Modern foundry is a complex technological method, in which blanks of metal parts are obtained by pouring a molten metal alloy into a specially prepared casting mold; inside it there is a cavity of the required configuration. After hardening, the resulting workpiece is removed and processed to the desired state. The modern foundry industry confronts specialists with the task of obtaining workpieces that best fit the shape, requiring minimal costs for their modification.

The following is a description of the most famous types of casting in modern industry.

Essence and Basics

In foundries, products are produced by melting a raw material, then pouring it into a mold, and then solidifying it. Foundries produce a wide range of products: from engine components to various containers for the food industry. All products made of cast iron, up to half of aluminum parts, up to 20% of steel products, etc. are produced by casting.

All foundry technologies are based on the concept of fluidity, when a material heated to a temperature above its melting point turns into a highly viscous liquid. In this case, the effect of continuity of its flow in the required direction must be observed. This makes it possible to form the required workpieces during the solidification process of the melt.

All casting metals have a complex structure, therefore fluidity is influenced by:

- Viscosity.

- Surface tension.

- The nature of the surface oxide film.

- Presence, content and composition of inclusions.

- Hardening method.

- Chemical composition of the base material.

- Physical and mechanical characteristics, primarily specific gravity and melting point.

Fluidity is established based on the results of chemical analyzes and technological tests in relation to a specific casting material.

If previously the process of liquid metal flow was poorly controlled, which led to various casting defects - uneven structure of the final product and porosity, now the situation has changed. In order to produce castings with optimal quality and minimize production costs, computer modeling processes have been mastered, as a result of which flow rates and the presence of various cooling effects can be predicted. They are the ones that cause porosity in the cast product.

3-D modeling allows you to adjust:

- Melt viscosity;

- Cooling intensity;

- Degree of porosity.

The spatial model of the casting developed by the technologist, taking into account the listed factors, allows even at the technology design stage to optimize the design of the part (ensuring its optimal configuration), design casting equipment, and also create the best sequence of operations performed.

Application of shell forms

Molten metal is freely poured into shell molds based on thermosetting mixtures.

A type of casting method with one-time sand molds. The result is surfaces with high quality workmanship. The mixture is based on quartz sand and resin of synthetic origin. At 70 degrees, phenol-formaldehyde resins begin to dissolve, their melting point reaches 120 degrees. After a few seconds, the material begins to harden. At 450 degrees, the resin burns out. Methods for obtaining shell forms are based on the ability of resins to pass from a liquid to a solid state irreversibly. After pouring, the model is easily destroyed, freeing up the necessary space.

Technology of foundry production of ferrous and non-ferrous metals

The casting properties of materials take into account not only fluidity, but also the decrease in volume that occurs during the cooling process of the casting. This phenomenon is called shrinkage; it is 1...3% of the original dimensions. Since all metals are anisotropic, a distinction is made between linear and volumetric shrinkage, which determine the final balance of the metal. The first parameter is important for castings with an increased length to width ratio, and the second is important for castings of complex shapes.

During the cooling process of the metal, segregation is observed in its structure - heterogeneity of grains, which is caused by the different properties of the components. Impurities and non-metallic inclusions are also formed. Liquation negatively affects the properties of the final product, so they try to reduce the heterogeneity of the structure by all acceptable means. In particular, the current GOST 26645-85 “Castings from metals and alloys” limits the content of phosphorus, sulfur (as well as their compounds - sulfides and phosphides), a number of gases - hydrogen, oxygen, as well as the amount of slag not removed from the metal.

Depending on the casting properties of metals, a decision is made on the choice of appropriate technology for producing castings. There are free casting in molds (sand or metal), injection molding, squeeze casting, centrifugal casting, as well as combined methods, for example, liquid stamping.

Injection molding

Injection molding is used to produce critical castings. The process requires the use of special equipment where the metal is melted and then put into a mold where it cools and solidifies.

