Home / Consumables

Back

Reading time: 20 min

0

415

- General data Main differences between Steel 20 and Steel 20A

- Characteristics of material 20L

Total information

| Substitute |

| Steel 15, Steel 25 |

| Type of delivery |

| Long products, including shaped steel: GOST 1050-74, GOST 2590-71, GOST 2591-71, GOST 2879-69, GOST 8509-86, GOST 8510-86, GOST 8240-72, GOST 8239-72. Calibrated rod GOST 7417-75, GOST 8559-75, GOST 8560-78, GOST 10702-78. Polished rod and silver steel GOST 14955-77, GOST 10702-78. Thick sheet GOST 1577-81, GOST 19903-74. Thin sheet GOST 16523-70. Tape GOST 6009-74, GOST 10234-77. Strip GOST 1577-81, GOST 103-76, GOST 82-70. Wire GOST 5663-79, GOST 17305-71. Forgings and forged blanks GOST 8479-70. Pipes GOST 10704-76, GOST 10705-80, GOST 8731-87, GOST 8732-78, GOST 8733-87, GOST 5654-76, GOST 550-75. |

| Purpose |

| After normalization or without heat treatment, crane hooks, couplings, bearing shells and other parts operating at temperatures from -40 to 450 ° C under pressure, after chemical treatment - gears, worms and other parts that require high surface hardness with low core strength . |

The main differences between Steel 20 and Steel 20A

The addition of the letter “A” at the end of the designation of Steel 20 indicates that Steel 20A belongs to the category of high-quality steel. The main differences in the chemical composition are more stringent requirements for the Sulfur (S) content and broader requirements for the Carbon (C) content (see table).

| Chemical element | % | |

| Steel 20 | Steel 20A | |

| Carbon (C) | 0.17-0.24 | 0.15-0.25 |

| Sulfur (S), no more | 0.04 | 0.035 |

Therefore, Steel 20A is less susceptible to embrittlement.

Types of delivery

| B22 – Long and shaped rolled products | GOST 8510-86; 8239-89; 10551-75; 8240-97; 2879-2006; 2591-2006; 2590-2006; 8509-93; 1133-71; 11474-76; 9234-74; |

| B23 - Sheets and strips | GOST 6765-75; 14918-80; 19903-74; 82-70; 16523-97; 103-2006; |

| B24 - Tapes | GOST 3560-73; |

| B32 – Long and shaped rolled products | GOST 7417-75; 8560-78; 8559-75; 1050-88; 1051-73; 14955-77; 10702-78; |

| B33 - Sheets and strips | GOST 4405-75; 10885-85; 1577-93; 4041-71; |

| B34 - Tapes | GOST 19851-74; 10234-77; 503-81; |

| B62 — Steel pipes and connecting parts for them | GOST 22786-77; 8638-57; 8645-68; 53383-2009; 24950-81; 6856-54; 30564-98; 30563-98; 8646-68; 23270-89; 8644-68; 11249-80; 20295-85; 5005-82; 8642-68; 10707-80; 1060-83; 550-75; 8639-82; 8731-87; 8732-78; 8733-74; 8734-75; 12132-66; 9567-75; 3262-75; 14162-79; 13663-86; 10705-80; 10704-91; 5654-76; |

| B71 – Low carbon steel wire | GOST 5663-79; 1526-81; 792-67; 5437-85; |

| B72 – Medium and high carbon steel wire | GOST 17305-91; 9389-75; 7372-79; 26366-84; 3920-70; 9850-72; |

| B76 – Metal mesh | GOST 9074-85; |

Decoding the brand

The alloy belongs, according to GOST 1050-88, to structural high-quality carbon steels, which are subject to more stringent requirements for composition and production conditions.

The marking indicates the average content of the main component (carbon) in hundredths of a percent - 0.20%. As its concentration increases, the surface hardness of the material increases, but at the same time its ductility decreases. The range of permissible carbon concentrations in metal is established by standards within 0.17-0.24%.

