Marking - symbols

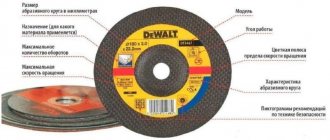

Abrasive wheels have special markings in the form of inscriptions and/or colored marks and contain:

Circle type

In theory, there should be a digital designation:

- 1- straight profile,

- 41 – cutting discs,

- 42 – discs with a recessed center.

But in practice, this will be an inscription in Russian and/or English: “cut-off wheel” - cutting wheel, grinding wheel - grinding wheel, flap wheel.

Circle dimensions

On the manufacturer’s website (see table below) it is stated as follows:

D – outer diameter,

T – height,

H – hole diameter.

However, in practice, the format will usually be: outer diameter x thickness x inner diameter.

Or even something like this:

The material the disc is intended to process

Indicated by an inscription on a circle (“metal” or “steel” - for metal processing, “concrete” - for working with concrete), a colored mark (blue - steel, green - concrete).

Also, sometimes an additional graphic image of the material is applied, which saves us from having to read the inscriptions once again.

In the circle shown in the picture above, the inscription metal and the image of sheet metal, metal pipe, roofing metal sheet and channel clearly demonstrate the material that can be processed.

Grain. Abrasive particle sizes

This parameter is indicated on the wheel in conventional units and indicates the abrasive fraction based on international marking standards.

There are also possible variations from one edition of GOST to another.

Bundle type

Bakelite, ceramics or synthetic rubber is used as a binding component.

7.1. Ceramic bond

V (K – old designation). In the case of a ceramic base, the tool has high fire-resistant, water-resistant and chemical characteristics, which qualitatively preserve the working edge. However, such a grinder disc is sensitive to mechanical shocks and bending loads. Ceramic bonded wheels are used for almost all types of grinding except roughing.

7.2. Bakelite bond

B (B is the old designation). Considering the bakelite base, I would like to note that such grinder wheels have higher rates of elasticity and resilience than their ceramic counterparts. The disadvantage of such a binder is its low resistance to alkaline components included in cooling fluids.

In addition, bakelite-based wheels are weaker than ceramic analogues in adhesion to abrasive grains and, therefore, can mainly be used for flat grinding. Grinder discs made of bakelite bond are used for manual work on rough peeling or on suspended wall surfaces.

At the same time, bakelite wheels have a polishing effect. For the purpose of cutting steel products, a soft bond and a thin abrasive are used. In turn, for non-ferrous metals it is advisable to use a hard bond with a coarse abrasive.

7.3. Vulcanite bond

This is a vulcanized synthetic rubber. The abrasive wheel is marked with the letter (R). The old designation is (B). This option is exotic and extremely rare.

Max. number of revolutions at which the disk can be used

The range varies from 6,600 to 13,300 rpm. Important parameter! If you neglect it, the circle may break into separate fragments during operation.

Accuracy class

AA, A and B. AA – high accuracy of geometric parameters A – Intermediate option. B - for less critical operations.

Best before date

The expiration date is applied by the manufacturer to the metal part of the mounting hole on the outside. The expiration date is the date of manufacture plus 3 years. The quarter is indicated by the letter V. The number indicates the month.

Security pictograms

I guess that no one cares about them, but besides the banal “put on headphones,” something really worthwhile may be applied. For example, do not use for face grinding.

Cutting wheel size 125mm, thickness 2mm, mounting hole 22.23mm, made using normal alumina alumina grinding grain, grit P36. On a bakelite bond with the presence of reinforcing elements.

Types of cutting discs

Cutting wheels for an angle grinder can be either made of abrasive material or all-metal. Depending on the type of material being processed, the type of cutting disc is selected.

For metal

If you need to cut metal, always use bakelite consumables with reinforcing elements. In this case, there must be at least 2 reinforcing meshes.

For ferrous metals, ordinary corundum is used, which contains, in addition to aluminum oxide, impurities of chlorine, iron and sulfur.

For cutting stainless steel, the presence of the above impurities in the cutting wheel is unacceptable, since they cause burning of the steel (overheating). As a result of this, alloying additives can burn out of the stainless steel, and it turns into ordinary steel, as a result of which the cut area begins to become covered with rust. Therefore, it is important to carefully read the information on it before purchasing a disc. A cutting disc for stainless steel is always marked with the letters “AS” and the word “INOX”.

For cutting non-ferrous metals, discs with large abrasive particles are used. For example, a cutting wheel for aluminum, in addition to coarse abrasive, contains special fillers that prevent clogging of the cutting edge.

Users of angle grinders often wonder: what cutting discs for metal are best to use? An ideal grinder disc should have:

- bakelite reinforced bond (RB);

- correctly selected type of abrasive: for stainless steel white electrocorundum (AS), for ferrous metal - ordinary corundum;

- disc thickness from 1.6 to 2 mm;

- outer diameter 125 mm;

- fine abrasive particles if cutting of steel structures is required.

It is not recommended to use abrasive wheels for cutting corrugated sheets, since the cut area overheats and the zinc, the main element that prevents corrosion, burns out of it. To reduce overheating of the material, some craftsmen use a circular metal grinder disc with fine teeth. But in both cases, the cut site must be treated with a special anti-corrosion compound, which can be purchased at a store that sells profiled metal sheets.

For cutting stone

For cutting stone at home, an abrasive disc made of silicon carbide (marked with the letter C) is suitable.

This cutting disc is used for small stone work, as it wears out quickly. But, due to its low cost, this consumable is quite popular among owners of grinders.

An abrasive disc for stone is not suitable for professional use. For these purposes, it is recommended to choose an all-metal cutting wheel with diamond coating.

On concrete

Discs for cutting concrete and reinforced concrete are made from high-strength hardened steel, with diamond chips applied to the cutting part. Also, these cutting wheels can be segmented or solid.

Before you start cutting concrete, you need to determine its type. It can be regular or reinforced (containing a metal mesh). It is also worth considering the age of the concrete.

- Young concrete has abrasive properties, so it quickly wears out the tool. To cut it, it is necessary to use segmented diamond discs for concrete of increased thickness.

- Old concrete is a very hard material. To process it, it is better to use a grinder wheel of moderate thickness.

For cutting reinforced concrete, install a universal diamond wheel.

For cutting tiles and porcelain stoneware

It is best to use solid diamond-coated cutting wheels for cutting ceramic tiles . These discs usually say “Wet cut”. As practice shows, this tool makes an excellent, smooth cut on tiles with a minimum of chips, even without the use of water, although this produces a lot of fine dust.

A solid diamond blade can also be used on porcelain tiles.

By the way, this wheel can be used not only for ceramics, but also for cutting thick glass.

On tiles, of course, you can use segmented (dry) and turbo discs, but the quality of the cut will be very low, since chips will inevitably form along its edges.

For cutting plastic

Plastic can be cut well with a regular abrasive metal tool. But there is also a special saw blade (three-toothed) designed for cutting wood, plywood and plastic. It can be used not only for cutting, but also for longitudinal cuts of material, especially thick ones.

When installing this tool, it is important to correctly determine the direction of rotation of the angle grinder spindle.

It is not recommended to use circular saws with many teeth on plastic and wood, due to the high probability of the tool kickback, which can lead to injury.

Grit size of grinding wheels

The choice of grain size of grinding wheels depends on the requirements for the cleanliness of the treated surface. Each grinding wheel has a designation (marking).

It is the markings that help you choose the right sanding tool or sharpener to perform a particular task. The grain size of grinding wheels for wood and metal is different, so the quality of processing depends on the correctly selected model. If there are rough strokes or visible notches on the surface of the material or tool being processed, it means that an error was made when choosing the grain size of the wheel.

