used - 24, 30; for working on soft non-ferrous metals, smaller ones - 60 or 40;

- the Latin letter is the hardness of the ligament. The first letters of the alphabet are the softest letters, the further from the beginning the harder. The softest bonds are selected for processing the hardest metals! You need to know this important ratio when choosing consumables for an angle grinder. During cutting, worn particles fall off and new ones, not yet dulled, come into play. If the bond is too tight, the cutting disc becomes “greasy”: it heats the metal and makes cutting difficult. At the same time, a circle with an overly soft bond wears down faster;

- the last Latin letter (or pair) is the name of the binding material, most often bakelite. Denoted as BF.

Marking of cutting discs and its meaning

Any cutting equipment for angle grinders must have accompanying markings, which reflect all the most necessary technical data. Only knowledge and ability to decipher the meanings indicated there will help you choose the appropriate type of nozzle. Below is the basic information that is required:

- The manufacturer's name is indicated at the very top.

- The size of the internal diameter (seat ring), thickness and outer diameter are marked directly under the seat hole and can be as follows: “180 x 1 x 22”.

- The material of objects on which it is possible to apply a circle. Typically, the inscriptions are made in Latin, for example, Metal - for abrasive models, Steel - cutting steel, Aluminum - cutting aluminum and other non-ferrous metals, Inox - stainless steel, Castrion - cast iron and cast steel. There are also universal samples on which the functionality is designated “Uni”.

- Types of nozzles that indicate the design features of the mounting hole. A flat circle is designated by the numbers “41”, which has an offset to one side – “42” (this is how sharpening and grinding attachments are usually marked).

- Bond material – refers to vulcanite, bakelite or ceramic base. On Russian models it is designated by two letters, for example, “BU” - “reinforced bakelite”. The same marking in English looks like “BF” - “Bakelite forced”.

- Type of material for making the circle. The letter “A” means electrocorundum, the letter “C” means silicon carbide. Before the letter there should be numbers indicating the size of the fragment (grain).

- Hardness is reflected in the letters “M” and “T” and must be followed by the corresponding hardness index.

- Maximum operating speed - it depends on the type of reinforcing ligament. For bakelite this parameter is set in the range from 80 to 100 meters per second, for vulcanite this indicator varies from 50 to 80 meters per second. The overall speed of work will depend on the rotation speed.

- Shelf life is the most important parameter responsible for the overall usability of the disc. Nowadays, few people pay attention to this period, which, in turn, often leads not only to the breakdown of the tool itself, but also to injury to the operator. Therefore, this parameter must be checked before purchasing. It is indicated in the form of month and year and is located on the steel part of the seat ring. If this period has expired, or there is less than a month left before its expiration, then the use of such an attachment is strictly prohibited.

IMPORTANT! In addition to the basic information, other data may be indicated on the front of the disk, at the request of the manufacturer. These may include the names of GOST, in accordance with which the wheel was produced, its imbalance class, sound index and similar optional information.

Price and manufacturers

metal disc from Hitachi

For rare household jobs, cutting discs from the low price category are quite suitable: “Sparta”, “Zubr”, “Tsentroinstrument”. With occasional use they will last quite a long time.

The quality of the abrasive material is not bad, the price is reasonable. The main thing when working with consumables of this class is not to work for a long time without breaks. If the circle stops sawing, it is cleaned with red or yellow brick.

Professional metal discs cost 3 times more. But only they are suitable for industrial use. These are consumables, “Distar”, “Hitachi”. They withstand daily work with the most difficult materials. Professional circles, as a rule, are intended to work with a specific material: reinforced concrete, granite, tiles, steel, non-ferrous metals.

Video with a metal cutting disc test:

Which grinder wheels are “so-so”, and which ones are good and last a long time.

For many people who have just bought an angle grinder, the problem of choosing cutting wheels arises. An angle grinder is a multifunctional tool; it can perform various types of work, and, accordingly, all kinds of circles and attachments for it. Let's figure out what kind of work can be done with a grinder and what disk attachments are used for this. This article will focus on cutting wheels.

Of course, most often a grinder is used when something needs to be cut; 70 percent of the work is cutting work. You can cut anything with a machine, from metal to various tiles and even wood. Of course, when using an angle grinder, carefully read the instructions, since many household models are not designed for sawing, for example, stone, since sawing dust clogs the grinding machine mechanism and it fails. In particular, models from the Sturm company, in the passport of which it is written in black and white that they should not be used for sawing stone. Therefore, when choosing an angle grinder, ask whether it can cut stone. After all, very often when doing household work it is necessary to saw ceramic tiles or cut off a piece of brick. So, what kind of cutting wheels are there?

For metal.

Sawing metal is the main use of an angle grinder. There are a great many types of cutting wheels for metal. Most often they use wheels from the Luga plant, although they are of so-so quality, they wear out quickly and a lot of dust is released when sawing. But their price is low, so they are used very often. The plant also produces an improved version of these wheels under Hitachi license; these wheels are 10-15 percent more expensive, but the quality is noticeably better. If a regular circle of size 230 mm costs 38 rubles, then the same Khitachevsky one costs 45 rubles. In appearance, the Hitachi circle cannot be confused with a regular one; it is all bright green.

