In this article I would like to talk to you about screwdrivers. It would seem a very simple topic that does not cause any special problems for a real man. However, not every person knows all the features about screwdrivers, and what can I say, even I myself don’t know everything, although throughout my entire life I have been doing what is called manual labor.

I can say with complete confidence that choosing a high-quality screwdriver is a very difficult task for many, which is not at all surprising, because approximately 90 percent of all screwdrivers that are sold on our market are made in China and, as you yourself understand, not everything made in China deserves our attention.

Although, of course, I can highlight several very interesting options that definitely deserve to be purchased, plus everything else, the price of Chinese goods is significantly less “biting” than that of German and American, Japanese and even domestic manufacturers .

Types of screwdrivers

Screwdrivers are divided into types according to the type of slot. The standard marking and its explanation are indicated next to the name of the form.

Flathead screwdriver - SL or slotted

Other names are straight or straight spline. The shape of the working part is a flat blade.

- Suitable for simple screws with one notch.

- Manufacturers additionally indicate the length, thickness or depth of the groove if the tool is intended to be used for work with specific fasteners.

- A slotted screwdriver is most often used for simple electrical fastenings.

- The disadvantages of flat models include the impossibility of centering - the bit tends to slip out of the screw.

The force is applied to the opposite (diagonal) outer edges of the slot.

Phillips screwdriver - PH or Phillips

Cone shaped bit with four edges for Phillips fasteners.

- The Philips cross profile is characterized by two grooves located at right angles to each other.

- This option offers a number of advantages over the classic flat shape - more points of contact, increased working contact.

- The force is applied along the four edges - screwing is less labor intensive.

- Disadvantage: Since the force is applied in a narrow area, there is a risk of damaging the screw or spline.

The Phillips profile is often confused with Pozidriv. Improper use can cause damage and rapid wear of the tool.

Hexagonal - H or HEX

These models or inbuses are recognized by their working part with a hexagon-shaped cross-section. Compared to a simple cross model, the torque can be increased up to 10 times.

There are three variants of HEX models:

- Internal - the protrusion is located inside and is intended for fastening screws that have a corresponding recess. A shape with six sides that are at an angle to each other.

The disadvantage is an increased concentration of stress, leading to deformation of the fasteners.

- External - protrusion along the rim, used for fasteners with non-recessed heads. Can be used as an alternative to a wrench. This option is also hexagonal in shape with six sides.

They stand at an angle of 120 degrees to each other.

- Vibration-proof - the model has a hole in the tip of the bit that matches the shape of the protrusion of the screw head. This ensures stability and protection from vibrations.

The functionality of all three types is identical.

Square – Robertson, Square Head

- Section in the shape of a square.

- Four surfaces at right angles to each other.

- Opposite sides are parallel.

- Due to the small disk area, the profile is ineffective for transmitting large torques.

This model is rare in Russia, practically absent in Europe, but widespread in the United States. In addition to standard applications, it is used in the mechanics of vintage cars.

Cross-shaped with guides - PZ or Pozidriv

The Pozidriv profile is produced in the form of two crosses, offset at an angle of 45 degrees for tight insertion into the fastener.

- The additional cross is narrower than the main one and less deep. This provides additional stability and stability.

- Pozidriv is an improvement on the classic Phillips profile.

- Four additional edges or rays besides the cross profile serve to push the tip out.

- The cross slot has a recess for the guide.

- It fits into the fastener more tightly than a simple cross shape.

There is a hole in the middle of the slot to increase the pressure force, but it does not eliminate the disadvantages of the classic cross-shaped design.

Star-shaped - TORX

A tool with grooves shaped like a six-pointed star.

- Used to transmit increased torque compared to classic variations.

- The spline or screw is not damaged during operation.

- There is no danger of the tool slipping, as sometimes happens with a flat profile.

- Reduced radial forces extend tool life. This is the result of a combination of the circular geometry of the spline lobes, the sidewalls and the 15 degree drive angle.

Please note the differences between TORX and TORX PLUS: they are designed for different fasteners, despite identical functionality and external similarity. TORX PLUS has flattened petals rather than rounded ones. This is a strengthened version of the model.

