Welding low alloy steels has found wide application in the manufacture of structures in construction. This is due to the fact that low-alloy structural steels have increased strength and, due to this, metal structures are lightweight and, therefore, more economical.

As a rule, the weldability of low-alloy structural steels is satisfactory. But, it is necessary to take into account that when the carbon content in the steel composition is more than 0.25%, there is a risk of the formation and development of hardening structures and hot cracks in the weld. In addition, other weld defects, such as the formation of pores, are likely to occur. And this happens due to carbon burnout during welding.

Electrodes for welding low alloy steel

Welding low-alloy steels , which have a yield strength of no more than 390 MPa, does not seem difficult. It is practically no different from welding low-carbon steels.

Steels of this type are not hardened and are not prone to overheating, which leads to a decrease in plastic properties. However, it is worth remembering that as the carbon content increases, the properties of steel change. For example, steels 15KHSND and 14G2 contain 0.18% carbon and have a tendency to form hardening structures and overheat in the temperature-influenced zone. For these reasons, when welding steels of this type, it is necessary to select an optimal mode that will not allow the formation of hardening structures and overheating of the metal structure. Welding is carried out using electrodes with a diameter of 4 - 5 millimeters. The welding process takes place in several balls. If the thickness of the metal being welded exceeds the thickness of 15 millimeters, then welding is carried out using the block method or cascade, however, the metal in the welding zone is not heated to a high temperature in order to prevent overheating of the affected zone.

For welding popular low-alloy steels 15HSND and 14G2, welding electrodes E55 and E50A are used, which must be calcined before use. When welding steels 09G2S, 14G2 and 10G2S1, electrodes containing 18 percent carbon are used. These electrodes are E42 and E50A. Carrying out welding work with steels with a yield strength of more than 390 MPa requires more attention. Steel with such properties is prone to the formation of crystallization cracks, but it is less susceptible to overheating of the heat-affected zone because it is alloyed. Welding of such steel is performed with electrodes E60, E50A and E55. E60 welding electrodes are used for welding low-alloy steel in all spatial positions of the weld, and to work with them you need to use direct current of reverse polarity.

For welding these types of steels, you can use electrodes UONI 13/55 , PSK-50 and SK"-50 . Low-alloy types of steel must be carefully prepared for welding before welding. They need to be cleaned of rust and various types of contaminants. The metal being welded and its adjacent parts must be cleaned to 20 millimeters. In addition, all sagging parts of the metal and protrusions must be processed with an abrasive tool and become flush with the rest of the metal. If the thickness of the metal being welded is more than 25 millimeters, then welding must be done using local heating at a temperature of 120 - 160 degrees. However, if the ambient temperature is -15 degrees Celsius or lower, then preliminary local heating of the metal is mandatory, regardless of the thickness of the product being welded or its shape and weight. Thus , by maintaining the required metal temperature during welding, you will be able to carry out the welding process of low-alloy steels successfully .

Source

Welding low alloy steels. How to weld low alloy steel

Welding of low-alloy steels has found wide application in the manufacture of structures in construction. This is due to the fact that low-alloy structural steels have increased strength and, due to this, metal structures are lightweight and, therefore, more economical.

As a rule, the weldability of low-alloy structural steels is satisfactory. But, it is necessary to take into account that when the carbon content in the steel composition is more than 0.25%, there is a risk of the formation and development of hardening structures and hot cracks in the weld. In addition, other weld defects, such as the formation of pores, are likely to occur. And this happens due to carbon burnout during welding.

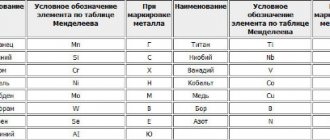

Common grades of low-alloy steels used in welding metal structures

Low-alloy steels, from which building structures are welded, contain no more than 0.25% carbon and no more than 3% alloying elements.

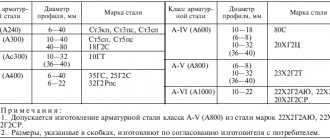

For the manufacture of metal structures for industrial and civil buildings, the most suitable steel grades are 15HSND, 14G2, 09G2S, 10G2S1, 10G2S1D, 16GS, 14G2AF, 16G2AF, etc.

