Advantages and disadvantages

Metal 9ХС has a number of advantages.

- Unique technical characteristics. This metal is considered quite durable. It produces wear-resistant products that are practically not subject to mechanical stress; they are very resistant to bending and torsion. Even with constant use, they will not become deformed. In addition, cracks and other small defects practically do not form on their surface.

- Increased hardness. It is achieved after annealing. Also, after this procedure, the material becomes absolutely susceptible to calcination.

- Corrosion protection. This steel contains chromium, which protects the material from the negative effects of water.

- Hardness. Tools made from such steel can easily cut other metals and dense wood.

- Same carbide distribution. This provides advantages when using this metal in the manufacture of thread-cutting devices that have a fine thread pitch.

In addition, it can be noted that the metal is characterized by increased hardenability and elasticity. It can hold an edge for a long time.

But 9ХС grade steel also has some disadvantages.

- Appearance. This metal will not shine; a peculiar pattern can be seen on its surface.

- Relatively high cost. Products made from this metal are produced by hand forging, which is why their price is quite high.

- Difficulty of processing. Even small errors in the manufacture of such steel can lead to a decrease in its quality. It behaves rather capriciously during heat treatment and sharpening.

- Loses its properties at elevated temperatures. When heated above 200 degrees, the cutting qualities of the tools are primarily reduced. It should also be noted that this variety is not suitable for the production of welded structures. During heat treatment, the material will require compliance with a specific optimal temperature regime.

- Care requirements. Chrome and silicon will not fully protect steel, so you will need to carefully wipe and dry tools after contact with water. Otherwise, over time it will begin to rust.

Explanation of markings

For marking steels and other materials, certain standards are being developed, the use of which makes it possible to simplify the process of determining the chemical composition. This steel is deciphered as follows:

- In the instrumental group, the first digit indicates the carbon content (in tenths of a percent), that is, in this case, 0.9% carbon. This element is considered the main one, as it determines the characteristics of the crystal lattice, hardness, strength, fragility and other qualities.

- As previously noted, the steel was alloyed to change some performance characteristics. Chromium and silicon, of which no more than 1.5%, were used as alloying materials.

In addition to the above elements, the composition contains many others that are an integral part of steels.

Main characteristics

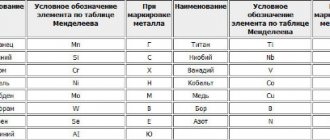

The main characteristics of this steel can be found in GOST 5950-2000 and GOST 2590-2006. First, we will analyze the chemical composition of this metal. It includes the following components:

- carbon;

- iron;

- tungsten;

- titanium;

- silicon;

- chromium;

- manganese;

- vanadium;

- molybdenum;

- nickel;

- copper;

- phosphorus;

- sulfur;

Chromium in the metal provides, among other things, increased hardness and strength. It is also responsible for the corrosion resistance of the material. Silicon, which is present in the composition, has the same property. Due to it, the strength of the steel increases, but at the same time the toughness and ductility decrease.

Copper can also significantly improve corrosion resistance. Molybdenum increases the elasticity of steel. Tungsten forms carbides, which give the finished alloy maximum hardness. Due to carbides, the grain size increases during the heating process.

Vanadium significantly increases the density of the material. Titanium is used to prevent intercrystalline corrosion. Manganese increases wear resistance and impact resistance.

Next, we will analyze the main physical characteristics of 9ХС steel. Its density is 7830 kg/m3. The electrical resistivity reaches 400 nOhm*m. The Rockwell hardness of the material will depend on the tempering temperature, it varies from 63–64 to 39–48 in.

The metal is calcined in workpieces with a diameter of up to 40 millimeters when cooled in a special oil composition and up to 30 millimeters when processed in hot substances. The microstructure of this metal after heat treatment is martensite and carbides.

Characteristics of steel 9ХС

Steel 9ХС is characterized by:

- elasticity;

- strength;

- wear resistance.

