Home production of chain-link mesh is important for both commercial and personal purposes. It is advisable to make it manually for the household to create cages for rabbits and various enclosures. If you need large volumes, it is better to order a ready-made PVC mesh.

To make chain-link mesh at home, there are two key methods: with and without a machine. At the same time, you can also create the machine yourself, since it is a structurally simple mechanism.

Video: making chain-link mesh at home

Why do you need to make a chain-link mesh yourself?

For suburban areas, without exaggeration, the ideal option for arranging an elegant and functional fence is a chain-link fence. You can install it yourself; it does not shade the garden, as solid types of fences do. And purely externally, mesh fencing looks more airy and bright.

With proper installation, such a fence will serve for several decades without losing its original appearance. However, it usually does not require any care.

Also, independent weaving of chain-link can be considered as a commercial activity. Such a business will not bring very high profits, since the cost of steel wire, which is required to make the mesh, is quite high. But if you periodically order a chain-link fence (for example, neighbors in a holiday village), a good addition to the basic salary will be guaranteed. You can make mesh in your free time and sell it at an affordable price.

What documents are needed to open

If full-fledged production is planned, we open an LLC, if the owner plans to enter into agreements with wholesale contractors. List of documentation for opening an enterprise:

- Application for the creation of a limited liability company.

- A decision signed by the founders on the formation of an LLC.

- Fiscal receipt for payment of state duty.

- Supporting documents for the payment of authorized capital.

- Notarized articles of association with articles of association.

You can prepare the entire documentation package listed above yourself, but to save time and avoid errors during registration, we recommend that you seek help from professional intermediary companies that deal with the preparation of such services.

How to make a hand loom?

For production, you can use a homemade device. The machine can be either automatic or semi-automatic.

The device is suitable for weaving mesh with arbitrary mesh size. The most popular sizes are 8x8 cm and 4.5x4.5 cm.

The machine consists of the following parts:

- a drum that feeds the wire;

- bent channel, section;

- metal rollers;

- bending machine.

A simple bucket can play the role of a drum. A wide board is used as a base. A bucket is placed on top, bottom up. To prevent the bucket from falling during the weaving process, secure it with any weight.

It is necessary to wind wire around such a homemade mechanism. Then it will be fed to a channel with three metal rollers. For their high-quality rotation, it is worth using bolts as fasteners. They are usually supplemented with small restrictive washers of about 1 mm.

The bending machine is also made independently. It is permissible to use a steel pipe of suitable size, but always with thick walls.

A spiral-shaped groove should be made in it at an angle of 45° to the axis. The size should be about 4-5 mm. At the end of the groove, about 5 cm before the end of the pipe, you need to make a round hole. All this is necessary in order to install a carbide knife (usually steel is used).

The pipe is connected to the angle using a welding machine. Then you should place the structure on a reliable base and fix it. It is important not to close the groove during welding.

The knife is secured using a screw or pin. The support can be adjusted using a washer. It is necessary to make the entire weaving machine step by step and extremely carefully. For simplicity, you will need drawings with dimensions and markings.

Additionally, you can make a lever. It will simplify the process of twisting the wire. It is attached directly to the visible part of the knife. This addition is especially relevant if you plan to produce a large amount of mesh.

Device device functions

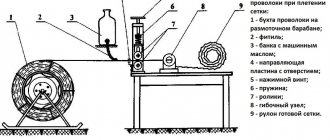

A homemade machine for making chain-link mesh consists of four devices:

- lubricating;

- server;

- winding;

- tension

The lubricating device is fixed on a plate with rollers. The basis for such a device is a bicycle pump.

The pump is mounted on the plate with the bottom up. The bottom is cut off, and the pump cover is easily fixed on the body, securing the plug in it. The plug is cut, and oil is poured into the pump. The edges of the pump are additionally strengthened with a bearing race.

The machine for the production of chain-link includes a feeding mechanism, which is based on industrial knitting equipment. A meter-long steel pin is fixed in the center of the base of the device. Two rods with a diameter of 10 mm are welded to it. A bearing with a ring and a driver is attached to the upper end of the pin.

The winding mechanism is a pipe with special spiral slots and a knife. The winding mechanism forms the desired cell size.

The tension mechanism of the device has the form of a right triangle, in which:

- a steel plate with holes for the rollers serves as the hypotenuse of the triangle;

- the remaining sides are made of steel angle.

For better tension, it is recommended to make about 30 holes in the hypotenuse plate.

Mesh production

First you need to do a little preparatory work. The wire for weaving is lubricated with oil; you can use already used material.

Even this process can be slightly automated and simplified at home. To do this, a small mechanism is constructed from a box with a through hole, with a diameter slightly larger than the cross-section of the wire.

Oil is poured inside, and the raw material is passed through this device and lubricated in the process.

The manufacturing process itself is quite simple. The weaving sequence usually looks like this.

- The end of the wire is bent with a hook. The bend should be approximately half the width of the mandrel knife.

- The hook is inserted into a groove on the pipe and clings to the edge of the steel tool.

- The knife must be rotated. As a result, the wire will wind, curl and move further along the groove. The output is a wavy wire. Its length is equal to the width of the future canvas. It is worth noting that the working surface must be of a suitable size.

- After reaching the required length, the wire is cut with pliers at the bending unit.

