If for industrial use the main factors are the corrosion resistance, strength and other physical and chemical characteristics of stainless steel, then in the manufacture of building materials, dishes, furniture and other consumer goods, the appearance of the metal also plays an important role.

supplies mirror stainless steel sheet (BA) with a thickness of 0.5, 0.8, 1, 1.2 and 1.5 mm, size 1000x2000 mm or 1250x2500 mm, made of steel grades AISI 304 and AISI 430 and used in construction, interior design , food, chemical, pharmacological and other industries.

Purposes and methods of processing

Processing of stainless steel products has several purposes:

- Elimination of minor defects (scratches, roughness, scale, welds and others) formed during the production process.

- Reducing deviations from the required size to a minimum.

- Increased hygienic characteristics - the smooth surface does not contribute to the accumulation of products in contact with it, and is also easy to clean.

- Giving the product an attractive appearance.

Processing is carried out manually, using grinding machines or on grinding machines using abrasive materials on a woven basis, grinding wheels or special brushes. The quality of the surface depends on the grain size of the abrasive material. At the final stage, to obtain a mirror surface, felt-based materials and special polishing pastes are used for processing.

Depending on the degree of processing, matte, polished and mirror surfaces are distinguished. Matte sheets are usually used for the manufacture of equipment frames, heating equipment and devices, finishing of building facades, and upholstery of fire doors. Ground rolled products – for the production of various types of products for the food, pharmaceutical and chemical industries. Mirror - for the production of furniture and accessories, decorative items, wall cladding and other tasks.

Most common brands

Each brand has its own characteristics, which determines the scope of its application:

- AISI 304. Easily weldable and electropolished, retains strength at low temperatures. Used in pharmaceuticals, textile, chemical industries.

- AISI 310S. The maximum heating is one and a half thousand degrees. Weldable in any way, not magnetized. Used for the production of equipment for furnaces.

- AISI 316Ti. Withstands a maximum of 300 degrees, but is highly resistant. Indispensable in the chemical industry and shipbuilding.

- AISI 321. Used at temperatures up to 800 degrees, does not magnetize. It lends itself well to welding, so various welding structures are made from it.

- AISI 430. Withstands heating up to 150 degrees, magnetized. Used in the production of machines, equipment manufacturing.

The most popular grades are ferritic (13–17% chromium) and austenitic (18% chromium) stainless steel.

Marking

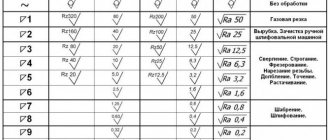

According to the European standard EN 10088, the following surface conditions of stainless steel are distinguished:

Using the numerical designations, you can determine the method of production of rolled products: hot rolled products are designated by the number 1, and cold rolled products by the number 2. Products with surface treatment in accordance with BA, 3N, 4N and DECO standards are packaged in protective film after treatment to prevent damage.

The most common methods of decorative surface treatment are those that meet standards 2B (smooth matte surface), BA (mirror surface that provides a fuzzy reflection of objects) and 4N (polished, non-reflective surface that shimmers in different colors).

Chemical polishing of stainless steel

Electrochemical and chemical polishing is used both for decorative surface treatment after coating and during the processing of parts.

Electrochemical polishing

With electrochemical polishing, the surface microrelief is much smoother than with mechanical processing.

The coatings obtained by electrochemical polishing are non-porous and finely crystalline, which helps reduce the coefficient of friction and makes it possible to impart special optical properties to parts. During electrochemical polishing, the metal surface becomes shiny as a result of different rates of dissolution of microprotrusions and depressions.

The effect of electrochemical polishing is explained by the formation of a thin surface oxide film on the metal, which prevents etching. The thickness of the film is not the same on microprotrusions and microdepressions, as a result of which the solution during electrochemical polishing has a stronger effect on those areas where the film is thinner, i.e. on microprotrusions.

The quality of electrochemical polishing depends on the current density, electrolyte temperature, solution composition and electrolysis time.

The most widely used electrolytes based on phosphoric, sulfuric and chromic acids. To increase the viscosity of solutions, glycerin and methylcellulose are introduced. Sulfureide, triethanolamine, etc. are added to electrolytes for electrochemical polishing as etching inhibitors.

Chemical polishing

The chemical polishing method has much in common with the electrochemical polishing method. The appearance of shine on the surface of parts here, as with electrochemical polishing, is also associated with the presence of a thin film that prevents etching in the metal recesses.

The preferential dissolution of protrusions during chemical polishing is achieved both due to their increased chemical activity and due to the higher rate of diffusion of metal ions and fresh electrolyte.

Electrochemical polishing of steel parts.

Comparative characteristics of electrochemical and chemical polishing processes

The main advantages of the electrochemical polishing process are high productivity, good adhesion of galvanic coatings to the electropolished surface, and the ability to eliminate the degreasing operation necessary for mechanical polishing.

The disadvantages of the electrochemical polishing process include the need to frequently change electrolytes due to the lack of a universal one for various metals; the need for mechanical polishing of the surface before electrochemical polishing; increased energy consumption.

The advantage of chemical polishing over electrochemical polishing is that it does not require the use of constant power sources. Chemical polishing is mainly applied to brass or aluminum parts of any complex configuration and size that do not require a mirror finish.

The disadvantages of chemical polishing compared to electrochemical polishing are lower gloss, greater aggressiveness of solutions and their fragility.

Compositions of electrolytes for chemical and electrochemical polishing of metals

Most electrolytes for electrochemical polishing of steel are based on mixtures of solutions of orthophosphoric and sulfuric acids with the addition of chromic anhydride.

