Victor, Rostov-on-Don asks a question: Good afternoon! I make furniture, including those with forged elements (legs, backs, tabletops).

Sometimes for my work I buy a twisted pipe, which I use as legs for tables and chairs. Can a twisted pipe be made with your own hands? The expert answers: Azhur and Decor machines are currently one of the most popular pipe bending machines. Buying them is more expedient than making them yourself. Making a twisted pipe with your own hands is not a difficult task, especially for a person who has the appropriate skills.

The main problem for a private entrepreneur or a small company is that the production of such a product is carried out on a special machine, the cost of which can reach several hundred thousand rubles. At the moment, the most popular machines are “Azhur” and “Decor”. It is enough to make such a machine yourself difficult. If you actively use twisted pipes in your work, then perhaps it makes sense to purchase such equipment. Working with the machine does not require special training. The operator needs to determine the required position of the sliders using the adjustment nanogram.

Each position corresponds to a certain pipe thickness. The design features of the machines allow the use of workpieces with a diameter of 1 to 15 cm. Then you should rotate the screws and place marks on the slides opposite the corresponding ruler divisions on the working plate of the equipment. After this, you can turn on the machine.

Thanks to the adhesion to the moving rollers, the workpiece begins to rotate clockwise, resulting in a finished product - a twisted pipe. The productivity of the most popular machine models is 120 m/h. Such equipment makes it possible to produce twisted pipes with a coil angle of 35, 45, 55 and 90°. Share a useful article: Similar articles:

Quite often, twisted pipes can be found in various fields of application. What are they for, what is the process of making them?

These products are used mainly for decorative purposes. Moreover, they do not always perform the function of a specific conductor of any liquid. Let's take a closer look at the scope of application of pipes, as well as the features of their production, the ability to do the work yourself, and what the homemade material will look like, and whether it is worth spending additional effort and money on making a machine.

Application

The twisted pipe making machine is a useful thing in various fields. For example, it can be used in furniture production, oddly enough.

This is because twisted pipes can be used as structural elements of various furniture options. Modern furniture production technologies mean a non-standard approach and the use of high-quality and reliable materials. Twisted pipes in the furniture industry can be found as elements:

- tables; chairs; legs of upholstered furniture; bar counters; shelves; beds; shelving.

Having a small furniture production, a machine for making twisted pipes can give a new round in production: give rise to fresh ideas, expand the range of products.

Another industry where you can often find twisted pipes is construction, or rather the design of the exterior and interior of a building. In the first case, supports for a canopy, porch fencing, railings for stairs, balcony posts and much more can be made from twisted pipes; in the second, pipes have also found application.

They can form a composition to decoratively complement the design, for example, as a stand for flowerpots. The machine for the production of twisted pipe will be useful in the production of stairs, structural decorative and functional elements of buildings. It can also be used in the production of awnings and gazebos.

In some cases, heated towel rails are made from twisted pipes.

Due to the fact that the pipe is made of metal, it can be used as a cavity for filling with hot liquid, water or oil. And the twisted shape will create a more original appearance. Moreover, such pipes can be coated with special heat-resistant paint - this will provide additional solutions for bathroom design.

To make a twisted pipe machine with your own hands, you need some engineering and technical knowledge. The main thing in do-it-yourself production will be the correct drawing up of drawings. Only correctly calculated and executed drawings will provide all the necessary parameters for the production of precision equipment.

However, if there is no time, energy and special need for serious brainstorming, it is quite possible to buy this machine. Despite its considerable cost, it pays for itself fairly quickly. Although, naturally, it would be more practical to take it as an addition to an existing production line, and not as an independent device.

Twisted and embossed decorative pipe: a beautiful and practical element for finishing work

Decorative pipes are products that are used for decoration indoors and outdoors. The internal part of such a product is no different from a regular pipe, however, the outer wall has a varied (depending on the specific case) relief. Today, the range of decorative twisted pipes of various shapes and sizes is incredibly wide.

Twisted decorative pipe is the basis of a wide variety of designs and structures

What are decorative twisted pipes used for?

The main difference from standard hollow parts is their appearance, which is aesthetically pleasing. That is why they are used to decorate the interior of rooms, as well as in the production of various designs. These custom products can be used in the same conditions as conventional pipes, and in some cases they are more efficient.

