The procedure for soldering two metal parts was known to the ancient Greeks. Today, the word soldering iron is more associated with the creation or repair of equipment powered by electricity. However, soldering irons are constantly used by jewelers, repairmen, and auto mechanics. And if you imagined an auto mechanic trying to solder something with a household electric soldering iron, then you are deeply mistaken, they use a gas soldering iron .

What it is?

A person who has at least once seen the operation of a gas welding machine can well imagine the design of a gas soldering iron . This tool consists of three parts:

- Gas filling tank;

- Flame adjustment button;

- Connector.

In fact, the design is a little more complicated, but if you do not plan to change the nozzle or air intake, and this is not worth doing, then you will not have to disassemble the soldering iron. The main advantage is the ability to use stings of different shapes and purposes. You can replace the working tip within a few seconds if it has cooled to an acceptable temperature.

The principle of operation of a gas soldering iron

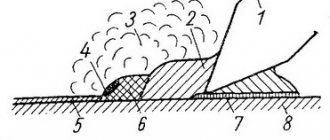

Unlike gas welding, when soldering with a gas soldering iron, an open flame is rarely used. The design of the soldering iron provides a special catalyst, which looks like a ceramic mesh coated with platinum. Thanks to the catalyst, the soldering iron flame does not burst out, but burns evenly on the surface of the ceramic grill and heats the tip. Ceramics is a fairly fragile material, so it is not advisable to drop the soldering iron. Many craftsmen make a catalyst for a gas soldering iron from a nichrome thread, which is quite capable of replacing the original.

So, let's take a closer look at how a gas soldering iron works:

- The tank is filled with gas , which is usually used to refill kitchen or ordinary lighters. Refilling a gas soldering iron takes 15-30 seconds, and the operating time of the tool will depend on the selected power;

- Fuel is supplied to the nozzle through a valve that controls the gas supply intensity, that is, the operating temperature;

- The gas is ignited using a piezoelectric element or flint, or simply from a match - it all depends on the model;

- Using the regulator button, the required flame length is set , that is, the temperature required for soldering.

You can bring the soldering iron into a state of “combat readiness” in half a minute, which is an undoubted advantage of the tool. In any case, before using a gas soldering iron, you should carefully study the instructions. Note “before” and not after half the apartment was almost burned down.

Gas soldering iron – what should you consider when purchasing?

What is the best gas soldering iron? The answer to this question depends on what the device will be used for. Gas soldering irons work best on relatively small parts. Before making your final choice, you should pay attention to:

- Soldering iron power - the principle is simple: the higher the power, the more parts can be soldered;

- Operating temperature depends on the selected solder. In stores you can find soldering irons with and without temperature adjustment. The first solution is better because it allows you to adjust the temperature for a specific job;

- Warm-up time is not a particularly important parameter. But if you are concerned about the device's quick readiness for use, you should pay attention to this. Gas soldering irons heat up from ten to several tens of seconds. In this regard, however, it is best to use transformer soldering irons, which are ready to go within 7-10 seconds;

- Gas filling method – these can be replaceable cartridges or tanks that need to be filled with gas yourself.

Post Views: 1,508

Use of gas soldering irons

The multi-faceted personality of the tool allows it to be used for various purposes:

- Heating of rusted parts, heat-shrinkable pipes, etc.;

- Cutting plastic – the best gas soldering irons are capable of not only cutting, but also fusing and welding plastic parts;

- Cleaning of old paints and varnishes;

- Soldering with a gas soldering iron (with an open flame, where the temperature rises above 1000 °C) allows you to solder using high-temperature hard solders;

- Repair various equipment, including automotive electronics, while standing on the side of the road;

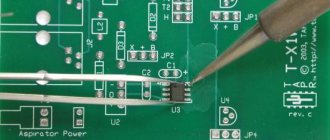

- A mini gas soldering iron, also known as a “pencil”, allows you to spot solder microcircuits and circuit boards even in conditions of complete absence of electricity;

- The tool has gained wide popularity among installers and electricians working on sites under construction or without power.