The main standard sizes of metal circles for an angle grinder: Internal hole 22.2 mm External diameter: 115, 125, 150, 180 and 230 mm. As you guessed, discs with a diameter of 115 and 125 mm are used on small angle grinders, 150 and 180 - on medium ones, 230 mm - discs for large angle grinders (power from 1500 watts and above).

Also note: Vulcanite wheel - ideal metal polishing

By stone.

Stone wheels are used for sawing brick, concrete, slate, porcelain stoneware, ceramic tiles, and paving stones. There are diamond cutting stones and dry cutting stones; the price difference between them is high. An ordinary disc for stone (Luga abrasive, Bosch) - looks the same as a disc for metal, only it says on it that it is for stone. Such discs cost much less than diamond ones, but they wear out faster. Can be used on white (silicate) brick, paving stones, slate. They can no longer take concrete, as well as tiles, for cutting which you simply need a diamond blade. Note that a Boshev stone circle costs about 100 rubles, a meadow circle costs 40 rubles, the difference between them is noticeable.

Diamond wheels are divided into 3 types: for dry cutting, for wet cutting and combined. Such discs are made of iron, with a diamond layer applied around their circumference.

For dry cutting (segmented).

It is divided into segments along the entire circumference, thanks to this there is much better cooling of the circle. You, of course, know that when sawing stone, the cutting blade gets very hot, so it is necessary that it be cooled. By the way, you can cut with a diamond disc for no more than 2 minutes continuously, so the diamonds will not fail. Red brick, white silicate brick, and paving stones are cut in this circle. The main purpose is sawing concrete. Of course, you can also cut tiles with it, but it is better to use a wet cutting disc for it.

Wet cutting disc.

Solid diamond wheel, the wheel is cooled with water. Most often they are used on special tile cutters - electric machines with water supply. Ceramic tiles and porcelain tiles are cut on them. For grinders, there are also such circles; they are used to saw tiles, which are pre-moistened with water. Standard sizes for grinders - internal diameter (fit) 22 mm For tile cutters - 2 types of fit, 22 mm and 25.4 mm.

Combined diamond cutting wheel dry/wet - “Turbo” series.

A universal diamond wheel with which you can cut any stone. It has proven itself to be excellent when cutting tiles “dry”; it cuts brick, concrete and other stone like clockwork. Cooling occurs due to the wave-like structure of the disk.

Another note: Carbide drill - we work on brick and concrete

Manufacturing companies

Let's figure out which diamond wheels are better, because it often happens that you buy a wheel and hope that it will last a long time, but after a short period of time it no longer cuts. Discs, just like power tools, can be professional or household.

Inexpensive discs for home use

You need to saw off a piece of brick or cut off a couple of tiles - for this, discs are for household use. Good options: “Sparta”, “Tsentroinstrument”. The quality of their diamond is not bad; if you use such a wheel infrequently, for household purposes, it will last for a long time. The most important thing is to use the diamond correctly, namely, you cannot saw metal, you cannot work continuously for a long time. If the circle does not cut, it is necessary to “open” the diamonds by making several cuts on fireclay (yellow) or red brick. The price for a diameter of 230 mm is around 500 rubles, 115-125 mm is 150-200 rubles.

Professional circles

If you have a production facility, even a small one, household discs will not last long, so you need to think about purchasing a professional tool. The price for them is high, about 3-4 times higher than for household ones. However, the durability is impressive. I remember when I was working as an engraver-mason, we sawed granite all season in one circle, every day. And he survived. There was that circle from the DISTAR company - the coolest, in my opinion, professional diamond discs. Therefore, if you have a production facility, you are engaged in laying tiles, paving stones and, as part of your line of work, you cut stone every day, then it is difficult to find a better choice than Distar discs. I definitely recommend it.

The approximate cost of such a 230 mm circle is around 2500 rubles. I note that they have a clear gradation of discs - there are pure ones for marble, for granite, porcelain stoneware, ceramic tiles, fireproof ones, for concrete, for reinforced concrete. So everyone will find a disk specifically for their work. And this is very important, because if you use the disk for its intended purpose, its service life will be significantly extended. Well, the sizes of disks from the Distar company are simply super - starting from 115 mm for a small grinder and ending with large circles for machines and wall chasers - sizes 350 and 400 mm.

Another note: How to drill holes for hinges? Forstner, of course!

Also, as an alternative, you can try Bosch wheels, they are also praised.

I think my review will help you choose the right diamond cutter for your needs, and the recommendations will extend the life of the wheel. Good luck with your cutting))

Review and comparison of cutting wheels

| Model | Outer diameter, mm | Thickness, mm | Price, rub |

| LUGA-ABRAZIV 115Х1.6Х22 А40 | 115 | 1,6 | 17 |

| KRATON 1 07 02 026 | 115 | 1,6 | 23 |

| ATTACK 1458910 | 125 | 1,6 | 56 |

| DEWALT DT42301-XJ | 125 | 3 | 89 |

| BOSCH Expert for Inox 180Х2,0Х22 | 180 | 2 | 110 |

| STOMER CD-230T | 230 | 1,8 | 235 |

LUGA-ABRAZIV

CRATON

ATTACK

DEWALT

BOSCH

STOMER