Steel grades such as 18G2S, 25G2S, 35GS, 20KhG2Ts, etc. are well suited for the manufacture of welded gas pipes. The same grades are also used in the manufacture of reinforcement for reinforced concrete slabs.

Features of welding low-alloy steels

Welding of structural steels 15HSND, 15GS, 14G2, 14G2AF, 16G2AF

For welding low-alloy steel grades 15HSND, 15GS, 14G2, 14G2AF, 16G2AF, etc. Manual arc welding with E50A or E44A electrodes is well suited. But the highest quality welded joints are obtained when welding with UONI-13/55 and DSK-50 electrodes. But, the best results are obtained when welding with direct current with reverse polarity. At the same time, welding must be carried out at low currents, 40-50 A per millimeter of electrode diameter.

Automatic arc welding of these steel grades is performed using Sv-08GA or Sv-10GA welding wire under AN-348-A or OSTS-45 fluxes.

Metal structures made from steels 15HSND, 15GS, 14G2, 14G2AF, 16 G2AF can be welded at an ambient temperature of at least -10°C. If the ambient temperature is in the range from -10°C to -25°C, then preheating is necessary during welding. The heating width of the welding zone is 100-120 mm on both sides of the seam. Preheating temperature 100-150°C. At ambient temperatures lower than -25°C, welding of the above steels is not permissible.

Welding low-alloy steels 09G2S, 10G2S1, 10G2S1D

Assessment of the weldability of steel grades such as 09G2S, 10G2S1, 10G2S1D, etc. can be given a good one (see the table of weldability of steels), and this is due to the fact that they are not subject to hardening, are not prone to overheating and are resistant to the formation of hot and cold cracks in the weld and heat-affected zone. Welding of low-alloy structural steels of these grades can be performed either by manual or automatic arc welding.

For manual welding, electrodes of the E50A and E55A brands are well suited. For automatic welding, welding wire of the Sv-08GA, Sv-10GA or Sv-10G2 brands is used. To protect the welding zone, fluxes AN-348-A or OSTS-45 are used.

Welding of sheets made of steels 09G2S, 10G2S1, 10G2S1D, with a thickness of less than 40 mm, is carried out without cutting the edges. And, subject to the technology and welding conditions, the mechanical properties of the weld are almost as good as the mechanical properties of the base metal. The uniform strength of the weld is due to the transition of alloying elements from the electrode wire into the metal of the weld.

Welding chromium-silicon-manganese low-alloy steels 25KhGSA, 30KhGSA, 35KhGSA

Welding of low-alloy steels 25KhGSA, 30KhGSA, 35KhGSA, etc. complicated by the fact that they are prone to the formation of cracks during welding and the appearance of hardening structures. And the smaller the thickness of the welded edges, the higher the risk of the formation of hardening zones and the appearance of cracks in the weld metal and, especially, the heat-affected zone.

The tendency of these steels to weld defects is due to the increased carbon content in their composition (0.25% or more). Welding of these steels can be performed with welding wire Sv-08 or Sv08A, as well as electrodes of these brands.

For particularly important welds, it is recommended to use Sv-18KhGSA or Sv-18KhMA electrodes with the following types of protective coating: TsL-18-63, TsK18M, UONI-13/65, UONI-13/85, UONI-13/NZh.

When welding low-alloy chromium-silicon-manganese steels, depending on the thickness of the metal being welded, the following welding modes are recommended:

Low-alloy structural steel 10HSND for welded structures

Substitute

Steel 16G2AF

Type of delivery

- Long products, including shaped steel: GOST 19281-89, GOST 2590-88, GOST 2591-88, GOST 8239-89, GOST 8240-89, GOST 6713-91, GOST 535-88, GOST 5521-93, GOST 8509 -93, GOST 8510-86.

- Thick sheet GOST 19281-89, GOST 19903-74, GOST 5521-93, GOST 6713-91.