- The finished workpiece should be moved away from you by the width of the cells of the future canvas.

- Next, the process of manufacturing the next segment begins. The new workpiece is independently screwed into the previous one. It is only important to always twist the knife in one direction. Otherwise, the workpiece will be damaged.

- The process is repeated until the canvas is ready.

During the manufacturing process, it is important to monitor quality. A well-made workpiece should lie absolutely flat on the table, without twisting into a spring.

If this is not the case, then the reason may lie in the elasticity and tension of the wire. Problems also arise with the angle of twist of the knife along the axis.

A homemade machine allows you to produce chain-link mesh in any quantity. A standard 1.5 m snake will require about 2.3 m of wire. One linear meter with cells 8x8 cm is made from 25 blanks. This amount of 2.5 mm wire mesh weighs about 2.5 kg.

The individual parts and canvases are easily fastened together. To make it easier to join the chain-link mesh, you don’t have to unscrew the outer wire. The finished canvas can be used immediately, for example, for a fence. For a longer service life, it is recommended to coat the mesh with paint after installation. The reliable layer is easy to apply with a brush and protects the wire from aggressive environmental influences.

Construction of houses

0 votes

+

Vote for!

—

Vote against!

Chain-link mesh is widely used both in construction and in landscape design. To weave it yourself at home, you will need a special device. Let's look at the features of its manufacture below.

Table of contents:

- Chain-link mesh - general concept and features

- Machine for weaving mesh netting: production and use

- Do-it-yourself chain-link mesh

- Tips for using a machine for producing mesh mesh

Chain-link mesh - general concept and features

Chain-link mesh is a structural material that is used in construction for the construction of fences, fences, enclosures for dogs, used for sifting sand and as a frame for weaving plants.

The grid got its name from its inventor, Karl Rabitz. To produce such a mesh, both simple machines are used, on which spirals are screwed into each other, and high-quality automatic machines, which produce a large amount of mesh in a short period of time. The basis for the production of chain-link mesh is low-carbon steel wire; it is also possible to use galvanized or polymerized wire. Stainless steel wire is very rarely used.

Chain-link mesh is a material for the construction of fences, used in mining, in construction work, is the basis for insulating surfaces, and is used to make cages for animals.

In relation to the shape of the cells, the chain-link mesh is:

- rhombic, with a sixty-degree angle;

- square.

Purchased chain-link mesh is transported in roll form, the height of the roll is 150 cm and the length is about 1000 cm. Depending on the manufacturer, the height and length of the roll can be adjusted. If the mesh is made on a simple or manual machine, then its end parts are not bent, otherwise, the spiral ends are bent and they are connected by twisting into a roll. To transport this material, its ends are wrapped with artificial fabric or plastic film.

The scope of use of chain-link mesh is directly related to being outdoors, so it is constantly under the influence of precipitation. If it is not treated using special technology, then after the first exposure to moisture it will become covered with rust.

There are several ways to protect the chain-link mesh from moisture:

- painting;

- galvanizing;

- polymerization.

The most common method is galvanizing. In most cases, galvanized steel is used in the production of chain-link mesh, so you should choose steel that contains as much zinc as possible. Wire production involves applying zinc to its surface using the hot-dip galvanizing method. If the wire is made using this method, its service life will be from twenty to twenty-five years.

If zinc is applied to the wire using the electrolytic method, its service life is significantly reduced and is no more than three years.

Chainlink mesh photo:

When using galvanized high-quality chain-link mesh on the banks of reservoirs, rivers or seas, it will still quickly rust. In this case, it is recommended to make a chain-link mesh from steel coated with polymers. If such a coating is of poor quality, it will quickly fade, crack and fade. When choosing a steel mesh chain-link with a polymer coating, you should give preference to its more expensive options and trusted manufacturers who guarantee the resistance of the wire to ultraviolet treatment and frost. When choosing a chain-link mesh with a polymer coating, pay attention to the spiral surface; the absence of cracks on it indicates the quality of the product, otherwise the mesh will not last more than a year, since water will get into the metal through small cracks and it will rust. The mesh size and wire diameter directly affect the strength characteristics of the chain-link mesh.

Machine for weaving mesh netting: production and use

To make a chain-link mesh with your own hands, you should use a simple device you made yourself. To build this structure, it is enough to have basic metalworking skills.

If we compare the chain-link mesh with other structures of the same type, then against their background it has a number of advantages. The manufacturing process does not require spot welding or an electric drive.

There are industrial purchased machines for weaving stacks of chain-link, but if you need to make it in a small volume, then it is better and cheaper to make a small machine with your own hands.

To carry out work on the construction of the machine you will need:

- a small part of the pipe;

- plates;

- several metal pieces;

- bearing races;

- rollers;

- Bulgarian;

- corners made of high quality metal;

- rope and chalk;

- file;

- sandpaper.

The mesh frame is formed by connecting flat wire. The main point is the construction of the snake in the form of a zigzag. This will require mechanisms for tensioning and winding. Tension prevents excessive twisting, and winding strengthens the structure. The helical spiral is very difficult to weave into the main part of the fabric. Since the wires run either softly or hard, they require constant adjustment. When the wire is bent, it changes and friction occurs with the machine, so lubrication, for example, using waste oil, is a mandatory component.

