What were you interested in when you typed “D2 steel” in the search? The characteristics of this steel, its pros and cons, whether it is suitable for making knives or were you simply interested in its chemical composition. Perhaps you wanted to buy strips or forgings of D2 steel and make a knife yourself? Today we will tell you everything we know about this steel, and also tell you where to buy D2 steel most profitably.

Steel D2 - Analogs

Let's start with analogues. Perhaps now you will say: “Oh, yes, this is our steel X...” and you will not read further. Take your time, the list of analogues is below, and then we’ll sort everything out.

Steel D2 - original. Developed in the USA, developed a long time ago, back in the 60s and for the needs of American industry. Currently they are produced in other countries, including Russia. Steel has the following generally accepted designations:

- X155CrMo12 - D2 steel is produced under this brand in Germany

- 1.2379 - this is how D2 steel is marked according to the European steel designation system

- SLD - that's what they mean in Japan

- SKD-11 - D2 steel marking in Sweden

- And of course, X12MF - an analogue of D2 steel is produced under this brand in Russia.

The Russian analogue of D2 steel is Kh12MF

We have sorted out the analogues and designation of D2 steel. The chemical composition is also not complicated.

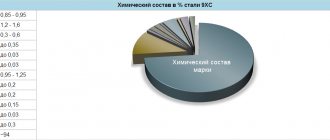

Chemical composition of D2 steel

| Carbon (C), % | 1,55 |

| Manganese (Mn), % | 0,35 |

| Chromium (Cr), % | 11-13 |

| Silicon (Si), % | 0,45 |

| Molybdenum (Mo), % | 0,90 |

| Vanadium (V), % | 0,90 |

| Steel hardness D2, HRC | 57-61 |

As you can see, the chemical composition of D2 steel is “not rich,” but, as they say, “less is better,” namely, a well-chosen composition of chemical elements in D2 steel gives it all those positive characteristics, which we will discuss below.

History of the appearance of the alloy

Steel grade D2 plate 250x80x4 mm. The alloy was developed in America in the 60s. for industrial purposes (production of knives and cutting tools). Nowadays such steel is produced not only in the USA. Alloys similar in composition to D2 have been developed in Japan, Germany and Sweden. The only difference is the amount of carbon.

The alloy has the following designations:

- X155CrMo12 – produced in Germany;

- 1.2379 – this is how D2 is marked according to the European steel designation system;

- SLD – alloy in Japan;

- SKD-11 – D2 marking in Sweden.

In Russia there is also an analogue - X12MF.

The alloy is actively used in the metalworking industry, automotive industry, and in the production of razor blades. In addition, it is used to create edged weapon blades.

Advantages and disadvantages

Like any alloy, D2 steel has its pros and cons. Its advantages are manifested:

- in the high hardness of the cutter, the ability to hold an edge for a long time;

- resistance to deformation;

- resistance to corrosion, although steel is not stainless;

- resistance to high temperatures;

- homogeneity of the internal structure after hardening;

- significant wear resistance;

- ability to withstand dynamic loads;

- quite affordable price.

The obvious advantages of knives made of D2 steel have made them popular among hunters and tourists. Household knives for use in the kitchen are also very popular.

The disadvantages of the alloy are mainly associated with its advantages, in particular:

- due to their high hardness, sharpening knives requires special tools, which is difficult to accomplish in field conditions;

- Despite their high resistance to corrosion, knives require careful care and avoidance of contact with aggressive environments.

Knives made from D2 steel are considered the best option for use in any conditions. With proper storage and proper care, they will last a long time, effectively performing their functions.

D2 steel pros and cons

The steel has a very high Rockwell strength; in our production it is 63-64 units. Technologically, this characteristic can vary from 55 to 69! units, but we settled on exactly 63-64, as on the golden mean, with low strength, the knives quickly become dull, and with too high strength, it is difficult to straighten.

Steel was originally conceived as a knife steel. Accordingly, there will be quite a lot of advantages, but there will also be a fly in the ointment.

Pros:

- high mechanical strength,

- sharp cutting edge, due to the carbon content it produces a very aggressive cut,

- high degree of corrosion protection,

- The cutting edge can be sharpened to razor sharpness. It will hold an edge for an extremely long time.

There are also small disadvantages.

Minuses:

- Although the steel is semi-stainless, it requires minimal maintenance.

