Steel 65x13 is a tool steel and belongs to the martensitic class. In Russia it is used for the manufacture of cutting tools, which have high requirements for corrosion resistance. Due to its use in medicine (the manufacture of scalpels and other devices designed for long-term use), this steel is also called “medical” or “surgical”. The predominant use of 65×13 steel for knives, the pros and cons of products made from it, are determined by the properties of the alloy.

Knife with steel 65x13 on the blade.

General information

Any alloy is mainly composed of carbon and iron.

Precisely calculated proportions make it possible to turn any piece of “iron” into a reliable and universal alloy that can be used in the manufacture of knives and other devices. Additionally, the composition has alloyed additives, which also play an important role and improve the quality of the material in every possible way. The properties and functions of steel largely depend on manufacturing technology and additional impurities. It is made in different variations, for example, composite, which includes several layers. In some cases there may be several dozen or hundreds of them. Since in addition to iron, chromium and carbon are also added in the manufacture of knife products, the correct ratio can result in reliable steel with preserved and pre-designed properties.

Steel 65x13 is the most common and popular steel in the production of knives. The material has all the necessary properties and an affordable price. It belongs to stainless steel, so it is an excellent option for the production of products for a wide variety of purposes. The presence of the letter X in the middle of the name indicates the presence of chromium, which makes it resistant to corrosion.

Steel composition 65×13

| C | Cr | Fe | Mn | P | S | Si |

| 0,60-0,70 | 12-14,0 | prevails | 0,25-0,80 | ≤0,030 | ≤0,025 | 0,2-0,5 |

Composition of impurities 65Х13

| Chromium (Cr) | 12,00-14,00% |

| Manganese (Mn) | 0,25-0,8% |

| Silicon (Si) | 0,20-0,5% |

| Nickel (Ni) | 0,5% |

| Phosphorus (P) | 0,030% |

| Sulfur (S) | 0,025% |

Features of steel 65×13

This type of stainless steel consists of an alloy of iron with a number of chemical elements: carbon, silicon, manganese, etc. Thanks to the high percentage of chromium, the cutting properties of the blade are improved. It became wear-resistant and hard. The blade does not corrode. With proper care, the product will not rust after a decade. Various types of knives are made from this steel:

- cutting;

- tourist;

- folding;

- kitchen

According to its characteristics, this steel is well suited for the manufacture of knives for various purposes. But the technology of its production requires strict adherence to the standard, competent hardening and annealing. The quality of the finished product depends on the conscientiousness and qualifications of the craftsmen.

Hunting knife

Hardness

This grade of steel has a fairly high hardness, but experts still cannot come to a single answer and argue about the hardness of the steel. This is due to the fact that not all manufacturers use the same technology when producing knives. If fired and hardened incorrectly, it will be very flexible and unusable. But, fortunately, most manufacturers understand the seriousness of the matter and approach this professionally, therefore buyers do not have questions about this.

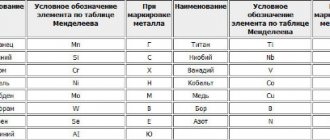

Alloying components

The presence of alloying components indicates the presence of certain properties of the material. Their addition contributes to the acquisition of flexibility or hardness of the metal.

- Manganese. Responsible for reproducing a unique texture and increasing the rigidity and strength of the blade. It is worth noting that the relative hardness and rigidity of 65x13 steel is obtained due to the presence of this component.

- Chromium. No material will be resistant to moisture without the addition of chromium. Wear resistance is one of the main qualities of knives. Chromium makes steel stainless when present at 13% of the total composition.

- Molybdenum. Performs a protective role - prevents fragility and brittleness. Gives a little viscosity and hardness; the composition must contain at least 1% of this component.

- Silicon is responsible for elasticity.

- Nickel. Serves as protection against corrosion and adds viscosity, and is also an alloying additive.

- Tungsten. In demand among manufacturers of expensive and luxury knives. Used to effectively and quickly increase wear resistance, increase hardness and withstand high temperatures. When combined with chromium or molybdenum it becomes extremely useful in improving cutting performance.

- Vanadium. Like most other additives, it performs a standard role and imparts strength to steel. Essential in the production of fine-grained alloys.

Where is 65x13 steel used?

The main direction in which most steels are used is the production of knives and blades. In addition, it can be used in the manufacture of various parts and medical products, for example, cutting instruments, razors. In some cases, if special characteristics are evident, steel can be used in constructive activities: the creation of steel sheets and other products that would be useful in use.