The most popular specific instruments on the market are:

- grinding wheel, grit 120;

- grinding wheel, grit 60;

- grinding wheel, grit 100.

The choice of grain size is determined by the type of grinding, the specific degree of surface cleanliness, as well as the grinding mode.

Grinding Wheel Grit Chart

How to choose the grit size of the grinding wheel? It is selected depending on the type of operation. It can be semi-finish or fine. Rough grinding involves the use of wheels with fairly large grain fractions. Finishing of a material or tool requires finer fractions. In addition, the choice of grinding wheel also depends on the technical features of the cutting tool and the sharpening mode.

Grit size of grinding wheels

The choice of grain size of grinding wheels depends on the requirements for the cleanliness of the treated surface. Each grinding wheel has a designation (marking).

It is the markings that help you choose the right sanding tool or sharpener to perform a particular task. The grain size of grinding wheels for wood and metal is different, so the quality of processing depends on the correctly selected model. If there are rough strokes or visible notches on the surface of the material or tool being processed, it means that an error was made when choosing the grain size of the wheel.

The most popular specific instruments on the market are:

- grinding wheel, grit 120;

- grinding wheel, grit 60;

- grinding wheel, grit 100.

The choice of grain size is determined by the type of grinding, the specific degree of surface cleanliness, as well as the grinding mode.

Grinding Wheel Grit Chart

How to choose the grit size of the grinding wheel? It is selected depending on the type of operation. It can be semi-finish or fine. Rough grinding involves the use of wheels with fairly large grain fractions. Finishing of a material or tool requires finer fractions. In addition, the choice of grinding wheel also depends on the technical features of the cutting tool and the sharpening mode.

The role of ligaments

In addition to the cutting substance itself, the method by which it forms the abrasive mass is also important. GOST allows the use of bakelite or ceramics as binders. The bakelite version is good for its higher density, so the wheel has a higher mass and is suitable for working on metal, but with a limited peripheral rotation speed (especially if a hand grinder is used). The use of ceramics makes the grinding wheel lighter, and the permissible speed of its rotation on the machine increases accordingly. However, the abrasive resistance, as well as the hardness of the wheel with ceramics, are reduced.

The connection also determines the method of attachment to the base of the body. For example, film fastening is suitable for ceramic bonds, but not for bakelite bonds.

A special type of ligament is fiber. This base is used in the so-called “cold” grinding of metal on a machine or machine, when the stainless steel surface or weld area is cleaned. In this case, the material being processed practically does not heat up, since the depth of the grinding zone is insignificant (the process is actually closer to polishing). Marking is carried out in accordance with the standards of GOST R 51967.

Other types of bonds are also used to a limited extent - from various epoxy compositions, magnesite, porcelain.

Features of marking cutting discs

The marking is applied to the front of the disc. It contains the following basic data:

- The name of the manufacturer must be applied to the disc.

- Outer diameter, thickness and installation hole size. The thickness is not always included in the marking. The internal and external diameters can be marked in two types: 125x1.6x22.23 (external/thickness/internal) or 180*22 (external and internal). Data can be displayed in both mm and inches.

- Purpose. Information is applied to the surface of the disk about what material it is intended to work with: “metal” (metal), “concrete” (concrete). Sometimes the marking includes more specific data - Steel (steel), Inox (stainless steel), Castiron (cast iron and cast metal), Aluminum (aluminum). You can also tell which material the disc is intended for by its color: green (stone and concrete), blue (metal).

- To mark the type of circle, the numbers are used - 41 (flat), 42 (off-center).

- Data on the binder composition is indicated in the form of letters. For metal work, disks based on bakelite binder are used. In the marking it is indicated as BU or BF.

For the production of wheels, two main types of binders are used - based on vulcanite or bakelite reinforcing composition. Bakelite substance is more popular, as it allows the additional use of fiberglass-based reinforcement. This provides the circles with increased strength.

Important ! Do not use diamond cutting wheels for working with metal. Even with all their high strength, they are not designed to work with this material.

These are the main parameters that can be found in the labeling. But there are other parameters that may be specified by manufacturers.

Design of diamond grinding wheels

The circles represent a body on which a layer of diamonds with different structures is applied. In addition to the diamond elements, the spraying includes a filler and a binder.

All products have different characteristics and differ in:

- the type and shape of the circle;

- case size;

- degree of grain size;

- type of ligament;

- diamond concentrations;

- imbalance class;

- accuracy class;

In addition, they are characterized by strength, hardness, and wear resistance.

Frame

For the manufacture of diamond wheel bodies, steel grades St3, 30, 25 and 20, aluminum alloys grades D16 and AK6 or polymers are used.

For grinding wheels shaped like AGC or A1PP, shanks made of U8 or U7 steel are required.

Diamond concentration

The concentration of the diamond-bearing layer, which is expressed as a percentage, is the number of grains in 1 cubic millimeter of powder used in the abrasive layer. This characteristic affects the efficiency and economy of the tool. The concentration depends on the grit - the higher the grit and the harder the material being processed, the greater the percentage of diamond concentration required for the job.

Diamond grinding wheels are available in 150, 100, 75, 50 and 25 percent concentrations. 100% is taken to be 4.39 carats (1 carat equals 0.2 g) contained in 1 cm3, which corresponds to 0.878 mg/mm³.

This indicator determines the productivity, cutting ability, service life and price of the tool. Optimal performance depends on the area and shape of the material being processed, the type of tool used, bond quality, diamond grain size, and processing conditions.

The choice of circle concentration is based on the following requirements:

- a high concentration is necessary if the contact surface between the workpiece and the grinding wheel is small (for example, during cylindrical grinding), this guarantees a long service life of the tool and increases its wear resistance;

- low concentration is selected for treating large area contact surfaces.

Grain

Grit is the size of a diamond grain or crystal intergrowth (this indicator is determined by thickness, width and height, but usually only width is taken into account). The degree of grain size determines the cleanliness of the surface after processing, work productivity, the amount of material removed per single pass of the wheel, tool wear and other indicators.

The grain size is indicated in accordance with GOST 3647-80 and is indicated in microns by a fraction in which the numerator in microns indicates the size of the upper sieve, and the denominator - the lower one. According to international standards FEPA (and GOST R52381-2005), the characteristic is indicated by the letter F with the corresponding number - the higher it is, the smaller the grain size.

The grain size is selected depending on the required surface roughness after processing, the type of material, the amount of allowance removed when passing the tool, etc.

The smaller the grain size used, the cleaner the treated surface is. But fine grain size is not always preferable - it gives high cleanliness, but at the same time leads to clogging of the tool and burning of the surface being processed. Using a fine-grained wheel also reduces productivity.

The grain size differs by fraction as follows:

- fine 100/80;

- average 125/100;

- large 160/125;

- larger 200/160.

Wheels with a lower index are used for final finishing of blades, knives, cutters and other products, for final grinding. The middle link allows you to achieve the necessary sharpness of the cutting parts, and coarse grains are used to level and remove part of the surface being processed.

It is advisable to use low-grain wheels to reduce surface roughness, and larger grains when it is required to increase productivity and with large allowances. The less viscous and harder the material, the higher the grain size index can be.

