Steel channel is a type of shaped rolled steel with a U-shaped cross section. For the manufacture of these metal products, carbon, low-alloy, corrosion-resistant steels are used. Galvanizing or painting can increase the corrosion resistance of products made from “black” steels. According to the production method, the channel is divided into hot-rolled and bent. Depending on this, the appearance of the products differs. The outer corners of a hot-rolled profile have clear outlines, while those of a bent profile are rounded.

How can you quickly calculate the area to paint metal structures.

When I give the task in my estimating courses to calculate the area to paint metal structures for a project, I observe the same picture.

Regardless of who the student is, a novice estimator or an already experienced specialist, everyone begins to frantically leaf through the project and calculate this area manually: “So, here the length is this, the width is this, the wall thickness is this, and now we add this to this...”

With rare exceptions, it happens that students, in search of a solution to a given problem, open tech. part of collection No. 13 “Protection of building structures and equipment from corrosion”

and begin to calculate the area to be painted according to

“Appendix 13.1.”

Of course, in most cases, these students are experienced estimators.

After receiving their results, I give them a new task. Only now, instead of a project with specifications, they receive the total tonnage of a particular design and that’s it. Neither the dimensions nor the thickness of the metal are indicated, nothing except that the ladder is like this, and the weight during installation is like this.

Almost everyone looks confused! Novice specialists begin to throw up their hands, and experienced ones begin to grumble and say that when they received similar tasks at work, they refused to take them into account. After all, without detailed data it is impossible to correctly calculate the area to be painted and, accordingly, the cost.

After testing them a little more, I begin to tell them about the wonderful Soviet reference book “CHECKING ESTIMATES FOR CONSTRUCTION WORKS BY P. E. KOMAROVSKY”

and that it is possible, using this reference book, to determine the area to be painted of metal structures based on their mass.

Experienced estimators unanimously began to assert that this method of calculating area is not suitable and that...

After listening to all their objections, I suggested that they still try to make a calculation based on the Komarovsky reference book.

In less than five minutes we already knew the total area to be painted, as well as the cost of this painting. Conversations immediately resumed on the topic of inaccuracy. Then I took out the specification for this ladder and asked them to make a calculation according to the exact data.

An accurate calculation took about 30 minutes. As a result, the difference in the cost of painting the stairs was 230 rubles in favor of an accurate calculation. All the students were surprised. Still, 230 rubles is not a big difference, but how much time was saved.

Bent channel assortment

The bent channel is distinguished by precise geometric dimensions and uniform wall thickness. This is explained by the fact that roll forming equipment serves not only to give the required profile, but also to correct some defects in the workpiece. The range of equal-shelf products is determined by GOST 8278-83. Depending on the material used to manufacture these metal products, the standard wall height varies:

- carbon boiling and semi-calm steel – 25-410 mm;

- calm carbon and low-alloy - 25-310 mm. Steel channel - a type of shaped rolled steel with a U-shaped cross section. For the manufacture of these metal products, carbon, low-alloy, corrosion-resistant steels are used. Galvanizing or painting can increase the corrosion resistance of products made from “black” steels. According to the production method, the channel is divided into hot-rolled and bent. Depending on this, the appearance of the products differs. The outer corners of a hot-rolled profile have clear outlines, while those of a bent profile are rounded.

Angle weight

Angle steel is one of the types of rolled metal, in the form of an L-shaped profile. Due to its low weight and high bending resistance, it is widely used in all sectors of the economy, in particular, it is most common in construction for reinforcing concrete in monolithic structures and floors. According to the cross-sectional shape, it is divided into equal-flange and unequal-flange.

The steel angle weight calculator from the KALK.PRO service allows you to determine the weight of rolled metal based on the known characteristics of the sides and the length of the profile. The steel grades used can be found in the grade registry, in the corresponding interface tab. The program algorithm makes calculations based on GOST 8509-93 “Hot-rolled equal-flange steel angles”, GOST 8510-86 “Uneven-flanged hot-rolled steel angles”.

Using a calculator, you can find the weight of all possible types of assortment, for example, a corner 40x40x4, 50x50x5, 63x63x5, 75x75x5, etc. If necessary, you can immediately use a metal grader or look at GOSTs in the corresponding tool tabs.

By default, the weight of 1 meter of corner is considered.

Calculation of corner weight

- Select the metal type (default is Steel ).

- Confirm the assortment type – Angle .

- Select the metal grade (default Steel St3sp ).