Manganese and silicon are used as deoxidizing agents. They help remove oxygen and other gases from the metal, which increase the porosity of its structure. The silicon content is in the range of 0.17-0.35%, manganese - 0.35-0.60%.

The alloy also contains other elements in small quantities that have a positive effect on its properties. However, their concentrations are too low:

- nickel – up to 0.3%;

- chromium – 0.2%;

- copper – 0.3%.

The presence in the metal of minimal amounts of harmful impurities is inevitable, deteriorating its mechanical properties:

- sulfur – up to 0.04%;

- phosphorus – 0.035%.

Decoding steel 10

The grade of steel indicates its chemical composition, quality and degree of deoxidation. The fewer numbers and letters in the stamp, the simpler the metal composition. One number denotes mild carbon steels, consisting of 98-99% iron.

- The word “steel” means that the brand is of high quality. The quality of steel is determined by the percentage of harmful impurities - phosphorus and sulfur; the lower the percentage, the higher the quality. There are steels of ordinary quality (st), high-quality (steel), high-quality (A) and especially high-quality (SH).

- 10 is the percentage of carbon in hundredths. Steel 10 contains 0.1% carbon. Carbon in significant concentrations changes the properties of the alloy, imparts strength and hardness, but reduces ductility and toughness. Carbon steels are not resistant to corrosion and are not used in aggressive environments, but are well suited for the production of mass-produced products due to their low cost and simplicity of the production process.

- Sp - means the degree of deoxidation - calm. If the degree of deoxidation is not indicated in the marking, as is the case with steel 10, then it is a mild steel. Deoxidation is the process of removing impurities from an alloy, primarily oxygen and nitrogen, in order to reduce the formation of bubbles and gas pockets when the alloy solidifies in the final stages of production. According to the degree of deoxidation, steel can be calm (sp), semi-quiet (ps) and boiling (kp). Boiling water contains the most impurities; its structure is porous and heterogeneous. Calm, maximum purified from impurities and homogeneous. Semi-calm occupies an intermediate position.

The composition of steel is not limited to the elements specified in the grade. The marking lists only those additives that are contained in significant quantities and affect the properties of the alloy.

Characteristics of steel 20

High-quality steel 20 must meet standards, have certain parameters and scope of use. Let's consider due to what characteristics the alloy remains in demand and popular.

Since steel grade 20 is a high-quality material, strict requirements are imposed on its chemical composition. Smelting is carried out according to the rules prescribed in GOST steel 20. The composition includes the following components:

- Iron (Fe) – approximately 98%.

- Carbon (C) – 0.2%. The number 20 in the name indicates the content of this element. Carbon is responsible for strength. The more it is, the harder and more durable the alloy becomes.

- Silicon (Si) – 0.17-0.35%. Needed to remove hydrogen, oxygen, nitrogen from the composition. They increase porosity and the number of gas pockets, which significantly reduce the strength of the metal.

- Manganese (Mn) – 0.35-0.65%. Also a serious deoxidizer, it also promotes the removal of sulfur. Improves surface quality, reduces the risk of cracks during hot working. Thanks to it, welding and forging proceed better.

- Nickel (Ni) – up to 0.3%, chromium (Cr) – up to 0.2%, copper (Cu) – up to 0.3%. The elements lead to improved mechanical and corrosion-resistant properties. However, since their number is small, they do not have a serious effect on the steel.

- Phosphorus (P) – up to 0.035%, sulfur (S) – up to 0.04. Harmful impurities. If their content is too high, the steel becomes too brittle. In addition, the viscosity index drops.

Deoxidation level

- Calm steel 20. Due to the introduction of silicon and manganese, oxygen is completely absent. Iron oxides are also in very small quantities. This ensures “quiet” solidification of the metal in the ladle. The homogeneity and density of ST20 at the outlet are excellent, only a gas shell is formed on top.

- Boiling steel. It is formed by the deoxidation of manganese, which leads to an increase in the content of ferrous oxide. The compound forms carbon dioxide. As a result, gas bubbles form, looking like a boiling mass. Such a metal is very porous, chemical elements are distributed unevenly, which causes deterioration in mechanical characteristics, increases the risk of cracks, and impairs weldability. But there are also advantages - low price, absence of unsafe waste.