Such products are extremely popular in the construction industry, where various frame structures are made from them. Such designs not only look much more presentable, but are also in no way inferior to conventional pipes in terms of technical characteristics. Let's consider the main structures and elements in which decorative twisted pipes are used:

- Decorative parts are often used to make stands for gazebos;

- various non-standard fences;

- Twisted products are very popular when installing grilles on windows;

- In addition, such parts are very popular in the furniture industry.

The twisted pipe can be used as a support in load-bearing structures

Twisted decorative pipes are used everywhere and the demand for them is growing every year. Thanks to this, products that are new in form and complexity appear.

Features of the production of decorative twisted pipes in industry

The production of such decorative products is not particularly difficult. In order to make such a part, you need a regular pipe, usually with thin walls. The most popular are those products that are made seamlessly, however, electric-welded parts are also suitable for creating a decorative relief pipe.

To produce decorative twisted pipes, the workpiece is processed on a special rolling mill. The hollow part passes through rolling rollers, resulting in the formation of a certain relief. The position of the rollers is adjusted depending on the diameter of the pipe.

Helpful information! Rolling equipment for making decorative twisted products includes three rollers located on a support. It is worth noting that each rolled part is usually equipped with an individual wire.

It is possible to adjust the support, which is used to strengthen the cutter. This allows you to process products with different cross-sectional parameters and control the angle of inclination of the cutting itself.

First of all, before starting the work process itself, it is necessary to set the necessary settings and adjust the elements of the machine so that you can install the workpiece of the required diameter.

After the above steps, the calipers are brought together and secured using the adjusting screw in the desired position. After this, you can begin the process of manufacturing the relief part. It is also worth noting that the notch can be of two types:

Decorative steel pipes do not look as impressive as products made from non-ferrous metals, but their cost is lower

There are no restrictions on length or material as such. Embossed decorative pipes are made from both ordinary steel and non-ferrous metals. The most impressive look are structures made from decorative products made of non-ferrous metals, however, the cost of such products is higher than steel ones.

Do-it-yourself machine for the production of decorative pipes

Not every owner can afford to purchase such an expensive product as a twisted (embossed) decorative pipe, however, if desired, this product can be made with one’s own hands. To do this, you will need to assemble a homemade machine, on which the work of obtaining decorative parts will be carried out.

Experts do not recommend doing this to those who do not understand machines and their structure at all. And for those who at least approximately understand the essence of the issue, this instruction may be useful.

Let's consider the main stages of assembling a machine for producing rolled metal with a pattern on the outer wall:

- First of all, it is necessary to make a special device that will serve as a support for working on a lathe (rest). To do this, you need to place three rollers in a certain position.

- Then you need to make guide elements for the steady rest. This will allow the support element to slide over them.

- The electronic part of the equipment must have a motor and a chain drive. The working process itself is quite simple: a round pipe is fixed in the chuck, after which it is necessary to engage the gear.

- Next, it is necessary to bring the supporting part in such a way that the rollers fix the pipe and the steady begins to slide along the previously installed guide elements.

You can assemble a machine for the production of twisted pipes with your own hands, but if you plan a large amount of work, it is better to buy a ready-made one

This machine is perfect for occasional or even one-time use, however, it is not suitable for the production of twisted decorative pipes on an industrial scale.

Industrial machines have many advantages compared to home-made ones: the ability to adjust the angle of inclination, the variability of processed diameters from 10 to 150 mm, as well as high productivity due to speed (120 km/h).

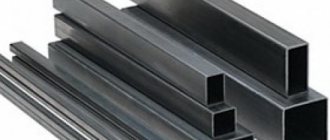

Types and characteristics of decorative profile pipes

Decorative profile pipe is one of the types of rolled metal, which differs from ordinary pipes in that it has a non-standard cross-sectional shape. In addition, the internal diameter of such products is changed, so they are ideal for making fences, as well as for forming frames of various structures. The range of profile decorative pipes is quite wide.

Helpful information! To make various fences, as a rule, pipes with a wall thickness of 3 mm are used.

However, there are also thin-walled products with a wall thickness of 1.5 to 3 mm. Such profile decorative parts are used, as a rule, in the furniture industry.