Vibration-proof TORX has the same properties as classic TORX. The difference is that the tool has a hole located in the tip, and the corresponding screw head is complemented by a small central pin.

Screwdriver device

The history of the appearance of the screwdriver begins at the beginning of the 16th century with the invention of the weapon for which it was made. In those days, only flat varieties were used. Nowadays, a screwdriver is a type of plumbing tool designed for screwing and unscrewing threaded fasteners. It is used in minor household repairs to work with screws and screws, that is, fasteners that have a slot or groove.

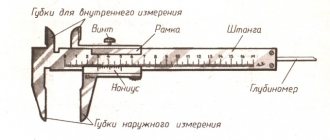

The design of the product is simple and straightforward, consisting of:

- Handles designed to provide ease of use.

- Rods of different lengths, allowing the tool to be used for different types of work.

- A tip or blade, which is also called a slot or sting. Its shape depends on the type of fastening hardware used.

Screwdriver tip

Belonging to a particular variety is determined by the blade of the screwdriver or its tip, located on the bottom of the rod. The slot is in direct contact with the fastener and is subject to increased mechanical stress. Because of this, it is made from durable alloys, such as steel with the addition of chromium, vanadium and molybdenum. To prevent the tip from slipping out during operation, a special coating is applied to it, which increases the coefficient of friction.

Initially, the sting was made in the form of a simple blade, since the fastening tools had a suitable groove in the head. Later, more advanced cross, hexagonal, square and star shapes began to appear for new types of hardware. There are also special tips for non-standard fasteners, used by highly specialized craftsmen.

Screwdriver shaft

Another important part of a screwdriver is the blade. For different models, it may differ in length and thickness, depending on the depth of the hole into which the hardware is screwed. That is, for short screws, a more compact rod is used, and vice versa. However, a long screwdriver does not always outperform its shorter counterpart in terms of convenience. In hard-to-reach places, a long rod is rather a disadvantage, because it can prevent the master from correctly positioning the tool and working with it correctly.

Screwdriver handle

The part of the rod that is in the hand is equipped with a handle. Its main function is to ensure ease of use. The material and shape of the product are selected individually to suit the master’s palm and the scope of work. Main materials used:

- rubber;

- plastic;

- tree.

Possible handle designs:

- standard round;

- hexagonal;

- T-shape;

- in the form of a pistol;

- There is also a double-sided screwdriver, the handle of which is located in the middle of the rod.

The diameter of the handle varies between 1-4 cm and directly depends on the torque delivered to the part. That is, the larger the diameter of the hardware for which the screwdriver is suitable, the wider its handle. Small tools are equipped with a thin handle to reduce the likelihood of stripping threads or deforming hardware. Some models have a hole in the handle for a safety cord. A tool with replaceable inserts in the handle may have a cavity for storing them.

Characteristics

The characteristics of a tool can be read by its full markings. For example, SL1*80 is a flathead screwdriver with a 5mm diameter blade, 80mm long, suitable for fasteners with a diameter of less than 3mm.

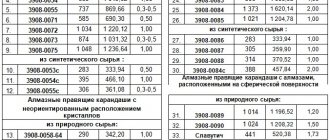

| Number | Rod Ø | rod length | Ø fastener |

| №0 | 4 mm | less than 80 mm | less than 2 mm |

| №1 | 5 mm | 80–100 mm | 2.1–3 mm |

| №2 | 6 mm | 100–120 mm | 3.1–5 mm |

| №3 | 8 mm | 120–150 mm | 5.1–7 mm |

| №4 | 10 mm | 150–200 mm | 7.1 mm and more |

In combination with the type marking (SL, HEX, PH, etc.), the table gives a complete picture of the characteristics and application features of a particular tool. Sometimes the marking is supplemented by an indication of the metal alloy from which the slot is made.

Screwdriver functions

Screwdrivers are equipped with additional sets of options, which are selected according to the type of work and requirements for the tool.

Electric installation work

The priority is protection against electric shocks and detection of electrical wiring.

- Dielectric coating is a tool for working with live wiring. Electrical insulation can withstand up to 1000 volts. Most often, such models are accompanied by red markings.

