Models.

When casting into the ground, molding is done according to permanent patterns.

By design, the models can be one-piece or detachable. With detachable parts and with signs ) for hollow castings).

To make artistic castings of relatively simple shapes, without high complex protrusions, large recesses (ashtrays, wall bas-reliefs, architectural casting parts, etc.), one-piece models are used.

Models of more complex products, the side walls of which have slopes in more than one direction, are made detachable. The parting line of the model must lie in the plane of the flask parting. Parts of detachable models are connected to each other with spikes. When making a mold, one part of the model is removed from the upper flask, and the other from the lower one.

If the product has protrusions that do not allow the model to be removed from the mold, the model is made with detachable parts that are attached to the main model with pins. After molding is completed, the model is first removed from the mold, leaving detachable parts in it, which are removed separately.

Models of hollow castings have marks (special cavities). At the locations of the signs, rods are attached, which form the internal cavity of the castings. When the casting cavity has exits on both sides (columns, pipes, bushings), marks on the model are also made on both sides. If the internal cavity only opens in one direction (as in busts and figurines), it is necessary to ensure that the rod sign is securely attached to the mold.

Models are made from various materials: wood, plaster, metal.

Wood is most often used as the cheapest and easiest to process material.

To make large architectural and artistic casting models with simple relief (columns, cabinets, gratings, pedestals), pine is usually used. Pine absorbs moisture poorly and is little susceptible to vibration. For the largest models with a complex surface, pine is unsuitable: it has large fibers, easily splits along them, chips in thin sections and gets rid of when processed on lathes.

Models that need to be processed on lathes are most often made from birch.

The most complex models, the surface of which is decorated with fine carvings, are made from durable and tough wood: apple, pear, mahogany or ebony. These models are much more expensive than pine and birch, but the good quality and long service life fully compensate for the cost of materials.

Unlike wooden ones, metal models have a number of advantages. They do not warp, retain their shape well, have a durable, clean surface and a significant service life.

For the manufacture of the model, cast iron is widely used as a cheap and fairly durable material. Large simple models that do not have sharp or small protrusions are often made from cast iron (models of gratings, columns, pedestals, handrails, etc.).

However, cast iron is difficult to work by hand, has low corrosion resistance, is difficult to solder, and, in addition, it is a brittle material, which is why the surface of the model is chipped.

Brass is one of the best materials for making models of small and complex artistic castings. Brass models do not rust, accept and retain embossing and engraving well, have a clean, smooth and flat surface, and are easily soldered. Models of small openwork cabinet decorations are usually made from brass, as well as models that need to be preserved for a long time.

The advantage of aluminum models compared to other metal models is their low weight. The disadvantages of these models include lower surface strength compared to models made of cast iron and brass. The surface of aluminum models quickly wears out; traces of punctures remain on it during molding, cutting pieces and molding. Repairing the models is difficult because aluminum is difficult to solder.

Plaster models are very convenient for preserving an artistic original, usually made by a sculptor from plastic, clay or wax. Plaster models are made by pouring a gypsum solution into a plaster mold prepared from a plasticine, wax or clay original.

IRON CASTING AND BASIC PRODUCTION TECHNOLOGIES

Cast iron casting in sand-clay mixtures

- Dimensional accuracy class for cast iron according to GOST R 53464-2009: 9-14

- Surface roughness of cast iron castings according to GOST 2789-73 Ra = 80-100 microns

- The minimum wall thickness obtained when casting cast iron is 3 mm

- Weight of castings from 0.5 kg to 40 tons

Cast iron casting in liquid-glass mixtures (ZhSS) and cold-hardening mixtures (CHS)

- Dimensional accuracy class for cast iron according to GOST R 53464-2009: 8-13

- Surface roughness of cast iron castings according to GOST 2789-73 Ra = 40-100 microns

- The minimum wall thickness obtained when casting cast iron is 3 mm

- Weight of castings from 0.5 kg to 40 tons

Characteristics of our iron casting production

- Area of the main foundry: 18,000 sq. m;

- Production capacity of the iron casting workshop: 24,000 t/year;

- Manual parade ground: 2000 sq. m;

Furnaces used for heat treatment:

- 2 furnaces with a load of 25 tons have working dimensions: B=2500 mm, H=1850 mm, L=5500 mm

- 2 furnaces with a load of 100 tons, with working dimensions: B=7000 mm, H=7000 mm, L= 14000 mm

Production time, level of complexity, guarantee for cast iron

- We will produce model equipment in 3 days;

- Production time for finished castings is from 5 days;

- We can produce thin-walled body parts, complexity group 6;

- We carry out laboratory tests (controlled parameters: chemical composition, yield strength, tensile strength, impact strength), and at the customer’s request we provide the results of fluoroscopy, ultrasonic flaw detection, magnetoscopy.