- Semi-quiet ST20. Something in between the previous varieties of the alloy.

Types of processing

- forged,

- calibrated,

- hot rolled,

- silver (it has a round base and is coated with a special composition).

The density of steel is 20 - 7850 kilograms per cubic meter. The melting point is 1500 degrees Celsius. The mixture becomes completely liquid at a temperature of 1600 °C. The alloy gives off heat easily, but also accumulates it well. Thermal conductivity coefficient is 48 W/(m deg), specific heat capacity is 490 J/(kg °C). Steel conducts current very well.

The material has low chemical resistance to most acidic compounds. If moisture gets on the surface, rust will remain on it. Because of it, the appearance and strength are greatly deteriorated.

To protect the material from corrosion, galvanic coatings (chrome, zinc, and other similar compounds) should be applied.

The steel is highly plastic, the strength is average, and the hardness is good. The elastic modulus is 200 MPa. The rupture occurs when the greatest elongation is reached at 23-26%, the relative narrowing is even greater - 55%.

Strength indicators are increased by peening, possibly rolling with rollers. Normalization or hardening annealing is performed. In this case we mean the thermal method of exposure.

It is characterized by increased viscosity; accordingly, the alloy is able to withstand impacts. Impact strength – 780 kJ/m².

It lends itself perfectly to pressure treatment and withstands any type of cutting. Stamping is mainly carried out hot. Does not crack during steam treatment and under high pressure. Weldability group 1.

- ST20 is included in the subgroup of cemented alloys. The hardness of the cemented layer is up to 62 HRC, while the core remains “soft”, in the range of 20-35 HRC.

- Chemical exposure and heat treatment (hardening) strengthen the metal and increase its service life.

- Weldability without restrictions, is not characterized by flake sensitivity, and is not prone to temper brittleness.

Structural quality carbon steel 20

Structural high-quality carbon steel is used for the production of hot-rolled sheets, circles, strips, seamless pipes, electric-welded pipes, hexagons, manifolds, pipelines, superheaters, other parts of high-pressure boilers, sheets for stamping, cemented products with a long service life at temperatures up to +3500C.

Steel 20 is one of the most practical steel grades, widely used for the production of steel pipes and hot-rolled sheets.

Metal grade Substitute

| 20 | 15 |

| 25 |

Composition of steel grade 20

The chemical composition of steel 20 is regulated by GOST 1050-58. According to his requirements, the mass fraction of carbon in the ladle sample of the alloy should be from 0.17% to 0.24%. Therefore, steel 20 is classified as low-carbon.

Standards for the content of other chemical elements in it according to GOST:

- nickel and copper - no more than 0.3%

- arsenic - not higher than 0.08%;

- manganese – 0.35% – 0.65%;

- chromium – not higher than 0.25%;

- silicon – 0.17% – 0.37%;

- sulfur and phosphorus - respectively, no more than 0.040% and 0.035%.

Characteristics of material 20L

Brand: 20L Substitute: 25L, 30L

Classification: Casting steel, unalloyed

Application: chabots, fittings, shaped castings of general mechanical engineering parts produced by the lost wax method, parts of welded cast structures and other parts operating at temperatures from -40 to 450 °C.

Types of supply of material 20L

| B42 - Rails. Overlays. Linings. Crutches | GOST 7370-98 Railway crosspieces of types P75, P65 and P50. Specifications |

| B82 – Steel castings | GOST 977-88 Steel castings |

Chemical composition in % of material 20L GOST 977 - 88

C Si Mn S P0.17 — 0.250.2 — 0.520.45 — 0.9 to 0.06 to 0.06

| Note: The proportion of phosphorus and sulfur impurities depends on the group of castings and the type of steel smelting |

The temperature of the critical points of the material is 20L.

