01/24/2022 Author: VT-METALL

From this material you will learn

:

- Description of Carbon Structural Steel

- Pros and cons of carbon structural steel

- Types of carbon structural steel in mechanical engineering

- Characteristics of carbon structural steel in construction

- Restrictions on the use of carbon structural steels

Carbon structural steels are in high demand in construction and mechanical engineering, but are also used in other industrial areas. Versatility is ensured by characteristics that allow you to choose the required combination of qualities.

However, this feature also has a downside - a complex classification with an abundance of markings. In our article we will tell you what carbon structural steel is, by what criteria it is classified and we will analyze the limitations in its use.

Description of Carbon Structural Steel

Structures and mechanisms involved in industry and construction work must be characterized by increased strength. Therefore, they are made from material with special characteristics, because the safe operation of the facility under any environmental conditions depends on them. Carbon structural steel meets all standards for chemical, physical and mechanical parameters.

This metal compares favorably with others in its ability to cope with constant and variable loads, and is resistant to wear and rust. Most often, ordinary carbon structural steel is used, but sometimes it is alloyed with certain additives to provide the material with new properties.

Carbon structural steels contain iron, silicon, copper, manganese, and other substances. However, the main additive is carbon, since the key characteristics and degree of strength of the metal depend on it. Carbon concentration determines an object’s resistance to cold brittleness, ability to cope with production loads, and changing weather conditions.

VT-metall offers services:

Among structural steels, it is customary to distinguish several classes in accordance with the proportion of harmful substances - the latter are understood as sulfur and phosphorus. The higher this indicator, the lower the level of cold brittleness and red brittleness of the metal.

Unalloyed carbon tool steels

These steels, in accordance with GOST 1435-90, are divided into high-quality and high-quality.

High-quality steels are designated by the letter U (carbon) and a number indicating the average carbon content in the steel, in tenths of a percent. Thus, U7 steel contains 0.65-0.74% carbon, U10 steel - 0.95-1.04%, and U13 steel - 1.25-1.35%.

The letter A is added to the designations of high-quality steels (U8A, U12A, etc.).

In addition, the designations of both high-quality and high-quality carbon tool steels may contain the letter G, indicating an increased content of manganese in the steel. For example: U8G, U8GA.

Pros and cons of carbon structural steel

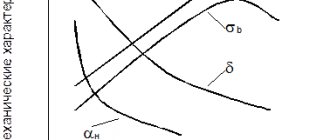

The advantages of such a metal become obvious after the products undergo heat treatment. Therefore, during the production process they are exposed to temperature in order to exhibit the following advantages:

- Hardening and tempering make it possible to increase the resistance of the material to plastic deformation. As a result, this indicator of carbon structural steel becomes higher than that of carbon alloys with equal carbon content.

- Under identical conditions, structural steel is calcined more strongly than carbon steel. Because of this, external elements with significant thickness are recommended to be made of structural steel with alloying additives. Thanks to the composition, the part is calcined through.

- Heat treatment of such steel can be carried out using so-called “soft” coolants, that is, oil. Using this approach, the likelihood of cracking and warping during the hardening process is seriously reduced.

- After heat treatment and alloying, the toughness and cold brittleness threshold of structural steel increases. Therefore, equipment containing parts made of this metal is considered more reliable.

However, carbon structural steel also has negative properties.

:

- Most products made from it are subject to reversible temper embrittlement.

- Under the influence of temperature, steel loses its original hardness and fatigue resistance.

- Forging and rolling lead to the fact that the structure of products changes to stitching. In deformation zones, they lose their uniformity, which makes the metal difficult to cut.

- Carbon structural steels alloyed with nickel are characterized by the formation of flakes, that is, light spots in the fracture. They appear when hydrogen dissolved in the metal escapes. In cross section, such defects look like cracks diverging in different directions.