Opoki.

A flask is a box without a bottom and a lid, designed for making a sand casting mold. The mold is assembled from two or more flasks, which are connected to each other by pins 1 through ears 5 located on the side walls. To prevent the molding mixture from falling out, the flask is equipped with ribs 3 and shoulders 4, which are located at the parting plane of the flask.

Metal flasks are mainly used - made of cast iron, steel or aluminum. Wooden flasks are used in those rare cases when it is urgently necessary to produce a small number of castings.

Production

In the industrial sector, namely in the production of machines and machine tools, drainage and water supply complexes, there is a high demand for parts made of cast iron, called “gray”. The reason for this lies in the fact that such material is durable and wear-resistant. These properties are ensured by the addition of graphite to the alloy.

Various industrial companies request such a service as custom casting of cast iron products. Despite the fact that there are differences in the requirements for the technological process, which are explained by the characteristics of the activities of individual customers, there is a general requirement. It consists in the fact that the production of cast iron must correspond to the characteristics of the part, which are indicated in the drawings and documents.

Rods.

Rods are used mainly for forming internal cavities and holes in castings.

When pouring a mold, the rods are usually surrounded by melt on all sides, so they must have high gas permeability, strength, pliability, and knockout, which is ensured by choosing the appropriate core mixture and rod design.

The rods are made in core boxes. To increase the strength of the rods, a wire frame is molded into them.

When pouring metal into the rod, many gases are formed, for the removal of which ventilation channels are prepared in it by applying, laying wax wicks (when drying the rod, the wax is melted, and the cords are then removed), installing mesh tubes and straw strands, which burn out when poured, laying coconut burnt (in large rods).

Complex rods are glued together from several parts. To increase gas permeability, strength and reduce gas-forming ability, the rods are dried. The temperature and duration of drying depend on the mass of the rod and binder material. Drying duration ranges from several minutes to several hours and is established experimentally

Rods made from a mixture based on clay are dried at 350-400 oC, those based on concrete - at 200oC. If the core mixture contains starch, drying is carried out at 165-190 oC, in the case of a thermosetting resin binder - at 150-160 oC, in the case of an oil binder - at 150-200 oC.

Precise installation of the rod is achieved with the help of marks - special fixing cavities in the mold.

The dimensions of the signs are selected taking into account the mass of the rod and the melt pressure. Their configuration should exclude the possibility of any displacement of the rod.

Sometimes the fastening of the rod in the signs is not reliable enough, for example, when using long rods that can bend when pouring. In this case, other methods are used. Thus, the rods can be secured with special stands - draws. The shape and size of the foals depend on the mass and configuration of the supporting surfaces of the rod and the shape.

When making relatively small artistic castings, it is more convenient to fasten the rods using ends and frames. During the final finishing of the castings, the ends of the frames are cut off and the surface is caulked.

In some cases, the rods are secured by hanging them in the upper flask. This is how various pedestals for figurines are made.

Materials

The range of materials for injection molding is huge! There is a huge range of standard materials, as well as things like anti-static plastic, thermoplastic rubber, chemical resistant plastics, infrared, bio-compost material... and with color layout or masterbatch you also have an endless choice of colors.

Vacuum forming uses a more limited range of materials, but are readily available: sheets of ABS, flame retardant ABS, HDPE, HIPS, conductive HDPE, conductive HIPS, PP, PVC, clear HIPS, UV stable HIPS & PETG. Various colors and special effect sheets are also available.

Technology for manufacturing raw sand-clay molds.

One common method for making art castings is hand-molding raw sand and clay molds. Consideration of this method allows you to become familiar with the basic principles of manufacturing casting molds.

When making artistic castings, the molder uses a fairly large arsenal of tools, which includes a shovel for filling the flask with molding mixture, a sieve for sifting the mixture to separate lumps, hand tampers for compacting the flask, smoothers for lancets and hooks for finishing the mold cavity, steel needles-chokers for gas exhaust channels.

Casting aluminum into sand and clay molds.

Good day, pikabushniks and pikabushnitsy. In this post I would like to talk about one of the methods for making metal castings. Specifically, address signs. These are the ones.

Furnace and crucible for melting metal. Since we use low-melting aluminum, we need a temperature of at least 660 degrees. We did all this in a cleared warehouse on a homemade stove and “by eye.” So, there was no specific temperature regime.

Lump molding.

Art casting models often have an extremely complex surface with various kinds of depressions and protrusions that prevent the model from being removed from the mold. To produce molds based on such models, piece molding is used.

