| Brand: | R6M5K5 |

| Class: | High-speed tool steel |

| Used for rental: | Sections and shapes: GOST 19265-73, GOST 2590-2006, GOST 2591-2006 Calibrated rod: GOST 19265-73, GOST 7417-75 Ground rod and silver: GOST 19265-73, GOST 14955-77 Strip: GOST 1926 5- 73, GOST 4405-75 Forgings and forged blanks: GOST 19265-73, GOST 1133-71 |

| Industrial use: | For processing high-strength stainless and heat-resistant steels and alloys under conditions of increased heating of the cutting edge. |

| Material hardness: | HB 10-1 = 269 MPa |

| Critical point temperature: | Ac1 = 840, Ac3(Acm) = 875, Ar3(Arcm) = 805, Ar1 = 765 |

| Forging temperature, °C: | Start 1160, end 850. Cooling in wells at 750-780 °C |

| Cutting ability: | — |

| Weldability of material: | Not applicable for welded structures |

| Flock Sensitivity: | Not sensitive |

| Tendency to temper brittleness: | Less inclined |

| Analogues: | R9K5, R18, R6M5 |

Decoding

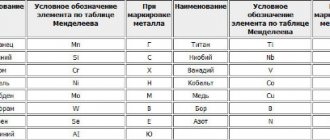

- The letter P indicates that the steel is high-speed;

- Number 6 - indicates the presence of Tungsten (W) and its average% in the steel (in this steel the Tungsten value is 5.70–6.70%);

- The letter M indicates the presence of Molybdenum (Mo);

- Number 5 - indicates the average% Molybdenum content (in this steel the Molybdenum value is 4.8–5.3%);

- The letter K indicates the presence of Cobalt (Co);

- Number 5 - indicates the average% Cobalt content (in this steel the Cobalt value is 4.7–5.2%).

Pros and cons of steels R18 and R6M5 for knives

In the manufacture of knives, steel grades P18 and P6M5 are often used. Both alloys offer similar benefits. Among them are resistance to wear (no need for frequent sharpening), corrosion, ease of grinding and maintenance, and high sharpness of the cutting edge. These knives are strong, durable, and versatile in use.

Among their disadvantages, we can note the rather high cost of models from well-known manufacturers. But the costs are fully compensated by the impeccable quality and appearance of the products.

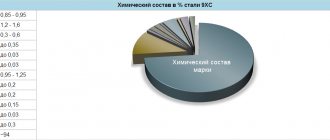

Chemical composition of steel R6M5K5

| Chemical element | % |

| Carbon (C) | 0,84 – 0,92 |

| Silicon (Si) | 0,2 – 0,5 |

| Manganese (Mn) | 0,2 – 0,5 |

| Nickel (Ni) | up to 0.6 |

| Phosphorus (P) | up to 0.03 |

| Chromium (Cr) | 3,8 – 4,3 |

| Molybdenum (Mo) | 4,8 – 5,3 |

| Tungsten (W) | 5,7 – 6,7 |

| Vanadium (V) | 1,7 – 2,1 |

| Cobalt (Co) | 4,7 – 5,2 |

| Sulfur (S) | up to 0.03 |

| Copper (Cu) | up to 0.25 |

| Iron (Fe) | ~75 |

Alloy Application

The given qualities of this steel determined its direct place in production. It is mainly used for cutting other materials under extremely high temperature conditions. It is much more practical to use a quick cutter for these tasks than any stainless alloys. A characteristic feature of R6M5 is its excellent edge retention due to its high hardness.

This beautiful metal also withstands shock loads very well, which makes it in demand in the manufacture of cranes, drills and reamers.

Knife blade made of R6M5 steel.

R6M5 with its properties is dynamically used for the production of knives. Due to the widespread use and production of this tool, there are many well-known manufacturers, for example, the same Rapid.

Numerous experiments are being carried out using knives made of P6M5. They are effective at cutting the following objects with increased strength: thick ropes, wood, bones, etc. The most spectacular successful test was cutting an iron plate with a knife made of P6M5, which was several mm thick - not without difficulties, but it was successful.