A dielectric screwdriver can be covered with a layer of insulation along the entire length of the rod up to the slot.

- Tester, probe - a device is built into a screwdriver that can detect hidden wiring and the presence of current in the outlet. When a voltage source is detected, the tool emits a light or sound signal.

The indicator screwdriver signals when the upper part is clamped with a characteristic glow. More often, these models are produced in transparent cases.

Difficult operating conditions

To access hard-to-reach places, unscrew rusty fasteners or carry out long-term large-scale work, special tools or improvised means are used.

Some screwdriver models have features that make working in difficult conditions easier. There are no universal options; the tool is selected for a specific task.

- Hard-to-reach places - screwdrivers with a flexible shaft are used for easier access. Most often, such models provide additional reinforcement, a spring frame or a magnetic bit.

- Processing tight fasteners - most often, difficulties are caused by corrosion, which firmly adheres the screw to the surface. For such tasks, models are used that can withstand the impact of a handy tool (hammer, chisel).

The impact screwdriver is equipped with a metal body and handle. When the auxiliary tool hits the end, the screwdriver slot rotates.

- Long-term work - most often these are processes that require repeated twisting of fasteners. To simplify the work, reversible screwdrivers with a ratcheting mechanism are used.

If you need to screw in more than ten bolts, use a mini-analogue of a screwdriver - a cordless screwdriver.

Different types of fasteners

For work with non-uniform fasteners, models with a bit change function are used. If you have to work with flat and cross-shaped fasteners at the same time, combo models are preferable.

Most often, this is a handle with an insert rod on which various types of bits are attached. Flipping the shaft in combo models turns the cross bat into a flat one. Another option is a permanent rod with a magnetic holder for a replaceable slot.

For diverse jobs, it is often not a specific model that is chosen, but a set of screwdrivers. It is a small case or suitcase containing several screwdrivers or just one - a basic one and a set of replacement bits for it.

Special screwdrivers

Unlike standard varieties, which have a wide range of applications, there is also a specialized set of screwdrivers that is used for a narrow scope of work. Such tools are not stored in every home, but are purchased by craftsmen for their specialization. These include:

- A universal set of screwdrivers with the ability to replace tips.

- Reversible models with a ratcheting mechanism that allows you to unscrew hardware without removing the tool.

- Dielectric variety for safe electrical work.

- With flexible shaft for working in hard-to-reach places.

Universal screwdriver

Almost every craftsman who carries out minor household or cosmetic repairs has in his arsenal a set of screwdrivers for precision work with replaceable attachments. It consists of:

- handles with a rod and a lock;

- a set of replaceable tips or bits;

- storage case.

This set is good for its versatility, which is where its name comes from. Depending on the configuration, the tool can be equipped with 8, 10, 16, 24 or more tips of different shapes and sizes. That is, a screwdriver with replaceable bits completely replaces all other non-highly specialized varieties and helps the master use different hardware without a large number of tools at hand.

Ratchet screwdriver

Another improved type that can be included in a repair screwdriver set is a model with a ratcheting mechanism. People also call it a “ratchet”. The mechanism is mounted in a rod and handle. Thanks to it, the tip rotates freely in one direction. Advantages of the model:

- You can use the tool with one hand, both left and right.

- There is no need to grab the handle when working.

- There is no need to remove the tool from the fastener head when unscrewing it.

- You can change the direction of work using a special lever, coupling or slide switch.

- You can lock the rod in the handle by moving the lever to the central position.

Dielectric screwdriver

A special metalworking tool for working near conductors or with parts under dangerous electrical voltage for human life and health is called dielectric. Such a screwdriver is almost completely (except for the tip) covered with a special protective compound that does not conduct current. The insulation of each instrument may differ, as it is designed for different voltages. Such instruments always have a mark indicating the maximum permissible safe levels of use.

Screwdriver with flexible shaft

Special screwdrivers for precision work in cramped conditions are equipped with a special flexible shaft that replaces part of the rod. It consists of a cable with an armored base and a soft body. On one side it is equipped with a special base, which is attached to the rod. The required tip is fixed on the second part. The device transmits torque to the fastener. This can be very convenient when assembling furniture and working in confined spaces with different planes for fastening hardware.