These properties are determined by its chemical composition, the features of which are already visible from the marking - 9ХС, which indicates the amount of carbon in the alloy and the main alloying elements:

- The number “9” indicates the carbon content in the alloy – 0.9%.

- The letter "X" stands for the chemical element chromium. The alloy contains 0.95-1.25%.

- “C” indicates that the alloy contains silicon - from 1.2 to 1.6%.

Carbon is one of the main elements of any type of steel. The higher its percentage in the alloy, the stronger and harder the metal will be. 9ХС contains the optimal amount of carbon so that the steel is hard, but not too brittle.

Alloying elements in 9ХС steel are minimal. Chromium is responsible for the strength of steel. Another important function is to prevent the development of corrosion. But for full protection, the alloy must contain at least 13%. There is significantly less chromium in 9XC, but even in this amount it performs its function: short-term contact with water is not dangerous for knives. Silicon has a similar effect on metal as chromium. It is added to steel to increase its heat capacity and increase strength.

In addition, 9Xc contains 9 more substances that are added to improve the quality of steel:

| Name | Quantity | Description |

| Manganese | 0,6 % | Increases wear resistance and resistance to shock loads. |

| Nickel | 0,35 % | Increases the hardenability of steel and protects the metal from corrosion. |

| Copper | 0,3 % | Improves the anti-corrosion properties of the alloy. |

| Molybdenum | 0,2 % | Increases the red resistance and elasticity of steel. |

| Tungsten | 0,2 % | Forms carbides, which give the alloy special hardness. Thanks to them, the grain size does not increase when heated, and when tempered, the metal becomes less brittle. |

| Vanadium | 0,15 % | Reduces grain, increases steel density. |

| Sulfur and phosphorus | 0,03 % | They are considered harmful impurities; more than 0.045 makes the steel red-hot. |

| Titanium | < 0,03 % | To prevent intergranular corrosion. |

Main physical characteristics of 9ХС steel:

- hardness, HRC = 63,

- density - 7830 kg/m3;

- forging temperature range: from 1180 to 800 degrees.

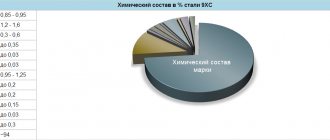

Chemical composition of 9ХС steel

| Chemical element | % |

| Carbon (C) | 0,85 – 0,95 |

| Silicon (Si) | 1,2 – 1,6 |

| Manganese (Mn) | 0,3 – 0,6 |

| Nickel (Ni) | up to 0.4 |

| Phosphorus (P) | up to 0.03 |

| Chromium (Cr) | 0,95 – 1,25 |

| Molybdenum (Mo) | up to 0.2 |

| Tungsten (W) | up to 0.2 |

| Vanadium (V) | up to 0.15 |

| Titanium (Ti) | up to 0.03 |

| Sulfur (S) | up to 0.03 |

| Copper (Cu) | up to 0.3 |

| Iron (Fe) | ~94 |

Mechanical properties of 9ХС steel at elevated temperatures

| Test temperature, °C | σ0.2 (MPa) | σв (MPa) | δ5 (%) | ψ % | KCU (kJ/m2) | NV |

| Delivery status | ||||||

| 20 | 445 | 790 | 26 | 54 | 39 | 243 |

| 200 | 320 | 710 | 22 | 48 | 88 | 218 |

| 400 | 330 | 620 | 32 | 63 | 98 | 213 |

| 600 | 170 | 200 | 52 | 77 | — | 172 |

| 700 | 83 | 98 | 58 | 77 | 147 | — |

| Sample 10 mm in diameter, 50 mm long, rolled. Deformation speed 20 mm/min. Strain rate 0.007 1/s | ||||||

| 800 | 110 | 130 | 26 | 68 | — | — |

| 900 | 65 | 74 | 41 | 95 | — | — |

| 1000 | 42 | 46 | 52 | — | — | — |

| 1100 | 20 | 31 | 54 | — | — | — |

| 1200 | 15 | 20 | 83 | 100 | — | — |

Heat treatment and sharpening

There are certain requirements for heat treatment of steel of this grade that must be observed. A preliminary analysis and x-ray of the structure are performed. This will allow timely identification of all defects present on the surface. At this stage, the hardness of the alloy is monitored. To properly harden the material, it will be necessary to maintain the recommended temperature.