Injection molding is used to produce thin-walled parts with a large number of ribs and undercuts. Such castings are used in household appliances, power tools, car parts, etc. Molds for injection molding are not limited in cross-section.

Advantages of the method:

- Possibility of obtaining parts with complex shapes and small sizes.

- High quality surface.

- Increased (compared to conventional foundry technologies) accuracy.

- Stability of casting metal characteristics.

- High performance.

Restrictions:

- High cost of equipment and accessories.

- Relatively low tool life.

- Increased level of initial financial costs.

Injection casting justifies itself with significant production programs, or with increased requirements for the quality of finished castings (in particular, to eliminate subsequent mechanical modification).

The injection molding process cycle is very short, typically 2 seconds to 2 minutes, and consists of the following four steps:

- Clamping parts of the mold, with one half fixed to the equipment, and the second being able to slide along the guides;

- Supplying the melt into the closed volume of the mold. The injection volume is determined by the volume of metal (taking into account its shrinkage), pressure and feed power;

- Cooling of the melt during contact of the metal with the walls of the mold. In some cases, shrinkage is taken into account by pressing the movable half of the mold against the surface of the hardening part;

- Removal of the formed casting from the tooling, the time of which is calculated based on the thermodynamic properties of the material and the maximum wall thickness of the part.

After an injection molding cycle, some post-processing is usually required. Thus, when cooled, part of the material located in the mold channels hardens. This excess metal must be trimmed using cutters. If necessary, it can be added to the melt, using it for casting the next batch of products.

Lost wax casting

This method was used for casting sculptures many years ago. In the 40s of the twentieth century, it found application in the field of mechanical engineering.

It is characterized by a labor-intensive process and high prices. But in many situations the use of such technology is justified, for example:

- In the absence of subsequent mechanical processing.

- If the machining itself is too complex and time-consuming.

- Difficult-to-cut alloys are used.

There are a large number of castings made using lost wax models, as well as recipes for model and molding mixtures.

A mixture containing 50% stearin and paraffin is widely used. Under slight pressure, a low-melting alloy in a molten state is placed into the mold from the furnace. The result is fusible models that maintain precise dimensions.

The low-fusibility model is removed from the mold when the product has completely hardened. Then everything is assembled into blocks with a gating system. The next stage is immersion in a refractory suspension, the composition of which includes 70% quartz flour and 30% hydrolyzed ethyl silicate solution with increased adhesiveness. The block with the models is sprinkled with quartz sand and then dried. These operations are repeated several times to ultimately obtain a structure with a thickness of 5-8 millimeters.

Melting occurs with the help of hot air, the temperature of which will be 120-150 degrees; the use of cold water is also acceptable. The lined and dried mold is placed in the metal jacket when it comes to large varieties of castings. Then everything is covered with sand and compacted, or covered with metal mixtures.

Then the finished mold is calcined until the temperature reaches 850-900 degrees. Under such conditions, all remaining fusible metal burns out. The mold itself becomes a durable ceramic shell.

The molten alloy is placed into a mold. Use centrifugal forces when the need arises.

The casting blocks are knocked out of the flasks after the metal has hardened. Separately, the ceramic crust is beaten. To do this, the castings are leached in a bath of solution at 120 degrees. Then all that remains is to rinse everything in hot water. Many factories automate and mechanize processing processes.

To obtain precision castings, the industry began to use the following technologies:

- According to gasification models.

- Based on burnt-out models.

- By defrosting.

- Based on soluble.

- Gas-firing models or the use of foam models are one of the most promising methods.

In this case, it is assumed that one-piece forms will be used. The model is not extracted from them. The heat of the molten metal provides gasification. The mass of the final castings ranges from 0.2 kilograms to several tons.

Expanded polystyrene itself, which is used in the manufacture of parts, is characterized by its low density. Its decomposition occurs at 300-350 degrees. As a result, only styrene vapors are released; processing is carried out even with ordinary wire and knives.

