What kind of steel is this

The X12MF brand appeared in the 30s of the last century. Soviet engineers developed a new alloy for the needs of a rapidly developing industry. Initially, cutters and stamps for printing and various woodworking tools were made from this steel.

Around the 50s, craftsmen began to use this material to make table and utility knives. Now the X12MF brand is very popular. It is widely used in mechanical engineering. Tourist and hunting knives are also made from this alloy.

Industrial production of steel X12MF.

Price

The popularity of X12MF steel exists due to its availability and the possibility of using recycled materials.

It is not easy to give more information than there is about the X12MF steel grade, which has been known for 90 years, since the times of the Soviet Union. Over these decades, information about it has been repeatedly given in periodicals in the most expanded format; there is a lot of specialized literature. Used by most of our knife makers. The reason for this popularity is due to the affordability of steel and the stable quality of manufactured products.

Read also: Making a mold for steel casting

X12MF steel was created by Soviet engineers for the needs of Soviet industry in the 30s of the 20th century. Initially intended for metal processing by stamping. According to the purpose, the biochemical component of the alloy and the entire technological process were developed.

Ratnikovsky knife

Later it was found that the characteristics of the alloy already introduced into production corresponded to the production of edged weapons on an industrial scale. Steel X12MF had all the necessary properties:

- appropriate viscosity;

- stable anti-corrosion properties;

- excellent performance on compression, elasticity, hardness and rigidity.

Therefore, in addition to industrial use, the alloy began to be used for knives made for special forces. For example, military personnel of the NKVD troops were armed with these weapons.

Chemical composition

| substance | % |

| carbon | 1,45-1,65 |

| silicon | 0,1-0,4 |

| manganese | 0,15-0,45 |

| nickel | up to 0.35 |

| sulfur | up to 0.03 |

| phosphorus | up to 0.03 |

| chromium | 11-12,5 |

| molybdenum | 0,4-0,6 |

| vanadium | 0,15-0,3 |

| copper | Up to 0.3 |

| iron | ~84 |

Each element of the alloy is responsible for a certain quality of the resulting material.

The importance of chemical elements in the composition of steel for knives:

| Carbon (C) | The most important element in steel, it increases its strength. |

| Chromium (Cr) | Gives the alloy increased anti-corrosion properties. Affects the ability of steel to harden. The high chromium content in the alloy increases its brittleness. |

| Manganese (Mn) | Increases hardness, wear resistance, resistance to impact loads, without reducing ductility. |

| Molybdenum (Mo) | Prevents brittleness and maintains strength at high temperatures. Also increases elasticity and resistance to oxidation. |

| Silicon (Si) | Increases the strength and wear resistance of steel, making it more stable and reliable. |

| Vanadium (V) | Responsible for the elasticity of steel. Enhances the properties of chromium. |

| Nickel (Ni) | Increases corrosion resistance and prevents steel from rotting. Increases its strength. |

| Sulfur (S) | It is a harmful impurity, reduces ductility and corrosion resistance. Typically, the sulfur content of high-quality steel is limited. The presence of sulfides is unacceptable for critical parts. |

| Phosphorus (P) | Also a harmful impurity. Increases the brittleness of steel, especially with high carbon content. |

Chemical properties

Two components are responsible for obtaining the final properties of a X12MF product: the chemical composition of the alloy and thermomechanical processing (intermediate and final). Naturally, both components depend on each other, and this subtle relationship is determined as a result of numerous studies and experiments:

The above products have high requirements:

- in terms of strength when processing metal using cold stamping and rolling;

- good heat resistance. — The set of these properties of the X12MF brand is ensured by a high concentration of the following elements, each of which brings its own characteristics:

- C - 1.45-1.65%;

- Cr - 11–12.5%;

- Mo - 0.4–0.6%;

- Si - 0.1–0.4%;

- V - 0.15–0.3%;

- Mn - 0.15–0.45%;

- Cu - 3%;

- Ni - 0.35%.

Explanation of steel X12MF

In this case, only the main elements are indicated in the labeling:

- index: X12 - chromium content 12%;

- M - molybdenum (without digital index, content should be up to 1%);

- F - tungsten (content also up to 1%).

Read also: How to connect two lamps to one wire

Carbon is not indicated in this case, since by default its content is determined to be around 1.5%.

Carbon is the most important element that increases strength. His participation has both positive and negative effects. At the same time as strength, it reduces ductility, which makes the steel difficult to deform.

In addition, carbides at high concentrations are distributed unevenly, and also coagulate during further aging, which leads to heterogeneity of properties in the alloy itself: in the area of segregation, the alloy is strongest, and the depleted area becomes vulnerable when heated above 300 ºC. Therefore, during intensive work, when the working surface heats up, softening occurs.