The heat treatment itself occurs by heating the metal and then cooling it. Most often it is carried out either at the intermediate or at the final stage of manufacturing. It should be remembered that it directly affects the strength of steel. Cooling of the metal, as a rule, occurs in a special oil.

Most often, this hardening is carried out in special electric furnaces equipped with a sealed casing. As a rule, such equipment is equipped with a special system for adjusting and maintaining optimal temperature conditions. During processing, the hardness of the steel is periodically checked.

Sharpening the material allows you to remove a small layer from it and give it the desired shape.

After such a procedure, small marks will remain on the metal surface. As a rule, after this the product is also polished and fine-tuned. They are carried out in order to give it its final shape, the sharpening angle.

Most often, a variety of abrasives are used for sharpening. This procedure is carried out not only during the steel production process, but also in the future as the products are used.

After all the processing, the steel is produced in the form of large sheets. They may vary depending on length and thickness.

Source

Hardness of steel 9ХС depending on tempering temperature

| Temperature, °C | HRC∂ |

| Quenching 840-860°C, oil | |

| 170-200 200-300 300-400 400-500 500-600 | 63-64 59-63 53-59 48-53 39-48 |

| Heat resistance of steel 9ХС | ||

| Temperature °C | Time, h | HRC∂ |

| 150-160 240-250 | 1 1 | 63 59 |

Application

9ХС grade steel can be used in the manufacture of a wide variety of devices. Most often it is used to create sharp and reliable knives and blades. It can also be perfect for the production of cutting parts for tools, including axes.

Knives and blades made from this metal are perfect for hunting and fishing. They are often taken for hiking trips.

They easily tolerate the effects of unfavorable environmental conditions. Such knives can withstand strong impacts and twisting. At the same time, they will retain excellent cutting properties for a long time. All of them are made by hand. Sometimes these cutting tools are also used for the needs of the food industry.

Sometimes 9ХС steel is used in the manufacture of various drills. But at the same time, they can only be used for working with soft materials, most often with wood of various species. Cylindrical reamers are also produced from it. They are used to improve the dimensional accuracy of holes and to remove roughness.

Areas of application

The following is made from tool steel 9ХС:

- drills used for drilling soft materials (wood), since metal reacts to overheating and high rotation speed;

- reamers - a cutting tool used to process holes after drilling;

- taps used for cutting internal threads;

- impact stamps used for stamping finished products.

This metal is used to make knives that can be used not only at home, but also in camping conditions. The unique characteristics of the material allow it to cut wood and even metal. The main advantages of knives made using 9ХС steel include the following qualities:

- elasticity and resistance to bending;

- long-term preservation of sharpening quality;

- increased hardness threshold;

- resistance to high temperatures and humidity.

9ХС is an alloy steel with high strength characteristics. The knives hold an edge for a long time, so the “9ХС” marking applied to them guarantees high quality products and a long service life. In addition, such knives are made by hand using the forging method.

This brand can be replaced with both Russian and foreign analogues. The first include CVH and CVSG. Among foreign alloys, the following brands have similar characteristics:

- DIN;

- WNr;

- 150Cr14;

- 90CrSi;

- 90CrSiS.

Alloy Use

The use of 9ХС occurs in the following cases:

- Making drills. But they can only be used for drilling holes on soft objects, mainly wood. Since the tool reacts negatively to high rotation speeds and overheating, it is recommended to adjust the speed when working with a soft structure.