When P6M5 is used to make knives, it is usually hardened to HRC 60-62, although sometimes this parameter is brought to HRC 66-67.

Benchmade is one of the largest companies producing knives using P6M5 steel. This alloy is unique in its composition, it contains large amounts of molybdenum and tungsten, but the result is a very fine-grained steel, ideal for creating blades.

GOST and TU steel R6M5

Information about R6M5 steel is available simultaneously in several GOSTs and TUs. All contain products and their technological parameters. Despite the redirection of rolled metal to hard alloys, due to its properties, R6M5 is still very popular in many industries.

Mechanical properties of R6M5K5 steel in a heat-treated state at elevated °C

| Test temperature, °C | 200 | 400 | 500 | 550 | 600 | 650 |

| Bending strength, MPa | 3820 | 3980 | 3040 | 2980 | 2790 | 2500 |

| H.V. | 833 | 769 | 726 | 686 | 626 | 528 |

| HRC ∂ (HB) | 64 | 62 | 61 | 59 | 57 | 52 |

Peculiarities

Steel grades R6M5 and R18 are used not only in the manufacture of knives, but also in the production of taps, drills, and industrial cutting tools. They are distinguished by their ability to maintain hardness and sharpness when exposed to high temperatures and significant shock loads. The high content of carbon and tungsten in the composition gives steel these characteristics.

Heat treatment

To give knives made from P18 and P6M5 increased strength and wear resistance, the metal is subjected to appropriate heat treatment. It takes place in 2 stages:

- Hardening – heating to a temperature of 1200-1300C. To avoid the formation of cracks, it is carried out gradually. First, the metal is heated to a temperature of 400-500C, then to a temperature of 800-850C. At maximum heating, the workpiece is subjected to heat treatment for a limited time (10-15 seconds for each millimeter of thickness). During hardening, the carbide decomposes, the alloy is saturated with tungsten and carbon.

- Vacation is carried out at a temperature of 550-560C. It is carried out in 2-3 stages, each lasting at least an hour. At the same time, the strength characteristics of the metal increase.

Steel is heated in special salt baths, which consist of barium chloride (78%) and sodium chloride (22%). Magnesium fluoride is used to deoxidize the solution.

Production of cutting tools

After heat treatment of the steel, the production of cutting tools begins. For this purpose, the workpieces, which are previously checked for compliance with GOST requirements, are sent for grinding. Products made from P18 steel are easier to grind, but they also retain their sharpness for a shorter period of time. Knives made from R6M5 alloy can only be sharpened with professional tools and skills, but their sharpening quality is much better. In production, specialized machines are used for grinding workpieces made of steel R18 and R6M5.

Knife Grif steel P18, birch bark handle.

Use in cutting

Knives made of steel P18 and P6M5 are quick-cutting and universal in use. The metal performs well under heat and mechanical stress. It does not lose strength or deform. Manufacturers of knives made from these steel grades conducted experiments during which they successfully coped not only with slicing various food products (meat, bones, cartilage), but also with cutting wood and even metal plates several millimeters thick!

Physical properties of R6M5K5

| Test temperature, °C | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| Modulus of normal elasticity E, GPa | 2,2 | — | — | — | — | — | — | — | — | — |

| Density, pn, kg/cm3 | 8200 | — | — | — | — | — | — | — | — | — |

| Thermal conductivity coefficient W/(m °C) | — | 27 | 28 | 29 | 30 | 32 | 36 | 34 | 36 | 29 |

| Electrical resistivity (p, NΩ m) | 458 | — | — | — | — | — | — | — | — | — |

| Linear expansion coefficient (a, 10-6 1/°С) | — | — | — | — | — | — | — | — | — | — |

| Specific heat capacity (C, J/(kg °C)) | — | — | — | — | — | — | — | — | — | — |

R6M5K5 high-speed tool steel

Decoding

- According to GOST 19265-73, the letter P means that the steel is high-speed.