Dremel versatip how to refill

If you use a low temperature colored or glitter glue stick, the glue may lose its pigment. Additionally, high temperatures will cause the glue to become too thin and leak out of the glue gun.

Overview of glue guns:

GG910 - High Temp (165 degrees Celsius) GG920 - Low Temp (105 degrees Celsius) GG930 - Dual Temp (105 and 165 degrees Celsius modes) GG940 - High Temp (165 degrees Celsius)

Overview of Glue Sticks:

GG01 - high temperature (165 degrees Celsius), multi-purpose adhesive for use in GG910 or GG930 guns (in high temperature mode) GG02 - low temperature (105 degrees Celsius), multi-purpose adhesive for use in GG920 or GG930 guns (in low temperature mode) GG03 - high temperature ( 165 degrees Celsius), wood glue, for use in GG910 or GG930 guns (in high temperature mode) GG04 - low temperature (105 degrees Celsius), decorative gloss adhesive for use in GG920 or GG930 guns (in low temperature mode) GG05 - low temperature ( 105 degrees Celsius), decorative colored glue for use in GG920 or GG930 guns (in low temperature mode) GG11 - high temperature (165 degrees Celsius), multi-purpose adhesive for use in GG940 gun GG13 - high temperature (165 degrees Celsius), wood glue, for for use in the GG940 pistol

What happens if I use a low temperature glue stick with a high temperature glue gun?

If you use a low temperature colored or glitter glue stick, the glue may lose its pigment. Additionally, high temperatures will cause the glue to become too thin and leak out of the glue gun.

How long can I use the 940 glue gun after unplugging the cord?

It depends on the application. Typically, the glue in the gun chamber cools in about five minutes. However, after this, electricity will be needed to warm up the glue and replenish the glue gun chamber.

What attachments are suitable for engraving tools?

To do this, you can use only two attachments, replaceable engraving burs. These are Carbide Bur #9924 and Diamond Bur #9929. Attachments designed for Dremel Multi Tools will not work with this tool.

What is the difference between carbide and diamond burs?

Carbide bur has proven itself in general engraving work on most known materials. Diamond bur is designed to work under heavier and longer loads, so it is best used when engraving on hard materials (for example, glass). The results will be the same, but with such an attachment you can process harder materials and (or) ordinary materials, but for a longer time. Diamond bur is not suitable for engraving on steel. include a link to search for attachments

Comparative characteristics of electric and gas soldering irons

Mobility and convenience:

- Electric – tied to the network , limited by the length of the cord;

- Gas – full mobility ; can be used in hard-to-reach places; does not require electricity; Having a gas cylinder on hand makes it easy to refill at any time.

- Electric – the average tip heating time is 3-5 minutes ;

- Gas – ready for use in 10-30 seconds ;

- Electric - only expensive models ;

- Gas - any model has the ability to adjust the flame and several modes: using a replaceable tip, you can solder with a gas soldering iron using a thin stream of heated air, burner.

- Electric - virtually all models have an operating temperature of 450°C ;

- Gas - depending on the tasks, the temperature can be adjusted from 500 to 2000 °C .

Read also: How to reduce engine speed without losing power

Gas soldering iron from China

- Price: $6.29

- Go to the store

Due to my occupation, there was a need for a non-volatile soldering device. I chose this sample for reference. It arrived in a classic manner, in three weeks, even though I ordered paid delivery.

The inscription on the packaging is in Chinese, there is no English translation either. The only thing that is clear is the refill capacity – 8 ml. The soldering iron is empty, because filled with gas will not be allowed through customs. After opening at customs, the package was sealed with tape.

First refueling. When the volume is ¾ full, the filling valve begins to spit and does not want to let in more gas than designed.