The winding system is characterized by certain dimensions that cannot be adjusted; the shape and diameter of the cell depend on it. When the turns are formed, the stitching is directed so that it is harmoniously woven into the mesh fabric. After this, the unnecessary fragment is cut off.

We invite you to familiarize yourself with the step-by-step structure of the mechanism that weaves the chain-link mesh. The main working tool is a structure made from a winding block, which includes a screw (screw sleeve and winder), a winding plate and a knife. These parts form the spiral shape and are subject to severe wear. Therefore, they need to be made from high quality and durable components. The rotation of the knife is responsible for the formation of turns of the required sizes. The main function of the screw is to create the correct distance between the turns. Thus, a grid with the same cell size is obtained.

The coiling plate is a flat metal strip that has a hole at the end with which it is attached to the handle. When using wire with increased rigidity, the plate is twisted in a screw form by no more than sixty degrees. The higher the rigidity of the structure, the greater the degree of twist.

The auger looks like a hardened steel pipe, which has a spiral cut over its entire area. It is better to purchase such a bushing, or order it from a mechanic, since making it yourself will not lead to the desired result.

Position all components so that the person operating the machine can easily turn the handle and guide the wire. Do not allow the wire to get tangled during weaving, to avoid this, in the middle part of the bay you need to place the bucket upside down, and put a piece of metal pipe or other weight on the end of the wire. This procedure will help prevent ringing. Pass the end of the wire through the tension rollers, and use the screw to adjust the gap between them. Next, you need to insert the wire into the winding mechanism and twist it, first one or several times, until the required cell size is obtained. Monitor the evenness of the outgoing line; to check it, inspect it lengthwise. When twisting the wire to the right or left, adjust the wire tension. When the wire turns out perfect, start twisting the mesh until you have the required amount.

Building a machine for making mesh netting is not a complicated process that requires close attention and some carpentry skills. To improve this unit, it is possible to install a controller that will independently count the turns and facilitate the wire manufacturing process.

Also, such a device is equipped with an electric motor, which drives the handle using an electric drive. Although the presented machine model is easy to assemble, it is most suitable for home use and is capable of making a small amount of mesh.

Do-it-yourself chain-link mesh

Before considering the process of producing chain-link mesh with your own hands, we suggest that you familiarize yourself with its advantages over other building materials.

If you use chain-link mesh as a fence, then its installation is much more profitable than the installation of a conventional wooden fence, which requires periodic painting and repair. Moreover, it is possible to make a mesh at home. To do this you need a special machine.

To perform the work, you will need to have a wire machine, the main function of which is to form spirals on the wire.

We invite you to familiarize yourself with the manufacture of a manual machine for chain-link mesh. It has a very simple design. Before you begin, you should determine the width and length of the zigzag that will be created when constructing the mesh. After this, you should draw this zigzag on a wooden surface. Drive nails into the corner parts and tighten the wire. It is advisable to use gloves that will protect your hands from scratches. Place the wire on the board and loop it around each nail. The remaining wire must be cut off and then the spiral removed. This procedure should be repeated 15 to 40 times, depending on the length of the wire.

Now let's get acquainted with the design of a more complex machine for making chain-link mesh. Variants of machines that feed wire using a drum imply uneven wire feeding. Since it is located on a large roll, moving which requires a large amount of force, and when this does happen, the drum rotates inertia and the wire is fed unevenly and intermittently.

To avoid such a mistake, use a device similar to the element of knitting machines, in which the thread is pulled upward.

To make such a feeding device you will need:

- bearing,

- leash,

- ring,

- steel plate - as a support.

The central part is a metal axis, the length of which is about one meter. A bearing is installed at its end, which has a leash and a ring. Several rods with a diameter of 1.2 cm are welded to the axle.

All wire is installed on a steel plate, which acts as a platform. The end of the wire is pulled out of the tension device through the ring and a tension device is installed, which contains a lubrication system and rollers.

To construct a tensioning device, the following is required:

- bearing race;

- bicycle pump housing;

- roller;

- holes for the roller axle.

The tensioning device has a frame in the form of a right triangle. a metal corner acts as the legs, and the hypotenuse is a five-millimeter metal strip, seven centimeters wide. This strip has holes into which rollers are installed. At the corner there is a device that provides lubrication of the wire as it moves. To make it you will need a bicycle pump. You need to saw off the bottom from the body part and attach it to the strip using clamps. The pump cover must screw well onto the body, as it secures a felt plug on which cuts need to be made. They are necessary for the free passage of wire through the lubricating device. Do not allow the wire to touch the edges of the tube; a hard metal ring must be installed on it. To do this, use a bearing race.

The winding device is a pipe that has a spiral slot with a knife. The size of the vertical diagonal of one cell is equal to the size of double the internal size of the pipe.

To form a spiral-shaped slot in a pipe, you must first draw a spiral on paper, which is glued to the pipe, and then, using a grinder, cut the pipe in pre-marked places. Use a file or sandpaper to sand the surface. It should be smooth and even.

Select a steel corner that has 2 cm flanges. Prepare two pipe-sized pieces, and then form the structure.

The process of making coiling knives has its own nuances, namely:

- each pipe should contain three or four knives of different shapes, since soft wire requires flat knives, and elastic wire requires twisted ones;

- the size of the shanks should be the same - length - 5 cm, diameter - 2 cm;

- to make a straight knife, any metal is suitable, but for twisted products, choose stronger types of steel;

- Do not allow the knife to dangle freely in the inside of the pipe.