Brief characteristics of knife steels

In general, in addition to iron, they always contain carbon and chromium. Note that carbon in knife steel cannot be less than 0.5%. Experts believe that the optimal content is 1%. Steels that already contain 1.25% carbon become very hard, but at the same time extremely brittle. If there is a need to create such a material, then vanadium and molybdenum are included in its composition.

However, there are also damask steels, which generally contain 1.5-2% carbon (up to 4% in some cases). Their strength and flexibility are determined by a special forging and hardening technology.

Advantages of knives made of steel 65×13

Let us take a detailed look at the advantages and disadvantages of products made from this type of steel. There are rave reviews and sharply negative statements on the Internet. The undeniable advantages include: the hardness of the steel, ease of sharpening. The working edge does not chip and resists impacts and bends well. The absence of alloying additives that impart increased strength allows the product to be made to absolutely any geometry.

Thus, the advantages of knives made of steel 65×13 are their following qualities:

- Good resistance to oxidation and various adverse external factors.

- Low price range.

- They do not require special care.

- Sharpen quickly and sharply.

- They are easy to process (polishing, cleaning).

Steel knife

Steel. Characteristics of stainless steel

To put it very simply, steel is an alloy of iron and carbon. A lot of carbon is cast iron, a little is tin. The “middle” state can be called steel. Its different types are determined not only and not so much by the proportions of iron and carbon, but by alloying with various additives and impurities that give the steel different properties.

The properties of alloys depend both on the chemical components that are included in their composition and on the technological conditions of production. Sometimes steel is made composite, when it consists of several layers of different grades, or Damascus, when the material contains several hundred layers (of the same grade). The material may contain the following additional components:

- If the total volume of the additive does not exceed 1.5%, then we are talking about modifiers that help improve the mechanical, physical and chemical properties of this category of materials. More than 1.5% are alloying additives that give the steel corrosion resistance.

- Carbon. This element, as we said, is present in all types of alloys, giving them rigidity and strength. Excess of it turns steel into cast iron.

Disadvantages of knives of this type

When talking about imperfections, there are a number of details that need to be mentioned.

- Moment one. There is a common belief that 65x13 steel is not very hard and products are susceptible to deformation under light load. To indicate the hardness of steel, specialists use Rockwell units. For working knives it should be in the range from 40 to 60 units. In this case, this figure is 57-59 HRC, i.e. almost ideal. However, there are unscrupulous manufacturers who violate manufacturing technology and perform low-quality hardening. In the worst case scenario, they replace 65×13 steel with another, lower quality one. Visually, the buyer cannot control this moment. Consumer complaints about the “softness” of the blade become clear.

- Second point. If you use the knife for its intended purpose, there will be no complaints about quality. You must clearly understand for what purpose you are buying a knife and list the tasks facing it. If you need an inexpensive work or gift option that does not involve significant loads on the blade and its cutting part, then knives made of 65×13 steel will be the best option. However, for high loads it is better to choose a knife made of steel of a different grade.

- Third is the manufacturer. There is a huge amount of counterfeit goods from China on the market. The declared marking 65×13 in reality can turn out to be anything. In addition, Chinese manufacturers often overheat the steel, which makes the product brittle. The slightest loads in this case lead to deformation of the blade or its breakage.

Steel hardness 65Х13

Maintaining an edge directly depends on the hardness of the blade. Steel 65X13, thanks to additives in certain proportions, the alloy has this indicator quite high. With proper heat treatment, steel can achieve hardness in the range of 56 to 59 HRC.

This indicator corresponds to universal-purpose knives. This grade of steel is used to make knives for a wide variety of purposes. There is ongoing controversy surrounding the proper production of blades from this alloy

The main reason is the technological process, which includes proper firing and hardening. These processes greatly affect the quality of the finished product. When properly produced, 65X13 steel is strong, hard and resilient.

To obtain the hardness of the required quality, the samples are placed under a press with a diamond tip. Failure to comply with production technology and neglect of the necessary rules leads to poor quality results.

Such knives quickly break, bend, and the cutting edge often jams. It should be borne in mind that it is almost impossible to properly harden 65X13 steel at home.

Manufacturers worth attention

Domestic steelmakers have maintained a high standard in the production of knives for several centuries. The undeniable advantages of Russian products include decent quality combined with an affordable price. If we talk about steel 65×13, then the technologies for making knives from it are available in the arsenal of all major manufacturers.