The gas burner divider was tightened too much; I had to resort to pliers, holding the divider body through a cloth. After removal, I installed the tinning tip. I do not recommend touching the tip with the catalytic filler with your hands - it is better to handle it through a dry, clean cloth to avoid damaging this very catalytic layer. To light the burner you need an external lighter, just a pun. The flame from the soldering iron tip is not strong from the beginning of operation, after 10 seconds the open flame goes out and the work of the catalytic layer is visible. We try to tin the sting, it turns out easy. It is quite difficult to adjust the temperature of the tip right away. At the beginning of work, you have to wait until the heat from the head heats up the tip itself. After 10 minutes of operation, the temperature has to be reduced, because... Overheating of the working part of the tip is observed, the solder simply rolls off the tip. When the gas runs out, this is after about 30 minutes of operation, gas, on the contrary, must be added, because the combustion of the catalytic mesh occurs “in jerks,” this can be seen from the degree of glow of the mesh itself.

Test soldering of wires with a diameter of 1 mm. The heat capacity of the head is enough for complete heating.

Checking the operation of the gas burner. The thought was the following: is it possible to use this device as a hair dryer when soldering small-sized elements. I put on the burner divider and light it. As with the soldering tip, we wait about 10 seconds to reach the operating mode. The flame stabilizes. After a minute, the cylinder heats up and the flame becomes more powerful. You can feel the temperature of the gas cylinder rising, at first it was scary - it wouldn’t explode in your hands... The adjustment is simple, by turning the ring around the body of the gas cylinder. When the ring is twisted too hard, play appears. It doesn’t interfere with work, but there is a feeling of fragility.

Looks better in the photo than in life. For experiments, let’s use a burnt-out comfort control unit from a car as a hair dryer. A fairly large free-standing diode, or rather its remains after heating with a burner flame, can be easily removed with tweezers. Seems not bad. I'll try to reheat the soldering of the burnt microcircuit. It didn’t work out... The housings near the relays began to melt, and the nearby SMD resistors also “floated” from their places. The housing of the microcircuit also began to melt, but did not move from the board. The problem is that it is impossible to determine what temperature the burner flame is. In closed board volumes this leads to undesirable results.

Testing the soldering iron on the road. The car is parked in the city center, but the nearest outlet is 200 meters away. The broken high-pressure hose “carried away” the wiring harness for controlling the stepper motor and the throttle cable position sensor. Wiring in oil and diesel fuel. I burn the ends of the wires and clean them. Tip soldering with flux and solder. The heat capacity of the soldering nozzle is enough to repair fairly thick wires. The torch will help with shrinking the heat shrink after soldering. I quite liked the result. There is no photo of the finished work - it was a pity to get the phone dirty.

To complete the experiment, we try soldering a medium-sized board. I found a Soviet-made hand dryer. First of all, I remove the “electrolytes” and change them to modern ones. I wonder how long the gas will last? I soldered all connections. The total time of using the sleeping bag with a full filling of the cylinder was 40 minutes. Not bad.

Otherwise, nothing prevents you from working with this soldering iron with SMD elements - as long as there is enough space. The material of the tip in the nozzle is copper. But apart from the standard needle, no other soldering attachments were offered for this soldering iron. Tips of the desired shape can be made independently from the housings of Soviet diodes, I found this on the vastness of U-Tube. The length of the shank of the tip itself is 4 mm, the depth of the hole for it is 6 mm. The thread on all connections is 5 mm, metric. Photo with M5 nut. This is for DIYers. It should be borne in mind that the longer the tip you make, the worse it will work.

Conclusion. The pin can help out when installing wiring and repairing wires in the absence of electricity. It can be used quite successfully when soldering medium-sized elements. A gas burner is convenient for heating heat shrink and wires for stripping insulation. Avoid using the burner in confined spaces of the vehicle, for example under the dashboard. It's well worth the money when ordering from China.

The device was purchased with my own money for personal use.

The main thing is to choose correctly

A master planning to purchase a new tool for himself will try to find out which gas spigot is better . There is no clear answer to this question. First you need to decide for what purpose you are going to purchase this unit, and then find a store where you can buy a gas soldering iron at an affordable price and of appropriate quality. Well, let's say you've already found a place - our store has goods from the best manufacturers. There are still goals.