- The number 6 following the letter P indicates the average mass fraction of tungsten in %, i.e. The average mass fraction of tungsten in steel is 6%.

- The letter M means that the steel is alloyed with molybdenum, the number 5 following the letter indicates the mass fraction of molybdenum in the steel in %, i.e. The molybdenum content in steel is about 5%.

- The letter K means that the steel is alloyed with cobalt, the number 5 following the letter indicates the mass fraction of cobalt in the steel in %, i.e. The cobalt content in steel is about 5%.

- According to GOST 19265-73, the designation of steel grade R6M5K5 does not indicate the mass fraction of chromium and vanadium.

Foreign analogues [1]

| Steel grade (Country) | Standard |

| 2723 (Sweden) | SS |

| 3243 (UK) | GB-03 |

| BM 35 (UK) | BS 4659 |

| 6-5-2-5 (Spain) | UNE 36073 (75) |

| F.550.C (Spain) | |

| EM 35 (Brazil) | ACO |

| VK-5E (Brazil) | Villares |

| HS 6-5-2-5 (Euronorms) | EN 96-79 |

| HS 6-5-2-5 (Germany) | DIN 17350 |

| HS 6-5-2-5 HC (France) | AFNOR NF NF A35-590 (92) |

| R8 (Hungary) | MSZ 4351 |

| SK5M (Poland) | PN/H 85022 |

| SKH 55 (Japan) | JIS G4403 |

| W6Mo5Cr4V2Co5 (China) | GB 9943-88 |

| R6M5K5 (Bulgaria) | BDS 7008 |

Type of delivery

- Long products, including shaped steel: GOST 19265-73, GOST 2590-88, GOST 2591-88.

- Calibrated rod GOST 19265-73, GOST 7417-75.

- Polished rod and silver steel GOST 19265-73, GOST 14955-77.

- Strip GOST 19265-73, GOST 4405-75.

- Forgings and forged blanks GOST 19265-73, GOST 1133-71.

Characteristics and Application

Tungsten-molybdenum steel R6M5K5 is used for processing high-strength stainless and heat-resistant steels and alloys under conditions of increased heating of the cutting edge. This steel is the main grade of high-speed steel with increased productivity, used for the manufacture of various roughing and semi-finishing tools (mills, cutters, countersinks, thread-cutting tools, etc.) intended for processing carbon and alloy structural steels at high cutting conditions, as well as stainless steels and heat-resistant alloys. It is recommended instead of R18K5F steel, as it is more economical, and instead of R9K5 steel, as having higher (25-30%) cutting properties [2].

The cobalt content in steel improves heat resistance up to 645 °C due to an increase in the temperatures of the α → γ transformation, difficulty in carbide coagulation and its effect on the formation of the θ phase. The positive effect of cobalt on the heat resistance and thermal conductivity of steels with 0.7-0.9% C should increase with increasing its content (up to 10-15% and higher). At the same time, mechanical properties deteriorate. An increase in the tungsten (molybdenum) content at a constant cobalt content has the same effect.

R6M5K5 steel has a heat resistance of 630 °C, which is lower than that of R12F4K5 steel; the secondary hardness of R6M5K5 steel is also lower and is 65-65.5 HRC. This is due to the need to assign lower quenching temperatures, and consequently, to the difficulty of saturating the solid solution to the level obtained with R12F4K5 steel. The wear resistance of R6M5K5 steel is lower due to lower hardness and the absence of MC carbides in its structure. The mechanical properties of R6M5K5 steel are 20-30% higher than those of R12F4K5 steel.

The technological disadvantage of R6M5K5 steel is increased sensitivity to decarbonization. Its sandability is good.

This determines the scope of application of R6M5K5 steel [3].