Parts with a wall thickness of up to 4 mm are considered medium and are used for supports in fences, as well as running parts of various mechanisms.

Profile relief pipes can also be thick-walled, with a wall thickness of up to 8 mm. The frames of buildings and massive machine tools are made from such products.

The most popular forms of profile parts with textured edges are:

- rectangular;

- square.

The length of such products can be from 6 to 12 meters. The design on the part is usually selected individually for a specific case. The cost of decorative profile pipes depends on the volume of products purchased.

Profile pipes with a relief surface are also popular

Advantages of embossed profile pipes

Like any other product, decorative profile rolled products have their own advantages that are worth paying attention to:

- Such products are quite durable and have a long service life. If you use a decorative profile part for arranging a fence, it is recommended to correctly design the future structure;

- the use of a relief profile allows it to be used in combination with other materials (for example, with a brick fence support);

- in addition, the relief profile can be adjusted to any span, having previously measured and prepared it;

- good transparency of the relief profile ensures a presentable appearance of the area from the inside, as well as from the outside. Thanks to this, the various plants growing on the site are not shaded;

- One of the main advantages of decorative profiles is the wide selection of products. If desired, everyone can choose something suitable to their taste;

Important! Experts recommend periodically applying an anti-corrosion coating to decorative profile products used to construct the fence. If the anti-corrosion coating is updated, the service life of such a fence will increase several times.

- Another advantage of such products is their high strength characteristics in comparison with a conventional round pipe of the same thickness and with the same cross-sectional parameters.

The above advantages allow decorative profile pipes to occupy a confident position in the modern building materials market.

Manufacturing

First of all, it must be said that there are several different ways to create these types of products, and they all depend on the availability of appropriate equipment.

Therefore, if you create a twisted pipe with your own hands, then you need to select all the necessary devices in advance and decide on the most convenient method.

These materials can have different shapes and structures

- In fact, the principle of creating such materials is to apply a kind of screw notch on the workpiece . Moreover, this procedure can be performed both cold and using special methods of heating the pipes to soften the base.

A special machine for creating such a notch

- Creating a machine for making a twisted pipe with your own hands is quite simple, but you need to take into account certain parameters and functions . At the same time, most experts are inclined to use a special broach, which has three or more rolling shafts that deform the workpiece in certain places if it is fed under rotation.

Another type of such equipment with automatic feeding

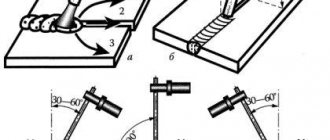

- Other craftsmen use a special workbench, on which the pipe itself is attached . After that, the manufacturing instructions require heating the workpiece, and then using forging hammers of a certain shape, apply the appropriate notch.

Tip! To make different shapes of coils, additional nozzles or inserts are usually used.

Their appearance depends only on the personal preferences of the master, based on the desire to achieve a certain appearance.

Making a similar structure using the forging method

Application area

Usually a twisted decorative pipe is created, rather than a bizarrely shaped supporting structure. The fact is that after such treatments, the technical characteristics of the material change greatly, and it can only be used as decoration.

To improve the appearance and protect against corrosion, all such structures must be torn with special compounds

It is worth noting that to obtain a better appearance, a layer of various materials is applied to the finished product. Their choice depends on the desire to achieve a certain effect or choose a specific interior. However, the price of some such dyes or enamels is quite high and causes additional costs.

Some types of structures using these pipes are real works of art and are very expensive

If the product is created by forging, it is usually blued, and gold or silver pipe paint is applied to certain areas. Chrome or nickel coating also looks good on such materials, but such work is very expensive.

Advice! Sometimes it is much easier to purchase such a factory-made design than to create it yourself.

This will help save money and time.

The quality of such products is determined by the depth of the notches and their uniformity, which also affects the cost of the final product.

Recommendations from the experts

- If you are making a twisted pipe with your own hands, then it is better to first test the existing equipment on a small piece of cutting, and only after achieving the desired result can you begin to work. This will allow you to determine the optimal parameters and modes.

Some versions of such elements are created exclusively by hand and used for the manufacture of decorative structures

- The thinner the wall of the pipe, the easier it will be to work with. However, when forging, you can use almost any available product.

