When riveting, press the handle of the riveter with one hand or two, it all depends on the type of tool (one-handed or two-handed). Make several movements with the handle, stop working when the protruding leg of the fastener comes off. During the work process, the following subtleties are taken into account:

When different models are considered, the diameter of the rivet body is first taken into account. If the fastener is massive, characterized by a large cross-section of the rod, use a more powerful tool. This need is due to the fact that you will have to put a lot of effort into the work process. Simple hand tools can be used to install rivets of minimal diameter. If you are deciding how to choose a device for installing rivets, consider 2 types:

The riveter is presented in 2 versions, differing in design and power: one-handed, two-handed. The latest model of hand tools is reinforced. It can be used to fasten metal with large rivets. For comparison, a one-handed riveter is designed to work with rivets with a diameter of up to 5 mm. The two-handed version copes with fasteners whose size reaches 6.4 mm. With its help you can perform large volumes of work.

Both types of riveter are often equipped with a rotating head. With the help of such a tool, fasteners are installed in hard-to-reach places. The head of the manual riveter rotates 360°. For comparison, simple models are equipped with a fixed head; they differ in price. The rotary manual riveter represents the group of the most expensive tools. When choosing, take into account the type of fastener and material, which will allow you to do the job efficiently. You also need to know the thickness of the workpiece joint.

Principle and features of the device

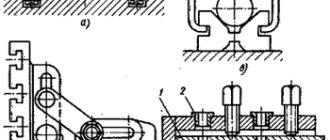

The operating principle of such devices is based on the transmission of force from the lever to the head. When a fastener is inserted into a hole, it is deformed under the influence of a manual riveter. As a result, the rivet remains on both sides of the material. To understand how the tool works, you need to study the range of fasteners. Rivets for manual riveters exist in 2 versions:

- monolithic;

- tubular.

The first option is used less frequently, since more advanced analogues have appeared - pistons or tubular fasteners. The monolithic version resembles wire. When it is inserted into the hole of the workpiece, under the influence of force, the rod is compressed and acquires a flattened shape on both sides. The operating principle of a manual riveter with pistons (hollow rivets) is different. You can find exhaust and threaded pistons. Such fasteners are a very reliable method of joining metal workpieces.

How to use a manual riveter correctly?

First of all, marking the workpieces is done. Without this, it will not be possible to connect the parts correctly. A hole is drilled according to the markings, the size of which had to be made 1 mm larger than the diameter of the rivet so that the fastener fits freely into it. If a hidden fastening is planned, you need to flare the hole. Then the head of the fastener secured with a manual riveter does not protrude much above the surface of the part. It will be recessed into the metal.

If a professional riveter is used, how to work with it? First of all, you need to find sleeves of different diameters on the surface of the tool. With their help, you can install fasteners of several sizes. Then you prepare the manual riveter with your own hands. Part of the fastening element (the one with the rod) is installed in the head; the head is located at the point of future fastening.

The rod should protrude at least 1 mm above the metal surface. If a manual riveter with a rotating head is used, adjust the tool. The movable structural element is installed in the desired position. Check the accuracy of the position of the tool relative to the markings on the metal surface. The manual riveter must fit snugly against the head installed in the hole of the workpiece. Only in this case can you obtain high quality fastening.

When riveting, press the handle of the riveter with one hand or two, it all depends on the type of tool (one-handed or two-handed). Make several movements with the handle, stop working when the protruding leg of the fastener comes off. During the work process, the following subtleties are taken into account:

- The length of the fastener depends on the thickness of the workpiece.

- To strengthen the connection, fasteners made of the same material as the parts being connected are used.

- The work is carried out with safety glasses and gloves, as the legs of the rivets may fly off.

- It is recommended to use a manual riveter equipped with a container for collecting fastener legs. Then the level of safety at the work site will increase: pieces of metal will not fly apart.

If there is too much clearance between the fastener and the workpiece, the quality of the fastener will deteriorate.

- It is necessary to firmly attach the joints to be connected and secure them.

- Drill a hole of such a diameter that it is a couple of millimeters larger than the diameter of the rivet.

- The rivet is inserted into this hole.

- A head is screwed onto the riveter, which corresponds in diameter to the rod.

- Then the riveter is pressed onto the rivet up to the sides of the body, the handles are compressed. In this case, the rod should come off. If this does not happen, the operation should be repeated.