Ac1 = 735, Ac3(Acm) = 854, Ar3(Arcm) = 835, Ar1 = 680 Technological properties of material 20L.

| Weldability: | no limits. |

| Flock Sensitivity: | not sensitive. |

| Tendency to temper brittleness: | not inclined. |

Foundry and technological properties of material 20L.

| Linear shrinkage: | 2.2 — 2.3 % |

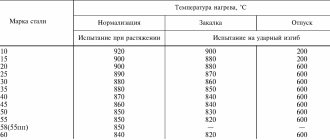

Heat treatment modes for 20L material

| Normalization 880 - 900 ° C or Normalization 880 - 900 ° C, Vacation 630 - 650 ° C |

Mechanical properties at T=20oC of material 20L.

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Castings, K20, GOST 977-88 | up to 100 | 412 | 216 | 22 | 35 | 491 | Normalization 880 - 900oC, Vacation 630 - 650oC, |

Physical properties of material 20L.

| T | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

| hail | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 2.01 | 54 | 7850 | 170 | ||

| 100 | 1.96 | 12.2 | 53 | 487 | 220 | |

| 200 | 1.88 | 12.7 | 51 | 500 | 294 | |

| 300 | 1.83 | 13.1 | 48 | 517 | 385 | |

| 400 | 1.73 | 13.5 | 43 | 533 | 490 | |

| 500 | 1.65 | 13.9 | 39 | 559 | 604 | |

| 600 | 1.52 | 14.4 | 35 | 588 | 761 | |

| 700 | 1.32 | 14.9 | 32 | 638 | 932 | |

| 800 | 1.2 | 12.6 | 27 | 706 | 1101 | |

| 900 | 12.4 | 27 | 706 | 1139 | ||

| T | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

Foreign analogues of material 20L

Attention! Both exact and closest analogues are indicated.

1.0443

| USA | Germany | Japan | France | England | Italy | Poland | Czech | Austria |

| — | DIN,WNr | JIS | AFNOR | B.S. | UNI | PN | CSN | ONORM |

1A

| ||||||||

| 1.0619 | ||||||||

| GP240GH | ||||||||

| GS45 |

| SCPH1 |

Designations:

| Mechanical properties : | |

| sв | — Short-term strength limit, [MPa] |

| sT | — Proportional limit (yield strength for permanent deformation), [MPa] |

| d5 | — Elongation at break, [%] |

| y | — Relative narrowing, [%] |

| KCU | — Impact strength, [kJ/m2] |

| HB | — Brinell hardness, [MPa] |

| Physical properties: | |

| T | — Temperature at which these properties were obtained, [Deg] |

| E | — Modulus of elasticity of the first kind, [MPa] |

| a | — Coefficient of thermal (linear) expansion (range 20o - T), [1/degree] |

| l | — Thermal conductivity coefficient (heat capacity of the material), [W/(m deg)] |

| r | — Material density, [kg/m3] |

| C | — Specific heat capacity of the material (range 20o — T), [J/(kg deg)] |

| R | — Electrical resistivity, [Ohm m] |

| Weldability: | |

| no limits | — welding is performed without heating and without subsequent heat treatment |

| limited weldability | — welding is possible when heated to 100-120 degrees. and subsequent heat treatment |

| difficult to weld | — to obtain high-quality welded joints, additional operations are required: heating to 200-300 degrees. during welding, heat treatment after welding - annealing |

Physical and mechanical properties

When considering the mechanical properties of 40X steel, it should be taken into account that it has high hardness and strength, the structure can withstand significant loads and is not subject to destruction during operation. Steel 40X is characterized by the following positive qualities:

- Quite high corrosion resistance, which is achieved by including chromium in the composition.

- High strength indicators. Hardness is measured in various indices, HRC and HB are often used. The hardness indicator corresponds to a value of 217 MPa.

- When choosing a more suitable material, attention is paid to specific gravity. The density of 40X steel is 7820 kg/m3.

Properties of St 40x

The elastic modulus and yield strength can vary over a fairly wide range, depending on temperature. For example, with a significant increase in temperature, the elastic modulus decreases. The yield strength determines how applicable the alloy is when producing workpieces by casting.

