A lanyard is a rigging device that allows you to attach ropes, cables, chains, ropes to supports and easily adjust the tension of guy wires when they weaken or sag during operation. These simple screw devices were initially used on ships, but gradually began to be used in other areas of human activity, for example, when installing or strengthening structures, securing transported cargo, when it is necessary to create a large tension force.

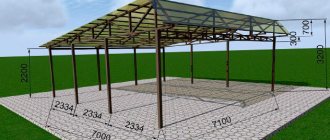

Today, cable tensioners are successfully used in various engineering structures; they help prevent emergency situations during cargo transportation, provide tension on cable fences, cable networks between houses, and hold antennas, masts, lightning rods, and bridges. In this case, the fixation of the cable can be temporary (for example, securing loads or installing tents) or permanent (for example, installing curtain strings or strengthening engineering structures).

The intended purpose of the device is determined by its design, standard size and strength characteristics. The most common standard mounting lanyard is a screw tie, depending on the size of which you can create a tension force from several kilograms to tens of tons. For high loads, only DIN 1478 (fork-fork) lanyard is used.

Operating principle and types of screw lanyards

A screw cable tensioner consists of a coupling-housing with two threaded holes for screws with different thread directions. When the couplings are rotated in one direction, they are screwed into the body, and in the other they are unscrewed, which allows you to continuously change the overall length of the tightening device. Adjustment does not require special physical effort and can be done at any time as needed.

The turnbuckle body has two versions - open or closed (bushing). The latter are suitable for harsh operating conditions, when there is a risk of damage, icing, clogging of the tension mechanism with dirt or sand. According to the manufacturing method, couplings are welded, stamped, forged and cast.

Screw heads are made in the form of a hook, a ring, a fork, a pin, or a combination of these, such as a hook-ring or a fork-eye. A high level of reliability is ensured by fork-fork tensioners. A welded stud-stud lanyard is used in cases where it is necessary to connect it with other rigging elements or structures by welding, thereby creating a permanent connection.

Requirements for lanyard parts

GOST 9690-71 provides the following options for the design of turnbuckle couplings:

- Stamped closed couplings.

- Stamped open couplings.

- Cast couplings.

- Welded closed couplings.

- Welded open couplings.

In closed-type turnbuckles, the threaded part of the load element is completely located in the coupling body. This is considered safer, because if the gripping device suddenly breaks (which most often happens along the thread), its remains do not fly apart. Therefore, the maximum permissible tension force for closed lanyards is always greater than for open ones.

The manufacturing technology of the couplings also largely determines the capabilities of the lanyard. Thus, stamped couplings (the blanks for which are high-quality structural steel according to GOST 1050, steel grade 20 and higher) are strong and reliable. This is explained by the fact that the macrostructure of stamped products does not have cut fibers, and, therefore, there are no stress concentrators. The same is typical for cast couplings, however, the structure of the cast metal is coarser-grained, therefore, other things being equal, the body of a cast coupling will break faster than a stamped one.

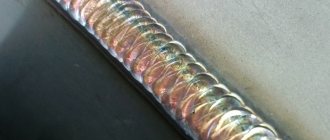

Welded couplings have the worst load-bearing capacity: in the weld zone, the strength of the metal is reduced by 20...25% (for the same reason, it is strictly forbidden to restore damaged lanyards by welding).

The standard allows two designs of round turnbuckles: with a through hole in the middle of the body, and without it. In the first case, the conditions for rotation of the housing when tightening are improved, but the cross-section of the coupling is weakened. The starting material for such couplings is seamless steel pipes in accordance with GOST 8734 made of steel 25 (in low-critical turnbuckles, duralumin and ordinary quality steel St. 3 in accordance with GOST 380 can also be used).

For the compactness of coupling lanyards, the diameter of the cargo grips is important. In closed couplings it does not exceed M42, otherwise the coupling becomes heavy and difficult to adjust. Open type couplings do not have such restrictions.

Turnbuckle couplings are manufactured for the following types of grips:

- BB (fork-fork).

- VU (fork-ring).

- UU (ring-ring).

- GG (hook-hook).

- VG (fork-hook).

- GU (hook-ring).

Standards, loads and sizes of lanyards

In the post-Soviet space, their production is regulated by GOST 9690, in Europe they adhere to the standards DIN 1480 and DIN 1478, in the USA ASTM F1145-05 applies.

Lanyard DIN 1480 is a general-purpose device not intended for work that involves lifting loads. It withstands high static loads, perfectly holds tension ropes and ensures reliable fixation of vertical structures. Its load capacity ranges from a few kilograms to 3 tons. In everyday life it is used, for example, for stretching clotheslines or strings for curtains.

Lanyard DIN 1478 is a cargo lanyard with fork hooks, made of high-strength steel, has a safety factor of at least 4:1 and is designed for higher static and dynamic loads (up to 10 tons). Approved for use in systems with high tension, for example, when securing multi-ton cargo on transport, in the construction of suspension bridges, for organizing guy wires for awnings, tents, and massive antenna mast systems.