Marking and selection of grinding wheels

Grinding wheels are characterized by geometric shape (type), type of abrasive material, its grain size, bond type, hardness, etc. And when choosing a grinding wheel, such characteristics as the degree of hardness or structure may be more significant than the type of abrasive. The complete markings for grinding wheels contain:

- circle type;

- its dimensions;

- type of abrasive material;

- grit number;

- degree of hardness;

- structure (the relationship between the abrasive, bond and pores in the body of the tool);

- type of ligament;

- maximum speed;

- accuracy class;

- imbalance class.

| Type | Dimensions, mm | Abrasive | Graininess | Hardness | Structure | Link | Speed, m/s | Accuracy class | Unbalance class |

| 1 | 150x16x32 | 25A | F46 | L | 6 | V | 35 | B | 3 |

The marking of wheels, made in accordance with various editions of GOSTs, has some differences regarding the designations of grain size, hardness, grade of abrasive and binder. Manufacturers label their wheels differently, using old or new designations and excluding certain characteristics. Below are examples of deciphering the designations of grinding wheels.

Grinding wheel marking 1 - abrasive material: 25A - white electrocorundum; 2 - grain size (old marking): 60 (according to GOST it should be 63) - 800-630 microns; 3 - hardness: K - medium-soft; 4 - structure: 6 - average; 5 - ligament: V - ceramic; 6 — imbalance class: 2

Grinding wheel marking 1 - abrasive material: 25A - white electrocorundum; 2 - grain size (old marking): 60 (according to GOST it should be 63) - 800-630 microns; 3 - hardness: KL - depending on the circumstances, can be K or L - medium-soft; 4 - ligament: V - ceramic. Grinding wheel designation 1 - abrasive material: 25A - white electrocorundum; 2 - grain size (old marking): 25 - 315-250 microns; 3 - hardness (old marking): SM2 - medium-soft; 4 - structure: 6 - average; 5 - bond (old marking): K - ceramic; 6 — accuracy class: B 7 — imbalance class: 3

Marking of abrasive wheel 1 - abrasive material: 25A - white electrocorundum; 2 - grain size: F46 - average size 370 microns; 3 - hardness: L - medium-soft; 4 - structure: 6 - average; 5 - ligament: V - ceramic; 6 — peripheral speed: 35 m/s; 7 — accuracy class: B 8 — imbalance class: 3

Designation of the grinding wheel 1 - abrasive material: 14A - normal electrocorundum; 2 - grain size: F36-F30 - extended range including F36 (average size 525 microns) and F30 (average size 625 microns); 3 - hardness: QU - depending on the circumstances, it can be medium-hard, hard, very hard; 4 - bond: BF - bakelite with reinforcing elements; 5 — imbalance class: 1

The choice of grinding wheel brand should be made taking into account all its characteristics.

Types of grinding wheels and their sizes

| 1 | 150x16x32 | 25A | F46 | L | 6 | V | 35 | B | 3 |

The following types of grinding wheels are produced (in parentheses the designations according to the old GOST 2424-75 are given):

- 1 (PP) - straight profile;

- 2 (K) - ring;

- 3 (3P) - conical;

- 4 (2P) - double-sided conical;

- 5 (PV) - with one-sided groove;

- 6 (ChTs) - cup cylindrical;

- 7 (LDPE) - with two grooves;

- 9 - with double-sided groove;

- 10 (PVDS) - with double-sided groove and hub;

- 11 (CHK) - conical cup;

- 12 (T) - disc-shaped;

- 13 - disc-shaped;

- 14 (1T) - disc-shaped;

- 20 - with one-sided conical groove;

- 21 - with double-sided conical groove;

- 22 - with a conical recess on one side and a cylindrical recess on the other;

- 23 (PVK) - with conical and cylindrical grooves on one side;

- 24 - with conical and cylindrical recesses on one side and a cylindrical recess on the other;

- 25 - with conical and cylindrical recesses on one side and conical on the other;

- 26 (PVDK) - with conical and cylindrical recesses on both sides;

- 27 - with a recessed center and reinforcing elements;

- 28 — with a recessed center;

- 35 - straight profile, working with the end;

- 36 (PN) - with pressed-in fasteners;

- 37 - ring with pressed fasteners;

- 38 - with one-sided hub;

- 39 - with a double-sided hub.

Some types of grinding wheels

All types are described in GOST 2424-83.

In addition to the profile shape, circles are characterized by the size DxTxH, where D is the outer diameter, T is the height, H is the diameter of the hole.

Types of diamond and CBN wheels are regulated by GOST 24747-90. The marking of the shape of CBN and diamond wheels consists of 3 or 4 characters that carry information about the cross-sectional shape of the body, the cross-sectional shape of the CBN-containing or diamond-bearing layer, the location of the latter on the wheel, and the design features of the body (if any).

Designation of a grinding wheel with body shape 6, shape of diamond-bearing or CBN-containing layer A, with the location of diamond-bearing or CBN-containing layer 2, with design features of body C. Designation of diamond or CBN-containing grinding wheels

All types are described in GOST 24747-90.

The type and size of the wheel are selected based on the type and configuration of the surfaces being ground, as well as the characteristics of the equipment or tool used.

The choice of wheel diameter usually depends on the spindle speed on the selected machine and on the ability to provide an optimal peripheral speed. Specific wear will be the least with the largest diameter circle size. Smaller wheels have fewer grains on the working surface, each grain has to remove more material, and therefore they wear out faster. When working with small diameter wheels, uneven wear is often observed.

When choosing a diamond wheel, it is advisable to pay attention to the width of the diamond-bearing layer. When working “on the pass” it should be relatively large. When grinding using the “plunge” method, the width of the diamond coating should be commensurate with the width of the surface being processed. Otherwise, ledges may appear on the surface of the circle.

Abrasives

| 1 | 150x16x32 | 25A | F46 | L | 6 | V | 35 | B | 3 |

The most commonly used abrasive materials for grinding wheels are: electrocorundum, silicon carbide, CBN, diamond.

Electrocorundum

Available in the following grades: white -

22A

,

23A

,

24A

,

25A

(the higher the number, the higher the quality);

normal - 12A

,

13A

,

14A

,

15A

,

16A

;

chromium - 32A

,

33A

,

34A

;

titanium - 37A

;

zirconium - 38A

and others.

Silicon carbide

.

Two types of silicon carbide are available: black - 52С

,

53С

,

54С

,

55С

and green -

62С

,

63С

,

64С

, differing from each other in some mechanical properties and color. Green carbide is more fragile than black carbide.

Diamond

widely used for the manufacture of diamond grinding wheels used for finishing and sharpening carbide tools, processing parts made of hard alloys, optical glass, ceramics, etc. It is also used for dressing grinding wheels made of other abrasive materials. When heated in air to 800°C, diamond begins to burn.

Diamond grinding wheels

Elbor

(CNB, CBN, borazone, cubonite) is a cubic modification of boron nitride.