- Before starting to apply notches, experts recommend creating markings. This way you can not only get an idea of the final appearance, but also simplify the rest of the process.

If a decision has been made to use such material to support weight, then it is worth inserting a pipe of a smaller diameter inside so that the loads on them are distributed evenly

Conclusion

By studying the video in this article, you can become more familiar with these types of materials and methods of their manufacture. At the same time, taking as a basis the text given above, it is worth concluding that this work may require certain skills, especially if the product is created by forging.

Usage

The most important thing in operating a machine for the production of twisted pipes is ease of use. If creating such a device requires serious calculations, drawings and a lot of time, then to use it, it is enough to watch the video once or twice or use photo instructions.

The principle of operation is the special rolling of a layer of pipe, without cutting all the metal. During preparation, the operator sets the position of the sliders according to the adjustment nanogram. The position is in strict accordance with the thickness of the material.

You can use products with a diameter of 1-15 cm. Afterwards, it is important to rotate the screws, making marks on the sliders. Installation takes place opposite the marks on the ruler, which is located on the work plate.

As soon as the preparatory work is completed, it is necessary to turn off the machine.

The pipe can rotate clockwise. The knives create the necessary cuts without completely damaging the metal. The angle of the pipe turn will also depend on the device.

The most common angles are 35, 45, 55, 90 degrees. The productivity of the device is up to 120 m/h, but it depends on the model and manufacturer. Therefore, if this parameter is important, it is better to clarify it separately and in advance when choosing a machine.

If there is a sufficient level of orders, the machine usually pays for itself in just a few days.

Therefore, before purchasing, it is advisable to assess the volume of existing and subsequent work. Moreover, it is advisable to give an assessment based on the most critical indicators. Then the issue of payback will not affect. To summarize, it is worth noting that such a machine is an auxiliary device. Although, if you get regular orders specifically for twisted pipes, you can take more than one machine, specializing only in such production. A machine for making twisted pipes.

I want to do it, I have questions, I have a great desire to make a machine for making twisted pipes. If you have any thoughts, please share. I will be grateful

Features of manufacture and use

To begin with, it is necessary to say that such structures are made from products with thin walls. At the same time, a twisted pipe is characterized not by the method of creation, but by its appearance. Therefore, for the work you will need completely ordinary material and appropriate equipment.

Manufacturing

First of all, it must be said that there are several different ways to create these types of products, and they all depend on the availability of appropriate equipment.

Therefore, if you create a twisted pipe with your own hands, then you need to select all the necessary devices in advance and decide on the most convenient method.

- In fact, the principle of creating such materials is to apply a kind of screw notch on the workpiece . Moreover, this procedure can be performed both cold and using special methods of heating the pipes to soften the base.

- Creating a machine for making a twisted pipe with your own hands is quite simple, but you need to take into account certain parameters and functions . At the same time, most experts are inclined to use a special broach, which has three or more rolling shafts that deform the workpiece in certain places if it is fed under rotation.

Attached images

Machine for making twisted pipes. I want to do it, I have questions

I saw how it's done. A thin-walled tube is fed, and 3 rollers rotate along.

Machine for making twisted pipes. I want to do it, I have questions

Stakanov (14th February 2010 – 17:30) wrote:

3 rollers, rotating and moving along

Hmm... the rollers aren't going anywhere... Apparently like this: three rollers are installed at an angle (ascent of the helix) and, while rotating, tighten and deform the pipe. Machine for making twisted pipes. I want to do it, I have questions

no, I saw that the rollers were moving just right. Although a design is possible where the rollers stand and the pipe itself stretches and rotates.

Machine for making twisted pipes. I want to do it, I have questions

Stakanov (14th February 2010 – 19:00) wrote:

no, I saw that the rollers were moving just right.

Everything is correct, if you move the rollers and the pipe rotates, then the drive is needed only for the mobile carriage, if the rollers themselves rotate, then the drive must be installed on each one, this turns out to be 3 geared motors. Machine for making twisted pipes. I want to make it, I have questions. A machine for making twisted pipes. I want to do it, I have questions

log73 (14th February 2010 – 06:20) wrote:

desire to make a machine for making twisted pipes

Is this pipe not according to Schauberger by any chance? BB. Machine for making twisted pipes. I want to do it, I have questions

Has anyone tried to make such a machine? share

Machine for making twisted pipes. I want to do it, I have questions

Looks like no one is working on this machine? I have an idea (because for 300 thousand rubles.

