Concentration of diamonds in diamond wheels

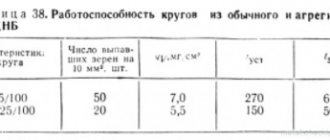

An important characteristic of diamond wheels, which determines cutting ability and productivity, is the concentration of diamond in the diamond-bearing layer. The industry produces standard proportions: 25%, 50%, 100% (at 100% concentration there is 0.878 mg of diamond grain in 1 cubic mm of diamond-bearing layer).

A characteristic feature of a diamond wheel is that the operation of the diamond-bearing layer occurs not due to complete wear of the grains, but due to their falling out of the wheel.

Material

Brand

| Bunch | Application | |||

| ker. | org. | meth | ||

| Elbor | ||||

| LKV40 | + | Grinding of heat-treated steels: hardened, nitrided, cemented, high-speed | ||

| LKV50 | + | High-performance (including high-speed and deep-feed) grinding of heat-treated steels, bleached cast iron, wear-resistant coatings | ||

| LKV60 | + | High-performance grinding at the most intensive conditions | ||

| LKV40M | + | Sharpening cutting tools made of high-speed steels | ||

| LKV50M | + | High-performance, incl. deep sharpening of cutting tools. Grinding flutes | ||

| LM | + | + | Final sanding. Superfinishing, lapping, polishing | |

| Synthetic diamond | ||||

| AC4 | + | Grinding glass, crystal, ceramics, magnetic materials | ||

| AC6 | + | + | Cutting hard alloy, ceramics, glass, incl. quartz, optical | |

| AC15, AC20, AC32, AC50 | + | + | High-performance grinding of hard alloys and special ceramics. Honing | |

| AS4M, AS6M | + + | Sharpening cutting tools made of hard alloys | ||

| AFM | + | + | + | Finish grinding of carbide, ceramics, fine honing, lapping, polishing |

to the begining

Selection of diamond layer concentration

When selecting the optimal concentration of diamond in the diamond-bearing layer, the following rule applies:

— with a small contact surface between the grinding wheel and the workpiece, for example during cylindrical grinding, it is necessary to select a high concentration of diamond. This ensures tool wear resistance, even under high loads (100%).

— with a large contact surface, it is necessary to take measures to reduce the temperature in the grinding zone and reduce the grinding forces to avoid burns. In this case, a low concentration of diamond (50%) should be used.

Wheels with a 25% concentration are used for finishing work.

Bunch

Types of ligaments used in production

| MaterialBundle | Ceramic | Organic* | Metal |

| Elbor | KC10, K27 | B48, B481, B482, B483, KB | |

| Diamond | K11 | B48, B481, B482, B483, B2-01 | M2-01, M2-02 |

*for effective operation of organic bonded tools, it is recommended to use grain with a metal coating.

Application of bonds for CBN and diamond wheels

| Bundle brand | Application |

| Ceramic | |

| KS10 | in wheels for external cylindrical, centerless, surface grinding |

| K27 | in wheels for internal grinding, profile grinding |

| K11 | for grinding operations with diamond wheels |

| Organic | |

| B48 | universal bond for grinding with coolant and dry at medium speeds, for CNC machines |

| B481 | for “dry” grinding, in cup-shaped wheels with a working layer width W > 5 mm |

| B482 | for grinding with coolant, in narrow-edge wheels (W ≤ 5 mm), for CNC machines, for cutting wheels |

| B483 | for dry grinding, in narrow-edge (W ≤ 5 mm) wheels |

| B2-01 | for grinding with coolant under light conditions, on manually operated machines |

| Metal | |

| M2-01 | For diamond grinding of glass, ceramics |

| M2-02 | For diamond cutting wheels |

to the begining

Application of diamond wheels depending on grain size:

The grain size of the wheel is selected depending on the required cleanliness of the surface being processed.