- does not tolerate lateral loads well, it is better not to pull out nails with it, for example,

- high strength makes sharpening in “field” conditions problematic.

Results:

- good value for money,

- holds an edge for a long time, but takes time to edit,

- requires minimal care, is not intended for chopping and throwing, does not like lateral loads.

Compromises

Even the best steel cannot combine all the highest levels of these characteristics. The best steel alloys for knives are obtained only by using a compromise, that is, a balance where hardness is correctly combined with rigidity. The characteristics of the D2 steel grade indicate that a good balance has been achieved here. You can make an exceptionally hard blade, but it will become fragile, even if dropped it can break into pieces. And if you do the opposite and achieve the greatest rigidity of the blade, it will be flexible, but the sharpening on it will disappear almost immediately. In terms of the characteristics of the D2 steel blade, it has been out of competition for a very long time, since the wear resistance of such steel is extremely high.

The most famous brands that make blades used it in their work. This grade is very weakly susceptible to corrosion, less than other carbon grades. It holds an edge for a very long time, and this is one of the main advantages of such products. However, analogues capable of competing for primacy have appeared quite a long time ago. For example, High Carbon or 20HC, a much more carbonaceous version of the D2 steel shown in the photo. Their characteristics are very similar: increased content of chromium and carbon, excellent cutting properties, high durability of the blade edge. Today, manufacturers in many countries widely use this version of steel to produce knives - they are moderately durable, hold an edge for a long time (in addition, they are much easier to resharpen and sharpen), and their corrosion resistance is simply excellent.

Chemical composition

Alloy D2 is based on high carbon steel. The carbon content in its composition is 1.4-1.6%. Its high concentration promotes the formation of large amounts of iron carbide. It is given special strength and wear resistance by refractory metals, the concentration of which is:

- molybdenum – 0.8-1.2%;

- tungsten – 0.9-1.1%.

They are introduced into the molten metal in powder form and replace iron in compounds with carbon. Strong tungsten and molybdenum carbides are formed, giving the metal the following properties:

- high strength when heated;

- hardening ability;

- uniform distribution of internal stresses arising during the hardening process;

- prevent fragility.

The anti-corrosion characteristics of D2 steel are increased by the addition of chromium in an amount of more than 11%. Additional strength is given to the alloy by chromium carbides formed during the interaction of elements.

Silicon and manganese are added in equal proportions, 0.6% each, and provide a stabilizing and strengthening effect on the internal structure of the alloy.

It is known that sulfur and phosphorus contribute to the deterioration of mechanical properties, reduce wear resistance, while simultaneously increasing the fragility of the metal. The content of these elements is reduced to the extent that their harmful effects do not affect the quality of steel:

- sulfur – 0.03%;

- phosphorus – 0.04%.

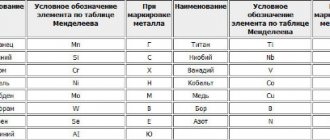

Alloying elements

The wear resistance and toughness of this grade of steel make it much more difficult to process; abrasive belts and tools wear out much faster, which also affects the cost of products made from PM supersteel. But the alloying elements added to the composition are also of great importance. Iron can only be hardened by combining it with carbon. Its quantity may be different, it depends on the grade of steel that needs to be obtained. In addition to carbon, the presence of which is mandatory, good steel can have a number of added elements that will refine it and radically change its properties.

Carbon gives steel rigidity and, together with iron, forms carbides - these are very hard metal-carbon compounds. Chrome, as already mentioned, will give this alloy resistance to corrosion. If the composition contains more than 13% of this element, the steel will turn out to be stainless. But that's not all the benefits brought by adding chromium. With its presence, steel gains wear resistance and hardness. Manganese promotes the formation of a granular structure in the blade material, which significantly increases the strength of the product, especially for tools. Silicon also helps give strength to steel and is used in forging. Vanadium (as well as tantalum, molybdenum, nickel, tungsten, cobalt) increases rigidity and wear resistance.

Technical features of D2 steel

There are five characteristics to evaluate an alloy:

- Hardness. It has a high rate of up to 64 HRC according to Rockwell.

- Rigidity. It is durable, but is not rigid enough, which leads to inconvenience when sharpening products.

- Wear resistance to abrasive effects. Due to its hardness, this alloy has a high indicator.

