The latest technologies make it possible to choose materials for fencing that do not require maintenance or further finishing. These include Euro picket fences. Having a metal base, structures made from this material are reliable and durable. It is accessible and easy to install. When assembled, the structure perfectly copes with protective and decorative functions.

Users often search for:

- Installation of a fence with brick pillars

- Fence made of metal profiles and bricks

Distinctive features

A metal picket fence is made from sheet steel. Prepared planks are used to fence the local area. For installation, racks and cross bars are required to hold the entire structure together. It will look like a regular wooden fence.

The metal picket fence can be from 0.4 to 1.5 mm thick, but there are other options. To prevent rust, you need to coat the product with a special compound or a layer of zinc. After this, the fence can be painted.

Bottom line

As you understand, there are quite a few types of metal fences and picket fences available today. This is not only extremely practical, but also a beautiful material that allows you to realize your most extraordinary design ideas. The metal picket fence is durable, requires virtually no maintenance, is not subject to rotting, shrinkage, does not burn and is easy to install. At the same time, the picket fence, unlike a solid profiled sheet, does not create shaded areas on the site and allows light and air to pass through well. And you can easily adjust the level of visibility yourself by installing strips with the necessary gaps.

The categories mentioned in the article are:

Metal picket fence

Advantages of a metal picket fence

- Long service life. A metal picket fence will last, on average, 30 years, and with careful care – about 50 years.

- Sustainability. When coated with special products, the metal picket fence will withstand any weather conditions. Additionally, it has good resistance to mechanical damage.

- Easy to install. There is no need to pour a foundation for the construction; you can handle the installation yourself.

- Compatibility with other materials. To create a unique design, wood or brick is suitable.

- Such a fence does not require maintenance; it is only necessary to update the color every few seasons. The metal is not subject to fire and has small dimensions, which facilitates its rapid transportation.

Compared to conventional corrugated sheets, metal picket fence has a high cost, but it pays off with a high service life and structural strength.

"Transparency" of the fence

The “transparency” of the fence is the distance between the picket parts (slats), which implies natural ventilation of adjacent areas and ensuring constant illumination by sunlight. The fence should not obscure the adjacent area. Starting from 2022, the transparency of the fence is regulated by local authorities (TSN), which are based on the terrain and climatic conditions of the region. On average, with a minimum distance from a residential building to the fence between two neighboring plots of 3 meters, the level of light transmission over the entire height of the fence is ±50%. This means that a fence with a maximum height of 1.5 m is installed, divided into sections of 2.5 m, and with a distance between individual pickets of no more than 30-45 mm.

Calculation of the distance between the picket fence slats:

Calculation of the interval between pickets

The interval between pickets in a fence is not regulated by law and is not specified in SNiPs. The initiators of construction agree on this at the general meeting of TSN, officially documenting all the requirements in acts. Average values of the gap between pickets when installing a standard (single-row) fence (for any choice of material - wood, metal, plastic):

Table “Average number of pickets in a fence”

Types of materials for picket fences

Thanks to the various sizes of metal picket fences, it is possible to design original designs. The strips are made from steel strips that have been processed in a rolling mill.

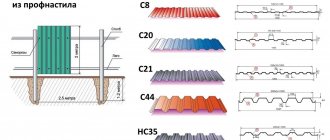

- Another type of material is metal profile.

- It is considered the most budget option, since the metal sheet is not processed in a rolling mill, but is cut independently.

- A picket fence made in this way will be less durable and have dangerous edges.

- A sheet bending machine is not able to make all the planks the same, which is why the fence will be less strong.

The quality of the fence will depend on the material from which it was made. Most often, cold-rolled sheets are used for picket fences, but sometimes hot-rolled sheets are also used for budget options. In both options, the planks must be treated to increase their service life.

Video description

Watch the video to see what a horizontal fence made from a wood-polymer composite board looks like:

A very original type of continuous horizontal fence is called a ladder (or herringbone) - when the pickets are stacked at an angle to the plane of the fence, overlapping each other.

Double sided

Both vertical and horizontal fences can be double-sided. It requires more material, but it looks beautiful from any side, not just from the street. In addition, such structures, with their sections being practically blank and impenetrable to view, do not interfere with the free movement of air, since they have sufficiently wide slots.

There are several types of double-sided fences.