For rough grinding, diamond wheels with grit size are used: 400/315 315/250 250/200 200/160 160/125

For finishing grinding, use diamond wheels with grain size: 125/100 100/80

For fine grinding, diamond wheels with grit size are used: 80/63 63/50 50/40

For finishing and polishing diamond wheels with grit: 60/40 40/28 28/20 20/14 14/10 10/7 7/5 5/3 3/2

Shallow plate. Marking 12A220

In appearance, the plate differs noticeably from the cup in depth; as a rule, the height is only 18 mm. In the other everything is standard, diamond grinding wheel 12A220 150*10*2*18*32 160/125 - plate with a diameter of 150 mm, width of the diamond layer 10 mm, thickness 2 mm, depth - 18 mm (shallow), fit 32 mm. Grain 165/100 is quite coarse compared to others.

Another note: How to drill holes for hinges? Forstner, of course!

Plates come in 150 mm and 125 mm diameters.

They are excellent for sharpening tools; moreover, they can be used to sharpen carbide tips on circular saws. In order to sharpen such tips, you will need a thin plate so that the edge can fit between the teeth.

Bundles for diamond wheels

Diamond wheels on a metal bond (M) (Bronze and its modifications are used as a metal bond). The metal bond is used for preliminary operations that require the removal of relatively large allowances, for sharpening carbide tools, grinding products made of carbide, glass, ceramics, semiconductor and difficult-to-cut materials using coolant.

M2-01 M1-01 M2-02

Diamond wheels on an organic binder (B ) (Bakelite is usually used as an organic binder). The organic binder is used for finishing and finishing work: fine sharpening and finishing of cutting tools made of hard alloys and superhard materials, finishing grinding and finishing of measuring tools, for processing high-hardness materials.

В2-01 В1-02 В1-01

Cubic boron nitrite (CBN) : Grinding and finishing of tools made of tungsten (P18, P12, P9), tungsten-molybdenum (P6M5) and other high-speed steels. Parts made of heat-resistant, stainless and high-alloy structural steels of high hardness (HRS 55 and above).

- Grinding and finishing of single-edged tools: medical, manicure, scissors, knives, axes, saws, skates, chisels, planes, chainsaw chains...

- Grinding and finishing of multi-blade tools: woodworking saws, reamers, countersinks, drills, cutters.

- Grinding of body parts, threads, gear tooth profiles... Parts whose high precision is limited by large thermal deformations.

Design and common shapes of diamond wheels

Let's tell you more about the design of a diamond wheel. Its main part is a durable disk with a hole.

Image #1: Diamond wheel design

Discs are made from materials of two groups.

- Structural steels (St20, St3, etc.). Discs made of these materials are characterized by increased resistance to mechanical loads and vibrations. Steels dissipate heat well.

- Aluminum alloys (D16 and AK group alloys). They have excellent thermal conductivity, but less strength. When processing workpieces at high speeds, discs of these materials are prone to vibration.

- Composite materials with the addition of polymers. Discs made from them are characterized by maximum vibration resistance, but strength and thermal conductivity leave much to be desired.

Some surfaces of the disk (1 more) are covered with a working layer. It includes:

- filler (this is powder made from boron carbide, electrocorundum, alumina, copper or graphite);

- ligament;

- diamond powder.

It is the working layer that comes into contact with the workpiece during processing.

Features of ligaments

In the manufacture of diamond wheels for metal, three types of bonds are used.

1. Bundles on metal bases. The latter include composites of zinc, aluminum, copper and tin. Metal bundles:

- are characterized by maximum strength;

- have high heat resistance;

- when used, the instruments do not become deformed for a long time;

- serve for a long time;

- quickly pickled;

- increase the productivity of diamond wheels for metal.

Tools with such bonds are used to remove large amounts of metal from workpieces. The main operation is pre-processing. The resulting surface acquires an eighth-ninth class of roughness.

2. Organic ligaments. They have low strength and heat resistance. Productivity and processing speed are at a high level. The tools are little greasy, but the working surfaces wear out quickly due to the increased consumption of diamonds.

Diamond wheels for metal with organic bonds are used when processing workpieces made from the following materials.

- Hard alloys.

- Difficult to process materials.

- Metals intended for the manufacture of medical and measuring instruments.