- Corrosion resistance. This type of steel is not stainless because it does not contain enough chromium, but it resists rust. Corrosion resistance is rated as average.

- Protection of edges from rubble. During operation, the blade of a D2 product can maintain its sharpness for a long time.

Characteristics of steel

The properties of steel depend on the addition of alloying substances to the alloy. But in general, the material for making knives is valued for the following characteristics:

- strength, elasticity, which gives the product resistance to longitudinal bending;

- withstands a wide range of temperatures (from - 30 to + 100 degrees Celsius);

- hardness, which is assessed on the Rockwell scale (the optimal indicator for knives is 55 units or higher);

- resistance to external influences, anti-corrosion properties;

- duration of sharpening retention (the blade will dull less often on a product made of hard steel, but it is more difficult to sharpen it and it is better to have it done by professionals).

The best kitchen knives in the world - top 10

Alloy properties

Although D2 steel has high anti-corrosion properties, it is not considered completely stainless. Corrosion resistance largely depends on operating and storage conditions. If products are left in a humid environment for a long time, rust stains may appear on them.

The physical and technical characteristics of D2 steel allow it to be used after appropriate heat treatment for the production of tools with high wear resistance and shock resistance:

- density – 7700 kg/m3; thermal conductivity indicator – 20 W/m2*deg;

- elasticity coefficient – 21*104 MPa;

- compressive strength increases from 1750 to 2200 MPa with increasing hardness in the range from 52 to 62 HRC.

Heat treatment

D2 steel is produced by the electroslag remelting (ESR) method, in which the molten metal is passed through a special flux. During the process, harmful impurities of sulfur and phosphorus are removed from the melt as much as possible, thereby improving the quality of the metal.

To obtain the required strength characteristics for knives, D2 steel is subjected to further heat treatment. During hardening, it is important to ensure uniform heating of the entire mass of metal, for which a short delay is sufficient. Heating is carried out in an oxidizing environment, which causes partial decarburization of the surface layer. It is removed during final processing.

The primary hardness of the metal is achieved by hardening at 1000-1010 degrees with exposure for 5-7 minutes. The tempering temperature range is 175-200 degrees. This mode ensures maximum cutting edge hardness – 61-62 HRC.

To make knives intended for certain dynamic loads, the steel hardening mode changes slightly:

- hardening - at a temperature of 1020-1040 degrees;

- vacation - 310-340 degrees for two hours.

The final mechanical processing of products consists of grinding and sharpening the cutter.

Thermo-mechanical treatment conditions

This type of steel requires hardening, which gives it greater strength. To harden an alloy not intended for making blades, an oxidizing atmosphere is used. Creating blades from D2 steel requires a different technology.

Heat treatment of D2 steel

For the production of cutting blades and parts designed for dynamic loads, different exposure times and temperatures are required. The most common treatment of steel for primary hardness, including low tempering and quenching in oil, under a stream of air or in hot environments.

To achieve uniformity in the structure of the blade, ensure uniform heating during hardening. The absence of oxidation during such processing prevents decarburization, which helps maintain strength and make the product more sharp.

Heating occurs at a temperature of +690…+850°C. After a few minutes or seconds, the alloy is cooled and alloyed with vanadium and molybdenum, which promotes hardening.

The production uses the electroslag remelting method. The molten metal is passed through a layer of slag, in the process being cleansed of harmful impurities, including sulfur and phosphorus.

After processing followed by heating, the steel is cooled and subjected to final mechanical processing in the form of grinding and sharpening the blade.

Carbon steels

Steel, from which a variety of knives can be made, is usually divided into two groups. Carbon steel, as the name suggests, contains carbon, and it must be at least 0.5%, since steel for knives must withstand hardening well. But if the carbon content is more than 1.7%, such an alloy will no longer be forgeable. Almost all carbon steels do not contain other alloy elements: molybdenum, vanadium, chromium, manganese and the like. Therefore, they are very simple to heat treat, and this is their main property. The heating range can be very wide, and almost any mistakes made by the master can be corrected during the forging-hardening process. Another property of carbon steel is that it is easy to process in an unhardened state - you can saw, drill, grind and much more. It can be easily sharpened to an exceptionally sharp state.