What is a manual riveter

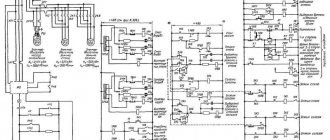

Riveters are these types of hand tools that are used to connect two metal workpieces up to 10 mm thick. The main purpose of the tool is to provide a permanent connection of sheet metal. The connection of metal sheets occurs through the through-mounting method. This tool is used when it is impossible to use welding and threaded connectors. Structurally, the tool has the shape of pliers and consists of the following components:

- Handle - sets the mechanism in motion by applying physical force of a person

- Clamping mechanism, which comes in two types - pull-out and threaded

- Head - the fixing part on which the consumable element is attached

This is a simple device that allows you to quickly and permanently connect sheet metal. Riveters are not only manual, but also pneumatic, electric and battery-powered, but the first type of tool is more popular. This is due to a number of advantages, the main ones being affordable price, ease of use and no need to use additional equipment.

Pneumatic, electric and battery-powered devices are more expensive and are intended to be operated by specialists. The main advantage of pneumatic, electric and battery-powered devices is that they do all the work, so the operator does not need to exert any effort. The relevance of their use arises in the case of using large diameter rivets.

This is interesting!

Manual riveters are also called riveters. They come in two types, and to find out what differences they have, let’s look at their parameters.

Popular models of riveters

Electric riveter ABSOLUT SK 1006

This model is used to work with blind rivets, the diameter of which varies from 3 to 5 mm. The tool is equipped with three replaceable nozzles with a diameter of 4; 3.2 and 4.8/5 mm. They can be conveniently placed directly on the riveter body using special fasteners.

Thanks to the powerful motor, the riveter has a fairly large pulling force of 8000 N. The ergonomic rubberized handle ensures convenient operation of the device.

Cordless riveter SKytools (Absolut) SK64

This riveter model is powered by two Li-ion batteries with a capacity of 4.0 Ah, which allow you to perform work for a long time without connecting to the mains. Three interchangeable heads and jaws included in the package allow the tool to work with rivets of various diameters (3.2–6.4 mm).

The brushless motor of the riveter increases its performance and makes it possible to extend the service life of the equipment. The light weight of the device (only 2.2 kg) and the rubberized handle will allow you to work comfortably for a long time without putting strain on your hands.

Riveter with rotating mechanism 0–360° (265 mm)

The lever riveter is used for joining sheet metal, metal profiles and sheet structures using rivets. To work in hard-to-reach places, a special head is provided that rotates at an angle of 0–360°.

An ergonomic handle with plastic pads will allow you to conveniently operate the tool, and the four removable heads included will make it possible to work with rivets of various diameters (from 2.4 to 4.8 mm).

Accordion riveter for high forces, up to 6.4 mm (300–745 mm)

This model is ideal for professional use. It allows you to fasten aluminum and steel blind rivets with great force (rivet pulling force exceeds 9000 N).

The tool works with rivets whose diameter does not exceed 6.4 mm. To release rivet frames, the design provides a spring-type lever.

Electric riveter ABSOLUT SK 1008

The electric tool allows you to work with blind rivets made of any material. The diameter of the fastening elements varies between 4–6.4 mm.

The retracting force of the riveter is extremely high - 16,000 N. This allows you to work with the hardest materials. Large tool stroke (up to 25 mm), three attachments and replaceable jaws included allow you to work with rivets of different diameters

Threaded riveter or nut riveter - its pros and cons

This is a special type of riveter, which is designed to work with threaded rivets. This type of tool provides a more reliable connection, and also allows it to be further strengthened through the use of bolts. The threaded connection ends up being permanent. The hole after the connection has an internal thread. The operating principle of threaded riveters is based on the fact that a threaded rivet is screwed onto the tool head (rod or threaded part). After this, a rivet attached to the tool is inserted into the hole, and the handles are compressed. When the handles are compressed, creasing or flaring occurs on the opposite side of the riveting, resulting in the formation of a head.

The design of the threaded riveter is shown in the photo. This type of tool is classified as powerful, and therefore the larger the size of the rivet, the more effort the operator must exert to make the connection. The advantages of such devices include high quality connections, which can be strengthened with a bolted element. In addition, the advantage is the ability to use rivets of different sizes, which also affects the quality of the connection. Such instruments have more disadvantages, and they manifest themselves due to the following factors:

- High cost of the tool: more than 2,500 thousand rubles

- The need to apply great physical effort, which increases depending on the diameter of the riveting

- Low connection speed, since the rivet must first be screwed onto the threaded tip of the tool, and after connection, the device must be unscrewed

- The high cost of not only the tool, but also the rivets

It is rational to choose a threaded riveter only when it is necessary to ensure a reliable connection of sheet steel, as well as in the presence of large diameter holes. The presence of holes at the joints allows the resulting structure to be fastened.