- Blinds are a structure made of wide horizontal pickets fixed between supports with an angle, which makes it look like slightly open blinds.

The reverse side of the fence looks no less attractive Source garantwood.ru

- Checkerboard is a picket fence fixed to the veins on both sides with offset and bridging the gaps.

- Braided fence - pickets are placed alternately on and under the veins, as if braiding them.

Types of coating

In addition to coating with a layer of zinc, another coating is applied to the metal picket fence, which comes in two types.

- Polymer. Protects against rust and mechanical stress for up to 20 years.

- Powder. This is a budget option, however, it requires an anti-corrosion coating, otherwise the metal may rust.

After coating the metal picket fence with zinc, you can begin applying paint. You can paint the fence yourself, or purchase a factory-painted picket fence, a wood-look metal picket fence, with patterns, etc.

Interesting design options for the top of structures

Most often found:

- Ladder. The planks alternate with each other. They put one longer, the other shorter, or vice versa.

- Wave. Suitable for sectional assembly. The top is made in a wavy shape.

- Trapezoid. The top of the fence is formed in the form of a trapezoid.

- Herringbone. The planks form a cone, which is very similar to the crown of a spruce tree.

- Arc. The upper cut is made convex or concave.

- Canyon. Long planks are installed along the edges of the span, the height of which gradually decreases as they approach the center.

- Peaks. The upper part resembles the shape of peaks, and there can be several of them in one section.

Less common is the design of the top line like a pyramid or wings.

The unusual spans will be complemented by a stone or brick base.

Size of slats

The top of the metal picket fence is available in three options: flat, semi-oval, or a designer version.

It is advisable that the edge be processed, otherwise it is easy to get injured on the fence.

The bar itself is available in three versions:

- Rectangular profiling. The most common type. The number of ribs must be at least 3.

- Longitudinal profiling. More durable and aesthetic than the previous option.

- Semicircular. It is rarely made and has its own production difficulties.

The dimensions of the planks range from 0.5-3 m. The width is 10-12 cm. The thickness of the plank determines whether it will need a foundation or not.

Popular manufacturers

Below are 4 metal picket manufacturing companies whose products are most often purchased.

Grand Line

The company is popular both in the Russian and European markets. Produces various products from metal profiles and PVC:

- corrugated sheeting;

- metal tiles;

- siding;

- fence;

- soffits;

- drainage systems;

- facade panels;

- standing seam, composite roofing.

All products are certified.

TPK Center Metalroofing

Produces and sells construction materials.

The Euro picket fence is made of steel 0.5 mm thick. The edges are rolled. Phytoresistant (does not fade in the sun), does not rust. Each plank is wrapped in film. The service life of the products reaches 50 years.

All products are certified.

EugeneST

The group of companies makes and implements:

- metal tiles;

- thin sheet steel with polymer coating;

- corrugated sheeting;

- metal siding.

EugeneST LLC produces metal picket fences under its own brand “Barrera”.

Color spectrum

With modern technologies, you can design in any color.

Most common colors:

- Green. Blends well with plants in the local area.

- White. Requires frequent maintenance, looks great with the French Provence style.

- Chocolate. Combines with other flowers and trees.

- Grey. Suitable for any design.

The assembly of the structure depends on the fixation methods and has three options:

- Vertical. The most common type of installation. It is permissible to leave gaps between the planks, or fasten them together without gaps.

- Horizontal. Not the most common option, but also quite relevant. Installation requires a lot of time and effort.

- Chess. Installation occurs vertically in two rows, leaving no gaps between the rows. Suitable for those who like privacy.

- A unique approach. You can create a herringbone or wave from the planks. It all depends on your imagination.

If you have no experience, it is better to order the installation of a picket fence from a construction company. You can install the fence yourself without resorting to outside help.

For independent work you will need a metal profile and special scissors. The difficulty is that the edges of the planks must be even, which will require additional time. The best option is to purchase a ready-made fence and install it yourself.

Euro picket fence classification

The material has several varieties depending on the profile shape, coating, design and color scheme.

Let's look at each of the parameters in more detail.

According to profile shape

There are the following types of Euro picket fence:

- M-shaped. The bar has two curved grooves on the surface with a slight deflection. Due to this number of ribs it has increased rigidity. One self-tapping screw is enough for fastening.