Reversible screwdriver

A more familiar name for a reversible screwdriver with bits is a “ratchet” or ratchet. The device has a special device that allows you to rotate the tool in a given direction with one hand without removing the hardware from the slot. That is, you can tighten and unscrew screws and self-tapping screws without tearing off the tip. With each turn, you will hear the characteristic crackling sound of self-cranking, hence the name. If you try to start moving in the opposite direction to the selected direction, the mechanism will block the device.

The minimum set of the reversing device consists of the following bits:

- two flat screwdrivers of different blade lengths;

- cross-shaped nozzle;

- hexagonal tips with internal and external projections;

- star bit.

Equipment

The features of the splines are discussed in detail above, so we will focus on the remaining components of the kit - the handles and rods.

Handles

Handles are made of plastic or polycomposite. To reduce slipping, a rubber coating, recesses or notches are used. The coating makes the tool ergonomic and comfortable.

- The ratchet mechanism is an attachable ratchet handle similar to those used in compound socket wrenches. During operation, the rod and tip rotate freely, and the handle remains motionless in the hand.

The model does not require unnecessary movements, therefore it is optimal for large-scale work.

- T-shaped - Swivel type models with a curved or solid top that supports the installation of an auxiliary arm.

- With a heel - most often found in impact screwdriver sets. Instead of recessing into the handle, a through stroke is used. The rod at the end free from the nozzle has a thickening - a heel, which softens the load from blows with a hammer.

Modified handles make screwing/unscrewing easier or increase torque. Most often, functionality is set by a button or reverse switch on the handle.

Rods

Shaft modifications allow you to add additional functionality to the tool.

- Non-standard length - elongated or shortened models of screwdrivers. Length restrictions apply to the shaft and handle. Suitable for processing hard-to-reach places. More often found in combo or flexible models.

- With a tip change function - the tool in this configuration is equipped with a ratchet mechanism or a standard handle. The option without a mechanism involves the use of a universal combo rod. For splines of such models, the kit includes replacement bits.

- Faceted rod - option with a square or hexagonal cross-section (standard - round). Supports the use of leverage to add torsional force. The lever is the tool at hand.

Bits and sockets are typical bit attachments.

There are magnetic models that support the grip of fasteners in inconvenient conditions. External parameters correspond to standard types of splines.

Types of screwdrivers

Electrician's kit - what tools are included?

What types of screwdrivers there are can be represented by a fairly large list. You should consider popular and highly specialized types of screwdrivers.

Dielectric

To work with electrical equipment, use a dielectric screwdriver. It does not allow current up to 1000 V to pass through it. The entire instrument is covered with special plastic up to the tip. Electricians use such OSHs to work in electrical cabinets and switchboards.

Tool with dielectric coating

Reversible

The sonic screwdriver is equipped with ratcheting mechanisms. When the tip rotates, the ratchet makes a ratcheting sound. The tool can only rotate in one direction. To turn on the reverse mode, move the lever. Thanks to this device, the master tightens or unscrews the screw without removing the tip from the fastener slots. Reversible tools are otherwise called minus screwdrivers.

Reversible screwdriver

Hexagon

Hexagon-shaped screwdriver slots allow you to apply maximum force to the tool without fear of cutting off the edges of the tip or slots. Fasteners are used in places where the requirements for the strength of the connection of parts are especially high.

Star-shaped

Star-shaped splines are especially popular in the countries of the American continent. In European products for various purposes, star screws are quite common in electronic devices. Their use is subject to the same requirements as for hexagonal tips.

Square

A square-shaped slot is not found in everyday life. Hardware with square openings in the heads is used for mounting parts of special equipment, including in the defense industry.

U-shaped OS

Tools with double tips are called spanners. They are used in elevator facilities. The complex configuration of the tips is aimed at preventing incidents of vandalism in elevator cabins.

Fork

Similar to U-shaped screwdrivers, except that instead of two blades, they have a triple tip. This is a purely professional tool. Screws with such slots are not found in everyday life.

Triangular

Triangular screwdrivers are professional tools. Triangle screwdrivers are compatible with slotted screws that have a similar configuration. Triangular screwdrivers are used for opening and installing panels where access to cabinets and panels with electrical or other equipment is limited.