Temperature of critical points, °C [2]

| Ac1 | Acm | Arm | Ar1 |

| 840 | 875 | 805 | 765 |

Chemical composition, % (GOST 19265-73)

| C | Si | Mn | Cr | W | V | Co | Mo | N | S | R |

| no more | no more | |||||||||

| 0,84-0,92 | 0,50 | 0,50 | 3,80-4,30 | 5,70-6,70 | 1,70-2,10 | 4,70-5,20 | 4,80-5,30 | 0,40 | 0,030 | 0,030 |

Final heat treatment modes

| Hardening | Vacation | |||||

| tп, °C | tа, °C | Wednesday | t, °C | τ, h | Wednesday | H.R.C. |

| 800-850 | 1210-1240 | Oil, molten salts or alkalis | 540-560 | Two-three times an hour | Air | 64-66 |

Hardness (GOST 19265-73)

| Delivery status | Hardness |

| Annealed rod and strip | Up to HB 269 |

| Samples. Hardening at 1230 °C in oil; tempering (2- or 3-fold) at 550 °C, 1 hour | St. HRСе 65 |

Mechanical properties of steel as delivered (after annealing) at 20 °C [4]

| σ0.05, MPa | σ0.2, MPa | σв, MPa | δ5, , % | ψ, % MPa | σcom 0.2, MPa | σcom, MPa | ε, % | tk, MPa | γ, % | KCU, J/cm2 |

| 240 (5) | 510 (20) | 850 (30) | 12 (1) | 14 (1) | 520 (13) | 2720 (80) | 54 (1,5) | 590 (18) | 60 (1,4) | 18 (1) |

NOTE

- σ0.05 — Elastic limit

- σ0.2 — Yield strength

- σв — Temporary resistance

- δ — Elongation

- ψ — Relative narrowing of the cross section

- σсж 0.2 — Compressive yield strength

- σсж — Compressive strength

- ε — Relative settlement at the appearance of the first crack

- τк — Torsional strength — maximum shear stress

- γ — Relative shift

Mechanical properties of steel as received (after annealing) at elevated temperatures [4]

| tsp, °C | σ0.2, MPa | σв, MPa | δ5, % | ψ, % | σcom, MPa | tk, MPa | KCU, J/cm2 | Hardness HB |

| 200 | 500 (50) | 870 (60) | 10 (2) | 11 (2) | 1100 (50) | 570 (30) | — | 258 (6) |

| 400 | 470 (50) | 770 (60) | 12 (2) | 11 (2) | 950 (50) | 500 (30) | — | 240 (6) |

| 600 | 330 (40) | 620 (50) | 28 (3) | 48 (5) | 730 (40) | 340 (20) | — | 165 (6) |

| 800 | 130 (20) | 270 (20) | 55 (4) | 60 (5) | 130 (20) | 120 (20) | — | 38 (4) |

| 1000 | 110 (20) | 130 (20) | 57 (4) | 50 (5) | 100 (20) | 60 (10) | 140 (15) | 26 (4) |

| 1100 | — | — | — | — | — | — | 170 (15) | — |

| 1200 | 40 (10) | 40 (10) | 87 (2) | 15 (2) | 70 (10) | 40 (10) | 75 (10) | 5 (1) |

Mechanical properties of steel as delivered at 20 °C [4]

| σ0.05, MPa | σв, MPa | σcom 0.2, MPa | σcom, MPa | tk, MPa | σben, MPa | KCU, J/cm2 |

| 2340 | 2050 | 3100 | 3750 | 1820 | 3000 | 25 |

Mechanical properties of steel in a heat-treated state at elevated temperatures [4]

| tsp, °С | σben, MPa | Hardness | |

| H.V. | HRСе | ||

| 200 | 3820 | 833 | 64 |

| 400 | 3980 | 769 | 62 |

| 500 | 3040 | 726 | 61 |

| 550 | 2980 | 686 | 59 |

| 600 | 2790 | 626 | 57 |

| 650 | 2500 | 528 | 52 |

Steel hardness depending on tempering temperature [2]

| tsp, °С | Hardness HRCе |

| 500 | 67 |

| 540 | 68 |

| 580 | 67 |

| 620 | 63 |

| 660 | 57 |

NOTE. Hardening at 1220 °C in oil; vacation three times for 1 hour.