- Cylindrical reamers. They are used to improve the accuracy of hole sizes and remove roughness. The device can be used to process vents in cast iron, alloys with medium hardness, and when working with non-ferrous iron.

- Taps. They are necessary for cutting internal threads, and are presented in the form of a screw with straight or helical grooves. When working, it is recommended to protect the product from intense loads.

- Stamps for cold work. Their use is common in factories for stamping finished products.

All actions with this material must be carried out strictly according to the rules. Otherwise, the product will lose all its positive qualities.

Advantages of the 9xc brand

When the task is to manufacture cutting elements or their components, specialists most often choose 9xc tool steel. This decision is due to a number of reasons.

In steel of this grade, the distribution of carbides over the cross section is more uniform. This provides advantages when using this material for the manufacture of threading tools that have fine thread pitches.

- Billets made of this steel, which are used for the manufacture of tools and knives, are highly resistant to cracking.

- A characteristic feature of this steel is its increased hardness in the annealed state. It can also be calcined without any difficulty and at the same time has good heat resistance. The same is true for knives.

Features of the material

Chromium is used as the main alloying additive in this steel. Its amount ranges from 0.95-1.25%. Chrome makes steel hard and durable. In addition, it protects iron from corrosion. Silicon has a similar effect. The amount of this substance in 9xc reaches 1%. Silicon increases the strength threshold, reducing the level of viscosity and ductility.

The disadvantages of steel are that it is not suitable for welded structures. The only possible method of using welding for such an alloy is contact welding. It is also important to use steel of this grade in normal temperature conditions. At high temperatures it loses its qualities.

Pros of the brand:

- More uniform distribution of carbides over the cross section. Which gives important advantages to this brand when making cutting objects from it.

- Steel is practically not affected by internal defects. Which can lead to breakage of the knife and a decrease in the important qualities of the blade.

- Increased hardness in the annealed state.

When heat treating steel, temperature control is very important. That is why all work with metal is carried out in electric furnaces with automated temperature control.

After all the necessary work, structural metallographic testing and X-ray analysis are applied to the product. Although flakes practically do not appear in 9xc steel, it is important to check its structure for quality. After such a check, you can be sure that the steel blade will serve faithfully for a long time.

Hardening and sharpening

- One of the main disadvantages of this steel is the difficulty of maintaining the temperature regime when working with it. Steel is very capricious and requires a special approach. Technical hardening of the product is an important stage in the production of knives. If the knife is overheated, it will become brittle. And if it is underheated, it will quickly become dull. Sticking to the “golden mean” is an important condition when working with this article.

Heating of the blade should not be done very harshly. A good master will carry out incomplete hardening, but partial. The blade must be subjected to more heat than the butt.

- Sharpening the finished blade is no less important part in making a knife than its hardening. There are two sharpening options suitable for this steel:

- Under 00. Sharpening using the end of a sharpening wheel until HRC 62 - 64 is achieved. These are the maximum values for metal knives. After which they will find their application where perfect sharpening is important.

- Under 450. This type of sharpening is used for power blades. With which you can chop branches, open canned food, etc. After such sharpening, the blades quickly become dull, but are suitable for more severe use. Knives with this sharpening are considered tourist knives and work well in wild conditions.

Advantages of 9xc knives

Many people choose knives made from this steel because they are not produced by stamping, but by real manual labor. Blacksmiths who work with this steel note its unruliness. But if they manage to curb it, then it becomes the best solution for making knives. And you can be sure that this steel, imbued with living energy and strength, will help create an exclusive and unique knife. Which can be used in everyday life or given as a gift.

This carbon alloy steel has excellent strength and the ability to hold an edge for a long time. When purchasing knives from, give preference to leading manufacturers. This way you can be sure that real blacksmiths worked on them. Professional equipment and experience in blacksmithing will help you create not just a knife, but a real masterpiece.