- Thin sheet GOST 17066-94, GOST 19903-74, GOST 19904-90, GOST 5521-93.

- Strip GOST 19281-89, GOST 5521-93

- Forgings and forged blanks GOST 1133-71

- Pipe OST 14-21-77

Decoding

- The number 10 indicates the approximate carbon content in hundredths of a percent, i.e. in steel 10ХСНД the average carbon content is 0.10%.

- The letter X indicates that the steel is alloyed with chromium (Cr).

- The letter C indicates that the steel is alloyed with silicon (Si).

- The letter H indicates that the steel is alloyed with nickel (Ni).

- The letter D indicates that the steel is alloyed with copper (Cu).

- The absence of numbers behind the letter designation indicates that the average content of the alloying element is up to 1.5%.

Characteristics and Application

Steel 10HSND is a low-alloy structural steel and belongs to the group of chromium-silicon-nickel and copper steels for metal structures, the structural class of the steel is pearlitic, well weldable. It is used for the manufacture of elements of welded metal structures and various parts that require increased strength and corrosion resistance with limited weight and operating at temperatures from -70 to 450°C.

Chemical composition, % (GOST 19281-89)

| C, no more | Si | Mn | Cr | Ni | Cu | P | S | N | As |

| no more | |||||||||

| 0,12 | 0,8-1,1 | 0,5-0,8 | 0,6-0,9 | 0,5-0,8 | 0,4-0,6 | 0,035 | 0,040 | 0,008 | 0,08 |

Chemical composition, % (GOST 19281-2014)

| C, no more | Si | Mn | P | S | Cr | Ni | Cu | V | other elements |

| no more | |||||||||

| no more than 0.12 | 0,8-1,1 | 0,5-0,8 | 0,03 | 0,035 | 0,6-0,9 | 0,5-0,8 | 0,4-0,6 | no more than 0.12 | — |

NOTES:

- The mass fraction of As (arsenic) in steel should not exceed 0.08%.

- The mass fraction of N in steel not alloyed with N is allowed to be more than 0.012%. if the mass fraction of N does not exceed the nitrogen equivalent (Neq).

- Steel 10HSND must be deoxidized with aluminum in the range of 0.02-0.06%.

- Micro-alloyed steels Al, Ti and Nb are allowed based on the mass fraction of Al not exceeding 0.05%, Ti not exceeding 0.04%, Nb not exceeding 0.05%.

Mechanical properties

| GOST | Delivery status | Section, mm | conditional yield strength σ0.2, MPa | tensile strength σв, MPa | relative elongation after rupture δ5(δ4), % |

| no less | |||||

| GOST 19281-89 | Long and shaped rolled products | Up to 15 incl. | 390 | 530 | 19 |

| GOST 19282-89 | Leaf and strip | St.15 to 32 incl. | 390 | 530 | 19 |

| St.32 to 40 incl. | 390 | 530 | 19 | ||

| GOST 17066-94 | Hot rolled sheet | From 2 to 3.9 incl. | — | 530 | (15) |

Mechanical properties at elevated temperatures

| tsp, °С | conditional yield strength σ0.2, MPa | temporary tensile strength σв, MPa | relative elongation after rupture δ5, % | relative narrowing ψ, % |

| 20 | 410 | 540 | 36 | 71 |

| 100 | 360 | 500 | 33 | 71 |

| 200 | 330 | 470 | 28 | 70 |

| 300 | 305 | 480 | 28 | — |

| 400 | 295 | 490 | — | — |

| 500 | 265 | 370 | 30 | 77 |

| 600 | 195 | 215 | 35 | 87 |

| 700 | 140 | 160 | 47 | 94 |

| 800 | 59 | 78 | 71 | 87 |

| 900 | 59 | 78 | 70 | 95 |

NOTE. Sheet 20 mm thick after normalization

Mechanical properties during tensile testing of long and shaped rolled products made of 10HSND steel (GOST 19281-2014)

| Strength class | Rolled cross-section dimensions, mm | steel grade | Mechanical properties, no less | ||