I can’t buy a machine yet) - do it not with electric power. drive, but with a manual one. But if you try to make it in the form of a die, with long handles, only instead of threads there are three rollers, albeit welded for now.

Hold the pipe motionless in two vices or something... and use the device to manually cut the turns. any thoughts on this?

Machine for making twisted pipes. I want to do it, I have questions, it will be a little hard with my hands, depending on the wall and diameter of the pipe... it still seems to me that it’s not realistic to use my hands, and it takes a long time, it’s easier to buy then we thought about making it with a lathe... it’s just the season, there’s a lot of work, we can’t keep up... probably closer to winter as usually a machine for making twisted pipes. I want to do it, I have questions

Are there any diagrams or photos of the lathe? or at least describe it. if it's not difficult

Machine for making twisted pipes. I want to do it, I have questions, but if I had the drawings I would have done it already =) while ideas are flying in my head =) ask Vasily, I think he wrote something about this device, if I’m not mistaken. on ostmetal Machine for making twisted pipes. I want to do it, I have questions

geras (May 7 2010, 19:01) wrote:

and if there were drawings, they would have already done it =) while ideas are flying in my head =)

Ask Vasily, I think he wrote something about this device, if I’m not mistaken. on ostmetal

I haven’t seen a lathe in person, they don’t let me in, but “kind” people told me about it in a very nice way. But the pillars are made like in this post: https://forum.ostmetal.info/showpost.php?p=...mp;postcount=51But their maximum pipe thickness is 1.5mm. What if it’s just a twisted pipe? I already wrote. There is decor-4 and openwork-4. Everything is clear. Geared motor: STM Italy RMI 85 | 1:49

Vasek (Feb 14 2010, 20:42) wrote:

Post edited by Vasek: 07 May 2010 – 19:58

Machine for making twisted pipes. I want to do it, I have questions

I think I should do it this way: I weld shafts with knurled rollers to the cams of the cartridge, a bearing inside the roller, set the angle according to the finished pipe, then a cardan (with length adjustment) - a suspension bearing - and 3 sprockets connected by a chain to the gearbox. Is this how it should work? It seems that the flexible shafts are adjustable in length themselves, there is no need to adjust anything, turning work is minimal, can’t you think of anything simpler?

Machine for making twisted pipes. I want to do it, I have questions. Good afternoon!!! I am new to the forum, but not new to blacksmithing. I would like to present our twisted pipe, made by hand. Everything was done simply - with a chisel. And the algorithm here is simple.

First, we mark the grooves with a machine, then heat it, then rotate it in the device on the hammer, put the chisel on, and knock. We adjust the depth ourselves. We don’t knock on a cold piece of iron, we’re not too lazy to heat it up.

Attached images

Machine for making twisted pipes. I want to do it, I have questions, Vintig, it’s beautiful. and more about the device and the chisel? Sincerely, Yura. Machine for making twisted pipes. I want to do it, I have questions

A device (a corner, for example) that serves as a guide is put on the lower head of the hammer. A pipe is inserted there. The chisel can be anything, it doesn’t matter. I’ll take a photo on Monday and post it.

Machine for making twisted pipes. I want to do it, I have questions. I think everything is clear in the photo)

All about machines for making twisted pipes

Quite often, twisted pipes can be found in various fields of application. What are they for, what is the process of making them? These products are used mainly for decorative purposes.

Moreover, they do not always perform the function of a specific conductor of any liquid.

Let's take a closer look at the scope of application of pipes, as well as the features of their production, the ability to do the work yourself, and what the homemade material will look like, and whether it is worth spending additional effort and money on making a machine.

Attached images

Machine for making twisted pipes. I want to do it, I have questions. It’s hellish work, but it’s beautiful. What is the thickness of the pipe walls? Otherwise, I think only thin-walled ones are used on machines. A machine for making twisted pipes. I want to do it, I have questions

Stakanov (February 14, 2010 – 22:00) wrote:

Although a design is possible where the rollers stand and the pipe itself stretches and rotates.

https://video.yandex....urstal/view/25/

Artistic forging is the production of products that perform not only practical, but also aesthetic functions, using hot or cold forging. The main difference between artistic forging and ordinary forging is that the forgings created acquire artistic significance, turning into a work of art.