- U-shaped. The shape resembles a trapezoid on the sides with flat edges. Screwed to the joists on both sides. If equipped with additional ribs and the edges are rolled, then the rigidity is not inferior to the previous type.

- Semicircular. Due to the non-standard profile shape, the cost of the picket fence increases. Rigidity is at a high level. It looks very original.

Photo: dimensions and shapes of the picket fence profile. From left to right: 1 – 128 mm semicircular; 2 – 118 mm rectangular; 3 – 80 mm rectangular.

The presence of a large number of ribs on the plank increases the bending resistance of the plank, and the rolled edges increase strength and eliminate the risk of injury during installation or operation.

By coverage

There are:

- Single-sided polymer. Provides an aesthetic appearance only from the street side. The inner part of the material has a light shade.

- Double-sided polymer. The picket fence is painted on both sides. The fence becomes equally attractive both outside and inside. The service life is higher than the previous type, but the price also increases by 15-20%.

- Printed color drawing. It is in demand because the coating perfectly imitates the structure of wood, stone, and brick. The most expensive type of material.

According to customer reviews, you can only distinguish a high-quality imitation up close. The European picket fence looks especially impressive with a “wood-like” coating.

By section design

The names may differ depending on the manufacturer. The most popular options are:

- Herringbone. The top of the bar has a sharp peak in the center.

- Hills. There are two identical elevations.

- Bumps. The peaks alternate with each other.

- Horizon. The top of the picket fence is level.

- Chamfer. The height at the edges of the planks decreases.

- Pyramid. A progressive elevation towards the center with an acute angle.

- Sunrise. A semicircular elevation in the center of the plank.

- Ladder. Picket fences of different heights alternate with each other.

- Slide. Uniform arc across the entire width of the strip.

- Trapezoid. The picket fence section is formed in the form of a trapezoid.

- Gull. The height gradually decreases towards the center.

- Chess. The picket fence is installed on both sides in a checkerboard pattern.

- Creek. There is a depression in the middle at an acute angle.

- Wings. An elevation is made in the center and along the edges of the section.

- Blinds. The planks are mounted in a horizontal position on both sides of the span.

- Wave. The picket fence is screwed along a medium-radius arc.

- European. The height of the slats increases closer to the edges of the section.

The optimal width of the picket fence is from 80 mm to 128 mm.

DIY picket fence installation

For installation you will need fasteners and diagrams, which are most often sold together with the metal picket fence.

For installation you will need:

- Shovel or drill. Necessary for creating a trench.

- Welding machine. Needed for welding horizontal strips with supports.

- Screwdriver. Needed for fixing planks with guide parts.

- Construction level, tape measure.

Materials needed:

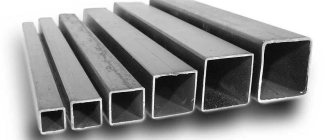

- Hollow pipes for vertical supports.

- Horizontal guides.

- Fence.

- Self-tapping screws.

- Soil mixture.

- Dye.

- Mixture for pouring the foundation.

Installation of metal picket fence

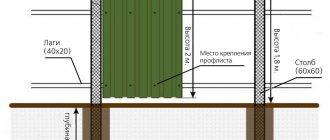

In places where the fence will be built, you need to drive in pegs and stretch the construction cord.

- Mark the installation locations of the support pillars.

- At the marked points, holes of approximately 60 cm are dug.

- Pipes are installed in the pits and driven in approximately 40-45 cm.

- The pits are concreted.

- The cross beams must be welded to the vertical pipes.

- Next comes the installation of the planks.

- The planks are fastened with galvanized screws.

The fence is covered with primer and paint.

Self-tapping screws or rivets

The planks are mounted to pre-screwed, welded joists using self-tapping screws or rivets.

Self-tapping screws are not ordinary ones, but roofing ones with a rubber gasket. They withstand any weather conditions very well. The rubber gasket ensures complete sealing of the hole. Easy to install. They have a large selection of colors, so you can always choose fasteners to match the design. The downside is that they simply unscrew, making it easier for intruders to enter the site.

As for the rivets, you will need a special gun to fasten them. Requires more time to install. Unscrewing them is a big problem. The connection point is poorly protected from rain. The choice of colors is small, so choosing a fence to match is problematic.

Builders recommend rivets for fences in summer cottages, where owners will only use them periodically. In the private sector, where the owners live permanently, it is better to use self-tapping screws.