Having the same hardness as diamond, it is significantly superior to the latter in heat resistance. CBN wheels for full-profile sharpening of band saws

Abrasive materials are characterized by hardness, grain size, abrasive ability, strength, heat and wear resistance. High hardness is the main distinguishing feature of abrasive materials. Below are comparative characteristics of microhardness and heat resistance of the main abrasive materials.

| Materials | Microhardness, kgf/mm2 |

| Diamond | 8000-10600 |

| Elbor (cubic boron nitride, CBN) | 8000-10000 |

| Boron carbide | 4000-4800 |

| Silicon carbide green | 2840-3300 |

| Silicon carbide black | 2840-3300 |

| Monocorundum | 2100-2600 |

| Electrocorundum white | 2200-2600 |

| Titanium electrocorundum | 2400 |

| Chromium electrocorundum | 2240-2400 |

| Electrocorundum normal | 2000-2600 |

| Corundum | 2000-2600 |

| Quartz | 1000-1100 |

| Titanium carbide | 2850-3200 |

| Wolfram carbide | 1700-3500 |

| Hard alloy T15K6, VK8 | 1200-3000 |

| Mineral ceramics TsM332 | 1200-2900 |

| High-speed steel hardened P18 | 1300-1800 |

| Carbon tool steel sealed U12 | 1030 |

| Carbon steel sealed St.4 | 560 |

| Materials | Heat resistance, °C |

| Elbor | 1300-1500 |

| Diamond | 700-900 |

| Silicon carbide | 1200-1300 |

| Electrocorundum | 1300 |

| Boron carbide | 500-600 |

| Mineral ceramics | 1200 |

| Carbide alloy VK8 | 900 |

| High speed steel P18 | 600 |

| Carbon tool steel U12 | 200 |

The choice of one or another abrasive material is largely determined by the characteristics of the material being processed.

| Abrasive | Application |

| Electrocorundum normal | It has high heat resistance, good adhesion to the binder, mechanical strength of the grains and significant viscosity necessary for performing operations with variable loads. Processing of materials with high tensile strength (steel, ductile iron, iron, brass, bronze). |

| Electrocorundum white | It is more homogeneous in physical and chemical composition, has higher hardness and sharp edges, has better self-sharpening ability and provides less roughness of the processed surface compared to normal electrocorundum. Processing of the same materials as normal electrocorundum. Provides less heat generation, higher surface finish and less wear. Grinding of high-speed and alloy tool steels. Processing of thin-walled parts and tools, when the removal of heat generated during grinding is difficult (stamps, gear teeth, threaded tools, thin knives and blades, steel cutters, drills, woodworking knives, etc.); parts (flat, internal and profile grinding) with a large contact area between the wheel and the surface being processed, accompanied by abundant heat generation; for finishing sanding, honing and superfinishing. |

| Silicon carbide | It differs from electrocorundum in its increased hardness, abrasive ability and fragility (the grains have the form of thin plates, as a result of which their fragility increases during operation; in addition, they are less well held by the bond in the tool). Green silicon carbide differs from black silicon carbide in increased hardness, abrasiveness and fragility. Processing of materials with low tensile strength, high hardness and brittleness (hard alloys, cast iron, granite, porcelain, silicon, glass, ceramics), as well as very viscous materials (heat-resistant steels and alloys, copper, aluminum, rubber). |

| Elbor | It has the highest hardness and abrasive ability after diamond; has high heat resistance and increased fragility; inert to iron Grinding and finishing of hard-to-cut steels and alloys; fine grinding, sharpening and finishing of high-speed steel tools; finishing and final grinding of high-precision workpieces made of heat-resistant, corrosion-resistant and high-alloy structural steels; finishing and final grinding of machine guides and lead screws, the processing of which is difficult with conventional abrasive tools due to large thermal deformations. |

| Diamond | Has high wear resistance and reduced heat resistance; chemically active towards iron; has increased fragility and reduced strength, which promotes self-sharpening; synthetic diamond of each subsequent grade (from AC2 to AC50) differs from the previous one in higher strength and less fragility. Grinding and finishing of brittle and high-hard materials and alloys (hard alloys, cast iron, ceramics, glass, silicon); fine grinding, sharpening and finishing of carbide cutting tools. |

Diamond wheels are capable of processing material of any hardness. However, you need to keep in mind that diamond is very fragile and does not withstand shock loads well. Therefore, it is advisable to use diamond wheels for final processing of carbide tools, when it is necessary to remove a small layer of material and there is no shock load on the grain. In addition, diamond has relatively low heat resistance, so it is advisable to use it with a coolant.

Grain

| 1 | 150x16x32 | 25A | F46 | L | 6 | V | 35 | B | 3 |

Abrasive grain size is a characteristic of grinding wheels that determines the cleanliness of the resulting surface. The grain is either an intergrowth of crystals, or a separate crystal, or its fragments. Like all solids, it is characterized by three dimensions (length, width and thickness), but for simplicity we operate with one - width. Many parameters depend on the grain size - the amount of metal removed in one pass, the cleanliness of the processing, grinding performance, wheel wear, etc.

According to GOST 3647-80, in the designation of the grain size of grinding wheels, the grain size is indicated in units equal to 10 microns (20 = 200 microns), for micropowders - in microns with the addition of the letter M.

In the new GOST R 52381-2005, which basically corresponds to the international standard FEPA, the grain size of grinding powders is indicated by the letter F with a number. The higher the number, the finer the grain and vice versa.

Diamond and CBN wheels have their own grain size designations. Their grain size is indicated by a fraction, the numerator of which corresponds to the size of the side of the upper sieve in microns, and the denominator corresponds to the size of the lower sieve.

The table below shows the ratios of grinding wheel grit according to old and current standards.

| Designation according to GOST 3647-80 | Designation according to GOST 9206-80 (diamond powders) | Size, microns | FEPA | |

| Designation for abrasive materials, excluding flexible materials | Average size, microns | |||

| F 4 | 4890 | |||

| F 5 | 4125 | |||

| F 6 | 3460 | |||

| F 7 | 2900 | |||

| 200 | 2500/2000 | 2500-2000 | F 8 | 2460 |

| F 10 | 2085 | |||

| 160 | 2000/1600 | 2000-1600 | F 12 | 1765 |

| 125 | 1600/1250 | 1600-1250 | F 14 | 1470 |

| 100 | 1250/1000 | 1250-1000 | F 16 | 1230 |

| F 20 | 1040 | |||

| 80 | 1000/800 | 1000-800 | F 22 | 885 |

| 63 | 800/630 | 800-630 | F 24 | 745 |

| 50 | 630/500 | 630-500 | F 30 | 625 |

| F 36 | 525 | |||

| 40 | 500/400 | 500-400 | F 40 | 438 |

| 32 | 400/315 | 400-315 | F 46 | 370 |

| 25 | 315/250 | 315-250 | F 54 | 310 |

| F 60 | 260 | |||

| 20 | 250/200 | 250-200 | F 70 | 218 |

| 16 | 200/160 | 200-160 | F 80 | 185 |

| 12 | 160/125 | 160-125 | F 90 | 154 |

| F 100 | 129 | |||

| 10 | 125/100 | 125-100 | F 120 | 109 |

| 8 | 100/80 | 100-80 | F 150 | 82 |

| 6 | 80/63 | 80-63 | F 180 | 69 |

| 5, M63 | 63/50 | 63-50 | F 220 | 58 |

| F 230 | 53 | |||

| 4, M50 | 50/40 | 50-40 | F 240 | 44,5 |

| M40 | 40/28 | 40-28 | F 280 | 36,5 |

| F 320 | 29,2 | |||

| M28 | 28/20 | 28-20 | F 360 | 22,8 |

| M20 | 20/14 | 20-14 | F 400 | 17,3 |

| M14 | 14/10 | 14-10 | F 500 | 12,8 |

| M7 | 10/7 | 10-7 | F 600 | 9,3 |

| M5 | 7/5 | 7-5 | F 800 | 6,5 |

| M3 | 5/3 | 5-3 | F 1000 | 4,5 |

| 3/2 | 3-2 | F 1200 | 3,0 | |

| 2/1 | 2-1 | F 1500 | 2,0 | |

| F 2000 | 1,2 | |||

| 1/0 | 1 and | |||

| 1/0,5 | 1-0,5 | |||

| 0,5/0,1 | 0,5-0,1 | |||

| 0,5/0 | 0.5 and | |||

| 0,3/0 | 0.3 and | |||

| 0,1/0 | 0.1 and | |||

The choice of wheel grain size should be determined by a number of factors - the type of material being processed, the required surface roughness, the amount of allowance to be removed, etc.