For individual production, foam models are taken and undergo manual processing. Saws, planes and machines become indispensable assistants in this process. Models can be made in parts and then combined into a single whole.

Foaming inside molds made of plastic or metal is a method that is used in the case of large-scale production. Polystyrene granules are loaded inside a mold with a cavity that resembles the model in configuration and size. The granules begin to foam and expand when heated and sinter with each other. The mold cavity is filled completely. The model is removed from the mold after cooling is complete.

Conventional methods are used to mold foam models in molds. Shaking and vibrating machines are used for molding sands.

The mold is filled with alloy when production is almost complete. The model is undergoing gasification. Gases are removed into vents. The casting is formed in the place where the model used to be.

Making castings on a foam base also involves other methods. At the final stages, model removal involves the use of the following technologies:

- Dissolution.

- Calcination of the mold.

- Electric smelting.

- Mold blowing.

Foam models can easily replace lost wax counterparts.

Squeeze casting

The technology is used when constant compensation for material shrinkage is required, and is used for casting large castings with thin walls. To do this, the movable half-mold receives forced movement towards the surface of the melt - by rotation, screw or plane-parallel movement. The sequence of transitions is as follows. The metal is poured into the lower part of the mold, then its moving part is moved until it comes into contact with the melt, while the excess is poured into the receiving ladle of the installation. Since constant thermal contact is maintained between it and the base metal, heat loss is minimal, and the physical and mechanical parameters of the material are uniform in all sections. The form completion rate also increases. After solidification, the movable half-mold moves to its original position, and the finished casting is pushed out of the cavity.

Advantages of the process:

- Increased structural homogeneity of the casting.

- High uniformity of physical and mechanical characteristics of the material.

- High process productivity.

Press casting is mainly used to produce products from aluminum cast alloys.

Equipment and forms

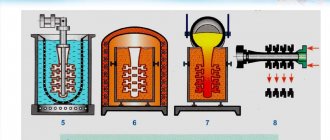

Arc or induction electric furnaces are used as melting equipment in foundries. The type of equipment is determined by the metals the foundry/site is working with: electric arc furnaces are ideal for working with steel or cast iron, while a foundry specializing in copper is more likely to use an induction furnace. Ovens can range in size from small tabletop units to those that weigh several tons.

Modern foundries are mechanized. Almost all operations of the cycle are subject to mechanization: from the production of cores to the actual casting. Molding machines are used in the serial production of castings. Manual molding is common only in small repair industries.

The main equipment includes:

- Melting furnaces;

- Pouring ladles;

- Loading and transport equipment - loaders, cranes, conveyors, etc.

- Control and automation equipment.

An electric arc furnace operates on the principle of periodic melting. The metal is melted by introducing electrical energy into the furnace through graphite electrodes. Additional chemical energy is supplied by oxy-fuel burners. Oxygen is introduced to remove impurities and other dissolved gas. When the metal is melted, slag forms and floats to the top of the melt; the slag, which often contains undesirable impurities, is removed before discharge.

An induction furnace transfers electrical energy by induction, where a high voltage electrical source induces a low voltage, high current in a secondary coil. Induction furnaces are capable of operating with minimal loss of raw materials, but are more used in the production of castings from non-ferrous metals and alloys.

All foundry equipment is specifically designed to operate reliably at elevated temperatures. The dominant trends in the production of this technology are scale, automation, rapid finishing of castings, increased safety and efficiency.

What lubricants are used? The choice depends on the brand of material and casting method. The initial concentrate in liquid form must be water-soluble, and in solid form heat-resistant pastes are used.

What types of metal can be used for work

Using foundry equipment, you can produce parts and blanks from the following types of metal:

- cast iron;

- become;

- copper;

- aluminum;

- bronze;

- brass

Copper alloy casting machine

Steel is the most common metal for making various parts. The production equipment can process the following grades of metal:

- low alloy;

- highly alloyed;

- carbon;

- alloy steel.