The alloy also has several significant disadvantages:

- Tempering fragility. After hardening, the structure becomes very susceptible to impact loads. The likelihood of increased brittleness can be reduced by following heat treatment technology.

- High tendency to form flakes. It is characteristic of quite a large number of different alloys.

- Poor weldability complicates the manufacturing process of various products. If desired, a variety of welding technologies can be used. The process is greatly simplified by preheating the structure. In addition, the structure is difficult to cut when using welding equipment.

- Flock sensitivity is a property that determines the high probability of internal cracks appearing after casting various products. Such defects often occur during hot deformation of alloy steel. Such defects cause high concentrations of hydrogen during heat treatment. The likelihood of defects can be reduced by strictly observing the temperature regime.

Welding steel

Recently, the method of vacuumization of the alloy has been quite often used, due to which the hydrogen concentration is reduced. That is why the quality of the resulting structure increases significantly.

Application of steel 20

Steel 20 is used for the manufacture of:

- pipes and pipe fittings, hooks and other parts operated under conditions of high pressure and temperatures from -40°C to 450°C;

- thin spare parts used in conditions of increased abrasion;

- stops, gears, fingers and other parts that are used under low load;

- welded profiles;

- (after chemical-thermal treatment) parts that require enhanced surface strength, but not the core (gears, worms, etc.).

Application area

According to the degree of weldability of the structure, it belongs to group 4. The weld seam can cause various cracks to form. That is why the 40X material is preheated before performing welding work, which avoids simply a huge number of problems with the operation of the resulting product.

In addition, it is necessary to carry out preliminary preparation of the edges for arc welding. When using contact point technology, heat treatment is required.

Other properties of the material in question determine its wide application. The following types of workpieces are supplied to production sites:

- Sheets. Sheet metal is widely used, for example, in cold or hot stamping. In addition, metal sheets are used for sheathing frame structures.

- Forgings are used as a basis for creating various products.

- Pipes are very common today, for example, when creating a heating system or for transporting various liquids.

- Rolled metal is used in the mechanical engineering field as a blank for various parts.

Circle f 160 st 40X with turning

After heat treatment, Steel 40 can be used to produce nozzles, reamers and tap bodies. An analogue of 40X steel can be used to produce various critical structures, for example, axles, shafts, gears, bolts or plungers. Foreign analogues can be used to manufacture parts that will be used outdoors at low temperatures. An example is the elements of bridges and railway structures.

To significantly increase the performance characteristics of the resulting products, various heat treatments are carried out.

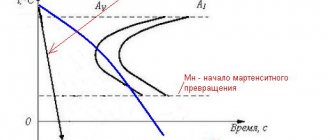

Hardening leads to a significant increase in surface hardness, but brittleness can only be reduced by tempering. It is possible to achieve the required indicators only if the specific features of the technology are observed.

Areas of application

Certain technical characteristics of steel 20 explain its use in different areas of industry:

- Production of pipe fittings (sleeve nuts, fittings, flanges, crosses, nipples).

- Manufacturing of building materials.

- Assembly of various metal structures, machines, ships, industrial equipment.

This metal is used to produce:

- Seamless pipes. Manufactured by cold or hot drawing. Their feature is high strength.

- All-welded cold-rolled pipes.

- Various profiles (wire, I-beams, channels, metal corners, sheets of different thicknesses, rods).

Products from this alloy are manufactured according to certain state standards:

- GOST 17305-91—production of wire of different sections.

- GOST 82-70 - production of metal strips of different widths.

- GOST 16523-97 - production of light sheets of small thickness.

- GOST 10704-9 - pipe manufacturing.

- GOST 8479-70 - production of forged parts, forgings.

- GOST 1577-93 - production of metal sheets of large thickness.

- GOST 14955-77 - production of silver and grinding rods.

- GOST 7417-75 - production of calibrated rods.

- GOST 8240-97, GOST 1050-88 - production of shaped and long products.

GOSTs indicate the basic requirements for finished products and their testing for admission to sale.