For One-way slot

The name One-way translated from English means “one way path”. Unscrewing hardware with such a head is only possible with a special tool. Any use of other types of tips results in cutting off the splines. The fastener resists unauthorized entry into various devices.

Bristol

The shape of the spline resembles a six-pointed gear. You can unscrew such hardware only with a Bristol tip. Otherwise, the slot is destroyed and the screw has to be drilled out. Hardware can be found in radio electronics service centers. They are used to protect against vandal penetration into devices.

For Torg-Set slot

The tip is made for a slot in the form of a cross with an offset center. Hardware with such splines is practically not found in Russia.

For muna Torx slot

Screwdrivers for this type of slot have a tip in the form of a six-pointed star. They are necessary in workshops where mobile phones and various gadgets are repaired.

For star spline

The star tip is designed for screws with six-pointed star slots. The stars have sharper peaks. The scope of application is the same as that of the previous type of tool.

It is important to distinguish between the last two types, because using PZ for screws with PH slots can damage the self-tapping screw. As a result, the fasteners will have to be drilled out, and the screwdriver itself will fail.

Splines and tips

Note! If you have to deal with soured hardware, use an impact screwdriver. It is equipped with a thick metal cap at the end of the handle that can withstand hammer blows. When struck, the tip of the tool rotates with powerful force.

Accessories

There are no individual accessories for screwdrivers. They are complemented only by kits that combine diverse types of attachments or screwdrivers.

Such a kit often consists of a housing with recesses for convenient placement of basic and spare parts.

- Small or budget kits are small plastic cases.

- Professional models - a suitcase with a handle for comfortable carrying, plastic or rubber-coated.

Inside contains a set of screwdrivers, replaceable heads or bits.

The larger the set, the more variations there are for different types of work, sizes and shapes of marks.

There are models supplemented with protective agents - anti-corrosion liquid, oil for lubricating metal elements, and a cleaning brush.

Rechargeable models are complemented by a charger and a replaceable battery. Household variations often do without these accessories - the buyer independently takes care of timely charging.

Peculiarities

The features of screwdrivers are considered in relation to the type of tool slot.

By slot type

- Flat - the tool tightens standard screws and screws, markings are marked along the width of the tip. Suitable for fastening with cross marks. Flat models are used for household and electrical installation needs.

- Hexagonal - for fasteners with hexagonal notches. Variants of a non-standard type are common, representing an L-shaped rod with edges, bent at the top.

The thickness of the rod corresponds to the slot of the fastener for which it is suitable.

Used for repairing electrical equipment and assembling furniture.

- Star-shaped - used in the repair of household appliances and mobile phones. They are rarely used in everyday life, as they require special skills.

- Cross-shaped ones are the most convenient for household and professional needs. There are models that support combination with a flat slot. Optimal for tightening all types of self-tapping screws and screws of suitable shape.

There are special models for narrow applications, adapted for use with only one or several types of fasteners:

- Spanners are two-pin variations for elevators with anti-vandal protection.

- Trefoils (Tri-Wing) - for aviation and complex electronics.

- Asymmetrical (Torq-Set) - aircraft industry only.

- Clutch - for Chevrolet and GMC trucks.

- Pentalobe is a pentagonal version for Apple technology.

These models are not used in everyday life, but without knowledge of their existence, repairing complex equipment is not always possible.

Design features

Flat and shaped screwdrivers have one thing in common - the design of the tool. It consists of a round metal rod with a tip and a handle.

Kernel

Indicator screwdriver - how to use it correctly

The steel axis is the part that transmits the force of the hand from the handle to the tip of the screwdriver. The material for this is especially strong steel. Products differ in the length and thickness of the rods, the cross-section of which can be round or multifaceted.

Important! The rod can have different lengths, diameters and cross-sectional shapes. Standard length is 100-200 mm. The shaft is usually coated with nickel or chrome to protect against corrosion. The rods are also made of stainless steel.

Lever

This part is mainly made of plastic. The quality of the material affects the durability of the handle. Modern handles of high-quality products have non-slip rubberized inserts, a finger rest, and a large area for hand grip and palm rest.