Despite the processing difficulties, 9xc steel is an excellent material for creating high-quality products. Due to its excellent qualities, this alloy steel surpasses all analogues. And they have found application in many areas of life. Everyone who has dealt with knives made from this material notes their excellent performance and characteristics.

Rate this article:

Rating: 4.8/5 — 5 votes

Chemical composition

To create 9ХС steel, 13 substances are used, the combination of which in the right quantities results in qualitatively better physical, mechanical and operational characteristics.

Here are the components that make up 9ХС steel:

- iron (Fe) – 94%;

- silicon (Si) – up to 1.6%, but not less than 0.9%;

- chromium (Cr) – up to 1.25%, but not less than 0.95%;

- carbon (C) – 0.9%;

- manganese (Mn) – up to 0.6%;

- nickel (Ni) – 0.35%;

- copper (Cu) – 0.3%;

- molybdenum (Mo) – 0.2%;

- tungsten (W) – 0.2%;

- vanadium (V) – 0.15%;

- sulfur (S) – 0.03%

- phosphorus (P) – 0.03%;

- titanium (Ti) – less than 0.03%.

Percentages may vary slightly among different manufacturers. Deviations should not exceed 1/10 of a percent, otherwise the properties of the resulting alloy may differ.

Composition and features

The 9xc tool steel contains a number of alloying additives. One of them is chrome. The percentage of this component in the alloy varies from 0.95 to 1.25% . The presence of this element increases the hardness of the material, increases its strength, as well as resistance to corrosion processes. Silicon also has similar properties, the share of which in the composition of tool steel of this grade is more than 1%. Thanks to it, the strength threshold of the material increases, and the ductility decreases slightly as well as the viscosity. But on the other hand, the level of fluidity increases and the threshold of cold brittleness increases.

Other properties of 9xs steel

If we talk about other positive qualities of this material from which knives are made, we note the tendency for the tempering ability of processing materials by cutting when the workpiece is in a hot state. In addition, it is necessary to note the lack of flone sensitivity in tool steel of this brand.

When choosing this steel for making knives, you need to be aware that it is not a suitable material for the production of welding structures. Workpieces made from this material can only be used for resistance spot welding . Tools made from this grade of steel can only be used on cold surfaces.

Heat treatment of material and its application

The heat treatment procedure for this steel for the manufacture of knives is carried out in electric furnaces with a sealed casing, equipped with automatic heating temperature control and a controlled atmosphere. In this case, at the stages of heat treatment the following should be carried out:

constant temperature control;

- metallographic control of the structure of materials, as well as the magnetic permeability of its main components;

- X-ray analysis of the presence of internal defects in the structure of the material;

- constant hardness testing.

For further use, steel of this grade is produced in the form of sheets that differ in thickness and length, as well as circles.

Use of steel

Modern equipment is used to produce products, and the workpieces subjected to processing can be of various types. The following can be made from steel of this grade:

- knives for special applications;

- parts used in mechanisms used for cutting and measuring work.

Features of 9ХС steel

In the manufacture of various construction tools, special steel 9ХС is used. Products made from such metal will be distinguished by maximum strength, reliability and durability. Today we will talk about the features of this material, its advantages and disadvantages.

Characteristics

9XC steel contains many alloying additives that provide the desired characteristics and properties. In addition to the main components, there are silicon, calcium, chromium, carbon, sulfur, in total 12 alloying and additional components. Thanks to this complex of substances, steel has the following main characteristics:

- density (r) – 7830 kg/m3;

- Rockwell hardness (HRC) depends on the tempering temperature - from 63-64 to 39-48 ∂;

- HB 10-1 = 241 MPa;

- forging temperature indicators: from 1180 to 800 degrees.

Due to its increased elasticity, pronounced strength, wear resistance and density, steel of this type is considered the best option for creating cutting tools and components of this type.