When the knives are ready, all that remains is to begin assembling the assembly table on which the chain-link mesh will be weaved. Before you begin, you need to install the wire on the feeder and then insert it into the feed structure.

Proceed to form the first spiral. By adjusting the rollers in the tensioning device, you need to achieve a perfectly flat spiral.

When weaving a mesh on such a machine, which has a diameter with a large cross-section, it will be possible to make about 90 meters of mesh in one day.

If the chain-link mesh is made from individual pieces of wire, then they are connected to each other by knots.

Tips for using a machine for producing mesh mesh

Do not install wire into the winder type device frequently. It's better to fill it all at once. This will make it easier to work with the machine, since initial refueling requires skill and time. To thread the wire you will need to perform a number of actions:

- bend the end of the wire 180 degrees;

- hook the hook onto the surface of the knife;

- insert the knife with the wire into the pipe;

- make half a turn and press the wire against the surface of the knife using a screwdriver;

- Do not allow the hook to unbend, as there is a risk of the wire jamming in the winder.

Therefore, if the wire runs out, you need to stop work before the end of the wire goes into the lubrication device and attach a new wire to it by creating a knot.

If the wire is too hard, it needs to be annealed. Although this process will make it softer, it will significantly affect its performance: firstly, not all areas are annealed equally, and secondly, if galvanized wire is used, then all the zinc will burn and it will not be resistant to corrosion.

When the mesh is being formed and you need to stop working, watch the position of the knife. It must be in an upright position.

The most durable and high-quality is galvanized mesh, its service life is several decades. Therefore, there is no need to skimp on choosing the right wire.

If the mesh is not needed in the near future, there is no need to weave all the spirals. Then put them in a separate place, this way you can save a lot of space.

Chainlink mesh video:

Making a chain-link without a machine

It is not always possible to make a tool for weaving a mesh. You can make a chain-link without a machine.

This process will take more time, but the quality of the result will not be affected. The material can be the same wire or plastic.

In the latter case, the mesh is purely decorative due to its lower strength.

It's quite easy to make any amount of mesh this way. Manufacturing occurs according to the instructions:

- To begin with, you should choose a tool that will give the wire the desired bend.

- You need a working surface, the length of which will correspond to the width of the chain-link. You can even use a simple wooden board.

- Drive the nails into the work surface in a staggered pattern. The distance between them forms the size of future grid cells.

- Cut soft steel wire into equal pieces. These are a kind of blanks for weaving. You may need quite a lot of them, depending on the desired length of the chain-link.

- It is recommended to protect your hands with durable gloves.

- Take a piece of wire and carefully bend it around the nails.

- The rods are easily connected to each other by weaving. You can also simply rotate one workpiece around the second, as if screwing it in.

There is another way to make a mesh yourself without a machine. You will need wire cutters to cut pieces of wire. Aluminum or similar raw materials are used, which are easily deformed. You should also take wooden rulers or electrodes bent in half. The process of making a chain-link using this method is simple:

- Take a ruler or electrode and wind the wire tightly. There should be no free space between the turns. In this case, it is the width of the ruler that determines the size of the grid cells.

- It is recommended to double-check the quality of the bends.

- The finished workpiece is removed and the next one is wound. It is important to make turns in one direction, otherwise the weaving will not work.

- All twisted workpieces must be stretched to the same length.

- The resulting spirals are threaded one into one using rotational movements.

- The first and last row must be additionally secured. This will prevent the mesh from accidentally falling apart.

Making decorative chain-link from plastic bottles with your own hands requires a little preparation. You should prepare the tape or tube in advance. Blanks are easily made from bottles in just a few minutes. Usually a small size in the range of 2-5 mm is used. Additionally, you should prepare a ruler and an alcohol lamp.

The robot principle itself is quite similar to wire weaving. The production of chain-link from plastic takes place in several stages:

- Squares should be drawn on the ruler to serve as guides.

- The edge of the ribbon or plastic tube is attached to the ruler using a clothespin.

- The workpiece is wound gradually. Each bend needs to be warmed up a little.

- Secure the second edge. Place the entire structure over the alcohol lamp again to warm it up further. This way all the turns will be fixed.

- Remove the workpiece. Treat all subsequent parts of the plastic tape in the same way.

- Screw in the cooled pieces. It is recommended to secure the upper and lower parts additionally.

Plastic

Making mesh out of plastic is a little more difficult, since it will need to be heated over an open fire. And here, the main thing is not to overdo it.

You will need the following materials; plastic tape about 4 mm wide. An alternative can be a tube with a radius of 1-1.5 mm. You can make both from a plastic bottle. A board, burner, or alcohol lamp.

You need to draw squares evenly on the board. They will serve as markings for the tape. The ends of the tape need to be attached to the board.

Wrap the plastic tape around the board and simultaneously heat it over the fire for about 60 seconds. Warm it over the fire again, first fixing the edges. Well, then, as in the previous method, we connect the finished curls together.

Check it out here too!