Extremely exclusive fence in the art deco style Exclusive forged table with glass Artistic forging

With the help of artistic forging, they make interior items, decorative elements, fireplace and garden grates, furniture, benches, and a wide variety of household products.

Owning artistic forging products has always been a sign of high status and wealth. A master blacksmith, or, as they are now called, a metal artist, took a long time to acquire his knowledge and skills, and develop his artistic taste. He had to work in very difficult conditions; the work required high costs for materials and was associated with the risk of injury and fire.

Ancient mythology even equated blacksmiths with gods - the Greek Hephaestus and the Roman Vulcan, the Scandinavian Thor and the Japanese Amatsumara were blacksmiths. Therefore, artistic forging, both in the past and today, is expensive.

Conclusion

By studying the video in this article, you can become more familiar with these types of materials and methods of their manufacture. At the same time, taking as a basis the text given above, it is worth concluding that this work may require certain skills, especially if the product is created by forging.

It should also be noted that the twisted pipe should not be used as a supporting structure. Lines of tension are created in it, and the strength of this material drops significantly.

History of artistic forging

The history of artistic forging begins in several points of the ancient world - in China and Mesopotamia, in Egypt and in Europe, in the area inhabited by Celtic tribes. It was there that forged products were first discovered, which, in addition to utilitarian, also had artistic significance.

History of artistic forging

Ancient craftsmen decorated their products with images and ornaments.

Artistic forging was noted in all sectors of the economy - they decorated weapons and household utensils, grilles and fences, parts of mechanisms and objects of worship. After the flourishing of the art of artistic forging in the ancient world, medieval craftsmen largely lost the achievements of the times of the Roman Empire. The patterns have become much simpler, twisted rods have practically disappeared.

The Renaissance was also a renaissance for the art of artistic forging. Ancient secrets were rediscovered, new methods and artistic techniques were developed. Italian craftsmen from the principalities in the regions of Milan and Turin were especially famous for creating magnificent armor and weapons.

Forged products Forged rocking chair

The beginning of the widespread use of water and steam energy to mechanize the work of forges and hammers led to the beginning of a technical revolution - it became possible to produce forged products in large quantities. However, artistic forging has not lost its special position and continues to be valued today precisely for its uniqueness.

The set of tools of the ancient blacksmith was simple, but it was very expensive. It included:

- Forge - a device for heating a workpiece to a high temperature. Hand bellows for blowing coals. Anvil - a massive metal casting or forging on which the workpiece is given the desired shape. Forge hammer and hammer. Pincers. Mandrels, chisels, etc. Container with liquid for cooling forgings.

With this minimum set, a blacksmith could forge simple products even under a bush. Nomads and any army of antiquity carried marching forges and sets of tools with them. The technological capabilities of camping forges were enough to forge arrowheads, horseshoes and other parts of horse equipment, repair metal parts of carts, and straighten a damaged blade or armor.

But in order to forge a ship's anchor or a cart axle, a stationary forge was required. A heavy large anvil, a large forge and bellows with hand or foot drive attached next to it were installed in it.

A strong workbench and a large vice were also installed. A large number of accessories, linings, punches, clamps, as well as measuring instruments in accordance with the era were also added to the tool composition. The blacksmith did not work alone - an apprentice with great physical strength and endurance first inflated the bellows so that the blank in the forge became red-hot, and then struck with a large forge hammer in the place that the master blacksmith had marked with a small hammer - the handbrake.

In a modern artistic forging workshop, there have been no fundamental changes in the composition of the tool, except that the measuring tool has become more accurate, and instead of installing a bulky forge and bellows, it has become possible to heat the workpieces in muffle furnaces or induction.

A special group of equipment stands out for cold forging - changing the shape of metal rods, rolled products or pipes in a cold state by applying mechanical force. It includes various machines for cold forming of rod and profile blanks

Cold forging technology has become widespread because it allows you to obtain inexpensive entry-level artistic products without lengthy training and complex equipment.