The smaller the grain size, the cleaner the processed surface is. However, this does not mean that finer grain size should be preferred in all cases. It is necessary to choose the grain size that is optimal for a particular processing. Fine grain gives a higher surface cleanliness, but at the same time can lead to burning of the processed material and clogging of the wheel. Using fine grains reduces grinding performance. In general, it is advisable to choose the largest grain size provided that the required cleanliness of the treated surface is ensured.

If it is necessary to reduce surface roughness, the grain size must be reduced. Larger allowances and increased productivity require larger grits.

In general, the harder the material being processed and the lower its viscosity, the higher the wheel grit can be.

| Grit numbers according to GOST 3647-80 | Grit numbers according to GOST R 52381-2005 | Purpose |

| 125; 100; 80 | F14; F16; F20; F22 | Dressing of grinding wheels; manual roughing operations, cleaning of blanks, forgings, welds, castings and rolled products. |

| 63; 50 | F24; F30; F36 | Preliminary round external, internal, centerless and flat grinding with surface roughness of 5-7 cleanliness classes; finishing of metals and non-metallic materials. |

| 40; 32 | F40; F46 | Preliminary and final grinding of parts with surface roughness of 7-9 classes of cleanliness; sharpening cutting tools. |

| 25; 20; 16 | F54; F60; F70; F80 | Finish grinding of parts, sharpening of cutting tools, preliminary diamond grinding, grinding of shaped surfaces. |

| 12; 10 | F90; F100; F120 | Diamond finishing grinding, sharpening of cutting tools, finishing grinding of parts. |

| 8; 6; 5; 4 | F150; F180; F220; F230; F240 | Finishing of cutting tools, thread grinding with fine pitch threads, finishing grinding of parts made of hard alloys, metals, glass and other non-metallic materials, fine honing. |

| M40-M5 | F280; F320; F360; F400; F500; F600; F800 | Final finishing of parts with an accuracy of 3-5 microns or less, roughness of 10-14 cleanliness classes, superfinishing, final honing. |

Hardness of grinding wheels

| 1 | 150x16x32 | 25A | F46 | L | 6 | V | 35 | B | 3 |

The hardness of the grinding wheel should not be confused with the hardness of the abrasive material. These are different concepts. The hardness of the grinding wheel characterizes the ability of the bond to hold abrasive grains from being torn out under the influence of the material being processed. It depends on many factors - the quality of the bond, the type and shape of the abrasive, and the wheel manufacturing technology.

Wheel hardness is closely related to self-sharpenability—the ability of an abrasive wheel to regain its cutting ability by breaking down or removing dull grains. During operation, the wheels intensively self-sharpen due to the splitting of the cutting grains and their partial chipping out of the bond. This ensures that new grains enter into the work, thereby preventing the appearance of burns and cracks in the material being processed. The lower the hardness of the wheel, the higher the self-sharpening ability. Based on hardness, circles are divided into 8 groups.

| Name | Designation according to GOST 19202-80 | Designation according to GOST R 52587-2006 |

| Very soft | VM1, VM2 | F, G |

| Soft | M1, M2, M3 | H, I, J |

| Medium soft | SM1, SM2 | K, L |

| Average | C1, C2 | M, N |

| Medium-hard | ST1, ST2, ST3 | O, P, Q |

| Solid | T1, T2 | R, S |

| Very hard | VT | T,U |

| Extremely hard | Thu | V, W, X, Y, Z |

The choice of grinding wheel hardness depends on the type of grinding, the accuracy and shape of the parts being ground, the physical and mechanical properties of the material being processed, the type of tool and equipment. In practice, in most cases, medium-hard wheels are used, which have a combination of relatively high performance and sufficient durability.

A slight deviation of the wheel characteristics from the optimal one leads either to burns and cracks of the sharpened surface, when the hardness of the wheel is higher than required, or to intense wear of the wheel and distortion of the geometric shape of the sharpened tool, when the hardness of the wheel is insufficient. Wheels for sharpening tools with inserts made of hard alloys must be selected with particular precision in terms of hardness.

Here are some recommendations that may be useful when choosing grinding wheels based on hardness. When sharpening tools with carbide cutters, the wheel must have high self-sharpenability. Therefore, when sharpening them, wheels of low degrees of hardness are used - H, I, J (soft), less often K. The more tungsten or titanium carbides in the hard alloy, the softer the grinding wheel should be.

When it is required to maintain high precision of shape and size, preference is given to those types of grinding wheels that have increased hardness.

When using cutting fluids, grinding uses harder wheels than when grinding without cooling.

Wheels on a bakelite bond should have a hardness 1-2 levels higher than wheels on a ceramic bond.

To prevent burns and cracks, softer circles should be used.

Structure

| 1 | 150x16x32 | 25A | F46 | L | 6 | V | 35 | B | 3 |

The structure of a tool is usually understood as the percentage of the volume of abrasive material per unit volume of the tool. The more abrasive grain per unit volume of the wheel, the denser the structure of the tool. The structure of the abrasive tool affects the amount of free space between the grains.

| Structure | Designation |

| Dense | 1, 2, 3, 4 |

| Average | 5, 6, 7 |

| Open | 8, 9, 10 |

| Highly porous | 11, 12 |

When sharpening cutting tools, it is advisable to use wheels with more free space between the grains, as this makes it easier to remove chips from the cutting zone, reduces the possibility of burns and cracks, and facilitates cooling of the tool being sharpened. For sharpening cutting tools, wheels on a ceramic bond of 7-8th structure are used, and wheels on a bakelite bond - 4-5th structure.

Bunch

| 1 | 150x16x32 | 25A | F46 | L | 6 | V | 35 | B | 3 |

In the manufacture of grinding wheels, abrasive grains are bonded to the base and to each other using a bond. The most widely used binders are ceramic, bakelite and vulcanite.

Ceramic bond

It is made from inorganic substances - clay, quartz, feldspar and a number of others by grinding them and mixing them in certain proportions.

Ceramic bonded grinding wheels are marked with the letter ( V

).

Old designation - ( K

)

The ceramic bond gives the abrasive tool rigidity, heat resistance, shape stability, but at the same time increased fragility, as a result of which it is undesirable to use wheels with a ceramic bond under shock loads, for example, during rough grinding.

Bakelite bond

mainly consists of an artificial resin - bakelite.

The marking of circles with bakelite has a Latin letter ( B

) in its designation.

The old designation is ( B

). Compared to ceramic, bakelite binder has greater elasticity and elasticity, heats the metal being processed less, but has lower chemical and temperature resistance, and worse edge resistance.

Bakelite bond can be with reinforcing elements ( BF

, old designation -

BU

), with graphite filler (

B4

, old designation -

B4

).

Vulcanite bond

is a vulcanized synthetic rubber.

The abrasive wheel is marked with the letter ( R

).

The old designation is ( B

).

In most cases, abrasive wheels on ceramic or bakelite bonds are used. Both have their own characteristics, which determine their choice for a particular job.

The advantages of a ceramic binder include strong fixation of grain in the binder, high heat and wear resistance, good preservation of the working edge profile, and chemical resistance. The disadvantages are increased fragility, reduced bending strength, high heat generation in the cutting zone, and, consequently, a tendency to burn the material being processed.

The advantages of the bakelite bond are elasticity, good self-sharpening of the wheel due to the reduced strength of grain fixation in the bond, and reduced heat generation. The disadvantages are more intense wear compared to a ceramic bond, reduced edge resistance, low resistance to coolants containing alkalis, low heat resistance (bakelite begins to become brittle and burn out at temperatures above 200°C).