- Do-it-yourself trolley - how and from what to build a decorative and tool trolley (135 photos and videos)

DIY nests for laying hens: drawings, tricks, best solutions and tips on how to make nests correctly (115 photos and videos)

How to hem felt boots with your own hands: materials, tools, useful tips for hemming. Step-by-step instructions with photos + master class with video!

Using and making a homemade machine

Producing chain-link mesh at home using a machine is much easier and faster. Buying such a machine is expensive, but making it yourself is much cheaper. To make a machine for making chain-link mesh, you will need:

- A piece of pipe.

- Metal pieces from different types of metal.

- Plate.

- Bearing races.

- Welding device.

- Bulgarian.

- Rollers.

- Metal corners.

- File.

- Chalk.

- Rope.

- Sandpaper.

The most important part of the machine is the coiling unit. It consists of a screw and a knife with which the wire is curled. The size of the cells depends on the format of these components. Rotating, the knife creates turns of a certain size, and the auger sets the distance between them (pitch). A flat strip of steel acts as a coiling plate. At one end there should be a hole for the handle.

The auger is a hardened steel pipe with a spiral slot.

In order to get such a groove, use a rope and chalk: attach a rope, outline it with chalk. Next, cut a slot according to the outlined pattern. Go over the cut with files and final sand with sandpaper. The length of the pipe should be sufficient to lay 3 full turns. There should be a space of no more than 1 mm between the knife and the pipe, otherwise the wire will be snagged. In this case, the knife should rotate absolutely freely, and its end should protrude 1-2 cm from the pipe.

For easy sliding of the wire, the corners and grooves must be well rounded and treated with oil.

- You need to cut 2 pieces from a metal corner, equal in length to the pipe. We weld them to the pipe so that it seems to be located between them. This structure is fixed to the base by screwing it to the working surface through special holes. Place the machine itself so that it is convenient for you to rotate the handle, parallel to directing the spiral. Do not allow the workpieces to become tangled under any circumstances.

- You can insert a piece of pipe into the center of the skein and attach a weight to the end of the wire by passing the end through the tension rollers. This helps get rid of wire ringing. The distance between the rollers is set using a screw.

- Before large-scale production use of the machine, you need to check it by passing the wire through the device. If you get an even row with the desired shape and size of the cells, then the machine is assembled correctly.

Elements of a homemade apparatus

A standard manual machine for the production of chain-link mesh includes:

- knife-plate;

- tension device;

- base;

- shaft and handle on it;

- screw.

Knife plate

The main functions in a homemade machine are performed by a knife plate and a screw. Thanks to these devices, the metal wire is twisted into cells. Both devices give the desired size to the grid cells.

When the knife rotates, coils of the required size are formed. The screw is responsible for the distance between the resulting turns.

The base material for the manufacture of the auger is a steel pipe. A slot is made in it in the form of a spiral. The slot can be made using a lathe, for which you need to wrap the pipe with a rope in the shape of a spiral, outlining it with chalk.

The surface of the pipe must be thoroughly sanded. To begin with, the surface is processed with a file and then with sandpaper. The length of the pipe should be such that the master can lay three turns of the strip. To simplify the process, it is possible to purchase a ready-made screw bushing.

Machine knife design

The knife is fixed on a shaft, which is equipped with a rotating handle. Special attention is paid to the distance between the pipe and the knife. It should be 1 mm. The knife in the pipe should have free movement and protrude a few centimeters.

Before starting work, it is recommended to thoroughly lubricate the corners and grooves to improve the sliding of the wire.

Two corners are cut for the pipe. Their length should be equal to the length of the pipe. Both corners are welded to the pipe on both sides.

It is necessary to secure the structure to the base. You will need to make holes in it through which the chain-link mesh machine will be fixed to the table.

Production of chain-link mesh as a business

You can make a good business in the home production of chain-link because of the demand for the product. it :

- Owners of cottages and gardens. The area is clearly visible through the mesh: if the owner is away with his neighbors, he still controls what is happening on his territory. The product is also needed as a support for a hedge.

- Animal farm owners. Chain-link is used for cages and enclosures.

- Enterprises using such mesh as a fence. The high strength of the wire used ensures the correct operation of the security service.

- Construction companies.

- The business of selling chain-link mesh will always be profitable. In addition, there is little competition in this area.

This business has a number of advantages:

- Small starting capital. The purchase of materials is affordable for people of average income. This eliminates the need for bank loans and reduces payback time.

- Small production areas. At the start of a business, a room the size of a regular garage is enough. There is no need to create special conditions for storing products.

- Gradual increase in production and profit with the arrival of new clients.

- The greatest demand for chain link is established in April-October, but you can start a business at any time of the year. The business itself is profitable, low-cost and profitable if you approach its organization correctly.

Recommendations for the production of chain-link mesh

- Any machine for weaving mesh netting is installed on the table so that its handle can rotate comfortably.

- To avoid tangling of the wire material during the manufacturing process of the mesh, it is necessary to place it on the pipe at one end and hang a load at the other. The end with the load is passed through tension rollers.

- The machine for producing mesh mesh must be checked before starting work. The wire is inserted into the winding mechanism and scrolled. The output should be a string with cells of the correct shape. The evenness of the line is checked along the weight. If there are obvious unevennesses in the line, additional adjustment of the machine rollers will be required.

- The choice of wire material matters. More often, steel wire with a polymer or galvanized coating is used.