The size of the screw tie is determined by the diameter of the thread, which has standard metric characteristics and a diameter from M5 to M56. The most popular models: hook-ring lanyard M8, M10, M12, M16 or ring-ring M8, M10, M12. Another important parameter of the product is its length when fully untwisted (L1) and in the screwed state (L), the difference between them (L1-L) is a linear value within which the tension of the rope branch can be adjusted.

Lanyard selection

Selecting a tool based on the expected load is a guarantee that it will not deform during operation.

The tables that the seller has will help you do this, where the manufacturer indicates which model is designed for what. But the choice depends not only on the weight of the load, but also on the function. The first parameter you need to pay attention to is thread diameter . Screw fasteners for M10, M8, M12, M20, M16 have different threads. The number following the letter “M” indicates the thread diameter in millimeters, M12 is a 12 mm thread. Marking T 10-01, T 30-01 indicates the load at which the part begins to collapse.

Lanyards are most often used when working outdoors, where they are exposed to moisture and temperature changes. Modern parts are not supplied without protection from such exposure; most often this is galvanizing.

Galvanized or stainless steel lanyard?

When choosing a screw tie, you should take into account the external conditions in which it will work and the degree of aggressiveness of this environment. For dry rooms and temporary outdoor use, it is enough to purchase a galvanized cable tensioner. For constant use outdoors, in places with a humid and frosty climate, closed stainless steel lanyards made of A2 steel are suitable, and in particularly aggressive conditions (chemical production, maritime shipping, hot shops, pools with chlorinated water) - made of acid-resistant steel A4.

Did you know?

If you need to cut a thread in a hole and don’t have a tap holder at hand, a regular screw lanyard will help out. Clamp the shank of the tap between its screws, and use the body of the device as a driver.

How to properly tension the cable

For proper operation of the lanyard, you should rotate its body evenly, which will cause the screws to move in opposite directions. The process ends when the cable tension reaches the level necessary to securely fix the object.

When performing tension, you should avoid overloading so as not to deform the lanyard or the tensioned cable. If the tension is too high, you should release it by rotating the lanyard in the opposite direction. It should be remembered that the load should only be axial.

It is recommended to perform the operation using a special torque tool, which allows you to adjust the tension force with great accuracy.

The lanyard can only be subjected to loads for which the tool is designed.

Cable-stayed fastenings (chain tensioners)

Hook-hook chain lanyard (ratchet) is the name of a cable-stayed fastening with hook grips, designed for securing large and heavy loads with chains on transport platforms. The devices have a ratchet or lever mechanism, through which a large tension force is easily created.

The chain tie-down is a simple and reliable manual mechanism used all over the world in securing systems for large-size and heavy-tonnage loads. It is used to tension fastening chains, which in turn securely fix and hold the load, preventing its spontaneous movement or fall during transportation by road, rail and other modes of transport. Based on their design, they come in two types, the characteristics of which are discussed below.

Ratchet type tightening device

This chain lanyard consists of a ratchet mechanism with a rotation switch and two rotary hooks located at opposite ends of the device. The tension of the fastening chains is ensured by the convergence of the hooks by turning the mechanism handle. The positive features of this ratchet include:

- ease of installation of the device into the mounting system;

- application of minimal physical effort when working;

- lever that does not require additional fixation.

Lever type tightening device

Its design also consists of two rotary hooks that ensure the engagement of the chain fastening branch, as well as an eccentric lever mechanism. In this case, the tension of the chains is ensured by applying manual force to the eccentric mechanism, which, passing through the point of maximum tension, self-clamps. Reliable fixation of the lever is ensured by the chain itself, which pushes the device to the sides and thereby prevents the mechanism from opening. The positive features of this chain lanyard include:

- minimal installation time;

- simplicity of design;

- small sizes;

- absence of a protruding lever in the operating position of the device.

Types of devices for tensioning cables

Before purchasing a tensioning device, you need to understand its markings, namely: C + C - hook and hook, C + O - hook and ring, O + O - ring and ring. These are the most commonly used, but there are others. In order to tighten or loosen the tension, you need to rotate the “ring”, after which the screws will move either towards the center or away from it. The type of tool depends on what kind of work you are going to do. Galvanized tools are used when you need high tension force. The cargo type is used when it is necessary to either tighten the cables or attach a heavy load. Such devices can reach a weight of up to 25 kg, and this tool can withstand up to 90 tons.

The “hook-hook” type of device is used when it is necessary to change the length or tension of a chain or cable, mainly when installing masts or antennas. The “ring hook” is also used in such cases. The moving parts of this version of the device have threaded threads, thanks to which the length can be adjusted. Also now there are options using modern technologies, using which you can adjust the smoothness of the tension. Such tools are used when working with fiber optic cables. In order to tension wires and cables under light loads, you can use closed tools.

Where to buy a lanyard in St. Petersburg?