Also at the bottom of the handle a transverse through hole is made to enhance torque. A rod is inserted through it to obtain additional force.

Professional OS on the handles have gel inserts that fit tightly to the palm, which ensures maximum transfer of force to the sting.

Sting

The effectiveness of the sting largely depends on the quality and strength of the tip material. Tips made from C-2 tool steel are considered high-quality and reliable tips. Particularly durable tips are made from molybdenum-vanadium alloy.

Flat head screwdriver

Pros of screwdrivers

The advantages of screwdrivers are based on the configuration and functionality. A convenient set of options does not always replace specific functions.

Basic advantages of options:

- electric models or battery type - increased operating speed;

- with reverse - support unscrewing of fasteners;

- ratchet - minimal load on hands;

- impact - cope with tight screws that a regular screwdriver cannot twist;

- indicator - the ability to determine the phase, search for live wires;

- dielectric - safe for electrical installation work, preferable when it is not possible to de-energize the room.

The advantages are usually combined. For example, a dielectric coating is combined with an indication option, and a battery is combined with reverse.

What are screwdrivers for?

First, let's talk a little about the purposes for which screwdrivers are generally used:

- To carry out the assembly and disassembly procedure.

- For working with motorcycles, scooters, bicycles, cars and so on.

- For electronics repair.

- For electrical installation work.

Without a doubt, it will be much easier and faster to tighten a screw using a screwdriver, but not every person has such a technique. Among other things, working with such a tool is not always convenient, because it is almost impossible to get into narrow places with a screwdriver.

Among other things, screwdrivers take a lot of time during operation and transportation. As you understand, in order to perform work with such a tool, you need to use either electricity or choose an option that runs on a battery.

Be that as it may, any home must have a screwdriver; without it, it is absolutely impossible to perform any procedure related to equipment repair, assembly, and so on.

Problems

Disadvantages that complicate operation are also associated with the set of functions. The fewer additional options a screwdriver has, the higher the chance that the tool will last a long time.

Problem areas:

- Rechargeable type - requires constant changing or charging of batteries. In conditions of major renovation of the premises, it quickly breaks down. More often this feature is found in Chinese technology, the quality of which does not always meet the needs of Russian conditions.

- Ratchets are sensitive to abrasives and dust. The mechanism fails when used in dusty areas or at a construction site.

- Drums are unsightly due to their metal casing; ergonomic models of this type are rare.

- Indicator - the main problem is the indicator light burns out, after which the model turns into a regular screwdriver. An audible indication requires changing batteries.

The current charge is not displayed on the case, so at the right time it is easy to find yourself without the corresponding functionality.

Models with reverse are not included in the list of problems, since the mechanism rarely fails. Dielectric variations are similar to ordinary ones, the only difference is in the coating, so their operation does not cause problems.

Screwdriver handle

The handle of a screwdriver is no less important than the shaft. When selecting a tool, you should study the profile of the handle, the base material, whether there are linings or additional coating. And also the ability of the handle to withstand the caustic effects of petrochemicals.

The shapes of handles are now limited only by the imagination of designers and industrial designers. But one parameter should be studied before purchasing - the transverse profile. It directly affects not only the comfort of work, but also the amount of torque that can be transmitted through the screwdriver to the fastener.

The three main types of handle profiles are round, triangular and hexagonal.

The round profile is convenient for the manufacturer, however, in terms of torque it is the weakest version of the handle. There is nothing for the palm to securely grab onto. Yes, and slippage is more than likely.

The triangular profile at the base of the handle is the best option in terms of torque. It follows the anatomical shape of a clenched palm and allows maximum force to be transferred to the fastener.

The hexagonal profile of the handle is the second best quality for transmitting torque to the fastener. It is better than the round one, but inferior to the triangular one, since it corresponds less to the anatomy of the hand.

How to choose a screwdriver

The screwdriver is selected in accordance with the tasks ahead and the type of fastener you plan to work with.

The following parameters will tell you about the quality of the tool:

- The strength of the rod is indicated on the body. A tool with a strength value in the range of 47–52 Rockwell units is preferred. An indicator below the indicated one indicates the likelihood of bending, and above it indicates a tendency to cracking.