But this deficiency is neutralized by adding chromium, manganese, molybdenum and tungsten.

The main alloying element of X12MF is chromium. It imparts corrosion resistance, increases hardenability and eliminates softening of steel. It is thanks to this chromium content that steel is characterized by high:

- heat resistance (no softening at high temperatures above 300 ºC);

- hardenability;

- resistance to warping during hardening.

Tungsten improves the cutting ability of steel, which is very important in the manufacture of knives. This is due to the ability of W to form refractory compounds, which, even when the cutting edge is heated, do not cause softening.

A high concentration of elements that increase strength gives the characteristics of steel negative qualities. They are neutralized by other elements, such as manganese and molybdenum. They also increase strength, but additionally work to increase hardenability (a property of steel that, when hardened, increases the thickness of the metal in which the necessary martensitic structure is formed). In addition, they reduce warping during hardening.

Vanadium, along with iron, forms VC carbides, which are characterized by even higher strength and refractoriness than FeC. Moreover, the content of this element in the range of only 0.3-0.5% does not reduce the ductility of steel.

Thermo-mechanical treatment

Molten metal is poured into molds to obtain:

- blanks of simple geometric shapes (circles, squares, etc.), from which parts are subsequently made by forging;

- finished products taking into account processing allowances.

When products are manufactured using the forging method, the structure is further improved. The changes that occur can be called an increase in density, because this eliminates defects:

- filling vacancies in the crystal lattice;

- dendritic segregation - grain refinement (elimination of the dendritic structure, which is inevitable during the crystallization of workpieces, ingots, increases plasticity, without loss of strength).

Complex molecular bonds in a saturated structure place high demands on temperature conditions. Heating of steel during forging should not exceed 1050 ºC. When the metal overheats, restructuring occurs, which causes brittleness; unfortunately, it is impossible to correct it.

The advantage of steel, such as low shrinkage, makes it possible to produce finished parts and precision workpieces by casting (dimensions taking into account allowances for processing). Then the final structure of the product is obtained by thermomechanical processing:

- Removing the excess layer ensures accurate dimensions and eliminates foundry costs;

- oil hardening increases the strength of the structure of the top layer;

- Vacation relieves internal stress.

Characteristics of steel

The mechanical characteristics of steel depend on the chemical composition of the alloy. Proper heat treatment is also very important. Any steel has 5 main characteristics:

- hardness - resistance to physical influences;

- rigidity - resistance to mechanical damage (chips, cracks);

- wear resistance;

- anti-corrosion resistance - resistance to rust;

- duration of use of the blade without sharpening.

For knife steels, the most important characteristic is Rockwell hardness. The higher it is, the longer the product will last and the sharpening will last. For the X12MF brand, this figure varies in the range of 61 - 64 units. This is quite a high value.

Advantages and disadvantages

| PROS | MINUSES |

| Low production cost. The material contains simple components, so products made from it are affordable. | Loss of shine upon contact with acidic foods. It will not be possible to polish the blade to a shine; it will remain cloudy |

| High cutting properties. | Special sharpening tools are required. In field conditions, it will not be possible to straighten the knife due to its high hardness. |

| Long retention time. The ideal sharpening angle is 35 degrees. | Strict temperature requirements during manufacturing. If the temperature is not maintained, the blade will become fragile. |

| Resistance when interacting with moisture. It is impossible to call completely stainless steel. However, it has high anti-corrosion properties. | Does not tolerate fracture loads well. May break if struck by a bone or a thick tree trunk. |

Quenching and tempering of hypereutectoid and ledeburite steel for die tools

The properties and behavior during heat treatment of hypereutectoid and high-chromium steel were discussed earlier, and the hardening regime was indicated in Table.

33. Therefore, only the main features and differences in the heat treatment of tools for cold deformation of metal are given here.

A tool for this purpose is often larger in size than a cutting tool. In such cases, steel hardening temperatures (except for X12M and X12 steel) should be assigned according to the upper limit specified in Table. 33, and when hardening a larger tool - 10-20° above this upper limit.

In carbon steel dies it is often necessary to ensure the deepest possible hardenability. The latter increases if the steel has a thin-plate pearlite structure before hardening. This structure is created in steel as a result of normalization. Therefore, it is sometimes advisable to normalize large carbon steel dies before hardening.

According to V.Ya. Dubovoy, the durability of large dies that received higher heating during quenching or underwent preliminary normalization increases approximately twice as compared to the durability of dies that were heated during quenching according to the usual regime established for carbon steel.