Hobby or home use - inexpensive models are suitable as a tool, but preferably not made in China. An average tool can easily cope with everyday tasks: soldering a part, connecting wires, soldering or cutting plastic, even starting a fire from wet wood. By the way, for lovers of hiking and relaxing in the lap of Mother Nature, we offer gas soldering irons and burners that will save you from the unnecessary hassle of cooking or heating food.

Professional soldering - this requires a tool with the ability to fine-tune and a wide range of tasks performed. An excellent choice would be the Dayrex gas soldering iron, which is suitable for working with hard and soft solders, heats up parts perfectly, and easily cuts plastic. It is better to refill a professional gas soldering iron (the instructions are often silent about such nuances) with proven, well-purified butane. Using cheap gas for a gas soldering iron, you risk quickly ruining the catalyst - it will simply become clogged with solid impurities. However, if such a problem does happen, then there is no need to panic - just take out the catalyst and clean it.

By trusting a professional gas tool, you get the opportunity to quickly get to work and carry it out at the highest level. And we, in turn, are always happy to provide you with gas soldering irons from trusted manufacturers and at affordable prices.

Dremel VersaTip Gas Soldering Iron

For the New Year I bought myself this gas soldering iron from Dremel:

The point of a gas soldering iron is that it can work far from an outlet: solder something in a car, on a boat, a model airplane, or an antenna on the roof. Using a hot air nozzle is convenient for shrinking heat shrink (which in some cases is much more aesthetically pleasing than blue electrical tape). They can also be used to warm castles in winter and light a fire using a gas burner.

I took Dremel because I use their Dremel 300 and am pleased with the quality and reliability, plus the cost is quite adequate (I bought it on Ozon.Ru for 1,485 rubles, in OBI it cost 1,999 rubles).

At the end of the note I will collect links to reviews of other gas soldering irons.

Nozzles

From left to right:

- Reflector.

- Hot air nozzle.

- Soldering nozzle.

- Cutting knife.

- Hot cutting knife.

- Catalytic nozzle. Other attachments are screwed to it (except for the reflector and the wide heating nozzle).

- Flat wide heating nozzle.

Package

A cellulose sponge in a tin is needed to wipe the solder off the tip. Before use, you need to wet it with water and squeeze it a little - it will swell. No need to wipe the soldering iron on a dry sponge!

An empty tin can is needed to store the cooling attachments. You can remove hot attachments using wrenches.

Reducing the minimum power for comfortable soldering

Initially, the soldering nozzle heats at a minimum of 450-500 degrees, which immediately oxidizes the solder. Soldering semiconductors and microcircuits at this temperature is not recommended.

To adjust, you need to remove the blue pin on the power regulator. Under the eyelet there will be a slot for a screwdriver. If you turn the spline, you can change the position of the adjusting ring relative to the valve.

Reduce gas supply to minimum:

- Set the regulator to minimum.

- Unscrew the slot.

- Turn the regulator to maximum.

- We tighten the slot.

- Carefully turn the regulator towards the minimum until it stops turning - the valve is closed. Turn the regulator a couple of millimeters towards the maximum.

- Unscrew the slot.

- Turn the ring to the minimum position.

- We tighten the slot.

The advantages of this setup:

- The sting does not burn as quickly. At 450-500 degrees the tip will burn very quickly.

- When soldering, the solder does not oxidize.

- Gas consumption is reduced.

- The soldering iron is less noisy.

- There is no brutal stream of hot air blowing from the nozzle on the nozzle, desoldering everything around.

- When the power regulator is in the minimum position in burner mode, the flame does not burn. In my opinion, this is not a problem.

Read also: The simplest DIY induction heater circuit

Refueling

I didn’t want to buy cheap Chinese gas for lighters.