In our Krepkom store you can buy hook-ring, ring-ring, hook-hook, fork-fork lanyards, as well as chain ratchets for transporting heavy equipment, equipment, and logs. All of them have been load tested and have a large safety margin (4:1, 5:1, 6:1). How much do these rigging devices cost? – The price of a lanyard largely depends on its size. The price range for “Strong” is as follows: from 150 to 7,000 rubles per unit of goods.

We hope this review article will help you make the right decision when choosing a rigging lanyard for tensioning a cable or chain.

Chains, slings, rigging Updated: 07/13/2021 13:55:41

How to prepare a lanyard

Before you start tensioning the cable, you need to prepare the tool, for which:

- wipe the lanyard with gasoline and polish it with a felt wheel;

- apply lubricant (molybdenum or graphite);

- check the mechanism by running it idle;

- if sea water gets on the lanyard, rinse it with fresh water;

- form a loop at the end of the cable using clamps and pass it through the thimble.

Rules for selecting a lanyard

Like any other rigging element, turnbuckles should be selected based on the conditions of the specific work being carried out: the size of the space, the need for anti-corrosion protection, the weight of the load, the operating force on the unit.

The type of head is selected according to the type of mate (the hook is fixed to the ring, etc.). The size of the tensioner head must match the size of the counter fastener. The selection of a lanyard for a rope is carried out if the head is attached to the rope directly, without additional devices. The diameter of the thread and the safety factor of the lanyard must correspond to the expected pressure force from the ropes.

All necessary characteristics are indicated by the manufacturer in special tables for each type of lanyard. Correct selection of a lanyard, based on future loads on it, will extend the service life and avoid deformation of the rigging element.

Scope of application

Due to their convenient use, chain ties for securing loads are found in a wide variety of applications. Ratchets are mainly used for particularly heavy and valuable cargo, where its safety and immobility during transportation is important. Most often, cargo securing means are used for transportation and reliable fixation:

- special equipment, including armored vehicles mounted on trawls or railway platforms;

- commercial and industrial cargo;

- luggage transported on an airplane, on a ship, in a railway container;

- super heavy loads.

Ratchets are often used in everyday life, for example, when moving and transporting fragile furniture. The cargo chain tie provides optimal securing regardless of the type of transport, be it a car van or a railway container. Load securing means can be used in various climatic conditions and industrial applications. To do this, their surface is galvanized or coated with a special paint that prevents corrosion and oxidation of the metal.

What should you consider when choosing?

- The chain type lanyard is designed for axial load, which means that it is not used for lifting loads.

- Chain ties must be selected taking into account the load power. Here it is also important to take into account the parameters of the chain, which depend on the steel class and load capacity.

- Devices must be certified and labeled.

offers a wide selection of different standard and custom lanyards. All supplied products comply with regulatory documents and are confirmed by quality certificates.

Chain lanyard with lever | ||||||||||||

| Size | Tonnage (t) | Chain, mm | Minimum ultimate load (t) | Maximum permissible load (t) | Weight, kg | Dimensions (cm) | ||||||

| A | B | C | D | E | F | G | ||||||

| 5/16-3/8 | 2,4 | 8-8 | 4,9 | 9 | 4,773 | 64.008 | 58.928 | 49.5046 | 39.497 | 28.498 | 28.498 | 1.295 |

| 3/8-1/2 | 4,2 | 10-8 | 8,36 | 15 | 5,864 | 72.39 | 67.0052 | 56.007 | 44.805 | 32.994 | 30.988 | 1.498 |

Chain lanyard with ring-ring ratchet | ||||||||||

| Size | Tonnage (t) | Chain, mm | Minimum ultimate load (t) | Maximum permissible load (t) | Weight, kg | Dimensions (cm) | ||||

| A | B | C | E1 | F | ||||||

| 5/16-3/8 | 2,4 | 8-8 | 4,9 | 9 | 3,545 | 35,356 | 3,302 | 6,604 | 55,118 | 2,006 |

| 3/8-1/2 | 4,2 | 10-8 | 8,36 | 15 | 3,545 | 35,356 | 3,302 | 6,604 | 55,118 | 2,590 |

| 1/2-5/8 | 5,9 | 13-8 | 11,81 | 20,9 | 3,864 | 35,356 | 3,302 | 6,604 | 56,3118 | 2,590 |

Chain lanyard with ratchet hook-hook | ||||||||||||

| Size | Tonnage (t) | Chain, mm | Minimum ultimate load (t) | Maximum permissible load (t) | Weight, kg | Dimensions (cm) | ||||||

| A | B | C | E | E1 | F1 | G | ||||||

| 5/16-3/8 | 2,4 | 8-8 | 4,9 | 9 | 4,773 | 64.008 | 58.928 | 49.5046 | 39.497 | 28.498 | 28.498 | 1.295 |

| 3/8-1/2 | 4,2 | 10-8 | 8,36 | 15 | 5,864 | 72.39 | 67.0052 | 56.007 | 44.805 | 32.994 | 30.988 | 1.498 |