| yield strength σ0.2, MPa | temporary resistance σв, MPa | relative elongation δ5, % | |||

| 345 | Up to 20.0 incl. St. 20.0 to 140.0 | 10HSND | 345 | 480 | 21 |

| 375 | Up to 20.0 incl. St. 20.0 to 50.0 | 375 | 510 | 21 | |

| 390 | Up to 20.0 incl. St. 20.0 to 50.0 | 390 | 530 | 18 | |

Mechanical properties during tensile testing of thick sheets, wide-band universal rolled products and bent sections made of steel 10ХСНД (GOST 19281-2014)

| Strength class | Product thickness, mm | steel grade | Mechanical properties, no less | ||

| yield strength σ0.2, MPa | temporary resistance σв, MPa | relative elongation δ5, % | |||

| 375 | Up to 50.0 incl. | 10HSND | 375 | 510 | 21 |

| 390 | Up to 50.0 incl. | 390 | 510 | 19 | |

Impact strength of long and shaped steel

| Strength class | Rolled cross-section dimensions, mm | steel grade | Impact strength, J/cm2, not less, at test temperature, °C | |||||||||

| -20 | -30 | -40 | -50 | -60 | -70 | 0 | -20 | -40 | After mechanical aging +20(-10/+15) | |||

| KCU | KCV | KCU | ||||||||||

| 390 | From 5.0 to 10.0 incl. | 10HSND | 49 | 49 | 49 | 34 | 34 | 34 | + | + | + | 29 |

Impact strength KC at subzero temperatures

| GOST | Delivery status | Section, mm | KSU, J/cm2 at temperature, °C | |

| -40 | -70 | |||

| KSU | ||||

| GOST 19281-89 | Long and shaped rolled products | From 5 to 10 | 49 | 34 |

| From 10 to 15 incl. | 39 | 29 | ||

| KSV | ||||

| GOST 19281-89 | Leaf and strip | From 5 to 10 | 49 | 34 |

| From 10 to 15 incl. | 39 | 29 | ||

| St. 15 to 32 incl. | 49 | 29 | ||

| St. 32 to 40 incl. | 49 | 29 | ||

Endurance limit in hot-rolled state

| Thickness, mm | σ-1, MPa | τ-1, MPa |

| 4-32 | 284 | 167 |

| 33-40 | 274 | 167 |

Technological properties

| Forging temperature, °C | start 1200, end 850. |

| Weldability | Weldable without restrictions. Welding method - RDS, ADS submerged arc and gas shield, ESW. |

| Machinability | Kv tv.sp. = 1.12 and Kv b.st = 1.4 in the normalized and tempered state σв = 560 MPa |

| Tendency to temper brittleness | less inclined. |

| Flock sensitivity | insensitive. |

Brands of imported materials used in welded joints with steel 10HSND (STO 00220368-011-2007)

| Structural class | Steel grades | Brands of imported materials according to foreign standards |

| Pearlitic | 10HSND | ASTM SA-455 Gr70, ASTM SA-515 Gr70, ASTM SA-516 Gr70, ASTM SA-537 Gr70, ASTM SA-662 GrA(C), ASTM SA-662 GrB, ASTM SA-737 GrB, ASTM SA-738 GrA , ASTM SA-333 Gr3(6), ASTM SA-350 GrLF2, API 5L X56-65 |

The use of 10HSND steel in the manufacture of welded joints of pipeline fittings (ST TsKBA 025-2006)

| Material grade | Temperature of the working medium (wall), °C |

| 10HSND GOST 19281 | -70 to 475 |

Welding materials used in electric arc welding of steel 10HSND (ST TsKBA 025-2006)

| Base material grade | Electrode type according to GOST, TU (recommended brands of electrodes) | Application temperature, °C | Additional instructions |

| 10HSND GOST 19281 | E50A GOST 9467 (UONI-13/55) | Not lower than -60 | — |

| Below -60 to -70 | After welding heat treatment - normalization plus tempering | ||