For now I use Kovea gas for gas burners:

The composition is 70% butane + 30% propane, and the Dremel VersaTip is designed for 100% butane. That is, it is not entirely correct to use such gas (but it is definitely better than cheap gas, which will quickly clog the nozzle and cause the soldering iron to fail).

The need to solder parts may arise when repairing radio equipment, household appliances, electronics, jewelry and various car components. A common tool associated with this type of work is an electric soldering iron. Not everyone knows about other varieties of this device, but modern models of gas soldering irons have a number of advantages over their electric counterparts. What is special about gas soldering irons, why they are good, how to choose them - read in our material, and at the same time pay attention to our independent TOP 5 best gas soldering irons for a variety of cases and for a variety of budgets.

Gas soldering iron from Aliexpress, advantages and disadvantages, description of work

Not long ago I carefully watched another interesting video on the topic of electronics.

I noticed a very unusual soldering iron in the frame. I noticed that it did not receive power from wires, but had to be refueled with liquefied gas. I became interested, and besides, by a happy coincidence, a batch of the same gas-powered soldering irons was sold in a nearby radio store. Don’t be upset if a gas soldering iron is not sold anywhere near you, you can purchase one on Aliexpress.

In common parlance they are called gas soldering irons. So I decided to purchase it to test its capabilities, advantages and disadvantages. Is this thing useful for certain types of work in the workshop?

Gas soldering iron: buyer's guide

What is a gas soldering iron?

A gas soldering iron is a universal compact device that is convenient to use when there is no connection to an electrical outlet, as well as when it is necessary to solder parts made of various materials. It is used for soldering radio components, heating pipes and threaded connections, soldering large elements using refractory solder, softening old paint and varnish coatings and other types of work.

To understand the principle of operation of the device, it is necessary to consider the features of its design. All models of gas soldering irons consist of the following elements:

- containers for filling with liquefied gas;

- gas burner with built-in ceramic grate;

- working nozzle.

When the device operates, the gas gradually leaves the tank and mixes with oxygen in the air. Ignition is carried out due to a piezoelectric element or an external fire source. The flame intensity is changed using a special button, which allows you to adjust the operating temperature. A ceramic grid coated with a layer of platinum serves as a catalyst, thanks to which the flame burns evenly and quickly heats the soldering iron tip.

The main advantages of gas soldering irons

The main distinguishing feature of gas soldering irons is the ability to operate autonomously. With the help of such devices, you can solder parts of various sizes in any conditions, and not just at your desk. Gas soldering irons can be used in hard-to-reach places, while the working area of electrical devices is limited by the length of the cord and depends on the location of the outlet.

Most models of gas soldering irons are equipped with a special lock that protects the device from spontaneous activation. Within 15-30 seconds they heat up to 450-2000°C and can operate in several modes:

- soldering with a heated tip using a connecting substance;

- burner - heat treatment of the surface of parts using an open flame;

- air soldering, carried out using a narrowly directed gas flow.

In order to start working with an electrical device, you will need to wait 5-7 minutes, while the ability to adjust the heating is provided only in expensive models. The operating temperature of such devices is 450°C.

What to look for when choosing the best gas soldering iron?

Since the range of gas soldering irons on sale is quite wide, choosing the best tool for a certain type of work is quite difficult. In order for the soldering iron to meet your expectations during operation, you should pay attention to the following characteristics when purchasing:

- Maximum temperature. The scope of its application depends on the temperature range of the soldering iron. The higher the heating temperature, the wider it is. Models that heat up to 1000-1500°C are suitable for home use. It is better for professionals to purchase a device with a maximum temperature of 2000°C.

- Availability of flame level regulator. This function provides the ability to select the desired temperature and combustion intensity for soldering parts made of various materials.

- Flame type. If the work requires significant heating of the surface, it is advisable to use a tool with a vortex flame flow. The pencil flame is suitable for applications where concentrated heat is required, while the jumbo, characterized by its sharp flame, is intended for heat-intensive and rough work. The multi-purpose flame is used where very high temperatures are not required.