But carbon steels also have some disadvantages. The main one is low anti-corrosion resistance. Skilled craftsmen minimize this error by polishing the product to a mirror shine. Such steel requires constant and careful care: after each use, the blade is cleaned of foreign products (including dirt), and then lightly lubricated with oil. However, it should be noted that even the most careful attention to the blade will not prevent changes. A gray coating and spots form on the surface of the blade if it comes into contact with any acids. This can be any fruit and many vegetables, such as tomatoes. Fatty acids also have a bad effect on carbon steel. Upon contact with them, the alloy changes color and becomes dull. It’s better not to cut even fried meat with such a knife. But all this does not threaten D2 steel, at least not to the same extent. This alloy is rich: it contains a lot of chromium and all the other components on the list.

Analogues of the alloy and its application

The D2 steel grade was developed in the 60s of the last century in the United States and was originally used for industrial needs. The alloy was used to make high-speed metal cutters that could operate at high temperatures. Today this brand is popular all over the world and has many analogues:

- Х155CrMo12 – in Germany;

- SLD - Japan;

- 1.2379 – in the European Union;

- SKD-11 - Sweden.

In Russia, a substitute for D2 steel is the X12MF grade, the composition of which is regulated by GOST 5950. Its range is represented by:

- various types of rental;

- calibrated rod and silver;

- strip and forged blanks.

Tool steel D2, like its analogues, has found wide application:

- in the engineering industry;

- production of metalworking tools;

- razor blades.

It is especially in demand as a material for the manufacture of elite knives, which is due to its ability to maintain a good sharpening for a long time. Normally it should be enough to cut up a large carcass. A wide range of knives are made from the alloy:

- universal folding ones, including gift options;

- neck hunting knives designed for skinning prey;

- tourist, having a wide range of applications;

- cutting, for cutting large carcasses.

Comparative characteristics of steel D2 and Kh12MF

The analogue in the Russian Federation is steel X12MF.

D2 steel contains carbon. Vanadium is used as alloying elements, which reduces the fragility of the blade, molybdenum improves the hardenability of the material to the full depth. Chromium protects steel from corrosion, but its level is not sufficient to classify the steel as stainless. Also, having melted, it is alloyed with silicon and manganese, the first element strengthens the steel grains, the second increases its hardness.

- Carbon – 1.4-1.6%.

- M-0.9-11%

- Mo- 0.8-1.2%

- Cr-11%.

The steel has a very aggressive and long lasting cut. Easy to sharpen and straighten. It is advisable to use ceramic abrasives for sharpening; diamonds form a too rough cutting edge. Or use diamond abrasives for initial roughening, and then move on to ceramics.

The steel resists corrosion quite well, but it cannot be classified as stainless steel because it lacks chromium. The knives will require simple care; wash and wipe after use. Pitting corrosion can be easily removed with a regular eraser.

The optimal heat treatment mode is 58-60 units. According to Rockwell, with such hardness the blade has balanced characteristics. The sharpness of the cutting edge is well maintained and at the same time the edge is not prone to chipping under strong lateral or impact loads. In the case of heat treatment at a hardness of 60-62 units. according to Rockwell, wear resistance increases noticeably, but at the same time the knife becomes brittle. For example, if you hit a bone with a knife while cutting up a carcass, you can get chips.

The advantages of knives from D2 include:

- Long time of maintaining the sharpness of the cutting edge;

- Good corrosion resistance;

- It has sufficient mechanical strength to withstand chopping blows without damage;

- As a rule, knives made of this steel have an acceptable cost.

The disadvantages include;

- In conditions of prolonged exposure to a humid environment, it is prone to the formation of corrosion spots;

About knife steels. D2 steel: most popular

Today, American semi-stainless tool steel D2 has firmly taken a position in the middle price segment of knives. It is used in both fixed-blade and folding knives by the world's largest brands and small artisanal manufacturers. The high performance qualities of this steel allow it to maintain its position in knife production for more than 60 years.

Photo source: https://knife-efes.ru/nozhi-po-vidam-stali/nozhi-iz-stali-d2/nozh-krot-1-1-1-1-1/

Historically, D2 is included in the category of tool, high-carbon and high-chromium steels. Production of chromium alloy steel began in 1821, and the first patent for chromium steel was issued to Julius Baur in New York in 1865. However, for more than 70 years, such steels were not used in production, since it was not possible to achieve good quality, and many cracks formed during forging. But the progress of metallurgy moved forward and in 1928 the first patent was issued for a composition that approximately corresponded to D2 steel. And by 1934, steel was created with the composition: 1.55% C (carbon), 12% Cr (chromium), 0.25% V (vanadium) and 0.8% Mo (molybdenum). Molybdenum was added to improve hardening, and vanadium improved toughness, which was achieved by refining both the grain size and carbide structure.