The depressions in the model are filled with high-strength molding sand, producing so-called pieces. The outer surface of the pieces is cut in the form of blocks with flat walls so that it is convenient to remove the flask stuffed onto the model from them. In addition, marks are cut into the surface of the pieces so that the pieces can be secured in the mold. The mold is filled according to the model with the pieces attached to it. After the mold is removed from the model, the pieces are placed on the mold. The mold produces an imprint of the surface of the model along with the pieces.

Consider, for example, the process of making a mold for the body of a “drovni” ashtray. It consists of the following operations.

1. The body model without a detachable head is placed on a sub-model plate. A piece is tightly stuffed near the back wall of the model. The surface of the piece is smoothed and sprinkled with separating sand.

2. The model with the stuffed piece is molded in the usual way in the upper flask with a side sprue. The flask is turned over together with the under-model slab and the surface of the mold is trimmed along the contour of the edges of the model.

3. The head is installed on the housing model. The surface of the connector is sprinkled with release sand. Thick paper is placed on the stuffed piece and the block is stuffed with the facing mixture. Then install the lower flask and fill it in the same way as the upper one.

4. Both flasks are turned over. After removing the sprue model, remove the upper flask. The model with the adjacent piece remains in the lower flask. The sprues are cut in the upper flask.

5. The piece adjacent to the back wall of the model is moved away from the model to such a distance that it can be removed from the blockhead. Having removed the model from the block, remove the detachable head model.

6. The detachable piece is placed in the old place, the seam is smoothed, the flasks are fastened and placed under the filling.

Features of work

The foundry industry provides mass production of molds of unprecedented precision with a minimum percentage of defects. You can create castings in three ways:

• in disposable models;

• by dissolvable stamps;

• in permanent-type workpieces made of refractory components.

Factories often use combined types of casting. The cost of custom metal casting services depends on the complexity of the casting configuration, the alloy used and the timing of the work.

Forming according to a template.

Pattern molding is used primarily for the production of castings in the shape of bodies of rotation, such as bells.

First, a thrust bearing is installed in a special hole on the floor of the foundry, into which a metal spindle will later be attached. The molding sand is compacted around the thrust bearing and then the spindle is inserted into it. The pit is filled with molding mixture and the mixture is compacted. The first template is put on the spindle and rotated around its axis to form the outer surface of the future casting.

Then the upper flask, the gating system models are installed and the upper flask is stuffed.

The upper flask is removed and the second template is put on the spindle. By rotating the template, the inner surface of the future casting is formed.

The casting mold is finished, the upper one is installed in its original place and the metal is poured.

Basic steel casting processes and technologies

Lost wax casting: technology, advantages and disadvantages

Steel casting is carried out using several technologies. This method of metal processing includes the following processes:

- Melting of the charge.

- Boiling.

- Subsequent deoxidation of non-metallic components.

Fuse

Steel melting can be done at home. To do this you need to have a graphite crucible. Fire-resistant brick is chosen as the base.

The furnace manufacturing procedure is as follows:

- At a short distance from each other, 2 copper busbars are installed, which are bolted to the brick. A metal plate is first laid underneath them, one end of which is bent.

- A transformer is connected to the buses.

- A crucible is placed on a metal plate in which the metal will be melted.

- The curved part of the plate touches the crucible.

The essence of the process is that graphite is a poor conductor of electricity, so when current passes it becomes very hot. Due to this, the melting of the metal occurs.

Melting steel at home

Additional Methods

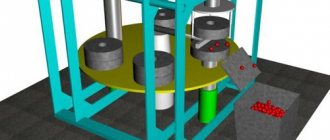

The following methods of casting parts exist:

- Oxygen converter. Based on the production of castings from cast iron. The process of oxidation of impurities occurs due to the supply of oxygen. The temperature in the chamber is 1600 degrees.

- Martenovsky. It is simple and convenient.

At the end of the process, molten metal is poured into molds. For this, there is a gating system, which consists of channels leading to casting molds.

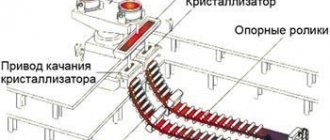

Steel ingots are produced using a continuous production method. The molten metal enters the crystallizer. There it hardens, and then is taken out and pulled by rollers. In order to quickly cool down, it is watered. At the last stage, it is cut into measured pieces.

Methods

Casting cast iron into cold-hardening mixtures is one of the modern technologies. This solution assumes that the molds are made from a mixture that includes binding elements, such as resins. The advantage of a mold made from such a mixture is increased tightness. Thanks to this, the possibility that the integrity of the product structure will be compromised during production is excluded.

Sand casting is also popular. This technology uses sand that has been compacted. This method is suitable for mass production of large parts, such as turbine blades or large parts of other machinery.

Currently, iron casting is undergoing active development. New production methods are being successfully introduced into the technological field.