Types of carbon structural steel in mechanical engineering

Carbon steels of ordinary quality, produced in accordance with GOST 380-71

This type of steel is the most common and is supplied in the form of rolled products in a normalized condition. It is used in mechanical engineering, construction, etc.

Carbon structural steels of ordinary quality are marked using the letters St and numbers ranging from 0 to 6. The latter indicate the grade number - the higher the number, the higher the proportion of carbon, strength, while the lower the ductility.

An index is written to the right of the brand number: kp - boiling steel, ps - semi-calm, sp - calm steel. Between the index and the brand number there is often a letter G, indicating an increased concentration of manganese. Steel groups are indicated to the left of the letters St. It is worth explaining that there are three groups: A, B, C, which are installed in accordance with the purpose and guaranteed properties of the metal.

Ordinary quality steels are divided into categories based on the requirements for standardized indicators, that is, for the chemical composition and mechanical properties. When marking carbon structural steels, the category is indicated by a number that is located to the right of the index of the degree of deoxidation.

Let’s say St6GpsZ means that we have steel of group A, grade St6, with an increased proportion of manganese, semi-calm, third category. If, when ordering metal, a certain category is indicated, but the degree of deoxidation is unknown, the category is written after the brand number separated by a dash, for example St4-3. For steel of the first category, the number 1 is not given, so the marking looks like this: St4ps.

For group A steels

The chemical composition is not regulated, but the mechanical properties are guaranteed. Such metals usually become the material for parts in the manufacture of which hot processing is not used, that is, welding, forging and other methods.

For steel group B

the manufacturer does not guarantee mechanical properties, and its key characteristic is considered to be its chemical composition. This metal is used for products undergoing heat treatment and hot forming, for example, stamping and forging.

Group B steel

are supplied in accordance with the mechanical characteristics that meet the standards for group A. While the chemical composition of this metal must meet the requirements for carbon structural steels of group B. This material is used in most cases for the manufacture of welded structures.

High-quality carbon steel for structural purposes, produced in accordance with GOST 1050-74

They differ from ordinary quality steels in the smaller proportion of sulfur, phosphorus and other harmful impurities in the composition. They also have narrower limits on the carbon content of each grade and often have higher concentrations of silicon and manganese.

Recommended articles

- Alloy steel: types, grades and purpose

- Corrosion-resistant steel: types and features

- High-speed steel - characteristics, markings, applications

To mark high-quality carbon structural steels, two-digit numbers are used, which indicate the carbon content in hundredths of a percent. You also need to take into account that this metal is supplied with guaranteed chemical composition and mechanical properties.

Based on the degree of deoxidation, boiling steel (kp), semi-quiet steel (ps), and calm steel, which does not have a corresponding index, are distinguished. The letter G also indicates an increased proportion of manganese, but within 1%.

This steel can be rolled, forged, calibrated, round with a special surface finish, which is known as silver

.

Carbon steels for special purposes, produced in accordance with GOST 1414-75

They have good and increased machinability and are therefore known as free-cut steels. First of all, such metal is used for the manufacture of mass-produced parts. When processing it on automatic machines, short and small chips are formed, lower consumption of cutting tools is ensured, and the level of roughness of the processed surfaces is reduced.

Automatic carbon structural steels with a significant proportion of sulfur and phosphorus are well processed. To achieve high machinability by cutting, selenium, lead, and tellurium are introduced into the metal as technical additives.

To mark this group of steels, the letter A and numbers are used, which can be used to determine the average carbon content in hundredths of a percent. There are such grades of automatic steel: A12, A20, AZO, A40G.

Metal of the first grade is used for the production of non-critical parts, while the rest are used to make elements designed to work under increased voltage and pressure. This steel is sold as rods of round, square and hexagonal sections. It is worth mentioning that such metal is not suitable for the manufacture of welded structures.

