A fence is an integral part of any site, both within the city limits and outside it. The functions of the fence and its appearance depend entirely on the wishes of the owner and his available budget for construction work. A fence made from a profile pipe can be an excellent compromise between too expensive and very budget options. It has the necessary protective properties, has an attractive appearance and, most importantly, it can be made independently.

Profiled pipe as a material for fencing

A profile pipe is a pipe whose cross-section is any geometric figure other than a circle. In the construction field, oval, square and rectangular rolled products are especially popular. With the same wall thickness as a round pipe, they have better strength characteristics.

In the nomenclature of rolled profile pipes you can find three main groups.

- Thin-walled. They are used primarily for the construction of fences. The group includes all products whose cross-section is 25×25 mm and the wall thickness is about 1 mm.

- Medium-sized. Serve as supports when erecting fences. These include products with a cross section of up to 100×100 mm and wall thickness in the range of 1-4 mm.

- Large size. Necessary in the construction of large objects (as the frame of a building, the base for production machines and similar purposes). The cross-sectional size for them is set to 200×200 mm, and the wall thickness is 4-8 mm.

For fences made of profile pipes (as support posts) and corrugated sheets, models with a cross-section of 40×40 mm or 50×50 mm and a wall thickness of about 3 mm are mainly used.

Peculiarities

One of the first striking features of fences made from profile pipes is the principle of their construction, which is an open type. This means that the resulting fence will have a protective function (from outside penetration), but will not hide what is happening in the internal area from prying eyes. This drawback can be partially hidden by sheathing the inside of the fence with sheets of metal.

The second feature is the affordable cost of the fence. It manifests itself both when purchasing the necessary materials and when hiring fence installation specialists. You can save even more by doing all the work yourself. With regard to profile pipes, this is quite realistic and affordable.

Experts also note a number of other parameters that have a beneficial effect on the popularization of fences made of corrugated pipe:

- high strength indicators combined with low weight of the structure;

- harmonious combination of profile pipe with other building materials;

- resistance to atmospheric influences and, as a result, a long service life;

- practicality and ease of the fence during use.

General information about the design

To assemble a fence from profile pipes, metal panels are used. They come in two versions.

- With a loose structure and supporting cross members for reinforcement.

- Frame, around the perimeter of which there are squares and other metal parts.

For structural integrity, all elements of the sections are welded together. As a result, the product receives the necessary parameters of reliability and strength, including easily withstanding the maximum fracture load.

Since profile pipes are the main element of both design options, high demands are placed on their production. For example, production steel is used for manufacturing, to which alloying additives are added to improve existing characteristics.

In appearance, profile pipes give the impression of a complete structure, however, in fact, they are hollow.

Installation of crossbars

After the concrete has hardened, you can proceed to installing the frame fence rails. They use the same square profile, but smaller in size (40x20).

The length of the crossbar must be no less than the length of the span; this will allow the logs to be joined directly to the support tube and will add reliability to the structure. If the logs are longer than the span, the excess metal can be cut off with a grinder.

The crossbars are fixed using brackets and bolts. The fence bracket without welding performs its function perfectly. A metal that resists oxidation well and does not rust, or is coated with an anti-corrosion substance, is better suited for fastening.

To install corrugated sheets, roofing screws are used. The sheet thickness must be at least 0.5 mm, and the wave height must not be more than 20 mm. If thinner sheets are used for the fence, it is necessary to install additional rigidity logs.

What types of profile pipe fencing are most in demand?

There are many types of fences depending on their design. However, for self-installation, experts recommend using only two: sectional and welded.

Welded fences from profile pipes

Welded fencing models are affordable and reliable compared to other options. The only negative factor when working with them may be the need to purchase or rent a welding machine. You also need to be able to work with it and know the basic principles of welding work.

The fencing is manufactured using the following technology.

- Leveling of rolled profiles. During production and transportation, it may receive deviations from the longitudinal axis, which must be eliminated before the main work begins.

- Trimming workpieces to the required dimensions. Carrying out trimming.

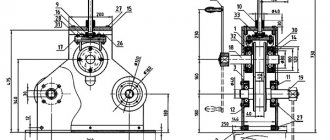

- Manufacturing of section frames by welding profile pipes.

- Installation of filling pipes and decorative parts.

Before starting work, you need to make sure you have a drawing of the future fence. You can create it in accordance with your own ideas or find a suitable sketch on the Internet.