Explanation of markings

Each type of steel has its own marking, which encodes the characteristics of the composition. The marking of 9ХС steel has the following meaning:

- the number “9” shows that the alloy contains 0.9% carbon;

- the letter “x” indicates the presence of chromium in the steel;

- the letter “c” indicates that silicon has been added to the composition.

The presence of carbon provides increased viscosity of the substance. Chromium is a universal component; it increases the thermal impact capabilities of the alloy, makes it as durable as possible and eliminates the risk of corrosion.

pros

9ХС steel has advantages that set it apart from other alloys.

- It has unique technical characteristics that allow it to be used in the manufacture of strong, elastic, wear-resistant parts with a high bending resistance coefficient.

- In alloy 9ХС, carbides are always evenly and correctly distributed over the cross-section, which improves the performance qualities of the finished product, in particular, threaded elements created from it.

- It has a high degree of resistance to mechanical damage and cracking.

- After annealing, it acquires another undeniable advantage - increased hardness and ductility to calcination.

- Has high thermal stability.

- The alloy is resistant to flocking during finishing.

Thanks to these advantages, 9ХС steel is a popular and practical tool alloy.

Minuses

There are also disadvantages to this alloy, which also need to be taken into account in the production of tools and cutting products.

- Specific requirements for heat treatment.

- Not suitable for welding work.

- When processing, strict adherence to temperature conditions is required.

- Complicated mechanical processing.

Only highly qualified specialists need to work with 9XC alloy, as there are conditions and nuances that must be met.

Blade made of 9ХС steel.

Reviews of knives from 9ХС

For the needs of the food industry, hunting, tourism and other activities, knives made from 9ХС steel are often used. Impressions of use are mostly positive. Users note difficulties in sharpening and the possibility of nicks. In general, owners of 9XC knives are satisfied and note the high strength of the products, long-term retention of the original sharpness after sharpening.

9ХС is a specialized alloy used for durable cutting tools, threaded components, and abrasion-resistant parts. If the technical requirements for processing are met, this metal alloy is quite good in operation.

What knives is it used for?

9ХС steel is widely used for the manufacture of knife blades. No special equipment is required to give the alloy the desired shape, which is why knife makers love this brand.

Knives made of 9ХС steel are most often purchased for tourism, hunting, and fishing. They cope remarkably well with the tasks that arise in traveling conditions. Thanks to the special 9XC alloy, the knives are highly durable. It is able to withstand significant loads: impacts, torsion, contact loading.

Knife Marten 24.5 cm - 8100 rub.

One of the most important characteristics for a tourist or hunting knife is good cutting properties. Blades made of 9ХС steel can easily cut hard objects, such as tree branches or animal bones, and are suitable for cutting carcasses. They tolerate aggressive environmental conditions well and are not afraid of water and high temperatures. Although, due to the insufficiently high percentage of chromium in the composition, they cannot be classified as stainless.

Sources

- https://promgroupchel.ru/information/mark/leg/9xs/

- https://stroy-podskazka.ru/stal/marki/9hs/

- https://intehstroy-spb.ru/spravochnik/stal-9hs-dlya-nozhey-plyusy-i-minusy.html

- https://VashNozh.ru/stal/9hs

- https://top-nozhej.ru/bez-rubriki/stal-9hs-dlja-nozhej-pljusy-i-minusy/

Analogs

Foreign analogues are:

- DIN

- WNr

- 150Cr14

- 90CrSi

- 90CrSi5

Blades made from this steel have proven themselves well in fishing, hunting and mushroom picking. They can be used during tourist excursions. Unlike more popular brands, knives made from 9xc by forging are more reliable and withstand aggressive environmental conditions well.

Tool steels are widely used today. They are highly durable. Thanks to which they have a wide range of applications. Modern industry makes it possible to produce tool steel of several grades. The material described in this article has all the necessary properties for making knives. Their characteristics are several times superior to knives made of bearing steel.