Zlatoust companies

Your choice is a Zlatoust knife? Do not doubt! Excellent quality. For two hundred years Zlatoust has held a leading position in the Russian market. On average, a hunting knife made of steel 65×13 costs from two to four thousand rubles. One of the most popular models, “Bear”, is in constant demand. Let's look at its technical characteristics:

- blade length - 139 mm;

- blade thickness - 2.3 mm;

- total length - 263 mm;

- steel - 65×13.

The blade has a thick wooden handle. Birch bark inlay. Comfortable, non-slip, pleasant to the touch. For little money, about two thousand, you get a worthwhile option for active recreation. A license is not required to purchase. The Bear is not considered a melee weapon.

Damascus steel knife

Pavlovian knives

Pavlovsk products are marked with original drawings that make them stand out from others. The quality of steel can withstand even corrosive criticism. For example, the Gyurza model is a good choice for hunters, fishermen and tourists. Powerful, reliable, awkward:

- Blade length 205 mm.

- Blade thickness 3 mm.

- Steel 65×13.

- Weight 136 g.

The workshops of Pavlovsk blacksmiths pay serious attention to the search for new forms in design and support the traditions of blade manufacturing. In the ranking of leaders is a young company that produces models for various purposes. Wide selection and reasonable prices. Buyers also have on the “white list” the workshops of the Shirogorov brothers, Sander, “Kizlyar” and Vorsma products.

"Bear"

The general characteristics are:

- The total length is 23.5 centimeters.

- The length of the blade itself is 11.5 centimeters.

- The blade width is 28 mm.

- Blade thickness - 2.8 mm.

The knife is equipped with a relatively thick handle (3.3 cm), which fits comfortably in the hand and does not slip, even if a person sweats. Other characteristics vary from manufacturer to manufacturer. So, in some cases there is a bear etching on the blade, while other manufacturers do not practice this.

As a rule, there is no guard on the blade, but many manufacturers additionally stipulate the possibility of installing one (even from precious metals). In all cases, the handle is made of walnut, but the method of its fastening is different (ordinary riveting is often found).

However, this is not what interests us. Why is the 65x13 “Bear” knife interesting to buyers, and what do people who have already made a purchase say about it? Firstly, they like the price: from 1,350 rubles in the “basic package”, without frills and precious metals in decoration. For this amount, judging by the reviews, you get an excellent knife for outdoor activities, which in the field can be sharpened almost “on a pebble.”

Since the length of the blade is within police standards, the “Bear” is not a bladed weapon. Many people like the simple geometry of the cutting part, without sharp or winding lines. The knife is easy to care for. When purchasing, it is important to pay attention to whether a particular manufacturer has skimped on normal varnish for the handle. Judging by the reviews, they often save on this. In addition, we strongly recommend choosing a model with a guard: some manufacturers have a handle that is not very well shaped, and therefore a hand smeared with blood or fat may slip onto the cutting edge.

For the same reason, we recommend buying a “Bear” with a birch bark handle, since your hand practically does not slip on it.

Sharpening tools

Now let's talk directly about sharpening tools. What they are and what they are eaten with.

There are, roughly, two types of machines and devices for sharpening. The first are manual and mechanical, and the second are electric. Let's say right away that electric machines, in our opinion, do not cope with their responsibilities. Cheap electric sharpeners equipped with diamond rotating discs can only sharpen ceramic knives decently. More serious electric machines are quite expensive and often difficult to use. We will not consider them.

You ask: “Why are they selling them then?” We answer - to earn money while there is a demand for a “magic” device - insert a knife, press a button, “tick” - and you’re done!

Let's talk about manual sharpening devices and about sharpeners with a mechanical (muscular) “drive”.

Traditional way

The traditional method, popular among old-school professionals, is hand sharpening on natural stones or water stones. Water stones (water stones because before use they must be soaked in water until all air bubbles come out of them) differ favorably from natural stones in that they have different grain sizes from coarse (100-120 grit) to very fine (10,000 grit).

Natural stones, for obvious reasons, cannot be presented in such an assortment. They are, as a rule, all small, finishing.

The method of sharpening both on natural stones and on water ones is, in general, similar. Only when working on water stones, we sharpen the cutting edge of the knife not on the surface of the block itself, but on the suspension formed on its surface (an aqueous “solution” of abrasive powder). Therefore, putting too much pressure on water stones is contraindicated. Excessive pressure will cause increased wear on the bar.