- Regular steel wire needs to be painted because it quickly rusts when exposed to rain. Galvanized is more expensive, but already has the necessary protection against rust. Polymer is used as a basis for chain-link mesh, but has a high price.

- The softness of the wire affects the type of knife used. If you plan to weave a chain-link mesh from soft wire, then take a flat knife. Hard requires the use of a knife curved around its axis. Stiff wire requires a larger bending angle.

Wire weaving. Working with wire mesh

Tuesday, October 02, 2012 23:57 + to quote book

Wire weaving. Working with wire mesh

Wire weaving. Working with wire mesh.

Wire mesh is a wonderful material because it is cheap, attractive and easily available. Its flexibility and lightness make it suitable for large-scale structures, which is why it is often used by sculptors. For simplicity, below we will call the horizontal (double twisted) sides of the hexagonal mesh cells twists, and the single sides - cores. It is recommended to wear gloves when working with wire mesh. Finish any project made from chicken wire by removing any sharp ends that stick out.

Weaving technology

The scheme for weaving a chain-link mesh on a homemade machine includes drawings and steps based on them:

- the wire used is coated with machine oil or by using a special lubricating device on the machine itself;

- the wire end is bent with a hook;

- the product is pulled through the groove, secured to a knife inside the pipe;

- the shaft rotates due to the lever;

- the shaft is rotated until a waveform is obtained;

- the wire is divided into pieces of the required length;

- The wire is wound on an inverted bucket;

- 1.45 meters of wire gives 1 meter of chain-link mesh;

- before stretching the mesh, its parts are fastened to each other;

- the outermost wire is unscrewed, the ends of the chain-link are applied one to the other, the removed wire secures it;

- The finished bonded mesh is fixed to a fence or other object.

The tensioning and fastening of the chain-link is done with nails and slats. The stretched and secured mesh needs to be painted over with a brush. This will ensure complete penetration of the paint into the weave.

Fencing designs

When planning to start work, you need to imagine what the final appearance of the fence will be. It is necessary to understand how to make a fence from a simple chain-link mesh, broken down into specific stages of work. This means that you not only need to buy material, but also choose the type of base for the mesh fence.

The photo shows an example of a beautiful fence.

Beautiful fencing decor

With guides

Installation of a chain-link fence using guides involves the construction of a rigid frame in the form of horizontal guides. The following are used as guides:

- profile pipe with a profile from 20x20 to 40x20 mm;

- metal rod;

- fittings;

- wooden bars.

Without guides

One of the methods for stretching mesh over a fence is to build fences without guides. A steel cable or wire is used as a tensioner, threaded through rigidly fixed supports. The extreme corner supports are well strengthened with stops. The wire or cable is pulled through the cells at the top and bottom of the fabric at a distance of 5-10 cm from the edge.

Tensioning is done using bolts with holes in the head or turnbuckles.

Sectional option

Mesh fencing in sections is the most durable type of structure. Each section is a frame made of a corner, profile or shaped pipe connected by welding. When filling, galvanized mesh 50x50 mm is used. When starting to create such a structure, you need to correctly calculate all the dimensions and provide the optimal method of fastening.

How much wire goes into a chain-link mesh?

Calculating how much material is consumed is very simple. There is a special formula for this that allows you to determine the amount of raw materials required and its cost. In this case, the cross-section of the wire core and cells, as well as the weight of the mesh, are taken into account.

Consumption formula per 1 sq. m looks like this: D2 * 13.4 / A, where:

- D2 – wire cross-section in a square;

- 13,4 – coefficient corresponding to the consumption weight;

- A – cell section.

The result is the weight of wire that needs to be used to produce 1 sq. m mesh of the required sizes.

For a standard mesh, which is intended for use in domestic conditions and has a cell cross-section of 50x50 mm, the wire consumption is 0.5 kg per 1 square meter.

Wire winding knife

For soft wire, you will need a flat knife, and for stiffer wire, the knife must have a large twist angle.

A knife for hard wire must be made of durable metals, but for a flat knife any kind will do. The knife must fit exactly the dimensions of the pipe so that there are no gaps. This may cause the mechanism to jam. However, the knife should rotate in the pipe without difficulty. For a twisted knife, you need to take a plate 1-2 mm wider than the required size. It is clamped vertically in a vice, heated and the upper part is turned to the required limit. The untwisted parts are cut off, the shank is attached, and then the required width is adjusted. Part of the knife near the shank is hardened, and the rest is ground.

- When producing mesh, the machine must be stopped when the knife is positioned vertically.

- And the correct position of the spirals during connection is facilitated by the position of the bottom wire in the desired direction, using the table board for installation.

- Elastic wire can be annealed to make it more obedient. But this requires special skills, otherwise you may end up with different stiffness along the entire length.

- You must remember to change the knife if, after working with a stiff wire, you have to curl a less rigid one. Also, their step length will be different, so you need to screw in the spiral more carefully.

The process of weaving a chain-link mesh

Before starting production, you need to wipe the steel wire used as the raw material with machine oil (you can use the used composition). Some home craftsmen simplify this process using a special mechanism (they do it themselves, of course). Such a mechanism is simply a small box with an outlet and an inlet (their diameter should be slightly larger than the cross-section of the wire). A lubricant is poured into it, through which the material passes before it enters the bending machine.