- Specify the corner parameters - width a, b (mm), shelf thickness t (mm) .

- Enter the length of the rolled metal L, m .

Retail Engineering

Gosstroy of the USSR in a letter dated May 23, 1985. No. AD-2314-4 established the procedure for determining the surface area of steel structures.

The total surface area of the rolled profiles that make up the structure is determined in square meters by multiplying the total mass of the rolled profiles that make up the structure by the corresponding surface area values (given below) contained in 1 ton of rolled steel sections.

| Profile name, number and section thickness | Surface area, sq.m/1 t. profile | Profile name, number and section thickness | Surface area, sq.m/1 t. profile | Profile name, number and section thickness | Surface area, sq.m/1 t. profile |

| Sheet steel and open bent profiles (surface shown is total on both sides) | |||||

| sheet thickness | sheet thickness | sheet thickness | |||

| 2,0 | 127,6 | 7,0 | 36,6 | 22,0 | 11,8 |

| 2,2 | 115,9 | 8,0 | 32,1 | 25,0 | 10,4 |

| 2,5 | 102,3 | 9,0 | 28,5 | 28,0 | 9,4 |

| 2,8 | 91,2 | 10,0 | 25,7 | 30,0 | 8,7 |

| 3 | 85 | 11,0 | 23,4 | 32,0 | 8,2 |

| 3,2 | 79,9 | 12,0 | 21,5 | 36,0 | 7,3 |

| 3,5 | 73,0 | 14,0 | 18,4 | 40,0 | 6,6 |

| 4,0 | 63,9 | 16,0 | 16,2 | 45,0 | 5,9 |

| 5,0 | 51,1 | 18,0 | 14,4 | 50,0 | 5,4 |

| 6,0 | 42,7 | 20,0 | 13,0 | 55,0 | 4,9 |

| Closed bent square, rectangular and pipe profiles (the surface is given on the outside of the rolled product) | |||||

| wall thickness | wall thickness | wall thickness | |||

| 2,0 | 65,2 | 8,0 | 16,6 | 18,0 | 7,5 |

| 2,5 | 52,1 | 9,0 | 14,5 | 20,0 | 6,7 |

| 3,0 | 43,5 | 10,0 | 13,1 | 22,0 | 6,1 |

| 3,5 | 37,3 | 11,0 | 11,8 | 25,0 | 5,5 |

| 4,0 | 32,9 | 12,0 | 10,8 | 28,0 | 5,0 |

| 5,0 | 26,5 | 14,0 | 9,3 | 30,0 | 4,7 |

| 6,0 | 22,0 | 16,0 | 8,1 | 32,0 | 4,4 |

| 7,0 | 19,0 | 17,0 | 7,6 | 40,0 | 3,5 |

| Equal flange angle steel | |||||

| shelf thickness | shelf thickness | shelf thickness | |||

| 3,0 | 86,5 | 9,0 | 29,5 | 20,0 | 13,3 |

| 4,0 | 65,0 | 10,0 | 26,3 | 22,0 | 12,0 |

| 5,0 | 52,0 | 12,0 | 22,0 | 25,0 | 10,6 |

| 6,0 | 44,0 | 14,0 | 19,0 | 28,0 | 9,6 |

| 7,0 | 37,0 | 16,0 | 16,6 | 30,0 | 9,0 |

| 8,0 | 33,0 | 18,0 | 14,9 | ||

| Hot-rolled channels (the total surface is shown on all sides) | |||||

| profile number | profile number | profile number | |||

| 5 | 47,1 | 16 | 40,5 | 22A | 34,9 |

| 6,5 | 46,4 | 16A | 38,7 | 24 | 35,0 |

| 8 | 45,4 | 18 | 39,3 | 24A | 33,3 |

| 10 | 44,7 | 18A | 37,7 | 27 | 33,2 |

| 12 | 43,1 | 20 | 38,3 | 30 | 31,4 |

| 14 | 41,6 | 20A | 36,4 | 33 | 29,6 |

| 14A | 39,7 | 22 | 36,6 | 36 | 27,7 |

| 40 | 26,1 | ||||

| I-beams (the surface is the total on all sides) | |||||

| profile number | profile number | profile number | |||

| 10 | 44,4 | 20 | 38,1 | 36 | 26,7 |

| 12 | 43,1 | 22 | 36,7 | 40 | 24,9 |

| 14 | 41,8 | 24 | 34,4 | 45 | 23,2 |

| 16 | 40,5 | 27 | 33,0 | 50 | 21,4 |

| 18 | 39,1 | 30 | 31,2 | 55 | 19,7 |

| 60 | 18,1 | ||||

| I-beams for monorails (the total surface is shown on all sides) | |||||

| profile number | profile number | profile number | |||

| 24M | 24 | 36M | 21,4 | ||

| 30M | 22,3 | 45M | 19,3 | ||

| Beams with parallel flange edges (the surface is the total on all sides) | |||||