Natural stones do not need to be soaked, but they should be moistened from time to time with water or soap suds (so that the surface of the stone does not become clogged with metal dust that will form during operation).

The sharpening angle is set intuitively. Various devices for setting the sharpening angle work only on wide knives with a thin spine (these are, as a rule, kitchen knives such as “Chef”, “Santoku”, etc.).

That is, you need to take a knife or a block and study, study, study, and not everyone likes this. Many, for example, are afraid of damaging (scratching) their knife while learning the sharpening process.

Mechanical devices

For such users, various mechanical devices have been invented to simplify sharpening and reduce its time.

Scraping-pulling scissors

It is better not to use various kinds of scraping and pulling knives with carbide (tungsten carbide, “win”) plates.

Although the sharpening is very fast (a few seconds), it is very asymmetrical and short-lived. It may only be suitable as an emergency sharpening (there is nothing at hand, and a knife or hatchet needs to be sharpened urgently). In addition, such sharpening on carbide elements spoils the cutting edge and greatly reduces the service life of the sharpened tool.

"V-shaped sharpeners"

The so-called “V-shaped sharpeners” are a base made of wood or plastic, on which long bars or cylinders are fixed at a given angle, similar in shape and operating principle to sharpeners, only on a stand and without a handle.

The bars, as a rule, can be set at an angle of 20° and 25°. The first option is suitable for kitchen knives, and the second for tourist and hunting knives. There is no need to intuitively maintain an angle when working with such sharpeners. It is enough to simply pull the blade from top to bottom from the heel of the blade to its tip, holding the knife strictly perpendicular (at a right angle of 90°) to the surface of the table, floor, or ground. Such sharpening does not present any difficulties.

The bars can be diamond-coated or made of hard ceramics. You can press on hard ceramics, but you should not put pressure on diamond (crystals will crumble out of the metal binder). Both can be moistened before use with plain water or soap suds. You can work without lubricant, but then you will have to wash the surface of the bars with a rough sponge and cleaning soap to remove waste metal (a gray coating that clogs the surface of the bar and reduces its working properties).

It is advisable that the set include bars with a medium grit of 400-600 grit (for sharpening) and fine grits of 1000-1500 grit (for finishing).

“V-shape sharpeners” are a good option for a home workshop. We can confidently recommend it to you for use. If we need a different sharpening angle, then we can take the abrasive rods out of the supply and work with them like regular grinding tools. The thing is two in one!

Special sharpening kits

Special sharpening sets with knife holder. The knife is fixed in them and held in a certain position. Here we no longer run a knife along a block, but work with a block fixed to a guide at a given angle. There are quite a lot of such sharpeners; we will roughly divide them into “Lansky-shaped” and “Apex-shaped”.

Other benefits

The working edge of such blades is not prone to chipping even with intensive use, and the knife will withstand both strong bends and blows well. Due to the absence of high-quality alloying additives in the steel, the blade will dull quite quickly, but it can be sharpened quickly. Of course, due to the same lack of additives, the tribological properties of this steel grade are not very good, but they are much better than those of really soft grades.

But experienced tourists and simply knife lovers talk about another advantage of this alloy and knives made from it. Since this material contains practically no alloying additives that would provide increased strength (more on this below), the geometric configuration of the knife can be absolutely any. This 65x13 (reviews say the same) compares favorably with “professional” steel grades, with which a similar approach will not work.

Ballast

Nitrogen, like some other elements, is always present in steel. Such elements are called ballast. However, occasionally they are still purposefully added to the composition of the alloy, since some of them can improve its performance. Some (sulfur and phosphorus, for example) should not be present in the alloy at all: their content is limited by numerous standards.

Why did we write all this out? The point is that you should clearly understand the general characteristics of knife steels, since many of them are very specific, bearing little resemblance, for example, to the alloys used to make boilers or something similar. Thus, in some cases, steel grade 65x13, the properties of which will be described in detail below, becomes completely unsuitable for the production of knives due to the high content of phosphorus and sulfur.

Analogs

Among the most famous foreign analogues of 65X13, the following steel grades can be specified:

- 440, X65Cr14 – in the USA and Canada;

- 3542, M11 – in Germany;

- MP13V, X60Cr13 - in the UK.

As a substitute for this material in domestic metalworking, steel types 40X13 or 95X18 are used, depending on the purpose of the end use.