The main operations are finishing, finishing, high-quality sharpening. The roughness class of the resulting surfaces is 11 or 12.

3. Ceramic bonds. The circles with them have a diamond-nickel coating. It is applied in one or several layers. Let us list the key characteristics of tools in this category.

- High cutting ability.

- Low price.

- Excellent thermal conductivity.

- High-quality removal of chips from machined surfaces.

Such diamond wheels for metal are used for processing workpieces from:

- germanium, sital, silicon and other semiconductor materials;

- stone;

- ceramics;

- technical glass.

The main operations are cutting and finishing.

Shapes of diamond wheels for metal

Most often, 8 types of diamond wheels for metal are used.

- Flat circles without grooves (D/N >= 1.8).

- Rings (D/N ˂ 1.8).

- Flat circles with one-sided relief.

- Flat cone-shaped models.

- Flat circles with one recess.

- Flat circles with two grooves.

- Cup circles (45° ˂ α ˂ 90°).

- Cup circles (α ˂= 45°).

All of these types of instruments have their own identification numbers. Familiarize yourself with them and the design features of the devices in the table below.

Image No. 2: shapes of diamond wheels for metal

Let's move on to a detailed study of the grain size of the tools.

Purpose of abrasives

Depending on the type of abrasive from which the grinding wheel is made, the scope of its application changes.

Normal electrocorundum has good viscosity, adhesion to the binder, and is heat-resistant and is well suited for working with steel, cast iron, bronze and brass due to its physical properties.

White electrocorundum has a more uniform structure, sharp edges, is harder than ordinary corundum and has less surface roughness. Designed for processing the same materials as conventional electrocorundum, but due to less heating and wear, it is also used for alloy and tool steels, sharpening saw teeth, cutting edges of milling cutters, knives, drills. Well suited for polishing products.

Silicon carbide is harder, but more brittle than electrocorundum. It has a higher abrasive ability, but the adhesion of the grain to the binder is weaker than that of corundum.

Diamond has great mechanical strength, but is sensitive to high temperatures, reacts with iron, is brittle, and has very good self-sharpening properties, which gives the blade durability.

Diamond grinding wheels are used for processing materials such as cast iron, glass, ceramics, and hard alloys. Well suited for finishing products, sharpening drills, cutters, saws, knives.

Elbor is second only to diamond in hardness, does not react with iron, is heat-resistant, fragile, and has good abrasive ability.

Used for grinding and processing of hard steels, tool sharpening, finishing, the scope of application of CBN includes areas where other abrasives are not used due to high operating temperatures.

Diamond and cubic boron nitride wheels

Diamond wheels, as well as wheels made of cubic boron nitride (borazon, cubonite, elbor) consist of a body and a working layer firmly fixed to it (Fig. 28).

Rice. 28. Design of a diamond wheel (AChK type): 1 - wheel body; 2 - diamond-bearing layer

The circle body is made of steel St.Z, 20, 30, aluminum alloy AK6 or D16. The working layer consists of diamond or cubic boron nitride grains, binder and filler. The characteristics of the working layer are determined by the grade of diamond or cubic boron nitride, grain size, concentration and binder. The layer thickness is 1.5-5 mm depending on the size of the circle.

The content of diamonds or cubic boron nitride equal to 4.4 carats (0.88 g) per 1 cm3 of the working layer, or 25% of its volume, regardless of the type of binder, is taken as 100% concentration. The scale of diamond concentration in a tool, adopted in the USSR and most countries of the world, is given in Table. 5. The table shows that at the so-called 100% concentration, diamond powder actually occupies only 1/4 of the volume, and the remaining 75% comes from the binder with filler and pores.

Grinding powders made from synthetic diamonds, used for grinding, sharpening and finishing cutting tools, are produced in three grades: ASO, ARS, ASV. The grain size of the grinding powder is indicated by a fraction in which the numerator corresponds to the largest, and the denominator corresponds to the smallest grain size of the main fraction in microns.

Synthetic diamond micropowders are available in two grades: ASM and ASN.