| E50A GOST 9467 (VP-4, VP-6) | Below -60 to -70 | — |

Welding materials used for steel 10HSND when welding in shielding gases (ST TsKBA 025-2006)

| Grade of welded steel | Brand of welding wire according to GOST 2246, TU, recommended shielding gas or mixture of gases | Application temperature, °C | Additional instructions |

| 10HSND | Sv-08G2S Argon GOST 10157, carbon dioxide GOST 8050 or a mixture of argon and carbon dioxide ((75-85)% Ar + (15-25)% CO2) | Not lower than -40 | — |

| Below -40 to -70 | Subject to normalization plus vacation | ||

| Sv-08G2SNTYUR TU 14-1-3648 CO2, Ar, CO2 +Ar, | Not lower than -70 | — |

Welding materials for submerged arc welding of steel 10HSND (ST TsKBA 025-2006)

| Grade of welded steel | Wire grade according to GOST 2246, TU, Recommended flux grade according to GOST 9087 | Application temperature, °C | Additional instructions |

| 10HSND | Sv-10NYU TU 14-1-2219 Sv-10NMA, Sv-08GA, Sv-08G2S AN-348A, OSC-45, ANC-1 | Not lower than -60 | — |

| Below -60 to -70 | After welding heat treatment - normalization plus tempering |

Welding materials for welding steel 10ХСНД with dissimilar steels (ST TsKBA 025-2006)

| Grades of welded steels | Welding materials | Additional instructions | ||

| Electrodes, type according to GOST 10052 (recommended brands) | Welding wire, GOST 2246 or TU | |||

| Group A | Group B | |||

| 10Х18Н9Л 12Х18Н9ТЛ GOST 977 08Х18Н10Т 12Х18Н9Т 12Х18Н10Т 12Х18Н9 GOST 5632 08Х18Н10Т-ВД TU 14-1-3581 10Х18Н9 10Х18Н9-ВД 10Х18Н9-Ш Т U 108.11.937 15Х18Н12СЧТУ (EI 654) GOST 5632 10Х17Н13М3Т (EI 432) 10Х17Н13М2Т (EI 448) GOST 5632 | 10HSND | E-10Kh15N25M6AG2 (EA-395/9) E-10Kh25N13G2 (OZL-6, ZIO-8), E-11Kh15N25M6AG2 (NIAT-5, TsT-10) | Sv-07Х23Н13 | The welded joint is of unequal strength |

| E-10Х15Н25М6AG2 (EA-395/9) 582/23, 855/51 | Sv-10X16N25AM6 Sv-06X15N35G7M6B Sv-03X15N35G7M6B | The welded joint is of unequal strength. Welding materials are used for products under the jurisdiction of Rostechnadzor | ||

Temperature of preliminary and accompanying heating and tempering when welding structures made of steel 10HSND (ST TsKBA 025-2006)

| Grades of welded steels | Thickness of welded edges, mm | Temperature of preliminary and accompanying, °C | Interval between the end of welding and the start of tempering, hour | Temperature, °C | |

| welding | surfacing with austenitic class materials | ||||

| 10HSND | Up to 30 | Not required | Not required | Not limited | Not required |

| Over 30 | 150 | 150 | 630-660 | ||

The use of steel 10HSND for the manufacture of pressure vessels (PB 03-576-03)

| Steel grade, standard or specification designation | Technical requirements | Working conditions | Test types and requirements | |

| Wall temperature, °C | Medium pressure, MPa (kgf/cm2), no more | |||

| Sheet steel | ||||

| 10HSND, GOST 19281 | GOST 19281 | -40 to 400 | Not limited | GOST 19281 |

NOTE:

- Sheets in accordance with GOST 19281 must be supplied with mandatory compliance with paragraphs. 2.2.1,2.2.2, 2.2.3, 2.2.7, 2.2.9, 2.2.12 GOST, and the macrostructure must be monitored in accordance with GOST 5520 from a batch of sheets.

- Tests are carried out sheet by sheet at operating temperatures below -30 °C, above 200 °C or at a pressure of more than 5 MPa (50 kgf/cm2) with a sheet thickness of 12 mm or more.