Types of blacksmithing

Blacksmithing works are divided into several subtypes:

- Free forging - a blank heated to the plasticity temperature is placed on one side of the anvil, and forming blows are applied to the other with a hammer or special tools. Stamping - a heated or cold workpiece is placed in a special form - a stamp, limiting it on all sides, and this form is already subjected to blows from a hammer or static pressure. Cold forging - a cold bar blank changes shape on special machines.

Free forging is in turn divided into subtypes:

- Ordinary forging - a blank is given the shape of a finished product in one or several successive forging cycles Welding - joining two or more heated parts into one product Crushing - a preparatory operation during which the pasty iron mass is compacted and welded into a single ingot.

Types of modern forging equipment

Modern blacksmith equipment for artistic forging is practically no different in form and purpose from ancient or medieval ones. The materials have changed - hammers and anvils, hammers and punches, vices and clamps are made from modern high-strength alloys, which significantly increases their durability and efficiency.

Another important change is the heating method. The traditional forge with hand or foot bellows is giving way to muffle furnaces for small workpieces and induction heating systems. This significantly reduces labor intensity, harmfulness and danger to health and property.

Forging machines

Forging machines are used for cold forging - changing the shape of a bar or profile workpiece under mechanical influence. These include:

Snail with a collar and a rotating blade Twister for cold forging Gnut for cold forging Waves for performing wave-like bending of the workpiece

- Bending is the general name of machines for bending a workpiece in one or several directions along a given radius. Waves for performing wavy bending of a workpiece, with a given pitch and radius of the wave. Twisters, or torsion bars - for twisting a workpiece (or a group of workpieces) along the longitudinal axis. Snails - for forming spiral curls. at the end of the rod.

Cold forging machine Machine for making twisted pipe

Cold forging is perfect for making elements of fences and trellises, balusters, scrolls, interior decor items and landscape design. A machine for cold artistic forging is easy to make with your own hands if the master has the skills of metalworking and welding.

Features of manufacture and use

To begin with, it is necessary to say that such structures are made from products with thin walls. At the same time, a twisted pipe is characterized not by the method of creation, but by its appearance. Therefore, for the work you will need completely ordinary material and appropriate equipment.

Manufacturing

First of all, it must be said that there are several different ways to create these types of products, and they all depend on the availability of appropriate equipment.

Therefore, if you create a twisted pipe with your own hands, then you need to select all the necessary devices in advance and decide on the most convenient method.

- In fact, the principle of creating such materials is to apply a kind of screw notch on the workpiece . Moreover, this procedure can be performed both cold and using special methods of heating the pipes to soften the base.

- Creating a machine for making a twisted pipe with your own hands is quite simple, but you need to take into account certain parameters and functions . At the same time, most experts are inclined to use a special broach, which has three or more rolling shafts that deform the workpiece in certain places if it is fed under rotation.

Induction heaters

The induction heater is designed to heat the blank to the plasticity temperature. Heating occurs due to the fact that eddy currents, or Foucault currents, are induced in the surface layer of a metal placed in a strong alternating magnetic field. With their help, you can heat the blank much more evenly, faster and safer than using a traditional forge.

An industrial induction heater, even of low power, costs tens or even hundreds of thousands of rubles.

Therefore, many diagrams like “How to make an induction heater with your own hands” are published on the Internet. It is important to understand that the design of the device uses high voltage and high power. For self-production, you will need engineering knowledge in the field of high-frequency currents and the skills of an electrician.

Products – Tekhmashholding – group of companies, official website

- Quite often, twisted pipes can be found in various fields of application. What are they for, what is the process of making them? These products are used mainly for decorative purposes.

Moreover, they do not always perform the function of a specific conductor of any liquid.

Let's take a closer look at the scope of application of pipes, as well as the features of their production, the ability to do the work yourself, and what the homemade material will look like, and whether it is worth spending additional effort and money on making a machine.

Technological features of artistic forging

The process of manual artistic forging of metal is divided into several separate operations. It begins with heating the blank in a forge or other type of heater.

Depending on the quality of the coal, the air supply to the forge and the mass of the billet, heating can take from several minutes to several hours. When making products with a complex shape, a large number of parts or holes, the product may cool down. Then it is returned to the forge and heating is repeated.