Technological properties

| Name | Meaning |

| Macrostructure and contamination | The macrostructure should not contain remnants of shrinkage cavities, looseness, subcortical bubbles, cracks, foreign metal and slag inclusions, or crusts visible without the use of magnifying devices. Acceptable macrostructure defects should not exceed 1 point for central porosity, point heterogeneity and segregation. Microporosity is not allowed. Contamination with non-metallic inclusions should be for rods up to 25.5 mm: oxides and sulfides - no more than 1.0 points for each parameter; silicates, globular inclusions and point inclusions - no more than 2.0 points for each parameter. For rods over 25.5 mm: oxides, sulfides and point inclusions - no more than 2.0 points for each parameter; silicates and globular inclusions - no more than 3.0 points for each parameter. |

| Microstructure | T/O rods (Quenching + Hodo treatment + Tempering) fine-crystalline martensite; amount of retained austenite 12.0-12.2; the average size of excess carbides is 13 microns; carbide heterogeneity 1.0-2.0. For hot-rolled bars, the permissible depth of the decarburized layer must comply with GOST 5950; for bars with a special surface finish, decarburization is not allowed. The supplier is permitted to guarantee that bars with special surface finishes are free from decarburization without testing. Carbide heterogeneity for rods with a diameter of up to 25 mm inclusive should not exceed a score of 2.0; for rods with a diameter over 25 mm - 3.0 points. The average size of large carbides in rods with a diameter of up to 20 mm should not exceed 13 microns. For rods with a diameter of more than 20 mm, the standard is established after data accumulation. Carbide heterogeneity of steel is assessed on heat-treated samples according to the following mode: Heating to 830-850 °C (holding time 15 minutes) + Heating to 1070-1110 °C (heating time - 1.5 minutes per 1.0 mm of maximum section, but not less than 4 minutes) + Hardening in oil + Cold treatment at a temperature of minus 70 ° C - minus 80 ° C for an hour + Tempering at 400-420 ° C (holding time 5 hours). It is allowed not to subject the samples to cold treatment. |

Comparison of steel 65×13 and 95×18: which is better

For the manufacture of cutting tools for home and professional use, 95X18 steel is also used. It is also called “knife steel.” It has similar characteristics to 65X13 steel, but with some differences.

Knife with 95×18 on the blade

Its carbon content (0.95%) makes it more labor-intensive to produce goods from it. It is necessary to strictly follow the heat treatment technology; even small deviations greatly affect the properties of the metal. The production process is more expensive, and the cost of products is higher.

The hardness of steel 95Х18 is better than that of 65Х13. The blade will retain its sharpness longer, but sharpening requires a special diamond tool.

Resistance to bending influences, i.e. product strength is lower. When working with a knife made of 95X18, strong lateral loads should be avoided so as not to cause breakage.

Prolonged contact with an aggressive environment should not be allowed; rust may appear on knives made from 95X18.

Both alloys have proven themselves well in the domestic market. If you need an inexpensive kitchen knife, it is better to choose a blade with a hardness of 52-57 HRC. It will retain its original properties for a long time and is easy to sharpen. For a hunting knife, it is preferable to take a harder material - it allows you to maintain cutting properties for a long time.

Scope of application of steel 65Х13

Steel 65X13 has proven itself very well in the medical industry. Scalpels and other cutting tools are made from it. This steel is used to create razors.

It is also used in the construction industry.

But most often it can be seen in knives. It is considered the best option for making blades. Among the products you can find:

- Kitchen. Such blades are produced in a very diverse and wide size range.

- Hunting. The products perform well in difficult conditions remote from civilization. Blades act as cutting and other functions. Massive knives have a wide blade and a significant cutting edge area.

- Tourist. You can easily split hard trees with a blade. Knives are specially made with increased thickness. A well-balanced blade will perform any task in survival conditions.

- Cutting. Cutting a carcass, pieces of meat and fish with such a blade will not be difficult. Cooking products of a professional and amateur nature are made from this steel.

- Razor blades. The best option for the manufacture of shaving machines. Even with a very thin blade, steel can be sharpened perfectly. Thanks to its characteristics, it feels great in a humid environment.

- Pen-cases. The narrow blade retracts into the handle and behaves perfectly for tourist and household purposes.

- Medical knives. Steel is ideal for making lancets and scalpels for surgical operations.

When purchasing a product, pay attention to the grade of steel. Marking steel 65X13 from a reputable manufacturer will give you the opportunity to use the blade for a long time. The knife will be easy to sharpen and will serve you faithfully.

Steel strips are the future knives.