- GOST 19281 applies to rolled products made of high-strength steels used for vessels that are not subject to heat treatment. The possibility of using rolled steel in accordance with GOST 19281 for vessels subjected to heat treatment must be agreed upon with a specialized research organization.

Thermal conductivity coefficient λ W/(m*K)

| Steel grade | λ W/(m*K), at test temperature, °C | |||||||

| 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | |

| 10HSND | — | 40 | 39 | 38 | 36 | 34 | 31 | 29 |

Young's modulus (normal elasticity) E, GPa

| Steel grade | At test temperature, °C | |||||||||

| 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | |

| 10HSND | — | 197 | 201 | 195 | 188 | 180 | 169 | 156 | 135 | 123 |

Find out more

Structural alloy steel 13HFA…

Structural alloyed steel 45KhN2MFA…

Steel S355K

Structural alloy steel 40X2H2MA…

Coursework: Development of technology for welding a section of a ship's hull

St. Petersburg State Marine Technical University

Department of Welding of Ship Structures

DEVELOPMENT OF WELDING TECHNOLOGY

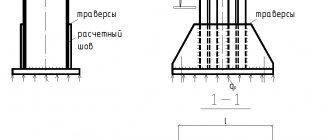

Section dimensions - S=16mm; A=7000mm; B=3500mm

Wall thickness of the transverse set S=10mm

The distance between the bulbs is 350, between the transverse brands - 850mm

1. Characteristics of steel 10HSND.

2. Features of welding steel 10HSND.

As already mentioned above, 10HSND steel belongs to the group of structural low-alloy steels.

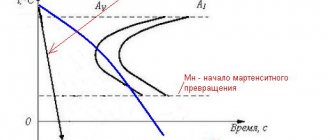

This group of steels behaves in the same way when welding as low-carbon steel, but there are differences in the action of thermal cycles:

1. There is a greater tendency for grain growth in the heat-affected zone, especially when overheated.

2. The possibility of the formation of hardening structures, which will cause the formation of cold cracks.

3. Reduction in the impact toughness of the metal in the heat-affected zone of the HAZ of the welded joint.

4. The resistance of the weld metal against the formation of hot cracks is lower due to the presence of alloying elements.

5. Sensitivity to stress concentrators and even thermal “burns”.

Low alloy steels can be welded well by all fusion welding methods. Usually there are no difficulties associated with the possibility of the formation of cold cracks caused by the formation of hardening structures in the weld or heat-affected zone. However, in steels containing upper limit carbon and a high content of manganese and chromium, the likelihood of cold cracks forming in these zones increases, especially with increasing cooling rate (increasing metal thickness, welding at subzero temperatures, welding with small-section seams, etc.). Under these conditions, prevention of cracks is achieved by preheating to 120 0 -200 0 C. Preliminary and subsequent heat treatment of steels used in critical structures serves this purpose, and also allows one to obtain the necessary mechanical properties of welded joints (high strength or ductility, or their required combination).

Therefore, when welding low-alloy steels, more stringent requirements are imposed on the welding mode parameters than when welding unalloyed low-carbon steels. Welding is limited to narrow limits of changing the mode parameters in order to simultaneously ensure the minimum occurrence of hardening structures and reduce overheating.

This technological process was written using the modern Vertikalv3 program, which made it possible to determine and calculate welding modes with higher accuracy, select the necessary equipment, welding materials, edge cutting, etc.

2.1 Clean parts for welding to bare metal

3. Covered electrode arc welding

3.2 Grasp the sheets along the entire length of the joints.

Electrodes UONII-13/55-4 GOST 9466-75

Seam=C8, Isv=150-210A, Ud=23V, L=14m, Lpr=35mm, Npr=41

4.1 Clean the weld from slag and metal splashes

4.2 Clean the weld bead flush with the base metal

5. Submerged arc welding

5.1 Weld the deck flooring sheets in the lower position on a copper slider in accordance with GOST-8713-79. Flux OSTS-45, wire 4.0 Sv-08A (according to RD5R.9083-92). Seam=C8, Isv=830-860A, Ud=38-40V, Vsv=15-17m/h, Reach=25-45, L=14m