The grain size of micropowders is indicated in table. 6. Table 5. Diamond concentration in the tool

| Diamond concentration, % | Diamond content per unit volume of the diamond-bearing layer, carats | Volume occupied by diamonds in the diamond-bearing layer, % | |

| 1 cm3 | 1 in3 | ||

| 25 50 75 100 125 150 175 200 250 | 1,1 2,2 3,3 4,4 5,5 6,6 7,7 8,8 11,0 | 18 36 54 72 90 108 126 144 180 | 6,2 12,4 18,6 24,9 31,1 37,3 43,5 49,7 62,1 |

Table 6. Grit size of micropowders

| Grain | Main fraction size |

| 60/40 40/28 28/20 20/14 14/10 10/7 7/5 1/0 | 60—40 40—28 28—20 20—14 14—10 10—7 7—5 1 |

Diamond wheels are made with a grain size of 50-40 and mainly with a grain size of 10-7 from ASO, ASP diamonds, less often from ASV and natural diamonds.

Two grades of grinding powders are made from cubonite: KO with grain sizes from 160/125 to 50/40 and KR with grain sizes from 250/200 to 50/40, KM grinding powders with grain sizes from 60/40 to 1/0. CBN grinding powders are produced in the LO and LP grades, and micropowders are produced in the LM grades.

Circles are made using four main bonds: organic, metal, ceramic and metal-galvanic.

Grit size of synthetic diamond grinding powders

| ASO ASR ASV | — — 400/315 | — — 315/250 | — 250/200 250/200 | — 200/160 200/160 | 160/125 160/125 160/125 | 125/100 125/100 125/100 | 100/80 100/80 100/80 | 80/63 80/63 80/63 | 63/50 63/50 — | 50/40 — — |

The main organic binder is bakelite, consisting of a binder (phenol-formaldehyde resin) and various fillers, the volume content of which usually ranges from 37.5 to 12.5%. Bakelite bonded diamond wheels have good cutting properties, which allows you to work with low cutting forces. The small amount of heat generated during grinding allows grinding without cooling, so these wheels are widely used when sharpening multi-edged tools.

Metal bonds are made from various compositions based on copper, tin, iron, aluminum, zinc and other metals. They are used in wheels intended for preliminary and finishing diamond processing with relatively low requirements for surface roughness (up to class 8).

Ceramic bonded wheels have the highest cutting properties and are mainly designed for simultaneous machining of carbide and steel holder, as well as for machining some high-alloy alloys and materials.

Diamond wheels are selected depending on their purpose and type of machine. The shapes of sections and designations of circles are regulated by GOST 16167-70* - 16181-70*. The most commonly used circles are given in table. 7. The shape and dimensions of CBN tools are regulated by GOST 17123-71.

Rice. 29. Finishing the cutting edge of the tool with a diamond wheel: a - incorrect; b - correct

When choosing the shape and size of diamond wheels and cubenite wheels, it is necessary to take into account that the wheels must have the minimum width of the working ring acceptable for the given grinding conditions.

When working with a pass, you can choose wheels with a wide ring, and when working using the plunge method, the width of the ring must necessarily be less than the height of the surface being processed, for example, the height of the saw tooth (blade). Otherwise, the working ring of the circle will not wear out to its full width, which will lead to rounding (collapse) of the cutting edge of the tool (Fig. 29). For work where greater edge stability is required, and for preliminary grinding, metal-bonded wheels should be used, and for finishing work, organic-bonded wheels should be used. Table 7. Section shapes and designations of diamond wheels

| Types of circles | Designation | Section shape | Main dimensions, mm | ||

| outer diameter D | diamondiferous layer | ||||

| width b | thickness s | ||||

| Flat straight profile | AMS | 12—500 | 3—50 | 2—10 | |

| » with undercut | Automatic reclosing | 100—320 | 3—80 | 1,5—3 | |

| » with double-sided undercut | APVD | 100—250 | 3—20 | 1,5—3 | |

| Cup conical | ABC | 50—250 | 3—20 | 1,5—3 | |

| Disc-shaped with an angle of 18° | AT | 50—300 | 2—10 | 1,5—3 | |

| Disc-shaped with an angle of 30° | A1T | 50—125 | 1—2 | 2—3 | |

| » for processing screw surfaces | AZT | 75—125 | 3—5 | 1,5 | |

Note. In the designation of cubenite circles, the letter A is replaced by the letter K, and elbor - by the letter L.