Tips for choosing

When choosing a blade, you should study all its parameters. An important characteristic is geometry. The thinner the blade, the sharper it is. The ideal cross-sectional shape is a wedge (isosceles triangle) or a wedge with a lead (the cutting edge is sharpened at a more obtuse angle).

The most important aspect is the handle. Its shape should be ergonomic, fit well in the hand, and not turn (round handles are a problem with this). There should be no sharp edges, corners, or too many recesses. Gift copies with all sorts of decorations usually turn out to be inconvenient in practice. You cannot choose the hilt of a dagger only by appearance. You definitely need to hold it in your hand. And for a fisherman, hunter or tourist, take into account how comfortable it will be to work wearing gloves or mittens. Many people prefer natural materials for the handle - wood, bone, birch bark, leather. Plastic is usually not so beautiful and noble, but is often stronger and more durable.

When choosing a folding knife, the most important thing to pay attention to is the opening mechanism itself, as well as the lock for locking it when opened. You should try folding and unfolding the “folder” several times and evaluate how convenient it is to do it with one hand. The blade should not wobble from side to side. If there is even a slight play, then most likely the purchase will soon become unusable.

The most popular brands are:

- specializes in the production of comfortable hunting, fishing, and tourist blades. The cost of products made from this type of steel starts from 3,000 rubles. Usually the company gives a branded leather sheath as a gift.

- Pavlovsk hunting knives can be purchased starting from 1,500 rubles. Tourist and universal ones are even cheaper. The variety of assortment is wider.

- As for knives produced by Zlatoust, the price range is even wider - from 2,000 to 18,000 rubles. This is due to the wide range of models.

All three manufacturers have a good reputation, their products are of high quality and are in demand.

Steel 65X13 is the choice of many. There is a wide variety of knives made from it. They may not be as durable as models made from other brands, but they are easier to use in everyday life.

The knife should have a comfortable and durable handle

When choosing a folding knife, you need to check the operation of the mechanism

It is recommended to purchase blades only from trusted manufacturers. Sources

- https://nazarklinok.ru/articles/o-nozhah/2017/stal-65kh13-dlya-nozhey-plyusy-i-minusy/

- https://VolgaProekt.ru/stati/raznoe-stati/stal-65h13-dlya-nozhej-plyusy-i-minusy.html

- https://www.atissteel.ru/stal-65h13-harakteristiki

- https://NpfGeoProm.ru/materialy/stal-65h13.html

- https://FB.ru/article/175251/harakteristiki-stali-h-svoystva-tverdost-otzyivyi-o-nojah-iz-stali-h

- https://VashNozh.ru/stal/65×13

"Tiger"

Another member of the knife “zoo”. Unlike the previous variety, it is officially a cutting variety. As in the previous case, a design can be applied to the blade. The possible names of wood for the handle are much wider: from the same walnut to wenge and other exquisite species. The Tiger knife 65x13 itself has the following characteristics:

- The total length is 27 centimeters.

- The blade is 14.5 centimeters.

- Noteworthy is the width of the blade, which is 42 mm.

- A leather sheath is included.

As you can see, the dimensions of this knife are much larger than those of the “Bear”. That is why it is especially popular among fishermen and hunters who prefer long forays into the forest: judging by the reviews, people are impressed by the long blade, which is convenient for cutting up prey. Like all other knives made of 65x13 steel, it dulls relatively quickly with intensive use, but sharpens just as quickly. In this case, as in the previous quality, it is often possible to get by with the simplest devices.

In some cases, manufacturers, in order to attract “aesthetes,” do completely exotic things with this knife. For example, you can find “Tiger” coated with titanium and tungsten coating, and almost all manufacturers offer gold-plated blades. But the practical value of such knives is close to zero.

Experienced users say that the spraying (subject to actual use) will in any case wear out and chip. As a result, the knife will look like a panda: alternating whole and tattered sections of the blade does not look very aesthetically pleasing. In addition, the price of such knives is appropriate: if a regular “Tiger” costs around 1,800 rubles, then “refined” options sometimes sell for 10 thousand, or even more.

By the way, about the manufacturers. Who was especially successful with 65x13 steel? Kizlyar is a particularly well-established manufacturer. So to speak, “number one” according to buyers. Experienced knife lovers claim that it is Kizlyarov’s “Tigers” and “Bears” that have the most optimal price-quality ratio.

What other knives are there made of 65x13 steel? Which models have the most impressive reviews?