Photo source: https://ravencresttactical.com/all-about-d2-steel/ D2 really gained recognition after the outbreak of World War II, when it began to be used to make dies for production lines. It was used to stamp parts of military aircraft and automobiles, which were assembled by hand on an assembly line. D2 has demonstrated the ability to cut other, softer steels without significant wear and excellent performance under severe operating conditions. After the war, steel was used primarily for making metal cutters, as its mechanical properties allowed it to operate at fairly high temperatures. Using tools from D2, the following were produced: rolling mill shafts, working tools of forming, stamping and trimming presses, dies, broaching and extrusion machines, working knives of cutting units, knives for the food industry and measuring instruments.

Photo source: https://spbknife.ru/nojy-skladniye/nogi-skladnye-ontario/nog-ontario-bob-dozier-arrow-stonewashed-d2…

It began to be used for knife production in 1965 - 1966. Relatively high wear resistance along with good hardness and toughness were suitable for the manufacture of blades. Its main rival at that time was the recognized leader - 440C steel. D2 exhibited better wear resistance and toughness than 440C. However, the fact that it is not completely stainless and pitting points formed on it in a humid environment prevented it from gaining the popularity it deserves. In the cheap segment of knives, steels from the AISI 420 line were traditionally used in various modifications, and then new steels, such as Sandvic 12C27. In the middle segment there is 440C, and in the higher segment there are steels 154 CM, ATS 34 and VG-10, and since the late 80s steel has undergone powder processing, starting with S30V. D2 has been present in the knife market all this time, but in a narrow niche of survival, tactical and hunting knives. However, in the 10s of the 21st century the situation changed. Steels 154СМ, ATS34 and VG-10, excellent in their performance qualities, were supplanted by powders from premium knives and moved into the middle price segment, while maintaining fairly high production costs. And manufacturers all over the world turned their attention to D2, as a steel with clear properties, but less expensive to produce. It had a high percentage of carbon, excellent performance characteristics and a hardness of up to 64 HRC.

Analogs of American D2 steel in the world are: SKD11 (Japan), X150CrMoVCo12 (Germany), Cr12Mo1V (China), X12MF (Ukraine, Russia), etc.

Heat treatment D2 is carried out in air - this results in a more uniform grain size and less likelihood of stress in the metal than with rapid non-uniform cooling. The most modern method, most suitable for its production, is the ESR (Electro Slag Remelting) method, which helps to get rid of unwanted impurities. Electroslag remelting is a process in which molten metal, before solidification, passes through a layer of special flux or “slag”, which removes foreign elements such as phosphorus, sulfur, etc. from the melt. In addition, the quality of D2 can be significantly improved by using cryotreatment in liquid nitrogen , which relieves internal stresses of the metal and improves strength. Finishing the blade helps reduce the susceptibility of steel to corrosion: satin, stonewash, blackwash or simple but thorough polishing.

Photo source: https://agrussell.com/knife/Kershaw-Natrix-Copper—KE-7006CU

Despite the excellent qualities of the steel, the large carbides in D2 limit its strength, as well as the stability of long-term cutting edge retention. In order to overcome carbide heterogeneity, the American company Crucible (see article) began in 2007 the production of a powder version of this steel, under the brand name CPM-D2. The purpose of the new steel was to reduce the size of the carbide, which improves toughness, corrosion resistance and response to heat treatment. However, powder D2 is not widely used, since it does not show significant advantages over other powder steels, and it is not corrosion resistant.

Photo source: https://attackcopter.com/2020/02/29/kershaw-announces-the-dividend-with-multi-steel-composite-blade/

The sharpening of D2 steel has a lot to do with the quality of its workmanship. Due to the widespread use of this steel and its use on knives in the budget segment, the production standards of both the steel itself and its heat treatment turned out to be extremely unstable. In an effort to reduce production costs, many companies carry out heat treatment according to the most minimal scheme, without trying to obtain high performance from steel. Often, the manufacturer prefers not to risk a possible increase in fragility and underestimates its hardness, not even heating it to 60 HRC. This steel has low wear resistance. Another extreme is also possible, when the manufacturer tries to increase the hardness to the limit by hardening the steel to 64 HRC, but without using cryotreatment. Such steel becomes excessively brittle and vulnerable to lateral loads. Also, during such hardening, the chromium contained in the steel can be destroyed, and the corrosion resistance decreases; the steel actively rusts in any humid environment.