Accuracy class

| 1 | 150x16x32 | 25A | F46 | L | 6 | V | 35 | B | 3 |

The accuracy of the dimensions and geometric shape of abrasive tools is determined by three AA

,

A

and

B.

_

For less critical abrasive processing operations, class B

.

A

tool is more accurate and of higher quality .

For work in automatic lines, on high-precision and multi-circuit machines, high-precision AA

. It is distinguished by higher accuracy of geometric parameters, uniformity of grain composition, balance of abrasive mass, and is made from the best grades of grinding materials.

Unbalance class

| 1 | 150x16x32 | 25A | F46 | L | 6 | V | 35 | B | 3 |

The imbalance class of a grinding wheel characterizes the imbalance of the wheel mass, which depends on the accuracy of the geometric shape, the uniformity of mixing of the abrasive mass, the quality of pressing and heat treatment of the tool during its manufacturing process. Four classes of permissible imbalance of the mass of circles have been established ( 1

,

2

,

3

,

4

). Unbalance classes have nothing to do with the accuracy of balancing the wheels and flanges before installing them on the grinding machine.

Marking of grinding wheels

Grinding wheels can vary in geometric shape, type of abrasive material, as well as type of bond, wheel grit, hardness, etc. When choosing a grinding wheel, hardness and texture may weigh more heavily than the type of abrasive.

According to various editions of GOSTs, the marking of circles has different designation parameters. Almost every manufacturer labels their wheels differently.

Thus, the complete marking of the varieties of grinding wheels contains:

- circle type;

- grinding material;

- disk dimensions;

- degree of hardness;

- grain size;

- structure;

- binder;

- maximum rotation speed;

- accuracy class;

- imbalance class.

Features of metal discs for grinders

Cutting wheels are special attachments that are necessarily used when operating an angle grinder. During operation, they are subject to intense wear and require regular replacement. The discs are round in shape and have a hole in the central part.

Consumables differ in several ways. They have different thicknesses and diameters, as well as the dimensions of the internal hole, etc. All of them are reflected in the product labeling. To select the right disc, it is important to know the symbols applied to cutting wheels.

Explanation of markings

If you plan to use the discs in everyday life to perform simple tasks, it is not necessary to be able to decipher the markings. It is enough just to know the popular names of different species.

Most often you can find this classification:

- Velcro discs are distinguished by the application of dense, durable fabric to paper. Very common due to low cost, but not durable.

- Fiber disks are made from paper, which has many layers, in the center of which there is a fastening in the form of a support plate.

- Petal circles – have a special structure; individual segments are stacked on top of each other, forming a fan effect. The main purpose is to create a perfectly flat surface. Typically used for post-processing.

- Diamond blades – used for finishing and finishing of materials.

But universal sandpapers are not always suitable. Sometimes high strength is required, sometimes, on the contrary, you need a soft abrasive that will wear off during processing. For polishing, you often need a flexible wheel that can form a rounded surface.

Even if you only need to select a circle of a certain type, consultants in specialized stores can help you understand the designations specified by the manufacturer, and you can also figure it out yourself by simply studying the instructions supplied by the manufacturer.

It is worth noting that foreign manufacturers may adhere to other labeling principles and designate circles using Latin letters and special abbreviations.

In production, only a technologist or engineer should select disks. This is due to the fact that an incorrectly selected disc can fly apart during operation, damaging the surface being treated. Also, certain segments can harm employees. Even if the circle fits almost completely, this does not mean that with its help you can achieve the desired result. Even the slightest processing inaccuracy can negatively affect the quality of the product.

Additional information in the labeling

When choosing a cutting disc, it is important to consider not only the basic parameters, but also take into account other data that affect the quality of work. They can be clarified in the additional information contained in the labeling:

- Abrasive grain material . This can be electrocorundum (designation A) or silicon carbide (designation C). The grit size of these materials varies from 5 to 125. Corundum wheels are considered more efficient and productive.

- Hardness _ It is usually reflected in the marking after the disk size. Indicates the grain size and is marked in the form of a Latin letter from M to T. M is the minimum hardness, T is the maximum.

- Rotational speed . Indicates how fast the cutting wheel can be used. For wheels based on a vulcanite binder, the speed is usually 50-80 m/s; for wheels with a bakelite reinforcing layer, the speed is higher - 80-100 m/s.

- Best before date . This is a fairly important parameter that you should definitely pay attention to. During prolonged storage, the abrasive attachment may lose its performance properties and become unusable. Products with a bakelite type of binder are designed for storage for up to 6 months, with vulcanite type – 1 year. You should not stock up on a large number of attachments for future use; it is better to purchase discs before you plan to carry out metal cutting work. The expiration date is usually indicated on the inner metal ring.

Working with abrasive attachments that have expired is strictly prohibited, as this can lead to an emergency.

Instability class

The accuracy class has three values: AA, A and B. The first type is used for work on machines and automatic lines. Class A is quite accurate, and class B wheels are used for less critical operations when processing surfaces.

Instability has four classes (from 1 - the most accurate - to 4 - the roughest). This designation shows the specialist the relationship between the mass of the abrasive disc and the accuracy of its geometric shape. Often the accuracy and instability class markings are indicated side by side.

For example, the grinding wheel we are considering 25A F46 L 6 V 35 B 3 has accuracy indicators B and instability 3.

Thus, circles marked AA have the least imbalance, with accuracy A - 1 and 2, with the letter B - from 1 to 4 classes.

Binders

The abrasive grains, after being sorted by size, are combined into a single strong mass to form a grinding wheel of a certain shape using a binder.

Binders are divided into inorganic and organic. Inorganic binders include ceramic, silicate and magnesia binders, and organic binders include bakelite and vulcanite binders.

The ceramic bond is fire clay and feldspar. The mixture of binder and abrasive grain is pressed or cast. Cast wheels are more fragile and porous than pressed ones. Different hardness of the wheels is achieved by selecting the composition of the binder, and different porosity is achieved by pressing modes.

The ceramic bond is stable at high temperatures, has great chemical resistance, and therefore allows the use of various cooling and lubricating fluids during grinding. Ceramic bonded grinding wheels are made from normal electrocorundum, white electrocorundum, black and green silicon carbide.

The ceramic bond allows wheel speeds of up to 50 m/sec. Thin circles on a ceramic bond cannot absorb lateral loads.

The silicate bond consists of liquid glass. This bond does not provide a strong fixation of the grains in the wheel, since liquid glass weakly adheres to the abrasive grains. Silicate bonded wheels are used when the workpiece is processed without cooling and at the same time, the machined surface of the workpiece should not overheat. When heated, the binder easily releases dull grains from the surface of the circle, while new sharp grains are introduced into the work.

The magnesium binder is caustic magnesite and magnesium chloride (Sorel cement). Used for making circles from emery and natural corundum.

Magnesium bonded wheels are heterogeneous, wear out quickly and unevenly, i.e. they have low durability. They are very sensitive to dampness, under the influence of which they are destroyed, as well as to elevated temperatures.

Bakelite bond consists of bakelite resin in the form of powder or bakelite varnish. This is the most common of the organic ligaments.

Bakelite bonded wheels are made from all abrasive materials. They have high strength and elasticity, are stable at high temperatures, but their porosity is lower than that of ceramic bonded wheels.

Bakelite bonded wheels operate at speeds of 35-70 m/sec. This bundle allows you to produce cutting wheels with a thickness (height) of up to 0.18 mm.

During heavy work, where the cutting temperature reaches more than 300°, the bond quickly burns out and the grains crumble. Under the influence of alkaline liquids, the bakelite bond is partially destroyed, and therefore the use of coolants with a soda content of more than 1.5% is not recommended.