Scope of use of wheels: APP - external cylindrical grinding of cutters, milling heads, undercutting of circular saws, grinding of knife planes, saw blades; APV - fine sharpening and finishing of knife chamfers, side surfaces of saw teeth; APWD - fine sharpening and finishing of knife chamfers and side surfaces; АЧК - fine sharpening and finishing of knife chamfers and side surfaces; AT - finishing sharpening and finishing of the front edge of cutters and teeth of circular and frame saws; A1T - sharpening and finishing of multi-edge tools on the front surfaces; AZT - sharpening and finishing of a multi-edged tool with a screw tooth.

Grinding wheel grit

Certain numerical values are also used to indicate the grit size of the grinding wheel; they are presented in the following table:

| GOST | 12 | 16 | 25 | 40 |

| FERA | 100 | 80 | 60 | 40 |

As the number according to GOST increases, the size of the grains used in the manufacture of the wheel also increases, as well as the degree of penetration and feed when sharpening a band saw. However, the quality of the treated surface will be better when using fine-grained abrasive wheels.

Grinding wheel hardness

This indicator affects the self-sharpening ability of the abrasive wheel. When sharpening a band saw, the edges of the dull grains are chipped off and removed, thereby revealing new working layers of the wheel.

During the turning process, a harder wheel will hold its shape better, but its chamois will already become dull. To maintain high quality work, you will have to use more power and less feed. However, this may result in burns and risks. In addition, the relatively soft saw material will clog the pores of the wheel, which will affect the quality of sharpening.

If you use a sharpening wheel that is too soft, the bond may hold the grains very weakly, so they will begin to crumble from the body of the wheel. Soft circles will quickly lose their shape and wear out.

When working, the main thing is to choose the right level of hardness of the grinding wheel, and for this you should use the data in the table:

| GOST | M1, M2, M3 | SM1, SM2 | C1, C2 | ST1, ST2, ST3 | T1, T2 |

| FERA | Y, I, J | K, L | M, N | O, P, Q | R, S |

| Hardness | Soft | Medium soft | Average | Medium-hard | Solid |

Main characteristics of the tool

The equipment consists of a base on which a layer of powder is applied. The requirement for the selection of products for surface treatment is that the hardness of the tool should be higher compared to the workpiece.

If the difference is significant, overheating and thermal defects are possible. A small difference leads to tool failure or reduced productivity.

Features of the diamond-containing layer

The weight of a solid mineral is measured in carats. One carat is equal to 0.2 g. The grains are intergrown diamond crystals. The main characteristics of products include the size and density of particles. To hold diamonds in the working layer, binders are used, of which there are three main types.

Organic components emit little heat and are practically not salted. The advantages of the binder include strong retention of grains, including the fine fraction, which is why the equipment is used for finishing operations. The disadvantage is increased wear resistance.

Metal particles give the working layer strength; upon contact with the part, the powder heats up. Equipment with a bond made of bronze, aluminum, copper and other metals is prone to clogging and requires frequent editing.

The peculiarity of using tools with ceramic powder is for finishing viscous materials. Abrasive products are used for simultaneous processing of steel and hard alloys.

Uniformity and grain concentration

When producing powders, the compositions are divided into fractions. For this purpose, sieves with special cells are used. Product labeling is a fraction. The numerator is the size of the sides of the holes in the upper sieve, the denominator is the parameter of the lower cells.

When processing round parts, the contact point with the tool is minimal. In this case, choose abrasive products in which the working layer contains a high concentration of solid inclusions.

The uniformity and mass fraction of the abrasive affect labor productivity, the cutting ability of the tool and the surface cleanliness of the part.