In general, sharpening recommendations for D2 steel are similar to other non-powder steels. The steel takes well to sharpening with aluminum oxide abrasives, such as Boride T2 or PC series stones. Sharpening with silicon carbide stones is also possible, but it is important to consider that these stones require soaking in water and work with water, and D2, even in its best versions, is not stainless. If the steel on a particular knife exhibits high hardness, then organic-bonded diamond stones from the Venevsky Diamond Plant are perfect for sharpening it. Dialux pastes on a leather blank and diamond paste on an oak blank are suitable for finishing.

D2 steel today has become the flagship of the line of budget steels and, with good heat treatment, shows some of the best properties among non-powder steels.

Variety of products from D2

A wide range of different knives are produced from D2 tool steel. Among them:

- folding - for universal purposes, including in gift wrapping;

- neck ones, with the help of which you can skin an animal killed during a hunt and carefully remove its skin;

- tourist, with a fixed blade and a wide range of applications;

- cutting machines, which will help cut the animal carcass into pieces and chop the bones.

High-quality knives made of D2 steel can be purchased in the online store KavkazSuveninr Ali Askerov, among them: hunting, tourist, folding. Our website also presents tactical survival knives made by the best Kizlyar craftsmen, including products made from D2 steel.

Also in our online store there are many handmade knives for various purposes. All of them are characterized by high accuracy and compliance with the required product parameters, aesthetics, and the use of natural materials for decoration.

Domestic knife manufacturers are increasingly using modern and high-quality alloys in the production of knives, and among them, D2 steel (D2), which has gained wide popularity.

For many years, knives made from D2 steel have remained popular and in demand in many countries around the world. The high qualities of d2 steel, with its pros and cons, made it possible to use this metal to create various cutting tools in industries such as:

- metalworking;

- automotive industry;

- production of razor blades.

The blade never crumbles or jams. The knife cuts nails freely, while the cutting edge remains intact and maintains operating parameters.

Prolonged contact with water causes corrosion. This knife cannot be used at home. The blade begins to become rusty.

Hunting

For a real hunter, it is very important to have a good knife. It must easily withstand enormous loads and help in carrying out complex long-term work: cutting up a carcass, sanding it. The metal of a hunting knife must be hard and highly durable. Alloy and carbon steel are suitable for the blade.

Several important qualities of a hunter’s weapon depend on the chemical composition of the metal:

- the blade must remain sharp for a long time;

- do not be afraid of mechanical loads;

- have high cutting characteristics;

- tolerate temperature changes freely, maintaining its original properties.

Blades made of alloy or carbon steel are subject to corrosion. To increase their service life, the blade undergoes special treatment. After washing, it is thoroughly wiped, the dry surface is lubricated with a thin layer of industrial oil. Knives made from tool alloy steel are much less likely to develop corrosion stains. They can be used for work in high humidity.

Tourist

Knives for tourists are made from tool steel with a high content of carbon and chromium. Factories in Japan and the USA use D2 steel for the production of tourist knives. It is considered the best in the world for the production of blades. This material is characterized by increased corrosion resistance and the ability to maintain a sharp cutting edge for a long time. The hardness of the metal after heat treatment reaches HRC 60-62 units.

Since the chromium content in D2 is slightly lower than in real stainless steel, professionals advise thoroughly wiping the blades after work and trying not to leave the knife in places with high moisture content.

Household

Knives for household purposes are rarely made from d2, because during the production process the design of the tool has to be changed. A striking example of such a product is a blade made on the basis of the Uzbek sharp knife pchak. He is engaged in the creation of such devices. To obtain high-quality products, specially developed technology is used.

The knife is made in such a way that it does not need to be sharpened, but only slightly adjusted. As a result, the thickness of the cutting edge is maintained. It usually does not exceed 0.1 mm. In eastern countries, such a blade is considered a universal device. It cuts the ram freely and can be used as a military weapon.