The mesh manufacturing sequence is as follows:

- the wire at its end is bent into a hook;

- pull the resulting workpiece through the groove and connect it to the knife in the pipe;

- They begin to rotate the device (usually a lever is installed on it to simplify this operation) until the original workpiece takes on the shape of a wave.

The wavy wire is then placed into pieces of the required length and wound onto an inverted bucket. Please note that a meter of wave-shaped chain link is obtained from 1.45 meters of straight steel wire. Individual pieces of mesh are joined to each other immediately before the process of stretching it.

This procedure will be easier if you unscrew the outer wire. Then you can apply the ends of the mesh one to the other and secure them with the removed wire.

A chain-link fastened with a mesh can be mounted directly on a fence under construction (to posts made of reinforced concrete or other material that are dug in advance and securely fixed in the ground). It is recommended to install wooden slats on the posts. The chain-link is tensioned and secured to the slats using nails. The process of tensioning the mesh is simplified in cases where a tension beam or coupling is used (they are hooked onto some support - a wall, a tree, and then twisted with a strong rope).

Home craftsmen who have mastered the operation of making chain-link mesh with their own hands and have erected more than one reliable fence recommend painting the fence after installation. Moreover, they say that it is better to paint the mesh not with a roller, but with an ordinary brush. In this case, the quality of the layer application is higher - the paint penetrates the chain-link weaves without problems, and these places are very difficult to reach.

LiveInternetLiveInternet

-Music

—Categories

- Stencils (48)

- A (16)

- A - THIS IS A TRANSLATOR OF TEXT PAGES (5)

- AND THIS IS INTERESTING. (60)

- AND I NEED THIS NOW (62)

- ALOE (11)

- Angels (21)

- ENGLISH LANGUAGE (22)

- PANSIES (19)

- ARTISTS (TO BE REMEMBERED) (43)

- Grandma's TREATMENTS (36)

- Continuous Knitting (29)

- BEAD MK (385)

- BEADED DIAGRAMS (419)

- beading (403)

- DIVINE HOLIDAYS (PICTURES WITH CODES) (54)

- MASTERITZ ACTIVITIES (45)

- BROOMSTICK (50)

- BRUGGE CROUSE (91)

- TO THE PIGGY BANK (436)

- TO THE PIGGY BANK (313)

- INSPIRATIONALS (23)

- VIDEO RECIPES. (80)

- VIDEO KNITTING (636)

- VINTAGE FRAMES (97)

- STAINED GLASS AND STAINED GLASS MK (20)

- hair (123)

- collars (108)

- ALL TYPES OF BAKER (39)

- ALL TYPES OF TEST (102)

- everything for Easter (5)

- ALL FROM PAPER, CARDBOARD. (45)

- All about Lyra (205)

- ALL ABOUT HONEY (38)

- EVERYTHING (6)

- PATTERNS (197)

- BAKERY (20)

- RIBBON EMBROIDERY (162)

- WE KNIT ARANS (9)

- KNITTING (197)

- KNITTING (IDEAS) (423)

- KNITTING - learning to crochet (42)

- KNITTING - learning to knit with KNITTES (31)

- crochet (979)

- CROCHET (winter) (22)

- CROCHET (summer) (275)

- CROCHETING (PATTERNS) (86)

- TAPE KNITTING (53)

- KNITTING MK AND MASTER CLASSES (219)

- knitting (271)

- KNITTING (winter) (62)

- KNITTING (summer) (17)

- KNITTING (PATTERNS) (65)

- KNITTING PATTERNS (461)

- TUNISIAN KNITTING (90)

- KNITTING SHORT ROWS (4)

- LOINT KNITTING (35)

- FREEFORM KNITTING (46)

- KNITTING "PINEAPPLES" (11)

- KNITTING(ROMANIAN LACE.) (114)

- KNITTING(POCKETS, etc., etc.) (101)

- KNITTING (READING PATTERNS SYMBOLS) (56)

- KNITTING, ALL CRIB SHEET TO HELP KNITTERS (113)

- KNITTED BED (96)

- KNITTED COATS AND CARDIGANS (296)

- Knitted buttons. (16)

- KNITTED RIBBERS (104)

- KNITTED CORDS (77)

- knitted jewelry (543)

- GANUTEL (59)

- HOROSCOPE (68)

- WE COOK IN POTS. (4)

- WALNUT JAM, etc. (11)

- mushrooms (50)

- DECORATION AND PAINTING OF BOTTLES (73)

- Decoupage (161)

- DECOUPAGE MK OR MASTER CLASS (236)

- DECOUPAGE_PICTURES FOR DECOUPAGE (437)

- WE MAKE CANDLES AND CANDLESTICKS (19)

- denyushki (96)

- DESSERTS (230)

- KIDS (61)

- CHILDREN (BLANKETS FOR THEM) (196)

- CHILDREN (fun and games) (3)

- CHILDREN'S HATS (15)

- JONGSAN@ JONGSAN (16)

- DIET - WILL WE LOSE WEIGHT? (80)

- for children (926)

- For kids (607)

- FOR CHILDREN WINTER (155)

- CHILDREN'S BAPTISM DRESSES (25)

- FOR CHILDREN SUMMER (205)

- BOOTIES FOR BABIES. (112)

- FOR HOME (308)

- for luck (76)