The vulcanite bond is basically rubber. To make wheels, abrasive material is mixed with rubber, as well as sulfur and other components in small quantities. In special molds under pressure, the abrasive mixture is vulcanized, and the rubber becomes hard and elastic. At temperatures above 150°, the rubber softens and begins to burn out.

Vulcanite wheels are durable and elastic, which allows them to be used for slotting and cutting work. They have good polishing ability and can work with alkaline coolants. When grinding high-carbon steels, wheels on bakelite and vulcanite bonds are used to avoid burns and cracks. Wheels made of vulcanite bond are more elastic than those made of bakelite, but their porosity is less.

Currently, abrasive factories have mastered the production of wheels with fabric pads. The abrasive powder is mixed with bakelite resin and placed in a mold between layers of fabric. When the mold is compressed and heated, monolithic abrasive wheels are obtained, reinforced with gaskets. Such circles are very durable and allow you to work at a speed of 70 m/sec.

How to choose the right abrasive wheel for an angle grinder

To choose the right cutting disc, it is also important to take into account some nuances that the buyer does not always pay attention to:

- Mounting hole dimensions . The most popular are discs with a hole of 22 and 22.23 mm. There are slight differences between them. You can also find circles with a 32 mm hole on sale. They are designed for use with professional tools.

- Outside diameter . There are several basic standard sizes that are used for angle grinders of various capacities. Models 115 and 125 mm are designed for low-power household tools, 125 and 150 mm for medium-power tools, 180 and 230 mm for powerful professional ones.

- Thickness _ Using a thin circle, cutting a metal workpiece will be faster, since its contact area with the material is smaller, and therefore less effort is required for cutting. In addition, thin circles are more elastic.

- Hardness _ The stronger the material being cut, the harder the disc should be chosen to work with it.

When choosing, you should also consider the type of binder. Vulcanite discs are highly elastic. Typically, the thickness of such circles is from 0.8 mm. but they do not have high heat resistance. Therefore, if during cutting the temperature of the contacting areas increases significantly, productivity is significantly reduced.

Bakelite is not as susceptible to high temperatures, but when working with it, especially if the surfaces heat up to more than 300 degrees Celsius, sparks may form. In addition, the strength of the disc may decrease.

Grinding wheels

Sharpening machines are widely used today for sharpening any type of metal and steel tools: from countersinks, axes, knives to drills and chains. Despite the more than hundred-year history of the development of this machine and the improvement of technology, the main element of the electric sharpener, which directly affects the efficiency of the machine, is the abrasive grinding wheels. On our website you can find a large list of grinding wheels, some of which are presented in the table:

| vendor code | Name | Peculiarities |

| 1801.004 | Grinding wheel for chain sharpening machines T-108/85, T-108/85M | Made of corundum combined with ceramics, which gives it great strength characteristics. |

| 1801 001 | Straight profile grinding wheel 150X20X32 mm for T-150-200/250 (A36) | Thanks to the fine grain, it can produce a clean finishing of the treated surface |

| 2181912502501 | Straight profile grinding wheel 125*16*32 (C25) for T-125/120 | Multifunctional wheel designed for both sharpening cutting surfaces and metal surfaces. |

Classification

A non-professional classification, familiar to many, divides grinding wheels into the following types:

- Discs with so-called “Velcro” - a special fabric that is applied to sandpaper.

- Petal wheels - have a surface made of abrasive material arranged in the form of a fan-like overlay of layers. They are very durable, provide a smooth surface after processing, and are most often used for sanding pipes or wooden surfaces.

- Fiber discs consisting of vulcanized paper with a multi-layer structure. They are attached to the machine using a support plate with the required cross-section. Fiber discs are used for cleaning metal, wood, and steel products.

- Diamond wheels used for finishing. As a rule, they have little strength.

Abrasive disc size

The marking of abrasive wheels by size is written as follows: DхТхН (where D is the outer diameter, T is the height, H is the diameter of the hole). The D parameter can reach a maximum size of 1100 mm, the H value can be up to 305 mm, and the T parameter varies from 0.18 mm to 250 mm.

Read also: Do-it-yourself heating of a private house with electricity

The types of CBN and diamond discs are described in more detail in GOST 24747-90. The marking of the shape of such grinding wheels consists of three or four symbols indicating the cross-sectional shape of the body and layer, its location on the wheel, and also provides information about the design features of the body.

For example, 150x16x32 is the size of a 25A white electrocorundum abrasive wheel.

Reminder when choosing abrasive wheels:

- When choosing the diameter of the circle, you should take into account the number of spindle revolutions and the ability to provide optimal speed.

- The larger the diameter, the less specific wear of the circle. There are fewer grains on the working surface of small circles. So, during operation they wear out unevenly.

- When choosing a diamond wheel, you should take into account the width of the diamond-bearing layer. If used incorrectly, ledges may appear on the surface of the wheel.

Decoding cutting wheel parameters

Let's use an example to look at the markings of a cutting wheel and a circle and clarify some of the data that is reflected in it. For example, we use this marking option:

42 150x2.0x22.23 14A 63N 38 BU 80 m/s 2 class GOST 21963-82

- 42 – cutting device with an offset center.

- 150x2.0x22.23 – outer diameter 150 mm, thickness – 2.0 mm, mounting hole diameter – 22.23 mm.

- 14A – material of manufacture – electrocorundum.

- 63N – medium grain size.

- BU – reinforcement based on bakelite binder.

- 80 m/s – maximum operating rotation speed 80 m/s.

- 2 class – equipment of the second class of imbalance.

- Complies with GOST 21963-82 regulations.

The presence in the marking of information about the abrasive wheel belonging to a specific GOST indicates that during production the manufacturer strictly adhered to the standards, which means that this is not a fake.

Selecting an abrasive wheel

To choose the right abrasive tool, you need to know well the capabilities of the sharpening machine - power, operating speed, and the ability to adjust them. Also, for different types of surfaces to be treated, the appropriate type of sandpaper should be selected.

IMPORTANT! You cannot use the grinding wheel that is “to hand.” Always check that the sandpaper matches the material being processed.

It is also necessary to know whether the operation requires cooling and lubrication of the working surface of the grinding wheel. Failure to comply with the requirements of the abrasive manufacturer can quickly damage the emery wheel itself and damage the workpiece.

It is important to choose the correct grit size of the abrasive wheel

Popular: All about the characteristics of a hair dryer: rating of the best models

Surface treatment should begin with coarse grains, gradually moving to fine polishing with fine-grained sandpaper. By choosing the right tool, you can achieve high quality processing without even being a professional.

note

Worn wheels should not be immediately scrapped; there are special tools for straightening and restoring the surface of the abrasive.

- Electrocorundum wheels are suitable for processing non-carbide metals and composite materials, as well as for sharpening home cutting tools.

For ease of selection, they come in white, orange or blue. The low hardness of the abrasive, combined with the low strength of the bond, allows you to work with soft materials without fear of overheating and scaling. The quality of polishing and sharpening is high. Used for finishing materials. Disadvantages include rapid wear and loss of surface shape due to uneven use (appearance of grooves, rounding of corners). - Abrasive wheels made of silicon carbide are used for primary (roughing) processing, removal of irregularities, processing of welds and sharpening of tools made of hard alloys.