Technological properties [2]

Forging temperature, °C: beginning 1160, end 850.

Cooling in wells at 750-780 °C.

Forging and annealing temperature [2]

- forging temperature ranges 1160-850 °C;

- cooling after forging in wells at 750-800 °C;

- annealing at 840-860 °C, cooling 40 degrees/hour to 730-740 °C, holding for at least 4 hours, cooling 50 degrees/hour to 600 °C, in air;

- hardness after annealing no more than HB 269

Red resistance (GOST 19265-73)

| Temperature, °C | Time, h | Hardness HRCе |

| 630 | 4 | 59 |

NOTE. Sandability is good (GOST 19265-73).

Density ρп kg/cm3 at test temperature, °C

| Steel | 20°C |

| R6M5K5 | 8200 |

Thermal conductivity coefficient λ W/(m*K)

| Steel grade | λ W/(m*K), at test temperature, °C | |||||||

| 100 | 200 | 300 | 400 | 500 | 600 | 700 | 900 | |

| R6M5K5 | 27 | 28 | 29 | 30 | 32 | 36 | 34 | 29 |

Young's modulus (normal elasticity) E, GPa

| Steel grade | At test temperature, °C |

| 20 | |

| R6M5K5 | 220 |

Modulus of elasticity in torsional shear G, GPa

| steel grade | At test temperature, °C |

| 20 | |

| R6M5K5 | 83 |

Electrical resistivity ρ nom*m

| steel grade | ρ nom*m, at test temperature, °C |

| 20 | |

| R6M5K5 | 458 |

Bibliography

- Shishkov M.M. Brand of steels and alloys. 2000

- Poznyak L.A. Tool steels. Directory. 1977

- Geller Yu.A. Tool steels. 1983

- GSSSD 9-79 – State service of standard reference data

Find out more

Steel 3Х3М3Ф tool stamping…

Steel 12Х18Н9 corrosion-resistant, heat-resistant a...

Steel 35X structural alloy…

Steel 18Х2Н4МА (18Х2Н4ВА) structural alloy…

Decoding - what the marking symbols mean

Elements of equipment and devices have a high strength index, the material has excellent viscosity. Steel ensures long-term performance, both in product components and in blades or finished tools.

Such markings are a legacy of the Soviet era:

- The letter "P" is an indicator of high-speed steels. The expression comes from the translation of the English “rapid” - “swift”.

- The sign after “P” indicates the presence of tungsten in the composition as a percentage. For this particular metal it is in the range of 6% with minor deviations.

- This is followed by the letter “M”, meaning cash in the molybdenum mark. The next indicator is the percentage of presence of the element in the total mass.

- In addition to M, high-speed steels can include the following designations in their markings: “K” - cobalt, “T” - titanium, “F” - vanadium, “C” - zirconium.

Considering the designation “P6M5”, decoding can also include other letters. If the steel was smelted by electroslag remelting, an addition appears in the form of “Ш” (Р6М5-Ш). With the introduction of the latest technologies into the production process, the following wording now appears - P6AM5. This means adding nitrogen to the overall composition.

Characteristics and grades of HSS steel

High-speed varieties are high-carbon steels. Some brands contain a fairly large amount of tungsten. In addition, they may contain cobalt and molybdenum. If we talk about the hardness of alloys, the indicator is most often in the range of 62–64 units of the HRC scale. Comparing products made from high-speed steel and carbide, it is worth noting that the first option is distinguished by a fairly affordable price and increased wear resistance.

Recently, it has been customary to distinguish 3 main groups of HSS steel, each of which has its own characteristics:

- High tungsten content (T)

- High Molybdenum (M)

- High alloy

Tungsten steels

Not the most popular variety. This is due to the fact that tungsten is quite rare and expensive. The most common grades of tungsten steel are T1 and T15. The second contains cobalt and vanadium, therefore they are suitable for the production of accessories that have increased requirements for strength and resistance to high temperatures.