Die tools made from steel X12M, X12 and 7X3 must, as a result of heat treatment, be given high wear resistance with sufficient viscosity. Therefore, when hardening this steel, it is not necessary to transfer a large amount of carbides into solid solution. In addition, the deformation of a complex tool made from X12 and X12M steel during the hardening process should be minimal. For these reasons, there is no need to heat this steel to the high temperatures indicated in table. 33 and assigned to cutting tools. The heating of the die tool is used as follows:

Cooling of dies made of steel X12M, Xl2 and 7X3 can be done in oil or in a stream of air, after which the steel receives a hardness in the range of 62-65 Rc and a martensite structure with a significant amount of carbides that have not passed into solution (as well as 10-20% retained austenite) . Cooling high-chromium steel in a stream of air creates slightly lower residual stresses than cooling in oil. Therefore, to reduce the deformations that occur during hardening, dies made of X12M and X12 steel are cooled in air. However, dies of complex shapes, especially those with sharp transitions, are more rationally cooled in molten salts or in a special oven at a temperature of 450-475° and after holding for 10-20 minutes. transfer to air.

Steel X12M and X12, heated during hardening to 975-1050°, retains high hardness (60-62 Rc) after tempering at 425-475°; a further increase in the tempering temperature causes a decrease in hardness. Since these grades of steel are used to make dies that operate mainly under conditions of increased wear, the tempering temperatures of X12M and X12 steel are usually set within the limits specified here. Tempering is carried out once with a holding period of 2-5 hours depending on the size of the stamp. High-precision dies, in which it is necessary to maintain the size that was before hardening, are tempered 2-3 times at 509-520°, since additional tempering, promoting the complete decomposition of retained austenite, increases the size of the die. The hardness after such tempering is 55-60 Rс.

The tempering temperatures of stamping tools made from steel grades X, ШХ15, ХГ, Х09, 9ХС, У8-У12 are set within the limits specified earlier if the tool operates under conditions of increased wear.

If the dies experience impacts during operation and must have a higher viscosity, then their hardness after tempering should be below 60 Rc. In this case, we can proceed from the following data: for stamps of a simple shape, take a hardness of 57-60 Rc, and for stamps with sharp transitions - 55-57 Rc; for dies processing softer metal, for example, non-ferrous metals, 48-55 Rc. In this case, higher tempering temperatures are set for the stamping tool (Table 42).

Some types of tools, for example, punching stamps, punches, etc., have a long fastening part that works in bending, which requires a more complex heat treatment regime in order to maintain high hardness in the working part and obtain lower hardness with increased viscosity in the fastening part. parts. To create heterogeneous hardness along the length of the tool, you can use either different hardening modes for the working and fastening parts or a differentiated tempering mode. In the first case, the tool is heated in a lead or salt bath with only the working part, or it is heated completely in a furnace, but only its working part is immersed in oil.

Comparison with analogues D2 and K340

The Russian analogue of X12MF steel is alloy 95X18.

Initially, 95X18 steel was used to strengthen building structures, and later began to be used for the manufacture of knives. This knife is easier to sharpen than a blade made from X12MF. But the latter will be stronger.

Among the foreign ones, American D2 and K340 steel from the Austrian-Swedish concern Bohler Uddeholm are similar in composition and characteristics.

Knives made of D2 steel.

Experts believe that D2 and X12MF are similar in chemical composition and mechanical properties; there are no significant differences. You can choose a knife from one steel or another, based simply on personal impressions, which one you like best.

D2 steel is also a high carbon alloy steel. Originally developed for the production of cutting teeth. The Rockwell hardness of this steel ranges from 57 to 61 units.

K340 steel is more resistant to corrosion; the alloy does not contain harmful sulfur and phosphorus. The hardness of steel is 62-64 units. The main disadvantage of the K340 is its high cost.

| BRAND | ADVANTAGES | FLAWS |

| X12MF | High cutting ability, wear resistance, low price. | Does not withstand shock loads |

| D2 | Holds an edge very well, high strength. | Low corrosion resistance |

| K340 | Great mechanical strength | High price |

The best manufacturers in Russia

In Russia, knives made of X12MF steel are very popular. This is due to the fact that blades made from it are highly durable and can be sharpened for a long time. The cost of the products is very affordable.

We also recommend that you familiarize yourself with the current rating of the best steels for knives.

If the production technology is violated, steel loses some of its properties!

Therefore, you need to buy products only from trusted manufacturers, otherwise the knife may not withstand the first serious use. Excellent blades are made, for example, by the Albion forge (Nizhny Novgorod region), LLC PP Kizlyar, . These enterprises use both the latest production technologies and the experience of old, honored masters. Therefore, the products are of high quality.