- Volume of the fuel container. This characteristic determines the service life of the tool. The smaller the tank volume, the more often it will have to be refilled.

- Ignition type. Models equipped with a piezo ignition mechanism are more convenient than those that are started using fire sources. If you find yourself in the field without matches or a lighter, it will be impossible to use the latter.

Read also: What can be done with a pipe bender

Criterias of choice

| Maximum temperature | The temperature range affects the scope of the gas soldering iron, on average 1200 -1500°C, professional models - 2000°C |

| Is there a flame level regulator? | If provided in the model, then you can set a more accurate temperature for working with different materials. |

| Refill capacity, ml | The larger the gas capacity, the longer it can work on one refill |

| What type of arson | Some models come with piezo ignition, while simpler ones are ignited with matches and lighters |

Gas soldering iron attachments

TOP 5 best gas soldering irons

The best gas soldering iron for professionals

Dremel Versatip F0132000JC

Dremel Versatip F0132000JC priced at about 3,500 rubles. The soldering iron of this model is equipped with 6 nozzles and is suitable for operations such as melting, sealing, burning, removing heat shrink and hot cutting. Thanks to its high heating speed and fast recharging, the device is always ready for use. Additional features include a child lock, piezo ignition and a pencil flame level regulator. The set includes a hard case for storing the tool. The disadvantages are the rapid burnout of the catalyst, low inertia of the tip.

The best stationary gas soldering iron

Dremel Versaflame F0132200JC

Dremel Versaflame F0132200JC is the best multifunctional stationary soldering iron model. It costs about 3,500 rubles and is suitable for use both in workshops and at home. The instrument reservoir is filled with liquefied butane. The device comes with a removable foot. At maximum load, the soldering iron can work continuously for 70-75 minutes. It is equipped with a mechanism for blocking the flame, a flame level regulator and a piezoelectric element. The disadvantage of the model is the inability to work at low temperatures.

The best budget gas soldering irons

TDM-Electric Diamond SQ1025-0102

TDM-Electric Almaz SQ1025-0102 is an inexpensive soldering iron costing about 1000 rubles, the advantages of which include: the presence of three types of stainless steel tips (hair dryer, cutter and tip), fast heating, wide operating temperature range (450-1300°C), non-slip surface texture of the case. The packaging contains useful information about safe working practices. The disadvantages include starting using external fire sources and the inability to regulate the flame level.

A-HOT AH-063

A-HOT AH-063 is the best budget soldering iron with a piezo ignition function for spot work with materials such as wood, plastic or metal. The device costs about 1300 rubles. On the body of the instrument there is a button for fixing a thin pencil flame and a regulator of its intensity. The fuel used to operate the soldering iron is butane gas. Maximum heating temperature is 1200°C, tip length is 15 mm. The disadvantage of the device is the lack of additional attachments.

The best gas soldering iron with a set of attachments

DAYREX 626553

DAYREX 626553 is a convenient tool priced at about 3,800 rubles, with which you can carry out auto repair and jewelry work, welding, soldering, hot cutting and heat shrinking. A charged soldering iron can work for 1-1.5 hours. The device is launched using a piezoelectric element. Flame type: pencil. In addition to a set of nozzles, the kit includes a gas cylinder, a wrench, solder, a stand, and a sponge for cleaning the nozzles. The disadvantage of the model is frequent overheating of the tip.

Principle of operation

A fairly small soldering machine has a complex design, which includes the following elements:

- nozzle - acts as a source of fire;

- piezo ignition – reproduces the spark and promotes the formation of a flame;

- nozzles - the functioning part of the tip, heating the elements being soldered;

- fuel tank – used for refueling;

- plastic case - containing all the main working units;

- flame catalyst - acts as a fire controller;

- grille air intake;

- work regulators.

Before using the Dremel Versatip gas soldering iron, the device must be primed with fuel and equipped with a suitable tip. Next, with the help of regulating elements, the supply of fuel to the nozzle is turned on, after which ignition occurs and the heat power is regulated.