Chemical composition of tungsten HSS steels

| Type | Analogue | C | Mn | Si | Cr | V | W | Mo | Co | Ni |

| T1 | P18 | 0,75 | — | — | 4,00 | 1,00 | 18,00 | — | — | — |

| T2 | R18F2 | 0,80 | — | — | 4,00 | 2,00 | 18,00 | — | — | — |

| T4 | R18K5F2 | 0,75 | — | — | 4,00 | 1,00 | 18,00 | — | 5,00 | — |

| T5 | 0,80 | — | — | 4,00 | 2,00 | 18,00 | — | 8,00 | — | |

| T6 | 0,80 | — | — | 4,50 | 1,50 | 20,00 | — | 12,00 | — | |

| T8 | 0,75 | — | — | 4,00 | 2,00 | 14,00 | — | 5,00 | — | |

| T15 | R12K5F5 | 1,50 | — | — | 4,00 | 5,00 | 12,00 | — | 5,00 | — |

Molybdenum and high alloy steels

They are very widespread. May contain cobalt and tungsten. Those brands whose formula includes carbon and vanadium are characterized by increased strength and wear resistance, and resistance to abrasives. Alloys, starting with M41, are used to produce devices that retain their characteristics even when super heated. To create equipment designed for work at low temperatures, steels with molybdenum are also used, but they are subject to additional processing.

Chemical composition of molybdenum HSS steels

| Type | Analogue | C | Mn | Si | Cr | V | W | Mo | Co | Ni |

| M1 | 0,80 | — | — | 4,00 | 1,00 | 1,50 | 8,00 | — | — | |

| M2 | P6M5 | 0,85 | — | — | 4,00 | 2,00 | 6,00 | 5,00 | — | — |

| M3 | P6M5Ф3 | 1,20 | — | — | 4,00 | 3,00 | 6,00 | 5,00 | — | — |

| M4 | 1,30 | — | — | 4,00 | 4,00 | 5,50 | 4,50 | — | — | |

| M6 | 0,80 | — | — | 4,00 | 2,00 | 4,00 | 5,00 | — | — | |

| M7 | 1,00 | — | — | 4,00 | 2,00 | 1,75 | 8,75 | — | — | |

| M10 | 0,85–1,00 | — | — | 4,00 | 2,00 | — | 8,00 | — | — | |

| M30 | 0,80 | — | — | 4,00 | 1,25 | 2,00 | 8,00 | — | — | |

| M33 | 0,90 | — | — | 4,00 | 1,15 | 1,50 | 9,50 | — | — | |

| M34 | 0,90 | — | — | 4,00 | 2,00 | 2,00 | 8,00 | — | — | |

| M35 | R6M5K5 | 0,82–0,88 | 0,15–0,40 | 0,20–0,45 | 3,75–4,50 | 1,75–2,20 | 5,5–6,75 | 5,00 | 4,5–5,5 | up to 0.30 |

| M36 | 0,80 | — | — | 4,00 | 2,00 | 6,00 | 5,00 | — | — |

Chemical composition of high alloy HSS steels

| Type | Analogue | C | Mn | Si | Cr | V | W | Mo | Co | Ni |

| M41 | R6M3K5F2 | 1,10 | — | — | 4,25 | 2,00 | 6,75 | 3,75 | 5,00 | — |

| M42 | 1,10 | — | — | 3,75 | 1,15 | 1,50 | 9,50 | 8,00 | — | |

| M43 | 1,20 | — | — | 3,75 | 1,60 | 2,75 | 8,00 | 8,25 | — | |

| M44 | 1,15 | — | — | 4,25 | 2,00 | 5,25 | 6,25 | 12,00 | — | |

| M46 | 1,25 | — | — | 4,00 | 3,20 | 2,00 | 8,25 | 8,25 | — | |

| M47 | R2AM9K5 | 1,10 | — | — | 3,75 | 1,25 | 1,50 | 9,50 | 5,00 | — |

| M48 | 1,42–1,52 | 0,15–0,40 | 0,15–0,40 | 3,50–4,00 | 2,75–3,25 | 9,50–10,5 | 0,15–0,40 | 8,00–10,0 | up to 0.30 | |

| M50 | 0,78–0,88 | 0,15–0,45 | 0,20–0,60 | 3,75–4,50 | 0,80–1,25 | up to 0.10 | 3,90–4,75 | — | up to 0.30 | |

| M52 | 0,85–0,95 | 0,15–0,45 | 0,20–0,60 | 3,50–4,30 | 1,65–2,25 | 0,75–1,50 | 4,00–4,90 | — | up to 0.30 | |

| M62 | 1,25–1,35 | 0,15–0,40 | 0,15–0,40 | 3,50–4,00 | 1,80–2,00 | 5,75–6,50 | 10,0–11,0 | — | up to 0.30 |

When selecting products made from molybdenum material, it is worth considering the features of a particular brand:

- M1. Ideal for releasing drills. They are flexible and shock resistant. But they cannot boast of significant red fastness.

- M2. One of the most popular materials. Often used for the production of tools for various purposes. The product is suitable for intensive work using machines. The main feature of such a tool is its exceptional red resistance, which means the cutting element will retain its qualities for a long time. Our catalog presents drills of the HSS-STANDARD series made of this alloy

- M7. Ideal for producing large drills designed for drilling materials of increased hardness or thick sheets.

- M35. It has increased red fastness due to the increased amount of cobalt in the formula. But it has low resistance to shock loads.

- M42. Contains a large amount of cobalt, therefore it has excellent red fastness. In addition, it is extremely resistant to abrasion. Ideal for making accessories for working with particularly hard or even viscous materials. Core cutters made from this material are presented in the HSS-CO 8 line of drills

- M50. Often used to produce drills that come with portable equipment.

Analogs

The Russian steel grade R6M5 has analogues in various countries. All of them are marked HSS, which stands for High Speed Steel. And in translation this means high-speed steel. Domestic analogues are: R12, R10K5F5, R18.

But these alloys contain a high percentage of tungsten, which increases their cost in the market. Foreign analogues are comparable in price to R6M5 steel. Here are some examples of labels in different countries:

- Japanese – SKH51;

- American – T11302, M2;

- English – 3343, BM2;

- French – HS6-5-2, HS6-5-2HC, X85WMoCrV6-5-4, Z85WDCV;

- German – HS6-5-2, S6-5-2, S6-5-2S, SC6-5-2;

- Polish – SW7M;

- China – W6Mo5Cr4V2;

- Italian - HS6-5-2, X82WMoV6-5.

Difficulties in hardening high-speed steel

Heat treatment of P6M5 contains a number of specific features associated with the characteristics of this brand, as well as a long heating time for hardening. To reach 1230 degrees Celsius (hardening temperature according to GOST), 25 percent more working time is spent than for a similar grade P18. First, a vacation period is made at 200 and 300 degrees for an hour. Further processing is carried out in 3 stages:

- 690 degrees -3 minutes;

- 860 - also 3 minutes;

- 1230 - 1.5 minutes.

Then the steel is cooled. In further processing, a three-time vacation period at 560 degrees for 1.5 hours is used. During tempering periods, the alloy is supplemented with alloying additives that form carbides, which increases the strength of the final metal. Previous annealing of steel helps eliminate high brittleness with a high strength index.

Main characteristics

The basic parameters of steel of this grade are: high toughness, excellent wear resistance, and a good level of grindability. This grade is used in the production of many types of blades and cutting equipment for working with structural strength steels.

Knife with a blade made of steel R6M5.

A tungsten-molybdenum alloy is the second name of this brand, which can retain its characteristic qualities even under extreme temperature changes. Moreover, its bending strength reaches 4700 MPa. Its combination with impact strength gives it a noticeable superiority over many of its peers.

Sharp knife made from quick cutter R6M5

Attention!!!

This homemade product is posted for informational purposes only. The creation and use as a bladed weapon is prohibited; according to Article 223.4 of the Criminal Code of the Russian Federation, it is punishable by imprisonment for up to two years!

This steel is quite durable, it is enough for long-term heavy work. This steel does not lose its strength even at high temperature loads. The only drawback of this metal is that it is very difficult to harden it with your own hands. Hardening requires repeated heating, tempering, and special chemicals, such as saltpeter, for cooling. But if you process the metal carefully, without overheating, then you won’t need to harden it. So, let's look in more detail at how to make a knife from R6M5 steel.

Materials and tools used by the author:

List of materials:

— R6M5 steel (hacksaw blade); - a piece of wood for the handle; - epoxy adhesive; - a piece of brass for the handle; - oil or varnish to impregnate the handle.

List of tools:

- Bulgarian; - vice; - grinder; — orbital sander or machine; - drill; — a clamp (the author’s homemade one is made from wood); - marker; - sandpaper; - jigsaw.

Knife making process:

Step one. Cutting out the main profile

First we need to figure out what our knife will look like. Draw the profile of the knife on the workpiece using a marker. Well, then you can start cutting. We cut the workpiece using a grinder, but when cutting P6M5 there is one nuance. This steel is quite brittle and breaks when subjected to strong bending. All we need to do is make small cuts with a grinder in the areas that we need to remove. Well, then we break them off with pliers, like glass.

Step two.

Finalizing the profile Step three.

Bevels and sanding The final finishing is done by hand using fine sandpaper soaked in water. Well, at the very end, the blade can be polished on a machine using GOI paste or another paste.

Step four. Brass insert

There is a brass insert at the front of the handle. We select the desired piece of brass and drill a series of holes in it. Then these holes are bored out with a flat file so that the shank of the blade can fit in. At the same step, you can immediately give the workpiece an oval shape on the sharpener. The author immediately polished the part on the machine, since this would be much more difficult to do later.

Step five. Blank for handle

Step six. Final modification of the knife

When the glue dries, we take out our knife and draw the desired handle profile with a pencil. Next, we cut off the excess with a jigsaw; the fastest way to do this is with a jigsaw. We grind the handle to obtain the desired profile, rough processing can be done on a sharpening machine or grinder. Well, we carry out finer processing manually using sandpaper. Making the handle absolutely smooth.

I hope you liked the project and found useful information for yourself. Good luck and creative inspiration if you want to repeat the homemade product. Don't forget to share your ideas and developments with us.

Attention!!!

This homemade product is posted for informational purposes only. The creation and use as a bladed weapon is prohibited; according to Article 223.4 of the Criminal Code of the Russian Federation, it is punishable by imprisonment for up to two years!

Source

Become the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.

Where are high speed steels used?

The scope of wear-resistant metal depends on the composition that determines its working properties. Basically, this is a tool that has high demands on strength, heat resistance, and long service life.

- Production of drills, cutters, cutters, taps;

- Manufacturing cutting edges for tools, which in some cases can be removable;

- Parts for metalworking machines and equipment;

- Manufacturing of tools used for finishing hard-to-cut metal products.

Experts give the following recommendations on the use of these metal grades:

- Tungsten-molybdenum compounds are suitable for tools intended for roughing products, manufacturing cutters, broaches and shaver.

- Cobalt compounds are used for processing heat-resistant and corrosion-resistant products in difficult conditions.

- Vanadium alloys are used for finishing materials.

- The P9 grade is used to create equipment elements that are not subject to excessive load.

- Grade P18 is suitable for tools with complex shapes and shaped products with increased wear resistance requirements.

The range of metal products is represented by square, circle, strip, and sheet metal. Most often, cutting tools are made from a circle. Square steel is used for the production of electric planers, knives, and turning tools. If you have doubts about the correct choice of a suitable alloy, it is better to contact specialists. Specialized companies will be able to select high-quality rental products with the required performance characteristics.