The actual forging operations are as follows:

Draft.

Hammer blows are applied from top to bottom, the original height decreases and the width increases. This is preparing the workpiece for drawing. Drawing. Impacts on the workpiece are applied along the longitudinal axis along the length, and the workpiece is flattened in the direction of the blows, and thus its length increases. Distribution is a subtype of drawing, used to increase the diameter of hollow workpieces. Firmware - obtaining holes, recesses or grooves. Twisting - repeated rotation of one part workpieces are relatively different.

In this case, a vice, pliers are used, and if the workpiece has a significant cross-section, special gates are used. Chopping is the process of cutting a product into two or more parts. It is also used to correct the shape and size of the product. Sometimes a finished product is cut out of a workpiece using shaped stamps. Bending is carried out to change the shape of a product when making ring-shaped or bent-shaped parts. Welding is the connection of two or more parts into a single part.

When forging metal with your own hands, you should follow the general sequence of operations, while in the manufacture of each specific product, some of them may not be necessary.

Upon completion of forging, the product is dipped into a container with liquid for cooling and hardening. Traditionally, water is used, but when forging special types of steel, such as damask steel, various acids and oils are used. Legend has it that some masters, after mowing a sword, cooled it by sticking it into the body of a slave.

Types of artistic metal forging

The most complex and refined products are produced using traditional hot forging. Using this method, you can forge both ordinary lattice rods and openwork forging elements, such as leaves and flowers, stylized animal figures and intricate ornaments.

Hot artistic metal forging

Cold forging does not allow one to achieve the same heights of artistic expression, but it has its obvious advantages: low cost and high repeatability of products in a series.

Cold forging

Cold forging is sometimes also referred to as the embossing technique. In this case, a pattern consisting of many dents and dashes that form a highly artistic image is applied to a thin sheet of metal using a set of pointed tools and a hammer.

Advantages of embossed profile pipes

Like any other product, decorative profile rolled products have their own advantages that are worth paying attention to:

- Such products are quite durable and have a long service life. If you use a decorative profile part for arranging a fence, it is recommended to correctly design the future structure;

- the use of a relief profile allows it to be used in combination with other materials (for example, with a brick fence support);

- in addition, the relief profile can be adjusted to any span, having previously measured and prepared it;

- good transparency of the relief profile ensures a presentable appearance of the area from the inside, as well as from the outside. Thanks to this, the various plants growing on the site are not shaded;

- One of the main advantages of decorative profiles is the wide selection of products. If desired, everyone can choose something suitable to their taste;

Important! Experts recommend periodically applying an anti-corrosion coating to decorative profile products used to construct the fence. If the anti-corrosion coating is updated, the service life of such a fence will increase several times.

- Another advantage of such products is their high strength characteristics in comparison with a conventional round pipe of the same thickness and with the same cross-sectional parameters.

The above advantages allow decorative profile pipes to occupy a confident position in the modern building materials market.

Elements of forged patterns

Cold forging products can be classified as one of the typical elements:

Elements of forged patterns

Curl. A spiral curl can be unidirectional or bidirectional, that is, with a change in the direction of twisting the spiral. In practice, when using a 10-12 mm rod, you can get up to 5 turns of a spiral. Double curl, or Chinese lantern. This is a spatial structure of two or more elements, each of which is a regular double-row spiral.

It is made on the Volyuta twister. The curl is one-sided or double-sided, used for finishing gratings, balustrades, furniture. Twist. A rod (or several rods) twisted along the longitudinal axis. Used for balusters, decorative elements, handles of fireplace tools. Used as the final element on the bars of gratings, it is a peak to which a series of curls are attached.

All these elements can be obtained using hot forging methods, however, the labor intensity of the work and the required qualifications of the blacksmith, and, consequently, the cost, will increase many times over.

Conclusion

By studying the video in this article, you can become more familiar with these types of materials and methods of their manufacture. At the same time, taking as a basis the text given above, it is worth concluding that this work may require certain skills, especially if the product is created by forging.

It should also be noted that the twisted pipe should not be used as a supporting structure. Lines of tension are created in it, and the strength of this material drops significantly.