In recent years, the domestic industry has mastered the production of special kitchen knives made of D2 steel. The “Vegetable” and “Universal” blades are especially popular. High-carbon, semi-stainless steel d2, with a hardness of 61-62 units, allows you to perform any operations in the kitchen. Unfortunately, the cost of such products is very high (6000 -7000 rubles).

Knife Long Jack (steel D2, handle - Karelian birch)

Zorg folding knife (D2 GT steel, G10 handle)

Where can I buy?

There are many manufacturers of knives made of steel D2, X12MF... in Russia and abroad. Internet to help). But you can buy strips made from the German analogue of D2 steel, but they are less common..

Do you make your own knives? We brought this steel from Germany for you. The certificate, as they say, is attached:

Certificate for steel D2 (Germany)

Brought in sheets measuring 700x2000 mm, cut into strips on site. What do we cut with? Many people do not like laser, plasma or guillotine cutting. Therefore, we cut with a regular grinder. What sizes? We will cut off the ones that are needed. They brought a lot, so the prices are reasonable. For example:

- retail price of D2 strip size 250x40x4 (raw) ... 640 rubles

- retail price of D2 strip size 250x40x4 (hardened) ... 790 rubles

- small wholesale price (5 stripes) ... 5% discount

- small wholesale price (10 strips) ... 10% discount

- wholesale prices from 30 strips...on request.

For comparison, here are prices for a similar size in “other places”:

Prices for D2 steel at Artwood

Prices for D2 steel on Guns.ru

D2 steel prices at Foreshome

Let's summarize. Excellent steel, which has all the necessary characteristics for the manufacture of knife products. Now available in a variety of strip sizes for those making their own knives. If necessary, we will carry out heat treatment and surface grinding.

Plates, forgings of D2 steel for those who make their own knives. Buy D2 steel for knives in strip plates in our online store. Are you used to buying on AliExpress? You can now buy D2 steel from Germany on this site with free delivery. Here is the link.

Price

Knives made of D2 steel are produced by both domestic and foreign manufacturers. The products are low in cost. This is due to the fact that all the components that are used to produce this grade of steel are available and cheap. The average price for a knife is 2,500 rubles. Due to their low price and excellent characteristics, knives made from D2 steel are popular among buyers, especially among hunters and tourists.

Sources

- https://VashNozh.ru/stal/d2

- https://svarkaipayka.ru/material/stal/tehnicheskie-harakteristiki-legirovannoy-stali-d2.html

- https://damask-steel.ru/page/d2-plyusy-i-minusy-harakteristiki-otzyvy/

- https://www.nozhikov.ru/blogs/stati/stal-d2-kak-material-dlya-izgotovleniya-klinkovogo-oruzhiya

- https://kavkazsuvenir.ru/blog/stal-d2-dlya-nozhey

- https://posuda-gid.ru/nozhi/stal/35-d2-plyusy-i-minusy

- https://knifehacker.ru/stal-d2/

- https://top-nozhej.ru/bez-rubriki/stal-d2-dlja-nozhej-harakteristiki-pljusy-i-minusy/

Choice

When choosing a pocket knife, you always pay attention first of all to the type of steel that is used to produce the blade. Its use depends on its quality. The characteristics of D2 steel show that a knife made from this material will be good to use. After all, what is steel? It’s just an alloy containing iron, carbon and alloying additives that improve its basic properties. It is additives, heat treatment and rolling that distinguish different steels in the production of products. There are five main characteristics in total. Reviews of D2 steel say that neither it nor any other steel matches all five.

1. Hardness, resistance to impact. Metal deformation is measured according to the Rockwell method (non-destructive hardness testing).

2. Rigidity and resistance to damage (chips and cracks). You need to know that the harder the steel, the less rigidity it has. Reviews describe the characteristics of D2 steel exactly this way - very hard, but the rigidity is insufficient.

3. Wear resistance to adhesive and abrasive effects. Here the steel for the D2 knife gets the best characteristics, because the harder the steel, the more wear-resistant. But this property also depends on the chemical composition. The hardness characteristics of D2 steel match those of wear resistance, since it contains enough tungsten carbide.

4. Corrosion resistance and resistance to rust, which almost always appears from salt and moisture. The characteristics of the steel for the D2 knife at this point are not too enthusiastic.

5. Stability of the edges of the product from “blockages”, that is, how long the blade of such steel will be sharp during use. Here the characteristics of the D2 steel grade are excellent.