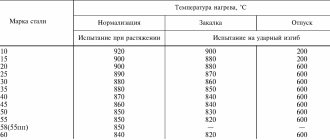

Electrochemical polishing electrolyte containing 500–1100 g/l phosphoric acid, 250–550 g/l sulfuric acid and 30 g/l chromic anhydride is universal for electrochemical polishing of all types of steel, including 12Х18Н9Т. Electrochemical polishing mode: temperature 60–800C, current density 15–80 A/dm2, time 1–10 minutes.

For electrochemical polishing of steel 12Х18Н9Т it is possible to use electrolytes containing surfactants. Metal removal during electrochemical polishing occurs more intensively in the electrolyte: phosphoric acid 730 g/l, sulfuric acid - 580–725, triethanolamine 4–6 g/l, catapine 0.5–1.0 at 60–800C, current density 20–50 A /dm2, time 3–5 minutes.

Chemical polishing of steel , in contrast to electrochemical polishing, is used less frequently, although it is easier to use and has a number of advantages. The solution for chemical polishing of steel 12Х18Н9Т contains (g/l): sulfuric acid 620–630, nitric acid 60–70, hydrochloric acid 70–80, sodium chloride 1-12, acid black dye 3M 3–5. Temperature 70–750C, time 5–10 minutes.

For electrochemical polishing of copper and its alloys, solutions of phosphoric acid with chromic anhydride are used: phosphoric acid 850–900 g/l, chromic anhydride 100–150 g/l, temperature 30–400C, current density 20–50 A/dm2.

Chemical polishing of copper is carried out in a solution (g/l) of phosphoric acid 930–950, nitric acid 280–290 and acetic acid 230–260 at room temperature (as opposed to electrochemical) for 1–5 minutes.

Electrochemical polishing of aluminum and its alloys occurs when the rate of dissolution of the oxide film on the surface exceeds the rate of its formation.

The electrochemical polishing electrolyte contains a mixture of phosphoric acid (730–900 g/l), sulfuric acid (580–725 g/l) and surfactant (triethanolamine 4–6 g/l, catapin BPV 0.5–1.0 g/l).

Electrochemical polishing mode: temperature 60–800C, current density 10–50 A/dm2, time 3–5 minutes.

For electrochemical polishing of aluminum with high silicon content, the following composition (mass fractions) is recommended: hydrofluoric acid 0.13; glycerin 0.54; water 0.33. temperature 20–250C, current density 20 A/dm2, time 10–15 minutes.

Chemical polishing of aluminum wrought alloys is carried out in a solution of phosphoric acid 1500–1600 g/l with the addition of ammonium nitrate 85–100 g/l at 95–1000C for up to 5 minutes.

Electrochemical polishing of nickel is carried out in an electrolyte: 1000-1100 g/l of sulfuric acid at 20-300C and a current density of 20-40 A/dm2 for 2 minutes.

The quality of electrochemical and chemical polishing of parts, like all galvanic processes, depends on surface preparation (see “First steps in electroplating, part 2.”) and the accuracy of technological operations (composition of electrochemical polishing electrolyte, process modes).

When performing electrochemical and chemical polishing processes, safety precautions must be observed (see “Safe electroplating”).

For the development of new electrochemical technologies, please contact us.

Attention! Electroplating training course! Find out more...

- "Anodizing aluminum."

- "Decorative coatings."

Electrochemical polishing of metals: description of the process, scope of application

A metal product can be given shine in various ways. To do this, it is not necessary to use special coatings; you can use the polishing method.

Process description

During electrochemical polishing, the treated metal surface acquires a mirror shine. Existing roughness is also reduced. The process goes like this:

- The part is considered an anode, that is, an electrode carrying a positive charge. It must be placed in a bath with a special composition.

- Another important component is the cathodes, which are necessary for the reaction to occur.

- As a result of exposure, a reaction occurs and dissolution occurs. It is uneven; first, the most noticeable roughness, which protrudes above the surface the most, is removed. At the same time, polishing occurs - the product acquires a mirror shine.

Removing noticeable large irregularities is called macropolishing, and smoothing out small defects is called micropolishing. If these processes occur simultaneously and evenly during processing, the product acquires shine and smoothness. It is also possible that shine will be obtained without smoothing or vice versa. The two types of polishing are not necessarily related.

Chemical polishing of metal results in the formation of a special film on the surface of the workpiece during the process. Its composition can be oxide or hydroxide. If it evenly covers the entire surface, this creates conditions for micropolishing. In this case, the outer part of the coating, located on the surface, continuously dissolves.

To be able to carry out micropolishing, it is necessary to ensure that a balance is maintained between continuous coating formation and dissolution; while working with the part, the layer thickness must remain unchanged.

This will allow the electrons of the metal being processed and the composition used to interact in the process without the danger of the metal product dissolving in an aggressive environment.

Macropolishing also directly depends on the film formed. It covers the product unevenly; on protruding irregularities this layer is thinner, so they dissolve faster due to the influence of current.

Care of the treated surface

To preserve the appearance and performance properties of treated stainless steel products, you must adhere to a number of rules:

- Do not use chemically aggressive substances for cleaning. Most types of dirt can be washed off well with warm water or a slightly alkaline (pH 9-11) soap solution. It is also permissible to use solvents that do not contain chlorine, with mandatory subsequent rinsing with water.

- Do not remove the protective film from the surface that complies with BA, 3N, 4N and DECO standards until the installation of the product is completed.

- Do not use abrasive sponges, brushes or cloths to remove dirt.

- Avoid contact of the surface with substances containing chlorine.

With proper and regular care, the surface retains its original appearance throughout its entire service life.