This material is widely used in mechanical engineering and machine tools due to its high strength and ductility. Cast iron products are no less popular. The greatest demand is provided by furniture companies that produce cast iron furniture and decorative elements.

Castings from steel 110G13L

Aluminum is one of the most common types of metal; it is characterized by its malleability, lightness, and the addition of magnesium or copper to the composition provides high strength to the product. Modern equipment technologies make it possible to cast aluminum parts and blanks of any complexity and configuration (weighing from 100 grams to several tons).

The main tool in foundry production

Foundry equipment includes models (templates), flasks and molds. What is a flask? This is a cavity into which molten metal is poured. The template is a replica of the object to be cast and is used to shape the casting. Models can be made of wood, metal or plastic. The main stages of obtaining equipment are:

- Obtaining a cavity;

- Dimensional processing of elements;

- Development and installation of clamping mechanisms.

Molds are developed taking into account metal shrinkage, for which compensators are provided. The walls of the molds have conical sections to facilitate ejection of the finished product from them. Hollow castings are created using a core, an additional volume of sand or metal that forms internal holes and passages in the casting. Each core is placed in the mold before pouring. To make it easier to remove the frozen casting from the mold, non-stick coatings are used.

There are two different types of casting molds: single-use and reusable.

The production of reusable pattern equipment is usually made from metal, disposable - from sand. To facilitate storage and use, the molds are always marked.

After the preparation of the molding sands is completed, the sand is placed around the model. Then the sample is removed, the rods are installed in place, after which the melt is poured. Casting tool design features are optimized for different metals and cavity complexity levels.

The cost of some types of foundry equipment and accessories is presented in the table:

| Name | Purpose | Approximate price, thousand rubles. |

| Kokili | For casting iron castings weighing up to 15,000 kg | 2 |

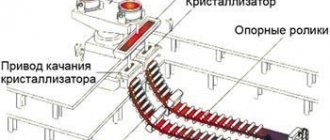

| Continuous casting line | For producing castings from non-ferrous metals and alloys | 7200 |

| Induction oven | Universal use | 800 |

| Injection Molding Machine | Same | 4500 |

| Induction melting complex | Same | 1500 |

| Continuous Vortex Mixers | For preparing sand mixtures | 13 |

| Centrifugal Casting Machine | Universal use | 25 |

| Mold | For casting iron | 1,5 |

| Knockout grid | To remove sand mold residues | 16 |

into the ground

Casting into the ground or into molds from a mixture of sand and clay is the oldest method of producing molten metal blanks. Over 80% of all castings come from it. It is distinguished by the simplicity and availability of the materials used.

The model and sprue kits are made from wood. After the model is ready, the molding mixture is mixed. The simplest ones include sand, quartz and clay.

Earth casting technology

Forming is done both manually and by machine. Manual mold making is used for the production of single or multiple castings and is considered unproductive. Machine forming is used on automated casting lines. Casting molds consist of two halves and are disposable. After pouring and cooling, the molds are destroyed. More than half of the waste material is returned to the molding operation after purification and recovery.

Defects in casting alloys

Before the casting production cycle is completed, the physical properties and structural integrity of the final product must be verified. Test methods can be destructive or non-destructive. The choice of defect detection method depends on the technological purpose of the part. Some purely aesthetic products require only a brief visual inspection to determine dimensional accuracy, presence of cracks, and quality of finish. For castings with industrial applications, all physical and mechanical properties of the metal (ductility, tensile strength, elongation, impact strength, hardness, etc.) are established during testing.

The most common casting defects are:

- Shrinkage defects. When metal hardens after being poured into molds or casting, it should shrink. When there is not enough metal, shrinkage of the cast iron will cause holes or voids to form in the casting. There are many types of shrinkage depending on its cause. With axial shrinkage, the material in the center takes longer to harden compared to the metal at the periphery, which leads to the formation of a cavity. This may be caused by the temperature at which the molten metal is poured, the speed of pouring, or the quality of the feedstock.