6. Assembly (a longitudinal set is installed to the panel)

7.1 Clean parts for welding to bare metal

8. Arc welding with coated electrode

Electrodes UONII-13/55-4 GOST 9466-75, Seam=T8 8 25 200, Ist=150-210A, L=63m, Lpr=25mm, Npr=253

9.1 Clean the weld from slag and metal spatter

9.2 Clean the weld bead flush with the base metal

10. Carbon dioxide arc welding with solid wire

Seam=T8 6, Iw=300A, Ud=28-30V, Vw=17m/h, L=56m, welding wire Sv-08A-1.6mm, carbon dioxide GOST 8050-76

12.1 Clean parts for welding to bare metal

Electrodes UONII-13/55-4 GOST 9466-75, Seam=T8 6 25 100, Ist=150-210A, L=28m, Lpr=25mm, Npr=161

14.1 Clean the weld from slag and metal spatter

14.2 Clean the weld bead flush with the base metal

15. Submerged arc welding

15.1 Weld T-beams according to GOST-8713-79. Flux OSTS-45, wire 4.0 Sv-08A (according to RD5R.9083-92). Seam=T8 6, Isv=830-860A, Ud=38-40V, Vsv=15-17m/h, Reach=25-45, L=56m

16. Assembly (welding the T-bar set to the panel)

17.1 Clean parts for welding to bare metal

18. Arc welding with coated electrodes

Electrodes UONII-13/55-4 GOST 9466-75, Seam=T8 6, Ist=150-210A, L=28m, Lpr=25mm, Npr=161

19.1 Clean the weld from slag and metal spatter

19.2 Clean the weld bead flush with the base metal

20. Carbon dioxide arc welding with solid wire

Seam=T8 6, Iw=300A, Ud=28-30V, Vw=17m/h, L=56m, welding wire Sv-08A-1.6mm, carbon dioxide GOST 8050-76

21. Control of the appearance of welds, the presence of marks - 100%

22. Ultrasonic testing of welds according to GOST 14782-86. - 50%

| Characteristic name | Meaning |

| Supply voltage | 2 x 380V |

| Rated frequency, Hz. | 50 Hz |

| Electrode diameter | 2-5mm. |

| PV at 300A | 40% |

| PV at 200A | 100% |

| Welding current adjustment range | 60- 300A |

| Open circuit voltage | from 25 V - 50 V |

| Power consumption | 9kW |

| Primary protection current | 25A |

| No-load current | no more than 1.6A. |

| Power cord length | 3m |

| dimensions | 410x140x400 mm |

| Weight | 42 |

Nominal operating mode, % 60

Power consumption, kW 60-500

Overall dimensions, mm 1050×760×960

Supply voltage, V 380

regulation limits 100-500

feed speed, m/h 120-1200

| Parameter name | VDU-1001 |

| Rated voltage of the three-phase current supply network, V at a frequency of 50 Hz | 380 |

| Primary power, kVA, no more | 82 |

| Open circuit voltage, V, no more | 85 |

| Welding current control limits, A (PVC/ZHVH) | 100-1001120-1000 |

| Rated operating voltage, V | 56 |

| Operating voltage regulation limits, V | 24-56 20-56 |

| (PVC/ZVC) | |

| Nominal operating time, duty cycle, % | 100 |

| Efficiency, %, not less | 79 |

| Weight, kg, no more | 500 |

Technical data of welding tractor

GOST 5264-80 “Manual arc welding. Welded connections. Basic types, structural elements and dimensions"

GOST 14771-76 “Arc welding in shielding gas. Welded connections. Basic types, structural elements and dimensions"

GOST 8713-79 “Submerged arc welding. Welded connections. Basic types, structural elements and dimensions."

GOST 14782-86 “Non-destructive testing. Welded connections. Ultrasound methods"

RD5R.9083-92

“Steel ship hulls. Welding of carbon and low-carbon steels"