Production at the forge

pros

Blades made of X12MF steel have many advantages.

The main quality of any knife product is hardness and the length of time it retains its sharpness. It is known that a sharp blade becomes dull faster. However, this cannot be said about blades made of X12MF steel. The duration of sharpening is ensured by a carbon concentration of up to 14.5 - 16.5%, which guarantees wear resistance and safety of the blade.

At the same time, these same characteristics reduce the anti-corrosion properties of the product. It would be wrong to classify this steel as completely stainless, but it will not instantly become covered with rust from being in contact with water.

The hardness of knives made of X12MF steel is 50 units, but even with this indicator, cutting properties are retained after chopping hundreds of test objects.

Additional components in the composition that give the following characteristics:

- molybdenum, which contributes to the homogeneity of the metal;

- vanadium, which improves the hardness of the alloy and service life;

- silicon, which increases strength.

Knife manufacturers have repeatedly tested their strength: they used them to chop bones, cut cans, and oak blocks. As a result, the knife does not become dull, and the sharp blade cuts a sheet of paper with the weight of the knife.

All metal knife set

Review of knives made of steel X12MF

Most often, hunting and tourist knives are made from X12MF material. They are chosen with special attention, because such a knife must perform many functions and be a reliable assistant to its owner. They use a knife to open canned food on a hike, perform work on arranging a rest stop, and cut up meat or fish.

Some people take several knives with them for different tasks, while others prefer to have a universal blade. But not only hunters and fishermen use knives. Many people like to have a small folding knife in their bag so that they can sharpen a pencil or cut sausage without experiencing everyday difficulties.

Biker - 1

. A convenient folding knife, useful at home and on the go. The handle consists of metal plates with plastic linings. Keeps its edge for a long time.

Characteristics:

- handle length – 130 mm;

- blade length – 98 mm;

- blade steel grade – X12MF;

- handle material – plastic;

Fisherman

Small hand knife with a handle made of Karelian birch, manufacturer Lemax. Useful for any fisherman, its sharp nose is perfect for opening the belly of a fish.

Comes complete with a sheath (sheath) made of genuine leather. The beautiful wooden handle and individual packaging make this knife a wonderful gift.

Characteristics:

- handle length – 125 mm;

- blade length – 135 mm;

- blade steel grade – X12MF;

- handle material – Karelian birch;

Finnish

Utility knife with elastron handle, . The handle has protruding corrugations, thanks to which the knife is perfectly held in the hand and does not slip out. Useful for fishing, hunting, and mushroom picking. The knife comes with a sheath made of genuine leather. Characteristics:

- handle length – 106 mm;

- blade length – 114 mm;

- blade steel grade – X12MF;

- handle material – elastron;

How to care

In order for knives made from this steel to serve for a long time, you need to follow simple care rules:

- wash and dry after each use. You need to wash it especially thoroughly if it has been in contact with acidic foods;

- lubricate the blade with oil once a month;

- To sharpen a knife, use a special whetstone with diamond chips;

- keep the blade in a sheath to prevent fungus from developing;

- treat the handle with an antiseptic.

Sharpening a knife is a very important process, so you need to use a high-quality diamond stone.

With proper care, the product will last a long time and retain its properties. Many people use such knives for more than one season, and no serious shortcomings are identified.

Owner reviews

Igor R., Leningrad region: “I have several knives for hunting and tourism. Experience has shown that X12MF steel is just right! I have a folding knife from this brand. All summer I went foraging for mushrooms, went fishing, but didn’t pay much attention to its care. The knife is still sharp, no signs of corrosion.”

Sergey N., Penza region: “Most of my knives are from X12MF. They darken a little, but there is no corrosion. With frequent use, sharpening lasts for 2 years. I recommend to everyone!"

Due to their high performance qualities and low cost, products made from X12MF steel are widely used in production and everyday life. They can serve a person for a long time without losing their properties. To do this, it is necessary to use knives for their intended purpose and take proper care of them.

Heat treatment modes for steels Х12Ф1 (Х12М)

⇐ PreviousPage 16 of 41Next ⇒

| Mode | Temperature, оС | Cooling medium | Hardness, HRC (after hardening) | Amount of austenite, % | Holiday temperature, оС | Number of holidays | Hardness HRC (after tempering) |

| I | 1070±10 | Oil (saltpeter) | 62–64 | 20–25 | 160 | 1 | 62–64 |

| II | 1070±10 | Same | 62–64 | 20–25 | 200 | 1 | 58–60 |

| III | 1170±10 | Oil (saltpeter) + cold treatment at -70°C | 51–53 | 30–35 | 520 | 2–3 | 60–62 |

| IV | 1120±10 | Oil (saltpeter) | 57–59 | 35–45 | Thermal finishing | 57–59 | |

Note: I – normal mode; II – used if treatment according to mode I does not provide the required viscosity; III – for cutting tools when wear resistance is required; IV - used when size constancy is required.