Material of manufacture

Hammer rivets can be made from various materials. For consideration are the most popular varieties.

Aluminum

This type of building parts is also often called exhaust. Their production is regulated by several domestic standards:

- with countersunk head - GOST 10300-80;

- with semicircular – GOST 10299-80;

- with flat – GOST 10303-80;

- semi-hollow - GOST 12641-80.

The size grid is quite varied: diameter - from 1 to 10 millimeters, length - from 5 to 45 millimeters. Moreover, these indicators may vary depending on the type of rivets (hammer, pull, threaded).

It is also important to note the fact that such aluminum parts can be made from several grades of material. Thus, the most popular raw materials are considered to be aluminum grades D18, V65, AMts, D19P, AMG 5P. They can also be duralumin.

Steel

Stainless steel parts occupy a special place among all hammer rivets. The production of these elements is carried out not only in Russia, but also abroad.

Most often, steel rivets are produced without any additional coating, and their sizes may vary. So, for example, the diameter of the cap can be from 1.8 to 55 mm, the height of the cap can be from 0.6 to 24 mm, the height of the entire element can be from 2 to 180 mm.

Due to such diverse indicators, these parts can be used for connecting sheets made of metal, for fastening facade plates to substructures, as well as for connecting metal structures with parts made of other materials.

Copper

Construction parts made from this material are characterized by several distinctive features:

- due to their antimagnetic properties, they are widely used in the radio industry;

- due to the fact that copper does not rust, rivets made from it are in demand in almost all areas (especially in cases where the materials fastened with them often come into contact with water and air);

- Copper elements are used to assemble apparatus and tools for the chemical industry, as they are quite resistant to the action of various substances manufactured artificially.

Most manufacturers produce copper rivets in standard sizes: from 2 to 8 mm in diameter.

Brass

Brass parts are quite flexible, but at the same time durable. And thanks to their appearance, they can perform not only their direct functions, but also serve as a decorative or design element. Most often, such elements are used in the industrial and instrument-making fields.

The length of brass rivets reaches 4–70 mm, and the diameter is 2–8 mm.

In order to choose the right crimp (mandrel) for brass parts with a semicircular head, you should choose crimps that have:

- long service life;

- uniform hardening;

- working ends are polished;

- Impact heads are inductively annealed.

Exhaust view of the riveter - what is it?

This is a tool whose operating principle is similar to threaded ones, only instead of a threaded rod tip, a cylindrical pin is used. These studs are mounted on rivets. The rivet is inserted into the tool hole and then positioned into the pre-drilled hole in the sheet stock. Impact on the tool handles leads to crushing of the rivet on the reverse side by pulling the pin outward. The pin is pulled out and a riveted joint is obtained.

The advantages of exhaust riveters include:

- Low cost, unlike threaded ones

- High speed of work completion

- Easy to install

- It turns out a secret connection

The only disadvantage can be considered that in this way it is impossible to connect sheet steel in which large-diameter holes are made. Such tools are intended for joining sheet metal with hole diameters up to 7 mm.

Types of tools by number of handles: one-handed and two-handed

In addition to the fact that riveters come in threaded and pull-out types, they also differ in the number of handles - one-handed and two-handed. A one-handed riveter is considered to be a tool in which one handle is movable and the other is fixed.

These are often exhaust devices that do not require much effort. They are designed for connecting rivets with a diameter of up to 6.4 mm.

Two-handed riveters are devices in which both handles are movable.

These are often threaded-type models, which require a lot of physical effort. They allow for riveted connections using rivets with a diameter of up to 14 mm.

Accordion riveters are a special type of tool that consists of one handle connected to a pressing mechanism in the form of an accordion or toad.

Such a tool also belongs to the category of traction tools, and the design cannot provide high clamping force. Accordion riveters are more expensive than conventional one-handed riveters.

All versions of hand tools are additionally equipped with swivel heads (except for the accordion), which allows riveting connections even in the most difficult to reach places.

The head of such tools has the function of moving up to 360 degrees, which greatly facilitates the use of the tool. However, the cost of such a device is 1.5-2 times higher than a conventional one with a fixed head. For home use, riveters with rotary heads are not needed, so it is not worth spending a lot of money just to have a multi-tool.

This is interesting!

Rotary rivet heads are used by specialists whose work involves the installation of sheet metal, as well as in the manufacture of structures, for example, mailboxes, etc.

The principle of operation and use of other types of riveters

Pneumatic riveters

You can use such riveters with much greater productivity. They have a higher speed of shooting rivets, as they work using compressed air. The main disadvantages are the high cost, design dimensions and weight. It is not advisable to use such a riveter for domestic purposes.

Electric riveters

Work with high installation speed and a wide range of rivet diameters. They have a high retracting force, for example, the Time Proof electric riveter - 8000 N. They do not depend on batteries. They have small dimensions and light weight. The installation speed of one rivet is 2 seconds.

Cordless riveters

They have even greater traction force than electric riveters - 15,000 N, light weight and similar installation speed. However, they depend on the battery charge. Ideal for fast work in places without access to constant power sources.

How to use an accordion riveter

The accordion riveter is less popular than the riveters listed above. It has small dimensions, a flat shape with an elongated barrel, which allows you to install rivets in hard-to-reach places.

Sources

Source - https://instrumentyvdom.ru/ruchnoj/printsip-raboty-ruchnogo-zaklepochnika Source - https://pro-instrument.com/ruchnoj/zaklepochniki-razbiraemsya-v-ih-raznoobrazii.html Source - https:// obrabotkametalla.info/instrument/pravila-polzovaniya-ruchnym-zaklepochnikom Source - https://foxremont.com/engineering/wiring/kak-rabotaet-zaklepochnik.html Source - https://remoskop.ru/zaklepochnik-jelektricheskij-vybor- nasadki-rabota.html Source - https://www.privarka-k97.ru/engine/glossary/zaklepochnik-dlya-rezbovyh-zaklepok.html Source - https://100krep.ru/zaklepochnik-ruchnoj-ustrojstvo-i- princip-dejstviya/ Source - https://td-fet.ru/2019/11/28/kak-rabotaet-zaklepochnik-chto-nuzhno-dlya-raboty-s-nim-i-kak-klepat/ Source - https: //tehpribory.ru/glavnaia/instrumenty/zaklepochnik.html Source - https://harpoon.pro/produktsiya/instrument/s-naznachenie-dlya_vytyazhnykh_zaklepok/tip_instrumenta-pnevmogidravlicheskiy/ Source - https://zlp.com.ua/blog /kak-rabotaet-zaklepochnik

What types of rivets are available?

The riveting method does not lose popularity, even despite the availability of different welding equipment. Not all materials can be welded, so the use of rivets has been and will always be relevant. Depending on the tool used, rivets or also called bosses are classified into the following types:

- Ordinary or classic - this is the simplest type of rivets, which have the shape of a fungus.

Designed for riveting two or more sheets of steel without the use of specialized tools. The principle of operation of such rivets is that the connection is made by crushing the head of the boss with a hammer - Semi-tubular - they look like a half-hollow rod.

The advantage of such equipment is that they do not require much effort to connect, but they have low strength, which is their disadvantage. They are usually used where there are small mechanical loads - Exhaust - they are also called embedded, tear-off and traction.

They are used in conjunction with blind riveters, and are often used not only for joining galvanized sheets, but also when installing fences made of corrugated sheets - Piston - used to ensure the connection of two parts where there is little or no load.

Commonly used on clothing as a decorative material - Threaded - they are also called nuts.

They are also intended for use in conjunction with a specialized tool - a thread riveter. This is the most reliable type of riveted connector

All types of rivets are used in different fields - mechanical engineering, auto repair, construction, manufacturing of sheet steel structures, tinsmiths, etc. Depending on the type of riveter, it is necessary to select the appropriate bosses. If you need to make a one-time connection using the riveting method, you will not need to buy a special tool. For this, classic rivets are used.

When choosing, you need to take into account that rivets come in different diameters, which affects the quality of the connection. Tie rivets are available in the following sizes:

- 2.4 mm

- 3 mm

- 3.2 mm

- 4 mm

- 4.8 mm

- 5 mm

- 6 mm

- 6.4 mm

Threaded rivets are also available in different sizes:

- M3

- M4

- M6

- M8

- M10

- M12

- M14

The larger the size of the rivet, the higher its cost, and, accordingly, the stronger the connection.

This is interesting!

Materials used to make rivets include aluminum, stainless steel, brass, copper and even steel.

Pull riveter: basic information

The principle of operation is almost the same as that of the threaded one. But the working part is a cylindrical pin. The pin is installed on a rivet, which is placed in the hole of the tool and then into the hole prepared in the workpiece. When the handles are moved, the rivet is crushed on the reverse side by the pin coming out. After removing the pin, a connected structure is obtained.

The positive characteristics of the model include:

- A simple diagram for installing fasteners.

- High performance.

- Possibility of creating a hidden fastening.

- The price is lower than analogues.

The disadvantage is that it is impossible to connect sheet material in which large holes are made - more than 7.0 mm.

Most importantly, these parts are divided into two more subtypes: nut and pull-out. The latter contain two parts: a tube and an interior, the so-called poisson or rod.

How does a riveter work?

A construction worker or a person involved in the loading and unloading of large metal structures and materials knows the answer to this question.

And for all other people interested in the mechanism of operation of this tool, the explanation is given below.

How the tool works

A riveter is a mechanical tool that allows you to quickly and accurately fasten together sheets of metal, the thickness of which is three millimeters.

With the same ease, it connects the profile and the corner with each other.

In order to carry out the riveting process, it is necessary to first do preparatory work.

Namely: drill a hole at the intended connection location.

Next, a rivet blank, previously inserted into the rivet gun, is inserted into the hole.

In this case, both ends of this workpiece must protrude from the planes or parts being fastened. When the handle of the tool is pressed repeatedly, a gradual flattening of this part occurs.

When its upper part is flattened as much as possible, the fastening on one side will already hold firmly, resting on the “thick” part.

After the riveting process is completed, the lower “tail” of the rivet part is bitten off with a special tool. You must always take into account the thickness of the parts being fastened. They need to choose the appropriate fastening size. For example, for metal sheets with thickness:

- Up to half a millimeter must be riveted with rivets with a size of 2.4 mm.

- Nine and a half centimeters – 3.2 mm.

- Twelve and a half millimeters - from 4 mm to 4.8 mm.

In this case, the hole for each rivet of different sizes must be drilled one millimeter larger than the diameter of the rivet. Accordingly, for a part with a width of 2.4 mm, a hole will be made two and a half millimeters thick, 3.2 mm - 3.3 mm, for 4 mm - 4.1 mm, for 4.8 mm - 4.9 mm .

The strength of a rivet of any size is determined not by its size, but by the quality of the metal, and the power of the resistance provided by the structural elements that were made with the help of rivets. If such pressure is high, the metal rivet gradually softens or deforms.

The operation of the tool is based on the effect of flattening the metal due to targeted pressure on a certain part of the piece (workpiece).

Rivets and working with them

An explanation of how a manual riveter works cannot be complete without considering the types of riveting tools (consumables - rivets).

There are two fundamental types of these parts: monolithic, that is, solid, and tubular.

The latter are usually called pistons.

Solid metal rivets are more like just a piece of thick wire and are used only for the hand-made type of riveting.

Much later than the beginning of the use of the described type, the now more commonly used pistons appeared - the second type (inside there is soft metal that is quite easily flattened when pressed).

Most importantly, these parts are divided into two more subtypes: nut and pull-out. The latter contain two parts: a tube and an interior, the so-called poisson or rod.

On top of such a simple design there is an enlarged part - a cap, which prevents the rivet from prematurely protruding or breaking. The poisson is inserted from the reverse side, that is, from the opposite side - where the head is located.

It turns out that rivets are inserted on both sides, subsequently flattened.

Riveters for threaded rivets

How does a riveter for threaded rivets work?

The principle is the same, but the peculiarity of the rivet material is that, after being screwed (hammered) into the structure, it is bitten off with a special construction tool.

And besides, you can choose any length this way.

If it comes to large volumes of rivet work, you need to take the so-called professional mechanism, which allows you to make a larger number of rivets with less effort.

A slightly more complex mechanism (besides the manual one) is called a pneumatic riveter. It works using compressed air.

Pneumatic devices require the use of a compressor. There are professional mechanisms that contain a hydraulic press in their design.

This type of riveter is called pneumohydraulic. As can be seen from the definition, it works thanks to two types of mechanisms that drive the main working element.

To select a tool for making a clear rivet joint between metal parts, including sheet metal and profiles, you need to take into account the thickness of the material being fastened.

More details about the pneumohydraulic riveter are presented in the video:

Noticed a mistake? Select it and press Ctrl+Enter to let us know.

A riveter is a tool designed for installing blind rivets. This is a fairly simple and reliable device. The connection created with its help is highly durable and resistant to vibration. In terms of strength, such fastening can be equated to spot welding. At the same time, riveters make it possible to connect various sheet materials, including plywood, and not just steel.

A riveter is a tool designed for installing blind rivets. This is a fairly simple and reliable device. The connection created with its help is highly durable and resistant to vibration. In terms of strength, such fastening can be equated to spot welding. At the same time, riveters make it possible to connect various sheet materials, including plywood, and not just steel.

How to use a riveter

Types of riveters

Although this tool has a very simple design, its implementation is still possible in various ways. Thanks to this, 4 types of riveters were developed:

- Mechanical.

- Electrical.

- Pneumatic.

- Hydraulic.

Mechanical

Mechanical devices in a reinforced two-handed version

They allow you to work with thicker rivets. If a one-handed tool is capable of tightening fasteners with a diameter of up to 4.9 mm, then a two-handed tool works with a thickness of 6.5 mm.

Electrical

Not long ago, electric riveters received a worthy competitor. A special attachment for a screwdriver works just as effectively and is cheaper. If the electric riveter itself can only work with fasteners, then buying a screwdriver is more profitable. You can put in it not only a rivet attachment, but also a drill or a bit for screws.

The electric riveter still has one advantage over the nozzle. Its design provides a special container for collecting torn tails from rivets. They do not need to be removed from the gun manually, which ensures high labor speed. In addition, they do not fall on the floor or ground, which eliminates the need for cleaning. Not every electric riveter has the function of collecting rods. Many, even expensive branded ones, do not have such a useful extension.

Pneumatic riveter

Pneumatic devices are very productive. Their mechanism ensures tightening when exposed to compressed air supplied from the compressor receiver. Working with such equipment is a pleasure, but there are some inconveniences. First of all, this concerns the need to use a compressor. A rather thick hose stretches from it, which hinders movement. In addition, the operating noise of the compressor can hardly be called quiet, and the rather short hose does not allow it to be placed far away.

Typically, pneumatic riveters are used in production. They are connected to a common compressed air supply line that runs throughout the workshop. At the same time, the noisy compressor is located far away. The quality of connections made by pneumatic tools is very high, which is why they are used to assemble interior parts of cars, buses, railway cars and other structures.

Hydraulic

Externally, such a tool looks like a pneumatic screwdriver. At the bottom of the riveter there is a reservoir with hydraulic fluid. The device is connected to a conventional compressor, like classic pneumatic devices. The supplied compressed air leads to the movement of hydraulic fluid, which triggers the mechanism for tightening and then unscrewing the stud.

When using a pneumatic-hydraulic riveter, you should pay attention to the settings. This tool requires precise adjustment. If the rod is set incorrectly, the device begins turning out the stud before the threaded sleeve reaches sufficient deformation.

Tips for using riveters

When using the tool, you need to pick up fallen rivet rods, since at the point of breakage they acquire a rather sharp edge, which often digs into tires. It can also get caught in shoes and cause injury. Some rivets have steel tails, which can be collected after work using a magnet.

There are cases when, after reaching a sufficient level of deformation of the fastener sleeve, the tool cannot pull out its rod. If this happens, you can break it manually or bite off the tail with wire cutters.

When choosing a specific model of a hydraulic riveter, it is necessary to take into account the following criteria:

Riveter operating principle of the tool

The operating principle of all types of devices is the same, but there are some differences. If you are using a manual riveter for the first time, it will be useful to learn about how it works.

The main operating principle of a manual riveter is based on the transmission of force from the lever mechanism to the head. To begin with, a consumable element is inserted into a pre-prepared hole. To ensure compression of the rivet, a compression mechanism is used, through which deformation occurs. As a result, the consumable element, due to the protrusions (skirts), ensures a reliable connection of the sheet material. How different types of riveters work, we will consider in detail below.

Threaded riveter, principle of its operation, step-by-step instructions

The most reliable connection is ensured using threaded devices. The principle of their operation is quite simple, but it causes some inconvenience - each rivet must be screwed onto the end of the tool before use. The instructions on how threaded devices work are as follows:

- Initially, it is necessary to drill a hole of the appropriate diameter in sheet steel - from 3 to 14 mm or M3-M14

- Install a threaded tip (rod) into the tool head of the appropriate diameter.

- Screw the threaded boss onto the tip until it stops.

- Install the rivet into the holes of the elements to be connected

- Perform riveting by acting on the levers (bringing them together)

- Next, to disconnect the tool from the resulting connection, you will need to unscrew it

- After this, the connection is ready for use, and a bolt of the appropriate diameter can be screwed into it

For clarity, below is a video that shows what a threaded tool is and how it is used.

Principle of operation

A riveter is a type of installation tool that allows you to connect parts together in cases where certain circumstances prevent you from using the classic installation method. Using rivets , you can reliably connect parts, providing them with increased resistance to various types of deformation.

The point of using rivet guns is to flatten the edge of the rivet in a special way so that it can be securely fixed in the mounting hole. Moreover, this work must be done as carefully as possible, without damaging the internal threads.

Using a riveting device, you can fasten together both metal elements and sheets of plastic in combination with other materials. When performing this type of task, it is recommended to use a small washer to evenly distribute the force applied.

The peculiarity of threaded rivets is that they allow not only to fasten several sheets of material, but also to subsequently install bolted fasteners in the place where they are located. This type of connection can also be made on the front side of an already painted wall or any other surface.

The reliability of the connection depends on various factors, not least of which is the outer diameter of the rivet. The larger the fastener, the more reliable and stable the connection between the materials will be. But there is one drawback associated with this point: it is much more difficult to install large fasteners. Often this requires the use of a powerful professional tool.

Modern models of riveters can work with materials with a thickness of 0.3 to 6 mm. To connect them, you can use rivets with different types of heads, including countersunk ones.

Riveter accordion toad principle of its use

The principle of operation of the accordion riveter is quite simple and uncomplicated. When using it, it is important to consider that there must be enough free space for riveting. The length of the tool in the extended position reaches 80 cm. The principle of using the tool is as follows:

- First you need to install the rivet into the device with the pin inward.

- Fully release the handle

- Install the rivet into the hole

- Compress the accordion-shaped mechanism

- Remove the remaining pin from the tool chuck

Detailed video description below.

The advantage of the toad is that the operator needs to exert less effort than when working with a tool that has one movable and fixed handle.

Features of working with the tool

To quickly learn how to handle a riveter and easily perform reliable connections of elements, it is enough to learn a simple procedure for working with it:

- The first step is to select rivets of the appropriate diameter. Most often, fasteners with a diameter of 2 to 4 mm are used. When working with large-diameter rivets, you will need a specialized tool, which is best suited to a pneumatic or pneumatic-hydraulic riveter.

- A hole is drilled in the working surface taking into account the outer diameter of the rivet. When using fasteners with a countersunk head, it is often necessary to first countersink the surface, which makes the rivet invisible.

- Before work, you should install a rod with a thread of the required diameter in the rivet gun and screw a threaded rivet onto it. It is important to ensure that the rivet is securely fastened, otherwise it may come loose during installation.

- It is necessary to insert the fastener into the hole until it stops, making sure that its head is tightly adjacent to the surface of the material.

- The riveter is positioned strictly at right angles to the surface and begins to exert force on the handle. During operation, the rod will begin to move inside the tool, providing the necessary pressure to deform the fastener.

- After installing the rivet, you should unscrew the threaded rod from the socket and make sure that the rivet is seated in the hole correctly. This can be judged if there are no distortions and gaps, as well as thread deformation.

How to remove a rivet

Sometimes there are situations when the fastener was installed incorrectly or in the wrong place and needs to be removed. This can be done in several ways.

In the first case, you will need a drill with a drill slightly larger in diameter than the internal thread size. When installing the rivet, you need to monitor the process and promptly change the drill to a larger one. When the problem is solved, the fastener will be divided into two halves - the head and the inner part.

You can also remove incorrectly installed fasteners by grinding off the head. A drill will also help in solving this problem, and when the head is destroyed, all that remains is to knock the rivet out of the seat.

Installation nuances

Before installing the fastener, special attention should be paid to choosing its length. To correctly calculate this rivet parameter, you need to add the thickness of the material and the diameter of the rivet. For example, if the cross-section of the fastener is 4 mm and the thickness of the material is 2 mm, then to make a reliable connection it is recommended to use a rivet with a diameter of 6 mm. After installation, it will “sit” securely in the seat and will allow you to screw a bolt in if necessary.

It is no coincidence that the riveter is very popular, because it has such advantages as ease of use and practicality. Although home craftsmen very rarely share their impressions of the practical use of this tool in everyday conditions. In many construction stores, a riveter is a rarity, not to mention fasteners for it, which many are forced to order online.

This tool has only recently become popular among the population. Most often it is used to perform reliable installation of license plates. It is also perfect for installing fences made of sheet materials, as well as mounting electricity metering devices on thin walls of panels. This installation method has surpassed in popularity even such a common type of fastening as welding, due to its reliability. And this is not surprising, since even under conditions of high loads, if the rivets begin to fail, it will not happen to all of them at the same time.

How to use a regular riveter - rules and recommendations

If you have an ordinary model of a riveter, then the instructions for using it are identical to using an accordion tool. A rivet is installed in the hole of the tool, having previously selected the required cartridge (depending on the size of the stud). Afterwards, the boss fixed in the gun cartridge is compacted into the preliminary hole of two sheet materials. By acting on the handle, the wall of the boss is compressed by pulling out the inner pin with the tip. The wall on the reverse side is flattened, thereby making a reliable connection. If protruding parts of the boss remain, they can be removed with pliers.

A diagram of the operating principle of a manual riveter is shown in the photo below.

Experts recommend a clear approach to the choice of rivets. The effectiveness of the connection depends on their choice. If the length of the boss is less than the thickness of the workpieces to be joined, then in the end the connection will not work. The length of the boss itself should be 2 times the thickness of the parts being connected, but no more.

How to choose a riveter: manufacturers and prices

When choosing a specific model, many rely on prices. But the spread is very wide - there are very cheap ones and almost identical in appearance, but many times more expensive. Even ten times more expensive. It’s worth saying right away that even for one-time work, buying a very cheap riveter is too risky. It may not work at all or work through the stump-deck.

If you only want to rivet a fence, for example, even then you will have to install hundreds of rivets. If you have to disassemble the tool after every 2-3 rivets, you definitely won’t like it. To choose a riveter that works well, look at the average price range.

- Stanley MR 99. Stanley is the oldest American company.

- NOBUS. Inexpensive tool, works reliably.

- Gesipa. A well-known company, but not everyone praises it. There are definitely cheaper ones that work at least as well.

- YATO copes with steel rivets better than Chinese ones with aluminum ones.

- To estimate the price range:

- NWS is a German company. The quality of the instrument is excellent.

- Topex. In some models I liked the ability to move the “spout” 90 degrees. Convenient if you have to work in hard-to-reach places.

- KRAFTOOL. All the tools are good and so are the riveters.

If you plan to use a riveter in professional activities, you need to choose a more expensive one. The company - at your own discretion, but from the category of professional or semi-professional models. Perhaps they do not differ structurally, but they have a longer resource and service life. That is, they are made more reliably and efficiently. And this explains the difference in price - more expensive/high-quality materials were used.

How to choose a quality device

Why does the question of how to choose a riveter remain relevant? After all, despite the fact that the tool belongs to the manual category, it has a fairly high cost. To save money, many buyers decide to take a desperate step - they choose cheap models. As a result, the device fails very quickly, and it turns out that the money was wasted. You should also not buy expensive models, since it turns out that the tool will simply lie on a shelf in the garage most of the time. What to consider when choosing a manual riveter - there are the following nuances:

- Device body material - do not buy plastic models.

No matter how colorfully manufacturers and sellers describe them, such instruments are toys that are only suitable for children. You need to choose devices only from high-quality steel. Reputable manufacturers indicate the type of steel used in the technical description - How much does the tool weigh? A good thread riveter has an appropriate weight, which allows it to be used for connecting rivets with a diameter of 12-14 mm

- Equipment - usually good and high-quality devices are sold complete with replaceable heads, as well as consumables.

In addition, the devices are located in special plastic, metal or wooden cases, which simplifies not only their storage, but also transportation - The manufacturer is very important, since today different manufacturers with unknown reputations appear on the market.

It is not recommended to tempt fate, so choose riveters from manufacturers such as Kraftool, Matrix, Gross, JTC, Stayer and others

This is interesting!

If you plan to use the tool frequently, then preference should be given to reinforced riveters.

They are more expensive than regular ones, but last longer and are designed specifically for long-term use. Drawing a conclusion about what types of manual riveters there are, it must be said that tie-type models are quite sufficient for home use. A threaded tool can also come in handy, but only if you plan to work with sheet steel. Proper storage and use will increase the service life of even a budget tool model.

Rating of the best manual riveters of 2022

Among the models of manual riveters for the home, users especially highlight inexpensive but reliable tools with additional attachments. They are universal in use and cope with most tasks.

Topex 43e791

The manual riveter made of cast steel has increased strength and durability. Suitable for riveting metals, plastics and other materials, works with fasteners up to 4.8 mm. The weight of the tool is 750 g; additional attachments are supplied in the kit.

The average price of a Topex riveter is 1200 rubles

JTC-5821A

Inexpensive threading tool suitable for use at home and in workshops. Comes with 3-6mm rivets, very easy and reliable to use. Supplied with a metal case with compartments for equipment and fasteners. Made from reinforced alloy for durability.

The average price of a JTC manual riveter starts from 2,600 rubles

Rapid RP100 Heavy Duty Press

Precise and powerful hand tools provide quality work with minimal effort. Capable of interacting with soft and hard pins up to 4.8 mm, even installs fasteners made of durable stainless steel. The riveter itself is made of light aluminum alloy and equipped with a comfortable soft handle. The housing has a pin receiver and a built-in key socket.

The average price of the Rapid RP100 riveter is 2000 rubles