Sectional fence made of profile pipe

If you do not have the skills to work with a welding machine, as well as the necessary equipment, you can use a diagram or drawing for installing a fence from a profile pipe. In this case, the assembly of the structure occurs directly on the site. Some companies, along with the sale of sectional fences, provide services for professional installation on site.

Among the main advantages of this design are the following points:

- high levels of resistance to climatic influences due to special processing of the modules carried out during their manufacture at the factory;

- a large selection of design designs (including the most complex ones), which are presented by companies in special catalogues;

- ease of installation, which is achieved by using clamps at key points as a fastening element.

Useful tips

During the welding and installation process, accuracy is very important; try not to harm the polymer coating. Scratches on the paint contribute to the formation of rust, which not only spoils the appearance, but also shortens the lifespan of the entire fence.

The supports and logs (crossbars) of the fence do not have to be metal. The material used is hardwood such as maple, ash or oak.

They are less reliable than profiled metal pipes, but are more flexible in processing, are not subject to fatigue and have good resistance to deformation. For a long service life of the fence, the wooden frame must be impregnated with a special solution, which will protect the material from rotting and repel parasites.

To maintain balance, the color of the corrugated sheeting must match the color of the fence fasteners. In construction stores, roofing screws with multi-colored caps are sold.

Ideally, the length of the crossbar and the distance between the supports should completely match. This will allow you not to worry about the need to cut off excess parts of the crossbar and will save materials.

What are the advantages and disadvantages of a corrugated pipe fence?

Regardless of the technology for manufacturing and installing fences from profile structures, all models have common advantages and disadvantages. The first ones include the following points:

- long service life and high strength indicators - the service life of a corrugated pipe fence can be several decades, provided that the foundation pouring technology is followed and a high-quality anti-corrosion coating is available, which will be regularly updated;

- easy adjustment of dimensions - when ordering designs for such fences, difficulties in manufacturing sections of the required sizes, as a rule, do not arise, since they can be of almost any size;

- a combination of different materials in one fence - for example, a profile pipe is widely used for a fence made of corrugated sheets, as well as in combination with brick and stone, which is used to line the part of the foundation protruding above the ground.

The disadvantages of the designs include the openness of the internal areas and the house to prying eyes. At the same time, it is impossible not to provide a fence for plants growing in the garden area. To eliminate the negative side, you can use corrugated sheet covering the inner surface of the fence. If you take translucent plastic instead, you will be able to preserve the positive aspect of the design.

Among the negative aspects of classic fences made of profile pipes (without the use of internal lining), there is also a strong wind blowability of the area. This is caused by the presence of a large number of free openings, since the structure consists of slats.

Which pipe to choose based on technical parameters

Determining which profile pipe to use when constructing a fence depends simultaneously on several parameters: the installation pitch of the pipes, the height of the fence sections, the average wind speed in a particular region and the type of finishing material.

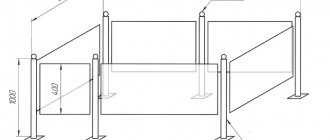

Section diameter and size

For fence heights from 1.6 to 2.3 m, it is recommended to purchase pipes with a wall thickness of 2 mm and a cross-section of 80×80 mm. For lower fences, it is possible to choose profile structures of smaller sizes - with a cross-section of 40×40 mm or 60×60 mm and a wall thickness of about 2 mm.

When choosing the length of pipes, you must rely on the presence of a foundation. In its absence, the pillars must go deep into the ground. For soft soil, the length of the immersed part should be 1.1-1.3 m, for dense soil - 0.8-1.0 m.

Number of support pipes

The number of supports is determined based on the pitch between them and the length of the perimeter of the fenced area. On average, the distance between two posts is set within 2.5 m. For areas with high wind speeds, it is recommended to reduce this value to 2.0 m. In this case, it will be possible to achieve an increase in structural strength.

Price

The cost of the fence depends on what technology will be chosen: from ready-made sections or they will be created after the construction of the fence.

So, for example, if you plan to install a fence with sheets of corrugated sheets or pipes with forging elements not on your own, then, for example, the price list and prices in it may be as follows:

- economy option. Its cost is approximately 1500 rubles. per 1 linear meter;

- the most popular option is about 1600 rubles. per 1 linear meter;

- premium option – 1800 rub. per 1 linear meter.