Since in steel type X12 the amount of retained austenite varies widely (almost from 0 to 100%), the change in volume that is observed during hardening is also significant. When hardened to martensite, the steel acquires a volume greater than the original, and when hardened to austenite, it acquires a smaller volume (see curve Δl in Fig. 3.5). At a certain temperature, the ratio of the resulting austenite and martensite is such that the volume of the hardened steel is exactly equal to the original. As follows from the graph shown in Fig. 3.5, this will occur during quenching from 1120 °C, when about 40% of retained austenite is fixed at a hardness of about HRC 58 (in this case Δl = 0). However, possible fluctuations in the quenching temperature, cooling conditions and other details of the thermal regime, as a rule, lead to the fact that the dimensions of the die will not be exactly equal to the original ones.

If the dimensions of the die have decreased, then tempering is given at 520 °C. As a result of such tempering, the retained austenite will partially transform into martensite, and the dimensions of the die will increase. If the dimensions of the die have increased during hardening (the die has “grown”), then tempering is carried out at 350 °C. At these tempering temperatures, austenite remains, but tetragonal martensite turns into tempered martensite, and the dimensions of the die decrease.

This operation is called thermal finishing. As a result of thermal finishing, it is possible to bring the dimensions of large stamps to the required value with an accuracy of ±0.1 mm.

Steels Kh12F1, Kh12M and the like are slightly deformed during hardening, and when thermal finishing is used, deformation can be reduced to almost zero. Therefore, these steels should be recommended for tools of complex shape, for which deformation during hardening is unacceptable. A significant disadvantage of X12 steel is its reduced mechanical strength, due to the presence of a large amount of carbide phase in this steel. Since the more carbides there will be, the more carbon there is in the steel, X12 steel (with 2.0–2.3% C) is used only for tools that are not responsible for their intended purpose and for tools that are simple in design.

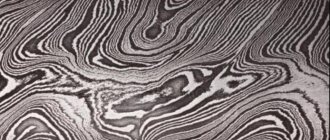

For X12 steels, as well as for high-speed steels, the distribution of the carbide phase is of great importance. The line distribution of carbides, the accumulation of carbides, i.e., everything that is called “carbide segregation” greatly impairs the strength of steel. The more bends, and therefore the smaller the cross-section of the metal (workpiece, rod), the more the accumulations of carbides are crushed, the better the quality of the steel (Fig. 3.6, a, b). Therefore, thorough forging should be recommended in cases where the stamp is large. Forging in this case is achieved by alternating upsetting and drawing. However, it is not always possible to eliminate “carbide segregation” to the required extent.

Steel of the class under consideration, but with a lower content of carbon and chromium and less prone to carbide segregation, is designated as X6VF. It contains less carbides than XI2 steel (12–14% Cr7C3 carbide in annealed Kh6VF steel versus 15–17% in Kh12F1 steel and 25–30% in Kh12 steel), and, other things being equal, it has less carbide segregation (Fig. 3.6, b).

Rice. 3.6. Microstructure of steel, ´ 100:

a – X12; b – Х6ВФ

The behavior of Kh6VF steel during heat treatment is the same as that of steels of the X12 type, however, an increase in the quenching temperature does not lead to such a sharp dissolution of the carbide phase as in steels of the X12 type. Therefore, this steel is usually hardened from 1000±10 °C (to obtain maximum hardness). In this case, about 8% of the 12% carbides will go into solution, and martensite will contain about 5% Cr.

This martensite is quite resistant to tempering. Tempering at 200 °C reduces the hardness to HRC 58, and a further increase in temperature (to 500–525 °C) reduces the hardness to a slight extent - from 58 to 55–56 HRC. Since strength and toughness also change little in the same tempering temperature range (this change in properties is also typical for steels of the X12 type), Kh6VF steel is tempered either at 150 °C (to maintain high hardness) or at 200 °C (for some higher hardness). viscosity). It follows from this that the areas of application and heat treatment modes of Kh6VF and Kh12F1 steels are generally similar, only Kh6VF steel has higher strength, but lower wear resistance, which is a consequence of the smaller amount of carbide phase in it.

⇐ Previous16Next ⇒

Recommended pages: