home

About company

Directory

Stainless steel pipe

Rolled pipes made from high-alloy steels have unique performance characteristics: stainless steel pipes made of 12Х18Н10Т steel (one of the most common grades of stainless steel) can be used at temperatures from −196 to +600°С. In highly aggressive environments, the operating temperature for stainless pipes reaches + 350°C; in nitric, phosphoric, acetic acid, in solutions of salts and alkalis, the average annual corrosion rate is only 5-20 microns per year (µm/year). Such properties, combined with wear resistance (the tensile strength of steel 12Х18Н10Т is 510 MPa), make stainless pipes indispensable in the construction of industrial facilities, in aviation, mechanical and instrument making, petrochemical and chemical industries, pharmaceutical and food production.

Alloyed pipe products are distinguished by production method:

- cold and heat deformed stainless steel pipes GOCT 9940-81;

- hot-rolled stainless steel pipes GOCT 9941-81;

- electric welded pipes made of corrosion-resistant steel grades GOCT 11068-81.

Depending on the class, the scope of application of stainless steel pipes has distinctions: cold and heat-deformed pipes are distinguished by high manufacturing precision and a mirror (shiny) surface, due to which they are used for the production of furniture and interior decoration; hot-rolled steel is used for installation of process pipelines, equipment production, and construction; electric welded pipes are not intended for operation under conditions of high pressure (design working pressure up to 16 MPa), as a result of which they are not used for critical pipelines.

Diameters of stainless steel pipes - GOST and size table

Pipes made of stainless steel alloys are now actively used for the installation of heating, water supply and sewerage systems. By choosing the diameters of stainless steel pipes according to a special size table, you can successfully select such products to solve various problems.

For each type of stainless pipes there are maximum permissible deviations from the parameters defined by the relevant standards

All pipes for the production of which stainless steel is used are produced in strict accordance with the regulatory document. GOST stipulates not only the chemical composition of the material for their manufacture, but also their production technologies, sizes and assortment.

Classification options

The entire range of pipes made from stainless steel is divided into several categories. The parameters by which this division is carried out are:

- design features (suture and seamless);

- production technology (cold rolled, cold drawn and hot rolled);

- cross-sectional shape (round and profile);

- wall thickness (thick-walled and thin-walled).

Stainless steel pipes of various sizes are actively used for arranging communications through which cold and hot water is transported, as well as for installing sewer systems. Such pipes, which have a significant diameter, are successfully used for the installation of main oil and gas pipelines.

The ratio of outer to inner diameter for thick-walled stainless steel pipes is in the range of 0.05–0.1

The high popularity of rolled pipes made of stainless steel is explained by a whole list of its advantages:

- exceptional durability;

- possibility of operation under high pressure;

- resistance even to significant temperature changes;

- high plasticity;

- resistance to corrosion, demonstrated even during operation in conditions of constant exposure to aggressive environments.

It should also be noted that the minimum service life of stainless steel pipes is 10 years.

Installation Tips

When assembling metal structures from stainless steel profile pipes, the parts are connected by welding or fastening with clamps. The elements can be fixed using electric arc, gas or resistance welding.

When arc welding, it is important to choose the right electrode. The quality of the weld depends on its diameter. If it is too thin, the welding process will be interrupted; if the electrode cross-section is too large, a thin-walled pipe can be burned.

Electric arc welding should not be performed in open areas. Such work is carried out in special premises. In this case, the ends of the parts to be welded must first be cleaned and degreased.

The contact type of welding forms a welding seam of increased reliability. There are no restrictions on ambient temperature and other weather conditions for its use.

General recommendations for carrying out any type of welding are as follows:

- When choosing a welding temperature, you should proceed from the thickness of the metal, since profile products are more susceptible to deformation than round ones.

- To maintain the internal clearance of the profile, it is necessary to prevent molten metal from entering the stainless steel profile pipe.

- When performing welding, it is necessary to carefully check the geometric coincidence of the ends of the parts being welded so that distortions do not occur in the metal structure.

Alternative to profile pipes

The use of profile stainless pipes is not always technically and economically feasible. It's not cheap. In addition, it cannot be used for laying pipelines transporting liquid and gaseous media under high pressure. This is especially true for electric-welded products with a seam: due to the presence of different angles inside such pipelines, blockages can quickly form at the bends. For the installation of such communications, only round pipes are used. And it doesn't have to be stainless steel.

Modern pipe products made of reinforced polypropylene are not inferior in a number of technical characteristics to stainless steel, but are much cheaper. Profiles made of plastic are more often used as ventilation ducts. They are available in white, so they fit more harmoniously into the interior of kitchens and bathrooms.

An alternative option for constructing a chimney could be a galvanized sandwich pipe. Galvanized steel is just as fire-resistant and fireproof as stainless steel, but is less resistant to corrosion from condensation. But the price of galvanized sandwich chimneys is much lower, as is the cost of installation. And in order to slow down the corrosive destruction of the metal, the surfaces of the chimney are coated with a special heat-resistant paint for galvanizing.

Aluminum pipes are also of good quality. They are lightweight, corrosion-resistant, and are a good option for making indoor decorative elements, furniture parts and other lightly loaded structures.

Main varieties

GOST also stipulates the range of stainless steel pipes, which includes the following products:

- used for transporting liquid and gas media – water and gas pipelines;

- coated with a special anti-corrosion compound;

- characterized by a slight wall thickness and having threads at the ends (such steel pipes, the diameters of which can be different, also have a reduced weight);

- produced using welding technologies and having longitudinal seams;

- seamless, made using hot-rolled technology.

It is worth dwelling in more detail on each type of stainless pipes, the range and diameters of which are specified by GOST.

The diameter of pipes of this type, as indicated by GOST, can vary within a fairly wide range: 15–50 mm. Depending on the pressure under which they are intended, such stainless steel pipes are divided into light, standard and reinforced.

Parameters of water and gas pipes

GOST stipulates that the ends of water and gas pipes must be cut at an angle of 90°, and the welds on their surface must be completely welded and sealed. In accordance with the standard, there may be minor chips on the surface of such steel pipes, but in general their walls should be smooth and free of cracks.

Pipes with anti-corrosion coating

Such pipes, which are also listed in the stainless steel product range, are distinguished by the fact that their surface is coated with zinc, which provides additional corrosion resistance. In accordance with the regulatory document, they should not have areas not coated with zinc, coating blisters, burrs and other defects.

The dimensions of the thread, if applied to the ends of such pipes, should not exceed 10 percent of the length of the product itself.

Thin-walled pipes with threads

These pipes, produced in various standard sizes, are used in cases where it is necessary to carry out repairs or change the design of the pipeline. Products of this type, which make it possible to obtain reliable and tight connections, are not thick-walled and are not produced with large cross-sectional dimensions.

Parameters of light series pipes manufactured for threading

There are no welds on the surface of hot-rolled pipes, which can be thick-walled, which gives such products high tightness and allows them to withstand even very significant pressure. These products, the standard sizes of which are also specified in the assortment, are distinguished by smooth walls and a minimal coefficient of thermal expansion.

The most common areas of application for such pipes, the sizes of which can vary quite widely, are:

- installation of pipelines for supplying cold and hot water;

- arrangement of sewer systems;

- installation of heating networks and communications for other purposes.

Dimensions of seamless hot-formed stainless steel pipes

It should be borne in mind that both thin-walled and thick-walled pipe products produced by welding can be used to supply water used for technical purposes, and not for drinking or cooking.

Advantages and disadvantages

Stainless steel profile pipes have the following qualities and advantages:

- High strength characteristics with low weight.

- Due to the flat edges, they are more convenient to install than round profile pipes.

- Resistant to temperature changes.

- The ability to withstand any type of load (transverse, tensile and torsional), since they are distributed to the walls at right angles.

- High corrosion resistance, long service life.

- Heat resistance.

- Good weldability.

- Aesthetic appearance.

- Wear resistance.

- Frost resistance.

- Completely inert to chemical influences.

The disadvantages of profile products include:

- Relatively high cost.

- Inability to use for water supply pipelines and heating system wiring.

Standard sizes

The list of standard sizes of stainless pipe products includes the following parameters:

- nominal diameter - internal diameter, which can vary between 10–150 mm (the larger this parameter, the higher the permeability of the pipes);

- thread sizes (in accordance with the requirements of the standard, this parameter can vary in the range of 3/8–6 inches);

- outer diameter, which, taking into account the size of the weld, can vary in the range of 17–156 mm;

- The outer diameter of steel pipes, which are made without the use of welded joints, is 16–159 mm.

Main dimensions of stainless pipes

Stainless steel pipes, depending on their type, are produced in accordance with the requirements of various regulatory documents:

- GOST number 3262-75 – water and gas pipelines;

- 10705-80 – obtained by welding;

- 20295-85 – intended for laying main pipelines.

Each of the above regulatory documents contains tables that indicate the range and standard sizes of such products.

Socket connection

To connect sewer and water lines, a socket connection is used. To do this, a special expansion is made at the ends of the pipes, into which the other end is inserted. Connection density is ensured by different methods:

- Sealing with cement. This method is used when connecting sewer systems. First, the gap is sealed using tow, and then cement mortar is poured.

The bell joint provides a reliable connection, but in some cases a so-called additional seal is installed, especially for metal sewer systems.

Brands and guaranteed parameters

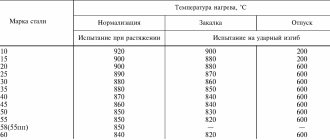

The tables contained in the regulatory documents for pipe products made from stainless steel contain various parameters. In particular, from these tables you can take information about the grades of steel used for the production of such pipes.

Permissible deviations from dimensions must be within the values specified in the table

Knowing the brand of material from which the pipe is made allows you to get an idea of which of its parameters are guaranteed. These include in particular:

- A – mechanical characteristics of the steel used;

- B – its chemical composition;

- B – the relationship between the chemical composition and mechanical properties of the alloy used.

Diameters of stainless steel pipes: GOST and OST

The diameters of stainless steel pipes can be found in State and Industry standards. They can be very different, ranging from small ones of a few millimeters to large ones (several meters). Stainless steel pipes are used in a wide variety of sectors of the national economy and industry, which is why the range in size is so huge.

If you require a specific size, we recommend that you first refer to the regulatory documentation. Here is a list of basic standards that can serve as references when finding the required diameter:

GOST 14162-79. Small steel tubes (capillary) - determines the technical conditions for manufacturing and the range of capillary tubes made of stainless steel. The sizes of these products are very small.

The main properties of round pipes

The main parameter by which the preparatory selection of pipes for implementation is carried out is the diameter. In the assortments for round pipes, the following types of diameters are distinguished:

- The external diameter is the main size in determining the ability of a product to be used in various areas of industry and everyday life.

- The internal diameter characterizes the throughput of the pipeline. The nature of the flow and loss of pressure when water moves depends on the size of this size.

- Conditional diameter. This size characterizes the approximate capacity of the pipes and may be similar for different sizes. For example, for standard sizes 45x2.5 and 43x1.5, the nominal diameter is DN=40.

- Nominal diameter. Calculated value when selecting the required parameter.

Availability in GOST is not a guarantee...

We want to clarify right away. As you can see, the number of different sizes in these standards is very large, but the number of factories that manufacture pipes is not so huge. In addition, any plant, first of all, cares about the economic efficiency of its production and tries to produce popular types of rolled metal.

Obviously, if the plant has all the above pipes in its assortment, it will be forced to curtail production. This will happen because a huge part of the produced goods will remain in warehouses unclaimed. In the real sector, only a limited number of diameters are used. And this can cause certain difficulties when searching.

Therefore, the presence of a size in the State or industry standard does not at all mean that it is available from suppliers. A size may be indicated in GOST but not be available on the market at all due to lack of demand.

The opposite is also true: the absence of a size in the standards does not mean that it is not on the market. The standards do not prohibit the production of pipes of intermediate diameters and thicknesses. Manufacturers often make such pipes because there is a demand for them and it is profitable.

Therefore, we want to give you one piece of advice: do not focus on standards when searching. Focus on the market itself and the capabilities of a specific supplier.

Non-standard diameters

Some sizes are much easier and cheaper to find on the market than others. For example, pipes with a diameter of 10, 20, 50, 100 mm are very easy to find. They are available from many suppliers. But if you're looking for a custom-sized stainless pipe, you may run into problems. It all depends on the demand and method of production of rolled products .

Hot-deformed and cold-deformed pipes of non-standard and unpopular sizes are much more difficult to find than electric-welded ones, since hot rolling technology requires special expensive equipment. Electric-welded pipes are much easier to produce, and therefore, even if you do not find the required size, it can always be made to order.

Making a batch to order can be a good solution if the required batch is quite large. However, this still involves additional difficulties: it is necessary to negotiate with the manufacturer and approve documents.

Therefore, we recommend that you avoid unpopular sizes where possible. This will save you from a lot of difficulties in the future. Well, if this fails, call our company. We will always help you.

To summarize we can say:

- Industry standards do not indicate all possible sizes of rolled products. What is specified in the standards and what is on the market are completely different assortments.

- The availability of a specific diameter on the market depends on many factors and, above all, demand.

- Custom electric-welded pipes are much easier to find than hot-rolled or cold-rolled pipes.

- If you can refuse to use unpopular diameters in your project in favor of more popular ones, then it is best to do so. This will save you a lot of time and money.

- If you still really need a non-standard or unpopular size, please contact us. We have extensive connections with manufacturers and other suppliers. We will try to help you in every way we can.

METAL TENDER

– metal trading system for buyers and sellers. All information on the site is for informational purposes only. For accurate data, please refer to the relevant GOST.

Our website uses cookies to improve your experience on the site. When you visit this website, you consent to the use of cookies in accordance with this cookie notice.

Add rolled metal to your request

The more detailed you fill out this form, the fewer additional questions our specialists will have and the easier it will be to find the required rolled metal.

Stainless steel pipes

| Seamless cold- and heat-deformed stainless steel pipes |

Stainless steel pipes

used in the chemical, petrochemical and pharmaceutical industries and are designed for transporting corrosive media.

Stainless steel pipes

are made by hot pressing from hard-to-deform corrosion-resistant, heat-resistant and heat-resistant steels and alloys.

Stainless steel pipes

supplied in length:

Stainless steel pipes

in a batch of unmeasured length, 5% of pipes not shorter than 0.5 m are allowed. Pipes are supplied in a heat-treated state.

Stainless steel pipes

made from corrosion-resistant steels, the chemical composition of which must comply with GOST 5632-72:

Stainless steel pipe range

unmeasured length from 1.5 to 9 m;

| ||||

hot pressing in combination with subsequent etching ensures high surface quality (roughness Ra - 1.1-1.6 microns).

| ||||

| Outer diameter, mm | Wall thickness, mm | Pipe length, m (no more) | ||

| 5 | 0,2-1,0 | 5-7 | ||

| 6-7 | 0,2-1,5 | 5-12 | ||

| 8-9 | 0,2-2,0 | 5-12 | ||

| 10-13 | 0,2-2,5 | 5-12 | ||

| 14-17 | 0,2-3,0 | 5-12 | ||

| 18-19 | 0,2-3,5 | 5-12 | ||

| 20 | 0,2-4,0 | 5-12 | ||

| 21-24 | 0,3-4,0 | 6-12 | ||

| 25/27/28 | 0,3-4,5 | 6-12 | ||

| 30/32-35 | 0,3-5,5 | 6-12 | ||

| 36 | 0,4-5,5 | 6-12 | ||

| 38/40/42/45 | 0,4-6,0 | 6-12 | ||

| 48/50 | 0,4-7,5 | 6-12 | ||

| 51/53/54/56/57 | 0,5-7,5 | 6-7 | ||

| 60 | 0,5-8,0 | 6-7 | ||

| 63/65/68/70/73/75 | 1,5-8,5 | 7 | ||

| 76/80/83/85 | 3,0-8,5 | 7 | ||

| 89/90 | 4,0-8,5 | 7 | ||

| 95 | 4,0-5,0 | 7 | ||

| 108-530 | 4,0-28,0 | on request |

Seamless hot-deformed pipes made of corrosion-resistant steel

Assortment

| Outer diameter, mm | Wall thickness, mm | Length of measuring pipes, m (no more) |

| 76 | 4,5-10,0 | 7-6 |

| 83/89 | 4,0-12,0 | 7-4 |

| 95 | 5,0-12,0 | 7-4 |

| 102/108 | 5,0-12,0 | 7-5 |

| 114 | 5,0-12,0 | 7-3 |

| 121/127 | 5,0-26,0 | 7-3 |

| 133/140 | 5,0-26,0 | 7-3 |

| 146/152/159 | 8,0-26,0 | 8,5-3 |

| 168 | 7,0-25,0 | 8-3 |

| 180 | 8,0-28,0 | 8-3,5 |

| 194 | 9,0-28,0 | 8-3,5 |

| 219 | 10,0-28,0 | 8-3,5 |

| 245 | 11,0-25,0 | 8-4,5 |

| 273 | 11,0-20,0 | 8-4,5 |

| 325 | 11,0-20,0 | 6,5-5 |

Electric-welded pipes made of corrosion-resistant steel

General characteristics of stainless steel pipes

Stainless steel pipe is a hollow and straight profile of different sections. Taking into account the cross-sectional shape, profile and round products . Today, stainless steel pipes are manufactured using one of three methods. The first involves the manufacture of products by rolling up a strip with further soldering of the joint with copper. The result is a soldered, rolled stainless steel pipe.

Seamless pipe rolling is produced using centrifugal casting or cold or hot deformation. In this case, the production of welded pipes occurs using plasma or laser electric welding. During this, the stainless steel is exposed to inert gases or high-frequency currents. This method makes it possible to make the cheapest products, since the manufacturing process does not take much time. In each case, the stainless steel is pre-hardened. This is required so that the raw material loses a high level of hardness and strength during manufacturing.

Advantages of stainless pipes

Stainless steel pipes have many advantages. The main thing is that a stainless product has increased resistance to corrosion . And since it contains 20% chromium, it also provides excellent resistance to most negative environmental factors. Due to this, such rolled metal has an almost unlimited operating time. It can be used for more than 400 years.

Stainless steel products can easily be restored to their aesthetic appearance, since steel is a homogeneous composition. The resulting scuffs and scratches can be easily polished and sanded, giving these pieces an attractive finish. This pipe product combines perfectly with modern finishing materials. The price of rolled pipes is relatively inexpensive, and the range has been very wide for many years.

How are they produced?

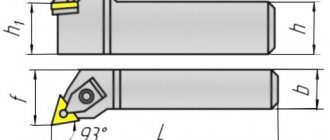

Profile pipes are made from stainless steel using two technologies:

- The finished product is formed from a blank in the form of a metal strip (strip).

- A round pipe is profiled.

Strip manufacturing technology

The method makes it possible to obtain a profile pipe made of stainless steel with a seam. Welding of sheet steel strips is carried out using high-frequency electric welding, laser or plasma welding in a conventional environment, as well as tungsten electrodes in inert gas (TIG welding). The production process itself is as follows:

- The strip is cut from stainless steel sheets on special rolling mills and fed into a sheet bending mill.

- The metal strip is formed on the rollers of a sheet bending mill into a round blank with open edges.

- The edges are welded using one of the selected types of welding. Excess metal (grant) is removed with cutters.

- The workpiece is calibrated on rollers to a given profile shape.

- The finished product is cut into pieces of the required length.

To relieve internal stress, the stainless steel profile pipe is subjected to heat treatment (annealing). The workpiece is heated to +550…650 °C for 60–90 minutes, followed by gradual cooling (tempering). As a result, it becomes stronger and more durable.

Profiling

This technology for the production of profile stainless pipes involves the use of seamless cold- and heat-deformed pipes of round cross-section as initial blanks. They acquire the desired profile shape when passing through calibrating rollers in a cold or heated state.

Next, the cold-deformed profile pipe is subjected to heat treatment. At the last stage, the rolled metal is cut into pieces and undergoes surface quality control, tensile tests, and geometric dimensions testing.

Popular range of stainless steel pipes

Stainless steel pipes according to GOST-9941 81

This standard, certified in the mid-1980s, describes seamless cold- and heat-deformed tubular products made from general purpose corrosion-resistant steel. The diameter (outer) of these pipes varies from 5 to 273 mm , their walls have a thickness of 0.20-21 mm.

Pipe rolling products are manufactured in standard (5-7 meters), as well as multiple measured and unmeasured lengths. The standard is quite loyal to consumer demands for corrosion-resistant products, therefore it allows their production with a length of 0.5-15 m. However, the production of all non-standard pipe products by the plant must be previously agreed with the customer.

It must be said that in one batch of manufactured products of unmeasured length there may be pipes:

- 0.5-0.75 meters (walls less than 0.5 millimeters);

- 0.75-1.0 meters (walls 0.50-1.0 millimeters);

- 0.75-1.5 meters (when their wall is specified as thicker than 1 millimeter).

In a batch of rolled pipes with these dimensions there can be no more than 6%. All corrosion-resistant pipes are divided into high-, normal- and high-precision products. Taking into account this indicator, the following deviations (maximum) of pipe products in wall thickness are permissible:

- 0.05-0.15 millimeters (usual accuracy);

- 0.03-0.10 millimeters and from -11% to +12.4% (increased accuracy);

- from -11% to +12.4% (high precision products).

The outer diameter of the pipes can have a permissible error from 0.15 millimeters (high-precision) to 0.4 millimeters (regular) or 0.7-1.3%. For pipes made of steel 06ХН28 MDT with a cross-section of more than 30 millimeters, a deviation of 1.2% is possible, a cross-section of less than 30 millimeters is 0.45 mm.

Requirements for cold- and heat-deformed stainless pipes

The ends of the finished pipeline are cut off (cut angle is straight), burrs are removed from them, which can lead to the formation of a chamfer and the formation of surface roughness. This is allowed by regulatory documents. Sometimes even customers negotiate with the manufacturer the need for chamfering at the ends of pipe products where the walls are more than 5 mm , since it makes it possible to make pipeline connections using welding more efficiently and effectively.

On any section 1 meter long, a stainless pipe can have the following curvature characteristics:

- 1 millimeter (walls more than 0.50 millimeters, cross-section more than 5 millimeters);

- 2 millimeters (pipes with walls up to 0.50 millimeters and a cross-section from 15 millimeters).

If we consider structures with walls less than 0.50 cm with a cross-section up to 1.5 cm, then there is no special approval in GOST for this case. The main thing is that the products are made without sharp bends. The ovality of rolled pipe should be such that the diameter of the products does not exceed the permissible errors in the size of their outer diameter.

The described products are manufactured from stainless metal from the following steel grades : 17Х18Н9, 08ХН28МДТ, 08Х17 Н15М3Т, 12Х18 Н12Т, 10Х23 Н18, 08Х18 Н10Т, 04Х18 Н10, 10Х17 Н13М2Т, 08Х13, 12Х17, 12Х18 Н10, 08Х22 Н6Т, 12Х13, 15Х25 Т, and some other high-alloy metals. The density level of these alloys ranges from 7.6-7.97 g/cm. cubic meters, regarding tensile strength – 37-587 kgf/mm. sq. and elongation – 16-46%.

These steel grades may include a small addition of rare earth metals, and at the same time comply with all 5632 standards. Much attention is paid to the presence of sulfur in products; it cannot be more than 0.02%. The finished pipe product undergoes heat treatment.

Stainless steel pipes according to GOST-9940 81

The next GOST also describes stainless steel pipes, but here we are talking about products that are manufactured using hot deformation. The outer diameter of these products is 56-326 millimeters, the wall thickness is 3.4-32 millimeters , they are made from the same grades of steel that are described in GOST 9941.

In many respects, both standards are absolutely identical. Therefore, we will not repeat ourselves, but will talk about the acceptance of finished products. It occurs in batches (they are assembled from identical geometric dimensions, grades of the original alloy, and heat treatment of products). No more than 200 products can be assembled into one batch.

Product quality control involves testing for:

- stretching (two pipes);

- flattening and spreading (one);

- intergranular corrosion (two products from the batch).

A batch is of high quality when all tests have shown positive results. If at least one shows poor quality of the products, then another test is performed, but now they use a double number of products. It should be noted that absolutely all products from the batch are subject to analysis of geometric characteristics, hydraulic pressure tests and ultrasonic examinations.

The quality of corrosion-resistant pipes is checked in the following ways:

- micrometer and staples (sheet) - external section and ovality;

- tape measure - their size in length (GOST-7502);

- using a straight edge and a feeler gauge – curvature.

During testing, stainless steel pipes are held under pressure for 10 seconds or more, tensile analysis is carried out according to GOST-10006/19040, and flattening is analyzed according to GOST-8695.

Types of pipes by production method

The following methods of pipeline production are distinguished: hot-deformed, cold-deformed, electric welded. The dimensions and maximum differences of products, production materials are regulated by assortments for round iron pipes, different assortments for each production method:

Hot-deformed seamless iron pipes GOST 8732

The production of pipes takes place in three steps. First, a hole is pierced in a round billet heated to 900-1200 degrees on special machines, and as a result a sleeve comes out. Next, the liner is rolled into a preliminary pipe, and the final step is calibration, rolling with final dimensions in thickness and diameter.

Interesting read: Lubricant for drilling stainless steel

The dimensions of the resulting products using this production method can be: external diameter 16-630 mm, wall thickness 1.5-50 mm. Product blanks are divided into several groups, depending on the production material used:

- A – the mechanical characteristics of the product are standardized.

- B – the chemical composition is regulated during manufacture.

- B – mechanical characteristics and chemical composition are immediately regulated;

- D – the chemical composition is standardized and the mechanical characteristics are checked on experimental samples;

- D – the value of the test pressure during testing is regulated.

Seamless iron pipes, cold deformed according to GOST 8734

Round iron blanks are used for rolling. The workpiece is heated in special furnaces to the temperature at which crystallization begins to obtain the required plasticity. Then it is stitched and goes into a rolling mill, where the preliminary dimensions of the product are formed using rollers. The final operation is calibration and cutting to a certain length.

Unlike hot-deformed pipes, cold-deformed pipes receive additional heat treatment during calibration, which makes such products stable and long-lasting.

Cold-formed products are divided into the following groups, where the main aspect is the ratio of the diameter D to the wall size S:

- Extra-thin-walled, with a D/S ratio greater than 40. If size D=20 mm or less, size S=0.5 mm or less.

- Thin-walled, with a D/S ratio of 12.5 and less than 40. In addition, pipes with D = 20 mm. and less, with S=1.5 mm, and less.

- Thick-walled, with a D/S ratio from 6 to 12.5.

- Extra thick-walled with a D/S ratio of less than 6.

Thin-walled and extra-thin-walled pipes are used in various hydraulic systems, auto engines, industrial refrigeration units, as well as in the honey and food industries. The main application of thick-walled pipes is in the oil and gas industry.

Thin-walled cold-rolled products

Electric-welded iron pipes according to GOST 10704

Production development contains several steps that are combined into one continuous process:

- Sheet cutting. It is produced on high-precision machines and allows you to obtain workpieces of similar sizes.

- To obtain an endless strip, the strips are welded together, having previously been passed through a system of rollers to eliminate surface imperfections.

- The resulting workpiece is passed through a system of horizontal and vertical rollers, with the help of which the product is formed.

- Welding of edges is done using frequency welding. The edges of the workpiece are heated by an inductor to the melting temperature, and then compressed by crimping rollers. Another method, when the edges are heated using a frequency generator, current is supplied to the edges using contacts.

Electric-welded pipelines are widely used when laying utility networks that can withstand enormous overloads and pressures. Products with a diameter of 1200 mm. are used in the installation of almost all main gas and oil pipelines.

Stainless steel pipe range

Rolled pipes made from high-alloy steels have unique performance characteristics: stainless steel pipes made of 12Х18Н10Т steel (one of the most common grades of stainless steel) can be used at temperatures from −196 to +600°С. In highly aggressive environments, the operating temperature for stainless pipes reaches + 350°C; in nitric, phosphoric, acetic acid, in solutions of salts and alkalis, the average annual corrosion rate is only 5-20 microns per year (µm/year). Such properties, combined with wear resistance (the tensile strength of steel 12Х18Н10Т is 510 MPa), make stainless pipes indispensable in the construction of industrial facilities, in aviation, mechanical and instrument making, petrochemical and chemical industries, pharmaceutical and food production.

Alloyed pipe products are distinguished by production method:

- cold and heat deformed stainless steel pipes GOCT 9940-81;

- hot-rolled stainless steel pipes GOCT 9941-81;

- electric welded pipes made of corrosion-resistant steel grades GOCT 11068-81.

Depending on the class, the scope of application of stainless steel pipes has distinctions: cold and heat-deformed pipes are distinguished by high manufacturing precision and a mirror (shiny) surface, due to which they are used for the production of furniture and interior decoration; hot-rolled steel is used for installation of process pipelines, equipment production, and construction; electric welded pipes are not intended for operation under conditions of high pressure (design working pressure up to 16 MPa), as a result of which they are not used for critical pipelines.

Loss of water pressure when moving in round pipes

When transporting liquids in pipelines, pressure losses occur, which depend on the following reasons:

- roughness of the internal surfaces of the pipe,

- losses during passage of cross-sectional narrowings in taps, adapters and other fittings,

- losses during sharp 90-degree turns of the pipeline,

- In addition, pressure loss depends on the viscosity of the water.

There are two modes of water flow: laminar and turbulent. Laminar is when the movement of water in pipelines occurs without mixing particles. With turbulence, there is abundant mixing and rotational movement of water particles. The flow transition from laminar to turbulent occurs when the Reynolds number Re>2300.

Laminar and turbulent flow

The Reynolds number depends on the flow speed, internal diameter and viscosity of water and characterizes the mode of movement of water. When calculating the characteristics of pipelines, it is necessary that the calculated Reynolds number be Re<2300. At the same time, there is less loss and cost of pump power for water movement.

Hot Rolled Stainless Pipe Dimensions

Hot-rolled alloy pipes in accordance with GOCT 9940-81 are produced in the following size range:

- outer diameters of stainless steel pipes (hot rolled)

: from 76 to 325 mm, permissible maximum deviations ±1.5% for normal manufacturing accuracy and 1% for high accuracy. Pipes with a diameter of less than 76 mm (from 53 to 73 mm) are manufactured in individual cases in agreement with consumers. - wall thickness

: from 3.5 to 28 mm, maximum deviations, depending on the manufacturing accuracy and the wall thickness itself, range from minus 15% to plus 20%. - measured length

: from 3 to 8.5 meters, with a minimum multiple of 300 mm. The unmeasured length is regulated in the range from 1.5 to 10 m, the limited length means a deviation from the measured length plus or minus 500 mm (deviation is allowed at one end).

Hot-rolled stainless steel pipe, assortment according to GOCT 9940-81

| Dn, mm | Maximum measured length of pipes in meters with wall thickness, mm | ||||||||||||||

| 3,5-8 | 8,5-10 | 11-12 | 13-14 | 15 | 16-20 | 22-26 | 26-30 | 30-32 | |||||||

| 76 | 7 | 6 | – | – | – | – | – | – | – | ||||||

| 83 | 7 | 6 | *** | – | – | – | – | – | – | ||||||

| 89 | 7 | 6 | 5 | 4 | *** | – | – | – | – | ||||||

| Dn, mm | Maximum measured length of pipes in meters with wall thickness, mm | ||||||||||||||

| 5-8 | 8,5-10 | 11-12 | 13 | 14 | 15-16 | 27-20 | 22 | 24-26 | |||||||

| 95 | 7 | 6 | 5 | 4 | 4 | 4 | – | – | – | ||||||

| 102,108 | 7 | 6 | 5 | 4 | 4 | 4 | 4 | – | – | ||||||

| 114 | 7 | 6 | 5 | 4 | 4 | 4 | 4 | 3 | – | ||||||

| 121 | 7 | 6 | 5,5 | 5,5 | 5 | 5 | 4 | 3 | 3 | ||||||

| Dn, mm | Maximum measured length of pipes in meters with wall thickness, mm | ||||||||||||||

| 5-8 | 8,5-10 | 11-13 | 14-17 | 18, 19 | 20 | 22-26 | – | – | |||||||

| 127 | 7 | 6 | 5,5 | 5 | 4,5 | 4 | 3 | – | – | ||||||

| Dn, mm | Maximum measured length of pipes in meters with wall thickness, mm | ||||||||||||||

| 4-8 | 8,5-10 | 11-13 | 14-17 | 18, 19 | 20 | 22-26 | – | – | |||||||

| 133, 140 | 7 | 6 | 5,5 | 5 | 4,5 | 4 | 3 | – | – | ||||||

| Dn, mm | Maximum measured length of pipes in meters with wall thickness, mm | ||||||||||||||

| 4-5,5 | 6-7 | 7,5-8,5 | 9-9,5 | 10-11 | 12-14 | 15, 16 | 17, 18 | 19 | 20-24 | 25, 26 | |||||

| 146, 152, 159 | 7 | 8,5 | 8 | 7,5 | 7 | 6,5 | 6 | 5,5 | 5 | 4,5 | 3 | ||||

| Dn, mm | Maximum measured length of pipes in meters with wall thickness, mm | ||||||||||||||

| 7-8,5 | 9-9,5 | 10-11 | 12-14 | 15-16 | 17-18 | 19 | 22-24 | 25-26 | 28-32 | ||||||

| 168 | 8 | 7,5 | 7 | 6,5 | 6 | 5,5 | 5 | 4,5 | 3 | *** | |||||

| Dn, mm | Maximum measured length of pipes in meters with wall thickness, mm | ||||||||||||||

| 8-8,5 | 9-9,5 | 10-11 | 12-14 | 15-16 | 17-18 | 19 | 20-24 | 25 | 26-28 | 30-32 | |||||

| 180 | 8 | 7,5 | 7 | 6,5 | 6 | 5,5 | 5 | 4,5 | 4 | 3,5 | *** | ||||

| Dn, mm | Maximum measured length of pipes in meters with wall thickness, mm | ||||||||||||||

| 9 | 9,5 | 10-11 | 12-13 | 14 | 15-16 | 17-18 | 19 | 20-24 | 25 | 26-28 | 30-32 | ||||

| 194 | 8 | 7,5 | 7 | 6,5 | 6,5 | 6 | 5,5 | 5 | 4,5 | 4 | 3,5 | *** | |||

| 219 | – | – | 8 | 7,5 | 7 | 6,5 | 5,5 | 5 | 4,5 | 4 | 3,5 | *** | |||

| Dn, mm | Maximum measured length of pipes in meters with wall thickness, mm | ||||||||||||||

| 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 26 | 28 | |

| 245 | 8 | 8 | 7,5 | 7 | 7 | 6,5 | 6 | 5,5 | 5 | 4,5 | 5 | 4,5 | 4,5 | – | – |

| 273 | 8 | 8 | 7,5 | 7 | 6,5 | 6 | 5,5 | 5,5 | 5 | 4,5 | – | – | – | – | – |

| 325 | – | 6,5 | 6 | 5,5 | 5 | 5 | – | – | – | – | – | – | – | – | – |

Note: the mark *** means that this size is produced only by agreement between the customer and the manufacturer.

Dimensions of Cold Rolled Stainless Steel Pipe

Stainless steel pipe GOCT 9941 81 cold-rolled is produced according to the assortment and has some differences from the size range of hot-deformed pipes:

- cold-rolled stainless steel pipe, outer diameters: from 5 to 273 mm, permissible deviations depending on the diameter and manufacturing accuracy from ±0.15 mm to ±1.2%.

- wall thickness: from 0.2 to 22 mm, permissible maximum deviations: from ±0.03 mm to ±12.5%, depending on the class of manufacturing accuracy and the wall thickness itself.

- measured length: from 4 to 7 meters, with a minimum multiple of 300 mm. Non-standard length is established by the standard from 0.75 to 12.5 m. Pipes of larger non-standard length (16 m) are produced by agreement with the consumer.

Applicability of products of different diameters

Depending on the external diameter, the products can be used in the following areas:

- For heating systems and hot water supply of residential and industrial buildings, iron pipes with a diameter of 40-50 mm are used.

- In hydraulic systems of working parts of machines and road equipment, depending on the amount of water supplied, the diameter can be from 8 to 50 mm.

- In huge apartment buildings, the diameter of the pipelines used to supply cool water is up to 150 mm.

- In the oil, gas and chemical industries, products with diameters up to 273 mm are used for internal transportation of raw materials.

- Large city boiler houses for supplying heating to the house, and water supply companies use diameters of up to 325 mm to supply water.

- Sewage pipes have a size of 530-1020 mm in diameter.

- In large systems for transporting gas and oil, huge sizes of 1020 mm and larger can be used.

- Pipes are widely used in construction for driving piles, foundation supports and bridges. The diameter of the products used is from 650 mm.

The actual dimensions of the products used may differ from the tabulated ones, and depend on the design features of the pipeline system used.

Products with a diameter of 273 mm

Stainless pipe weight

The weight of one linear meter of round pipe made of alloy steel grades is calculated by the formula:

- Mpm is the required weight of a linear meter in kg;

- Dn is the outer diameter of the pipe, mm;

- Tc—wall thickness, mm;

- ρ—specific gravity of the metal grade, g/cm³, reference value;

- π is a constant equal to 3.14.

| Metal grade | 08Х17Т | 04Х18Н10 | 08Х18Н10Т | 12Х18Н10Т | 10Х17Н13М2Т | 08Х18Н12Т |

| Specific gravity, g/cm³ | 7,70 | 7,90 | 7,90 | 7,90 | 8,00 | 7,95 |

For example, a stainless steel pipe 12Х18Н10Т ГОСТ 9941 81 with an outer diameter Dn=89 mm, Tc=3.5 mm, the weight of a linear meter will be equal to:

The calculated weight may differ slightly from the actual weight within the permissible deviations in length, outer diameters and wall thicknesses established by GOST 9941-81 and GOCT 9940-81.

You can also:

Atlant-Metal LLC © 1994–2011 All rights reserved.

Article rating:

Save to:

Stainless steel pipe diameters table Link to main publication

Materials used in manufacturing

The materials used in the manufacture of hot-deformed pipes are specified in GOST 8731, and for cold-deformed pipes in GOST 8733. In the manufacture of such products, blanks from ordinary carbon steel are used in accordance with GOST 380, high-quality carbon structural steel in accordance with GOST 1050, and structural alloy steel in accordance with GOST 4543. When manufacturing electric-welded pipes, all technical conditions for product materials are specified in GOST 10705.

Seamless pipes made of stainless steel are widely used in the industry. They are used in instrument making, in the manufacture of cars, in the chemical industry and in almost all other areas of production.

Stainless steel with matte surface

The entire range, as well as the technical conditions for stainless steel round pipes, are established in GOST 9941. According to the production method, they are manufactured by cold-deformed or hot-deformed method, in the following sizes:

- with external D 16-53 mm, wall thickness S 2-5 mm;

- if D is 53-73 mm, then S is from 4.5 to 10 mm;

- diameter D 84-80 mm, wall S from 11 to 15 mm;

- for diameters D 140-219 mm, S from 28 to 32 mm.

To protect stainless pipes from corrosion, it contains chromium, which makes it resistant to harsh chemicals. The surface of the resulting finished products can be matte or mirror-like, depending on the method of pipeline production.