- HOMEMADE BREAD (21)

- HOME AND CHILDREN'S MAGIC (26)

- JACQUARD PATTERNS (102)

- PAINTING (178)

- LIVE FLOWERS (81)

- conspiracies. (97)

- here you will find a lot of interesting things (108)

- HEALTH (393)

- HEALTH MK (52)

- umbrellas (108)

- PASTA PRODUCTS (22)

- GINGER AND ALL FROM IT (14)

- INTERESTING TIPS FOR WOMEN (175)

- Irish lace (663)

- IRISH LACE VIDEO (64)

- Confessional (57)

- for tea (537)

- CACTUSES AND ROSES (16)

- KANZASHIKI (89)

- PORRIDGE IS OUR STRENGTH. (3)

- QUILING (41)

- BRUSHES AND THEIR PURPOSE (68)

- KNITTING BOOKS (226)

- comments (150)

- canning (233)

- CRACKELURE (27)

- beauty (40)

- cookie creams (74)

- Cereals and their beneficial properties.. (17)

- DOLLS (42)

- SWIMSUITS (106)

- CUISINES OF THE WORLD (68)

- kitchen (354)

- KITCHEN(CHICKEN DISHES) (166)

- LEAVES, FLOWERS THAT TREAT (53)

- PATCH BLANKETS (17)

- HORSES (67)

- ONION PEEL (6)

- M-O-R-O-J-E-N-N-O-EEEEEE (20)

- MAKEUP (75)

- MACRAME (37)

- MOM (29)

- MASTER CLASSES AND MK (127)

- MATRYOSHKA POSTS (20)

- FUR KNITTING (42)

- eggshell mosaic (23)

- PRAYERS (122)

- PRAYERS DREAMS OF THE HOLY VIRGIN (13)

- MOTIVATORS (22)

- My cookbook (97)

- music (368)

- MUSIC CHANSON (17)

- MUSIC-CLASSICS (0)

- CARTOONS (51)

- SOAPS AND PERFUME (101)

- SOFT TOYS (WE SEW OURSELVES) (127)

- DRINKS (41)

- DRINKS (93)

- WEIGHTLESS PICTURES (ON FEATHERS) (18)

- NON-CONVENTIONAL TREATMENT (5)

- NEW YEAR'S KITCHEN (26)

- NEW YEAR (130)

- SOCKS (263)

- NEEDS, USEFULITIES (117)

- CHARMS (26)

- shoes (161)

- VEGETABLE GARDEN (planting, shoots) (52)

- DIARY CLOTHES (143)

- papier mache (23)

- EASTER (67)

- EASTER-BAKING (42)

- PERGAMANO (6)

- translator (3)

- TRANSLATIONS FOR KNITTING (9)

- ALTERATIONS (38)

- SAND (11)

- PLASTIC BOTTLES (16)

- SCARVES (HOW MANY USES IT HAS) (13)

- newspaper weaving (198)

- FOIL WEAVING (4)

- let's tell fortunes (29)

- salt dough crafts (27)

- CONGRATULATIONS FOR ALL OCCASIONS OF LIFE (19)

- BEDDREADS (5)

- HEALTHY PRODUCTS (15)

- useful tips for computer (79)

- PLASTIC BAGS. (25)

- Let's have fun? (134)

- SIGNS (7)

- SEASONINGS (11)

- PARABLES (41)

- HAIRSTYLES (39)

- SHELLS (7)

- HAPPY BIRTHDAY FRAMES (38)

- FRAMES (489)

- DRAWING VIDEO LESSONS (49)

- draw on stones (27)

- draw on stones (41)

- DRAWING WITH HENNA (3)

- RITUALS (3)

- CHRISTMAS. (6)

- Daisies (18)

- RUNES (946)

- RUSSIAN TSARS (20)

- Fish (110)

- SALADS (115)

- SEAFOOD SALADS (10)

- NAPKINS (241)

- WEDDING BOUQUETS (14)

- SECRETS OF HEALTH (INUSIONS AND ALL RECIPES) (202)

- TALES (323)

- TALES-2 (79)

- TABLECLOUTS (63)

- SKELETING LEAVES (9)

- SCRAP KITS (122)

- SNOWFLAKES (76)

- SAUCES (23)

- poems (427)

- bags (155)

- KNITTING PATTERNS (81)

- CHEESE (13)

- FABRIC AND KNITTING (97)

- STOT PAINTING (135)

- Stencils and WHAT NEEDS TO BE XERIED (593)

- TURKISH HARNESSES (100)

- STUDY FROM 1ST TO 11TH GRADES (37)

- LEARNING TO DRAW (37)

- Baubles (112)

- A LOT OF FILM IN ONE BOTTLE))) (140)

- MOVIES (77)

- MOVIES and CARTOONS FOR CHILDREN (57)

- MOVIES ONLINE (107)

- MOVIES-SERIES (75)

- FOIL (5)

- FENG SHUI (15)

- cold porcelain (543)

- COLD PORCELAIN (ALL YOU NEED FOR THIS) (38)

- CLEAN (70)

- WONDERS OF THE WORLD (98)

- shawls (181)

- SCARVES,SNOODS (63)

- Hats (398)

- BEADED CURTAINS (44)

- this is interesting (series of messages) (77)

- EGGSHELLS (21)