| profile number | profile number | profile number | |||

| 20Bx | 49,1 | 40Bx | 34,9 | 70Bx | 21,0 |

| 20B1 | 39,4 | 40B1 | 30,8 | 70B1 | 19,1 |

| 20B2 | 36,7 | 40B2 | 27,8 | 70B2 | 17,4 |

| 20B3 | 33,6 | 40B3 | 25,5 | 70B3 | 15,8 |

| 23Bx | 45,9 | 45B | 32,3 | 70B4 | 14,6 |

| 23B1 | 38 | 45B1 | 27,5 | 80B | 19,3 |

| 23B2 | 35,3 | 45B2 | 24,9 | 80B1 | 17,2 |

| 23B3 | 32 | 50B3 | 22,8 | 80B2 | 15,5 |

| 26Bx | 43,2 | 50Bx | 29,3 | 80B3 | 14,2 |

| 26B1 | 35,9 | 50B1 | 24,8 | 80B4 | 13,1 |

| 26B2 | 33,3 | 50B2 | 22,8 | 90Bx | 17,8 |

| 26B3 | 30,4 | 55B3 | 20,3 | 90B1 | 15,7 |

| 30Bx | 40,7 | 55Bx | 26,7 | 90B2 | 14,5 |

| 30B1 | 35,4 | 55B1 | 22,6 | 90B3 | 13,2 |

| 30B2 | 33,0 | 55B2 | 20,8 | 90B4 | 12,0 |

| 30B3 | 30,1 | 60B3 | 19,1 | 100Bx | 16,7 |

| 35Bx | 37,8 | 60Bx | 24,4 | 100B1 | 14,4 |

| 35B1 | 34,4 | 60B1 | 20,5 | 100B2 | 13,0 |

| 35B2 | 31,1 | 60B2 | 18,6 | 100B3 | 11,7 |

| 35B3 | 28,4 | 60B3 | 17,2 | 100B4 | 10,6 |

| Wide-flange beams (the total surface is shown on all sides) | |||||

| profile number | profile number | profile number | |||

| 20Shx | 38,9 | 40Shx | 23,2 | 70Ш1 | 15,8 |

| 20Ш1 | 33,8 | 40Ш1 | 20,4 | 70Ш2 | 14,4 |

| 20Ш2 | 31,2 | 40Ш2 | 18,9 | 70Ш3 | 13,1 |

| 23Shx | 37,9 | 40Ш3 | 17,9 | 70Ш4 | 12,0 |

| 23Ш1 | 30,9 | 40Ш4 | 16,2 | 70Ш5 | 11,0 |

| 23Ш2 | 27,8 | 50Sh | 22,6 | 70Ш6 | 10,3 |

| 26Shx | 33,2 | 50Ш1 | 19,4 | 70Ш7 | 19,5 |

| 26Ш1 | 28,6 | 50Ш2 | 17,4 | 70Ш8 | 8,8 |

| 26SH2 | 25,9 | 50Ш3 | 15,7 | 80Ш | 17,4 |

| 30Shx | 30,1 | 50Ш4 | 14,2 | 80Ш1 | 14,4 |

| 30Ш1 | 26,0 | 50Ш5 | 12,9 | 80Ш2 | 13,2 |

| 30Ш2 | 23,4 | 60Ш | 21,4 | 80Ш3 | 12,1 |

| 30Ш | 21,1 | 60Ш1 | 17,4 | 90Ш | 15,7 |

| 30Ш4 | 19,4 | 60Ш2 | 16,0 | 90Ш1 | 13,1 |

| 35Ш1 | 22,7 | 60Ш4 | 13,1 | 90Ш3 | 11,1 |

| 35Ш2 | 20,8 | 60Ш5 | 11,8 | 100Sh | 14,2 |

| 35Ш3 | 19,1 | 60Ш6 | 10,7 | 100Ш1 | 12,3 |

| 35Ш4 | 17,3 | 70Ш | 19,7 | 100Ш2 | 11,3 |

| I-beam columns (the total surface is shown on all sides) | |||||

| profile number | profile number | profile number | |||

| 20K | 32,3 | 30K1 | 21,4 | 35K8 | 10,0 |

| 20K1 | 29,6 | 30K2 | 19,9 | 40K | 19,9 |

| 20K2 | 26,1 | 30K3 | 18,3 | 40K1 | 17,5 |

| 20K3 | 23,7 | 30K4 | 16,7 | 40K2 | 16,0 |

| 20K4 | 21,7 | 30K5 | 15,2 | 40K3 | 14,5 |

| 23K | 31,6 | 30K6 | 14,1 | 40K4 | 13,1 |

| 23K1 | 27,5 | 30K7 | 12,8 | 40K5 | 11,8 |

| 23K2 | 25,7 | 30K8 | 11,7 | 40K6 | 10,8 |

| 23K3 | 23,2 | 35K1 | 19,3 | 40K7 | 9,8 |

| 23K4 | 21,9 | 35K2 | 17,3 | 40K8 | 9,0 |

| 26K1 | 26,1 | 35K3 | 15,6 | 40K9 | 8,2 |

| 26K2 | 23,3 | 35K4 | 14,2 | 40K10 | 7,8 |

| 26K3 | 20,9 | 35K5 | 13,0 | 40K11 | 6,2 |

| 26K4 | 19,2 | 35K6 | 11,9 | 40K12 | 5,2 |

| 26K5 | 17,6 | 35K7 | 10,9 | 40K13 | 4,4 |

| 40K14 | 3,7 | ||||

Calculation of paint consumption rates for 1 ton or more when painting metal structures