- Dispersive shrinkage. Dimensional changes in alloy elements can lead to a type of shrinkage where cavities form perpendicular to the casting surface. High nitrogen content or low carbon content can lead to this type of defect.

- Sometimes all foundry products may have the same type of defects in size. The reason is the different speed of solidification of different parts of the casting.

- Stitches or scars. This is a metallurgical defect, which is characterized by the presence of depressions on the surface of the casting. A defect is likely when graphite moves into shrinkage cavities during the melting process.

- Slag inclusions. They are small spots found on the surface of castings. Such inclusions are caused by contamination of the parent metal with carbides, calcites, oxides and sulfides.

- Failure to complete certain areas. Caused by the presence of gas in certain parts of the mold, reduced fluidity of the material. It will be necessary to increase its heating temperature and/or melt it in a vacuum.

Metal casting in CTS

The acceleration of the casting process led to the development of cold-hardening mixtures (CMC), which have become widespread. They have certain disadvantages. For example, some self-drying oils create a form that requires long drying periods, especially when air access is prevented. Urea-based synthetic resins, which are also designed for use as CTS, have very low breakdown temperatures, which in turn limits the versatility of the resulting form. Sand mixtures containing furan-based acid-curing resins (another but relatively new cold-curing binder) also have certain limiting characteristics. For example, they tend to cause the mold to stick to the casting, and the outgassing that normally accompanies pouring molten metal into molds becomes very pronounced and turbulent.

Modern CTS compositions are formed using binders containing at least one diphenylmethane ethoxylin resin or diphenol derivatives, to which at least one organic compound containing many reactive amino groups is added as a hardener.

Very good results are obtained when ethoxylin resins are synthesized from para-substituted diphenylmethane derivatives, especially bisphenol. Moreover, their epoxy equivalent exceeds 170.

Among the organic compounds that can be used as hardeners, promising compositions are those having many reactive amino groups and especially polymers (linear or ring), which include from two to five = NCH CH groups.

Selection of specialists

This profession involves the production of cast iron, steel or non-ferrous metal parts through various casting processes, as well as periodic testing of materials to ensure quality. A specialist in a modern foundry - a cutter, a melter, a moulder - must know the various types of molds and materials, the processing of foundry tools, and the chemical processes occurring during casting.

Professional training includes:

- Theoretical vocational training;

- Internship in the company directly at the workplace;

- Internship or retraining courses.

The last stage is intended for foundry specialists who want to improve their skills. Among them may be production operators, engineers, managers, metallurgists, personnel of quality assurance departments, and labor protection specialists.

The mandatory training or retraining program includes:

- Fundamentals of metallurgical processes (materials, thermodynamics).

- Types of equipment.

- Secondary metallurgical processes (pouring, metal mixing, cooling).

- Molds, their design and maintenance.

- Casting defects.

- Modeling of foundry processes.

Where do the supplies of raw materials and equipment come from?

Ferroalloys, alkali metal salts, boric acid, bentonite, etc. are used as the main chemical components. The main suppliers and delivery conditions are presented in the table:

| Provider | name of raw materials | Approximate price |

| MPI (Chelyabinsk) | Ferroalloys | 45…80 rub/kg |

| DOMINIK GEORG LUH TECHNOGRAFIT GMBH (Germany), Ekaterinburg | Graphite electrodes | 400…600 rub/t |

| BW KUNSTSTOFFE EK (Germany), Biysk, Belgorod | Electric foundry furnaces | On request |

| SMO Crl (Italy) | Press forms | 20000…30000 |

| SBM InfiSPA (Italy) | Mechanical and loading equipment | 80000…120000 |

Domestic raw materials are used, as well as those supplied from China, Sweden, and Ukraine.