Sheet steel, namely boiler steel, GOST 5520-79 and TU, are intended for the production of boilers and containers operating under pressure. Therefore, such carbon structural steels have found application in the manufacture of steam boilers, ship furnaces, combustion chambers of gas turbines, and other products. Their task is to cope with variable pressures and temperatures ranging from +450 °C.

An important quality of boiler steel is good weldability. To do this, titanium is added to the metal and additionally deoxidized with aluminum.

There are several grades of carbon boiler steel: 12K, 15K, 16K, 18K, 20K, 22K, the proportion of carbon in them is at the level of 0.08–0.28%. The metal is supplied in the form of sheets with a thickness of no more than 200 mm and forgings in the condition after normalization and tempering.

Features characteristic of carbon-containing alloys

Low carbon – low reliability with excellent flexibility. It is used to produce parts that have a complex structure in terms of design, and which are affected by minimal degrees of load. Distinctive parameters of carbon-containing alloys: about 18 for non-critical products that do not require heat treatment or normalization.

With an average C2 content - to produce products that require high strength, but with reduced flexibility. Parts requiring heat treatment: hardening of the upper part, quality improvement, normalization. To improve the cutting properties of steel with a medium carbon content, steel is annealed.

Steels with a high C2 content and with manganese impurities have improved qualities in terms of service life and elasticity. This makes it possible to use them as raw materials in the manufacture of springs.

Automatic – used in machine tools with automated control. Elements P and S in sufficient volume result in the production of chips. This fact is beneficial for the processing process. The downside is getting a surface other than smooth.

Structural steels in the engineering industry. The characteristic features of the chemical composition make it possible to note two large categories in structural steels used for the manufacture of engineering products:

- low-carbon, medium-carbon;

- low alloyed, medium alloyed.

Carbon alloys must meet a number of high-quality and mechanical properties, the most important of which include:

- impact strength;

- flexibility;

- reliability.

The structure of most structural carbon steels used for the manufacture of components in the mechanical engineering industry is equated to the hypoeutectoid pearlite type. The most popular models are 30Kh2GSN2VM, 25Kh2GNTRA and others. In order to increase the astringent properties of carbon-containing alloys of this type, molybdenum and nickel are added to the mixture of components.

Some items made from engineering-grade steel undergo hardening. Such products are divided into the following types:

- without hardening;

- the upper shell is strengthened;

- the entire presented volume is strengthened.

Single categories of structural alloys for mechanical engineering (08kp, 15kp, St.3). They are mainly used to produce sheet metal, without heat treatment. Precisely because sheet metal is used to make a wide variety of objects by changing the shape while cooled. The highest requirements are put forward for the quality of plasticity. Good ductility is due to a small amount of silicon and carbon. In addition to the ability to perfectly change shape when cooled, a model of such a material is characterized by good behavior when making connections by welding.

Structural metal alloys are of high quality; they also undergo heat treatment:

- hardening of the top coating, after which the metal is (not always) tempered;

- hardening carried out using standard methods. After it, a tempering is also needed (combining types of heat treatment of steel makes it possible to perform a high-quality welding connection);

- normalization of the environment.

Characteristics of carbon structural steel in construction

For construction needs, carbon structural steels with a small concentration of alloying elements, that is, chromium, manganese and silicon, are used. The share of carbon in them does not exceed 0.1–0.2%. This metal is characterized by good weldability and other properties important in the manufacture of building structures. These include:

- good malleability and fluidity;

- high hardness and toughness;

- optimal parameters of relative elongation and strength.

By producing products for the construction industry from low-alloy steels rather than carbon steels, it is possible to reduce raw material costs by a third. Alloying improves the hardenability of the metal and increases its yield strength.

Most often among carbon structural steels, the following grades are used, supplied in the form of long products, sheets, strips and rods:

- 14G2;

- 15HSND;

- 10G2S1;

- 18G2;

- 18G2S;

- 25G2S;

- 35GS.

The listed steels are well weldable and amenable to other processing methods, therefore they are suitable for the manufacture of building structures of any size and configuration without significant labor costs.