Site fencing

Prices for a sectional fence will be slightly different:

- economy – 1400 rub. per 1 linear meter (fence height size – 180 cm);

- medium – 1450 rub. per 1 linear meter (size of fence height - 200 cm);

- elite – 1800 rub. per 1 linear meter (the height of the fence is 200 cm).

The cost of fencing work includes:

- installation of prepared sections;

- painting metal elements;

- pouring the foundation;

- installation of additional elements, for example, sheets of corrugated board;

- installation of gates and wickets.

The average fence size is 180 cm.

How to make a fence from a profile pipe with your own hands

One of the advantages of fences made of profile pipes is a simple installation technology, thanks to which anyone can install it without special skills and knowledge. Knowing the technology of fencing construction and having all the necessary materials and tools available, the work will go quickly, and the end result is guaranteed to bring pleasure and well-deserved pride.

Basis: foundation, pillars and logs

For the installation of any type of fencing, the initial stage of construction is pouring the foundation and installing support pillars. A separate or strip foundation can serve as a supporting horizontal platform. The first option is considered more preferable for areas with sandy soil and lightweight fence structures.

To form a separate foundation, support pillars are selected from a pipe with a diameter of 80×80 mm (in some cases it is possible to use a section of 60×60 mm). Their length should be 3 m. Using a drill, create holes to a depth of 1/3 of the height of the pipe. For better stability, it is recommended to extend the pits below the soil freezing level. A mixture of sand and crushed stone is poured into the bottom of the resulting holes and compacted thoroughly. The layer height should be within 15 cm.

There is a second option - to form supports, pipes are driven into the ground. For these purposes, a heavy block of wood or a sledgehammer is used (a wooden spacer is placed between the pipe and the tool). In this case, it is necessary to constantly remember to control the angle of inclination of the support, especially taking into account the fact that the entire process of installing a fence from a profile pipe occurs from a stepladder, which is extremely inconvenient.

The dimensions of the strip foundation for the fence vary depending on what material of the posts is chosen - brick or pipe. In the first case, the support should be at least 30-40 cm wide and 1 m deep, in the second - the width should not exceed 25-30 cm and the depth - 60-70 cm.

As with a separate foundation, in this case you will need a sand and gravel cushion. In addition to it, it is necessary to take care of formwork above ground level and reinforcing reinforcement.

General installation technology

First of all, the foundation is concreted. Depending on the load, one of the two types described earlier is selected and carried out in accordance with the basic technology. All further operations are carried out exclusively after the concrete has hardened. To further secure the foundation structure, you can use tape braces.

Further work depends entirely on the type of assembly. Before proceeding with the main operations and welding a fence from profile pipes, you need to take care of the supports and the horizontal jumpers connecting them. After this, the fence is saturated with additional and decorative elements.

When working with sections of a fence made from a modular-type profile pipe, you simply need to connect all the parts with bolts according to the drawing and install the structure to the vertical posts.

As a rule, installing a fence from a profile pipe with your own hands does not cause any particular difficulties. The main rule is to constantly use a level and plumb line so that the structure stands level.

Fastening the veins

There are two main methods for installing and fastening joists: along the edge of the post or in its center. The first option is recommended to be used in cases where the fence is planned to be made solid, covered with corrugated board. In this case, you can do without careful measurements and selection of the pitch between the support pillars in search of the desired width of the sheets. It will be enough to take the logs and attach them to the barrier level with self-tapping screws.

If the veins are installed in the center of the structure, more care should be taken to ensure the required distance between the support pillars.

Support pillars made of profile pipes can be left in their original form, only covered with an anti-corrosion coating, or they can be refined. For these purposes, you can use brick or stone to lay the support at the height. You can also provide decorative lights at the top of the vertical pipes.

Calculation of the number of fence posts

The number of metal pipes cannot be neglected for the sake of reducing operating time, labor costs or cost. When the horizontal purlins do not fit together clearly, the entire rack looks unreliable; it is better to redo it. The number of supporting floors determines the reliability of the structure; it requires stiffeners. You can calculate it using a special formula: divide the area of the site according to the distances between the supports, including the calculation of the cross-section. Profile types are usually given a distance of 2 - 3 m, round ones - 2-2.5 m. The heavier the structure, the smaller the distance between the supports. The lightest fences - mesh, corrugated sheets - imply a distance of 4-6 meters.