They have a distinct green color. Such abrasives are wear-resistant and retain their original shape well. When working with hard materials, grooves do not form on them. Ideal for sharpening working carbide teeth of circular saws, drills, including pobedit bits. The disadvantage of such circles is high heating during operation. In some cases, it is necessary to supply a cooling emulsion to the work area. - For final polishing and removal of burrs from working with corundum and silicon carbide abrasives, vulcanite-based abrasive wheels are used. In fact, this is not emery - but a polishing disc, harder than felt. Made from vulcanized rubber with the addition of fine-grained abrasive. As a rule, electrocorundum sand. The tool is specific and is not suitable for changing the shape of a workpiece. But with its help you can perfectly smooth the surface being treated. After treatment with a vulcanite wheel, the surface quality can only be improved with the help of felt and GOI paste.

How to choose a grinding wheel, review of markings - video

Grinding wheels marking of abrasive type

Abrasive material (AM) is an element that removes layer by layer from the workpiece. The properties of AM directly affect the surface of the processed object.

The most popular abrasives, brief properties and specifics of application.

| Type AM | Specifications | Where is it used? |

| Diamond | It is characterized by increased wear resistance, burns at a temperature of 800 degrees | Excellent for fine grinding and finishing of materials characterized by increased fragility and hardness |

| Elbor | Has the same characteristics as diamond. But there is one feature - greater resistance to elevated temperatures. | Widely used for processing hard-to-reach materials, including high-alloy steels and alloys, suitable for sharpening blades made of high-speed steel |

| Electrocorundum | Synthetic material. Features good adhesion to the sanding disc and bonding element | This AM is used to process iron, cast iron, and most types of steel. |

| Silicon carbide | Characterized by increased hardness and elongation of grains | Suitable for sanding materials with low tensile strength. Excellent for processing cast iron, granite, porcelain, glass, ceramics |

Interesting: Each of the above materials has its own subspecies. They are distinguished by a more expanded range of technical characteristics, and therefore can be used to solve any specific problem.

We've sorted out the types of abrasive materials. Now we will provide you with a table of their markings - designation in regulations, for example, GOST.

| Type AM | As indicated in state standards |

| Diamond | AC4, AC2, AC6, AC32, AC50, ARB1, ARC4, ARS3 |

| Elbor | CNB, KNB |

| Silicon carbide green | 62C, 63C, 64C |

| Silicon carbide black | 52C, 53C, 54C, 55C |

| Electrocorundum normal | 12A, 13A, 14A, 15A, 16A,W |

| Electrocorundum white | 22A, 23A, 24A, 25A, WA |

| Chromium electrocorundum | 32A, 33A, 34A |

| Titanium electrocorundum | 37A |

Abrasive type

Today, a large variety of materials are used in the production of emery. This allows you to achieve optimal characteristics of the disk, achieve its high strength, durability or processing accuracy.

The most commonly found materials are:

- Electrocorundum - used when working with metal products, usually wrought iron. It is characterized by high heat resistance and good adhesion to the binder. The abrasive is very strong and has high durability. The most common electrocorundum is normal. White electrocorundum is also common. The abrasive is more uniform and has sharp edges that sharpen themselves. Because of its properties, it is used for final processing of parts made of high-quality steels. Less commonly, you can find chromium, titanium and zirconium electrocorundum. The higher the marking number, the higher the strength of the circle.

- Silicon carbide is characterized by increased strength and at the same time significant fragility. It is labeled as 52-55C and is used when working with porcelain, granite, ceramics, glass and many other durable materials.

- Elbor is a very hard material, almost as good as diamond, but more fragile. Such circles are marked CBN, KNB.

- Diamond is a very durable natural material and is characterized by low fragility. Such discs are used in the machining of alloys based on iron, glass, ceramics and silicon.

Diamond wheels are divided into several types:

- normal strength (AC2);

- increased (AC4);

- high (AC6);

- single crystals (AC32).

Grinding wheels used in everyday life

For non-professionals, but ordinary people, understanding the classification of this tool with specific terms can be quite difficult. Therefore, it is much easier to classify them by purpose and characteristic features. Thus, we have the following types of grinding wheels:

Self-adhesive Velcro disc - thanks to the application of a special sticky cloth on the sanding paper, it has good adhesion to the sander.

Petal circles - their characteristic features are incredible elasticity, as well as amazing adaptation to any material. This tool got its name due to the fan-shaped direction of the parts of the same name, fixed on a material with an abrasive base. The absence of secondary burrs is one of the main positive characteristics of this device. Such wheels are widely used for processing pipes and other metal materials, but are also used for working with wood and shaped surfaces. The circles have high mechanical strength.

Fiber wheels - use on a grinding machine is possible only if there is a support plate with the required cross-section. To create such a circle, you need multi-layer vulcanized paper. These wheels are used for cleaning surfaces made of wood, stainless steel, metal or steel.

Diamond grinding wheels - experts recommend using for the last stage in surface treatment. But when using this type, you need to remember about its high fragility and low durability, so the work must be delicate.

Types of sandpaper grit

As already mentioned, sandpaper grit is the size of the abrasive fragments. They are measured in micrometers. The smallest grain found in sandpaper is only 3-5 microns, the largest is 1000 microns (this is 1 mm). Based on grain size, fine-grained and coarse-grained abrasives are distinguished.

Usually we are only interested in the grain size or grit of the sandpaper

Russian standards

In order to be able to understand what specific material is in front of you, the dimensions of the abrasive grain are indicated in the marking. But things are not so simple with her. During the USSR, GOST (3647-80) was introduced, the designation according to which still exists, although in 2005 a new standard was introduced (GOST R 52381-2005), which was developed on the basis of pan-European standards. The difference between the old and new GOST is significant.

This marking method is used in some countries of the post-Soviet space.

According to the old standard, the minimum grain size is prescribed. That is, the higher the number, the larger the grain. But we must keep in mind that some of the grains are smaller. In addition, the markings (letter designation) for large and small grains are different. It's worth remembering. For coarse sandpaper, the grain size of the sandpaper is indicated in microns, and after it the letter H is written with a hyphen in front of it - “N”. For example, 63-N. This means that the minimum grain size on the sandpaper will be 63 microns or 630 micrometers (µm). But there will also be larger particles. How much bigger? Slightly smaller than the previous brand. In this case, only 80-N is larger than 63-N, that is, the grain will be slightly less than 800 microns. The second example is 6-H. The grain size is no more than 6 microns or 60 microns, and the largest ones will be no more than 80 microns (since the previous grade is 80-N).

- When marking fine-grained sandpaper, the grain size is indicated in micrometers, and after the number the letter “M” is placed (without a hyphen). Example: 14M. This means that the maximum grain size of sandpaper is 14 micrometers, but there are also finer grains up to 10 microns in size.

- According to the new standard (GOST R 52381-2005), the grain size of sandpaper is indicated by the number of fibers of the sieve through which the abrasive is sifted. It turns out that the lower the number, the larger the grain. The number is preceded by the letter “P”.

As you can see, it's already quite confusing. It is also worth saying that according to the old standard, fine-grained emery can have a double designation - with the letters M and H - as in the table. Moreover, more often the options in microns were in use. Therefore, the smallest grain - 5M or 00-N - is often called zero. This is because it is 3-5 micrometers in size. According to rounding rules, this can be considered zero. This is where the name came from.

Compliance tables for other countries

As we see, the situation is not simple. And there is also the American ANCI (USA and Canada), the European FEPA or its other name ISO 6344, the Japanese JIS and the Chinese GB2478. Moreover, on the market you can find material from almost all these countries/parts of the world. So it is advisable to have at least some data. The most common ones are shown in the tables.

Grit designation table for different standards: coarse grain

Sandpaper grit according to different countries' standards: fine-grained

Please note that next to each column the grain sizes in micrometers (µm) are written. Sizes vary

This may be important for work.