VIDEO: How to properly use a soldering iron and cut off the flame

Scope of application

Dremel soldering iron models are used to perform a variety of tasks. The list is not limited only to soldering work, it also includes:

- cutting of polypropylene pipes;

- surface heating of metal products to eliminate corrosion build-up;

- removing paint from various surfaces;

- burning illustrations on wood, etc.

Design Features

The Dremel Versatip gas soldering iron comes with a different number of attachments, depending on the version. Spare parts allow you to adjust the flame according to its shape. Some attachments make a pencil-type fire, which is used to perform painstaking work, for example, when connecting microcircuits and other small elements. There are also “Jambo” parts that create a voluminous and powerful torch for heating steel surfaces.

The device does not have a controller for the residual volume of liquefied butane. Therefore, you will have to monitor the consumption yourself based on visual factors - leakage of excess, compliance of the flame size with the mode.

Operating rules

The Dremel 2000 gas soldering iron requires compliance with certain rules during operation:

- It is not recommended to operate the device for more than 15 minutes. First of all, during operation of the device, harmful components are released, and the plastic casing of the product may melt.

- Before using the device, all flammable elements must be removed from the workplace. It is advisable that the table be completely cleared of unnecessary items.

- Installation of a new nozzle should be carried out only after the part in use has completely cooled. The fact is that the temperature of the element can reach 450-500ºС.

- The fire catalyst is made of ceramic material, which is both highly resistant to heat and brittle to mechanical stress. Therefore, it is necessary to avoid unreliable fixation of the part and its falling.

If you follow the recommendations, the Dremel 2000 gas soldering iron will last a long time and will properly perform its intended functions.

Model range and prices for Dremel gas soldering irons

On the company's official website there is a fairly small assortment of Versatip 2000 gas soldering machines. In general, they have distinctive characteristics only in terms of the set of additional accessories and attachments. Therefore, the choice should be made based on the needs of the work, since in some cases the basic configuration will not be enough.

Dremel 2000 6 - F013-2000 KA

Cordless soldering iron with six reusable tips. The device allows you to independently select the heating mode, while you can determine the control key intuitively. It should be noted that the device has a child lock.

2000 6 - F013-2000 KA

Fuel consumption is 12 g/h, the maximum heating rate reaches a temperature of 550°C-1000°C. 200. The cost of the set is 2,500 rubles.

Dremel 2000 Versatip Xmas- F013-2000KD

This option has technical characteristics completely identical to the previous set. A distinctive feature is the configuration, in this case it is more expanded.

Comparison table of the best gas soldering irons

Name

Main characteristics

Price

Dremel Versatip F0132000JC

Equipped with 6 nozzles, a child lock, piezo ignition and a pencil flame level regulator.

Dremel Versaflame F0132200JC

The device comes with a removable leg, a mechanism for blocking the flame, a flame level regulator and a piezoelectric element.

TDM-Electric Diamond SQ1025-0102

The presence of 3 types of stainless steel tips (hair dryer, cutter and sting), fast heating, wide range of operating temperatures (450-1300°C), non-slip texture of the body surface.

A-HOT AH-063

There is a piezo ignition function for spot work, a button for fixing a thin pencil flame and a regulator of its intensity.

DAYREX 626553

The device is started using a piezoelectric element, the flame type is pencil, there is a gas cylinder, a wrench, solder, a stand, and a sponge for cleaning the nozzles.

FAQ

Are gas soldering irons explosive? Gas soldering irons are not explosive devices, but safety precautions must be observed when working with them. Do not point the burner flame at flammable objects. If there is a gas leak from the device, the room must be well ventilated.

What gas can be used to refill a gas soldering iron? Before refilling a gas soldering iron, you must study the manufacturer’s operating instructions, which indicate the gas used to operate the device (propane or butane). In most cases, cylinders for refilling conventional lighters are suitable for this purpose.