Application of spring steels (some directions)

Spring steels live up to their name. An example are options marked 50ХФА, 60С2ХВА, 70С2ХА, others. They are characterized by excellent density qualities; it is worth noting the strength, reliability, elasticity, and viscosity of the material, which are also valuable when obtaining metal and subsequent use for its intended purpose. The described materials include low-alloy options, medium-carbon ones with a carbon content of 0.6 - 0.8%. If they are connected by welding, microscopic holes may appear, even in a longitudinal direction. They are used as raw materials in the production of various types of springs; they are also suitable for the production of springs for various areas of use.

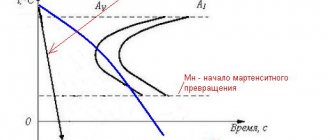

There is a category of structural steels called upgradeable steels. In the middle they contain martensite, similar in shape with needles. When considering the dense content of these alloys, one can notice the exclusion of non-metallic additives, carbide segregation, and mesh. The main advantage of low-alloy and high-carbon steels with a C2 amount of less than 1.05% is a high degree of hardness; another factor is the percentage of wear.

One of the features that you should pay attention to is the marking starting with the letter “Ш” (ШХ5, ШХ 15СГ).

Restrictions on the use of carbon structural steels

The share of carbon is fixed using a number in the marking - the quality and scope of steel products depends on this indicator.

| Name | Properties of products, possible areas of their use |

| Low carbon | Low-load parts are produced from this metal, because they have low strength, high ductility and are easy to weld. The products are also suitable for cold stamping, but they cannot be exposed to heat. The alloy is a material for complex car parts and critical welded structures |

| Medium carbon | To obtain such metal, carbon structural steel is improved by hardening and hot tempering to a temperature of + 650 °C. As a result, the strength level of the parts increases, while ductility decreases, which makes it possible to cut metal. This steel is used in mechanical engineering |

| High carbon | These materials have a significant manganese content, so they are used to make elements that have increased elasticity and wear resistance, for example, leaf springs. Annealing allows the material to be cut |

| Quality | The metal has a large proportion of sulfur-phosphorus and lead additives and is used for the manufacture of parts that undergo significant processing without harm to the tool itself. These are automatic steels with the addition of sulfur, phosphorus, and lead, which, in accordance with the name, are processed by automatic machines |

If it is necessary to achieve increased hardness and wear resistance of elements made of carbon structural steel, graphitization, cold hardening, and surfacing are used.

In order not to make a mistake when choosing a metal grade for specific tasks, it is important to understand the properties of structural steels listed above. If you still have doubts, you should consult with specialists - they will definitely help you choose the right material.

Production methods and quality division options

The production of carbon steels is based on the processing of cast iron and ferrous scrap with the reduction of sulfur, phosphorus and carbon to the required concentration. At the same time, various technologies are used, which affect the quality of the metal produced. As a result, the following types of steel alloys are obtained:

- high quality;

- quality;

- ordinary quality.

The first two types of carbon steels are produced using converters, open-hearth furnaces and more modern electric melting furnaces. The chemical composition of such steels and the concentration of impurities contained are strictly regulated by GOSTs 1435–99 and 1050–88. Thus, for high-quality steel alloys, sulfur can be used in an amount of no more than 0.04%, phosphorus - no more than 0.035%, for high-quality steel alloys, respectively - less than 0.018% and no more than 0.025%. Carbon steels of these categories have a structure of increased purity.

The smelting of steel alloys of ordinary quality is carried out on the basis of oxygen converters and open-hearth furnaces, then large ingots are formed from them. In comparison with the previous two categories, carbon steels of ordinary quality are characterized by the content of a large amount of harmful impurities. According to GOST 380–2005, they contain up to 0.05% sulfur and up to 0.04% phosphorus. Such material is subjected to hot and cold rolling in order to produce thin- and thick-sheet material and wide metal strips.