- Alloy - Cr-V or chrome vanadium is considered universal. It maintains sufficient mechanical strength.

- Equipment : ergonomic rubberized handles are preferred. The tool should not slip out of your hands, even if they are wet. It is advisable to select bits with magnetic coating for comfortable work with small fasteners.

For tools from Russian manufacturers, compliance with GOST 17199–88 is provided. In this case, there is a marking on the body or handle.

Impact screwdrivers

The main feature of such tools is that at the end of the handle there is a special place for striking with a hammer, as a result of which the bit rotates. This allows you to deal with frozen, rusty or painted fasteners. There are also impact power screwdrivers, the rods of which can be hexagonal or equipped with a special hexagonal amplifier for fixing the key.

Exploitation

The greatest danger when working with a screwdriver comes from improper use of the tool.

- Before starting work, select the appropriate type of screwdriver and make sure that the size of the working area matches the size of the fastening profile.

- When working, you must use it only for its intended purpose, do not heat it to temperatures higher than permissible, and do not use a screwdriver whose tip is damaged.

- The handle must be insulated and free of chips if work is carried out under voltage.

- The screwdriver shaft must be positioned along the axis of the fastener.

Guarantee

Hand tools come with a warranty that ranges from 12 months to lifetime service.

- The need to exchange goods or return money arises if the purchased screwdriver turns out to be defective, deteriorated or broken due to the fault of the manufacturer.

- Refusal to receive warranty service occurs in case of non-compliance with the rules for using the tool or in case of mechanical damage.

The budget segment allows people not to contact service centers, but to buy a new tool.

Malfunctions

Screwdriver malfunctions in their basic form are limited to broken handles or dull metal slots.

- If the handle is replaceable, it is replaced with an analogue one. Models with solid handles must be recycled. However, craftsmen fix broken plastic by heating or using superglue.

In this case, the durability of the repaired handle is not guaranteed; the tool is no longer suitable for screwing in self-tapping screws and tight bolts.

- A dull screwdriver is sharpened using a grinder and a cutting wheel, a Dremel or a needle file. The last option is the most labor-intensive. Sharpening a screwdriver with a disc requires fixing it at an angle of 90 degrees to create correct bevels.

Self-repair is only possible if the battery is dead or the ratchet is clogged. If the mechanism becomes clogged, the tool is disassembled, cleaned of abrasives and lubricated for prevention.

Models with complex mechanics are more often subject to repair under service conditions.

Impact screwdrivers

Dealing with a threaded connection that is rusted, coated with paint, or otherwise stuck requires a more efficient tool. Understanding how an impact driver works doesn't require much explanation. An impact screwdriver converts impact force into rotation, and is also equipped with a T-shaped handle or even a reversible mechanism with which you can change the direction of rotation.

Screwdriver manufacturers

FIT

Budget tool supplier from China. The company itself is located in Canada. They offer a large selection of hand tools. The warranty is for power tools only and is equal to 1 year.

Gross

German brand, the tool is produced in China. They have impeccable quality, reliability and ergonomics that meet European standards for work at a professional level. Warranty – 1 year.

Hama

A German company that produces tools and accessories in various industries. They provide a huge selection (more than 17,000 items of goods). Warranty terms are not specified.

JONNESWAY

Manufacturer of professional tools from Taiwan. Products are made from high quality materials according to generally accepted standards. It is used in enterprises with high equipment requirements. Lifetime warranty on products.

Makita

A Japanese manufacturer specializing in household appliances and tools, manufactured in China. Quality and durability are confirmed by a lifetime guarantee and an international quality certificate.

Stanley

The company is based in the USA and the instruments are made in Taiwan. They specialize in hand tools for professionals and amateurs. The main qualities of the products are innovation and convenience. Manufacturer's standard warranty is 1 year.

STAYER

A young Russian manufacturer specializing in the production of budget tools, power equipment, and thermal equipment. The company's products are famous for their high quality and long service life. The warranty on tools is 5 years.

Wiha

World leader in the manufacture of premium hand tools. They produce more than 3,000 types of tools that are famous for their quality and functionality. Warranty – 2 years.