On this page you can calculate the rate of practical consumption of paint and varnish material by weight (tonnage) of metal structures , taking into account the roughness and method of applying the paintwork material. The default calculation is per 1 ton. Indicate in the calculator the total weight of metal structures to be painted and get the rate of consumption of paints and varnishes for the total tonnage. The calculators are divided into two versions. In the first version, you can select a specific brand of varnish, primer or paint. The second version will be useful to you if you did not find the brand of paint in the first calculator. But it will be necessary to enter the data of the painting material.

The average surface area to be painted per 1 ton of metal structures is 29 m2.

Download VSN 447-84

Share on social networks

Page contents1 Calculator and formula for calculating the percentage of a number2 Calculator and calculation formula.

Page contents1 Calculation of the carbon equivalent of a metal2 Example of carbon calculation.

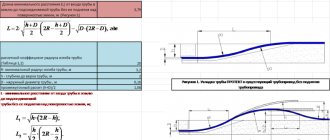

Page contents1 Calculation of area, amount of paint when painting pipes2 Calculator for calculating area.

Collection of construction calculators In this section you will find useful construction calculators.

By sending a message, you authorize the collection and processing of personal data (according to the legislation of the Russian Federation). Privacy Policy.

Corner surface area 50x50x5

Determining the required volume of paints and varnishes and assessing the financial costs of metal processing is impossible without calculating the area to paint metal structures.

Most organizations that provide painting of metal structures include the cost of this service in calculating the total cost of metal structures per 1 m². This method of calculation is quite acceptable when processing parts with more or less smooth surfaces, the area of which can be calculated without much difficulty.

However, if metal structures have a complex shape, this method is not used. This can be explained very simply: calculating the channel area is a complex process, and for openwork products it is not at all a feasible task. In these cases, it is customary to calculate the cost of painting metal structures per 1 ton, which significantly simplifies the process and avoids errors.

Channel marking (designation)

In order not to get lost in the variety of rolled products, a generally accepted channel designation (labeling) system is used. One of the documents regulating the marking of rolled metal products, including channels, is GOST 535-2005.

Channel designation system according to GOST 535-2005

Example of channel channel marking according to GOST 535-2005:

- Channel 16U V-GOST 8240-97 / St3ps5-1 GOST 535-2005 , where:

- 16U type and size of channel with a slope of the internal edges of the shelves;

- B – normal rolling accuracy;

- St3ps – steel 3 semi-quiet postaka;

- 5 – rental category number;

- 1 – rental group;

Example of channel channel marking according to GOST 11474-76:

- Channel B 120 x 50 4.91 B GOST 8278-83 / 2-St3sp GOST 11474-76 , where:

- Bent channel of equal strength with increased profiling accuracy (B) size 120x50, thickness 4.91 mm according to GOST 8278-83;

- B – normal rolling accuracy;

- St3sp – steel 3 calm postaka;

- 2 – 2nd category according to GOST 16523;