Why does a screwdriver spark?

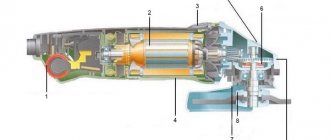

The main reason why sparks appear even on a new engine is the mechanical interaction of the commutator and brushes. Moving during operation of the tool from one commutator contact to another, the brushes alternately create and break contact with each of them.

Interesting materials:

How to call from Russia to Donbass? How to call DPR from Russia 2020? How to call DPR to Phoenix from Russia? How to call Chisinau on a mobile from Russia? How to call Crimea from Russia on a mobile phone? How to call London from Russia on a mobile phone? How to call Microsoft Russia? How to call Russia from Belarus MTS? How to call Russia? How to call Sberbank of Russia from Kazakhstan?

Causes

Transient processes occur in the rotor windings due to intermittent mechanical contact of the brushes with the commutator plates, which causes the formation of small arcs.

Important : a fully serviceable engine does not exclude sparking during operation. There are other reasons that cause severe sparking and create the possibility of motor failure.

Brush wear

With prolonged use or poor-quality brush material, they no longer press tightly against the contacts of the commutator. Due to poor contact, the engine does not gain speed or does not start immediately. A worn brush can be easily identified visually.

Sometimes it is not possible to correct the situation by replacing only the worn part. The brush holder and spring should be replaced.

Short circuit in the armature winding

The consequence of such a defect is uneven sparking on the collector. It will be stronger on some plates than others. Due to the presence of an interturn short circuit, the current in certain sections of the rotor winding will be stronger than in others.

Rewinding the rotor or replacing it will eliminate the problem.

Fault in the stator winding

A defect similar to a short circuit in the rotor winding occurs in the stator winding. You can check the presence by measuring the resistance of parts of its windings. If there is a strong difference, it is necessary to rewind the winding or replace it.

Pollution

The product of brush wear is graphite dust, which is an additional source of increased sparking. Dust accumulates between the plates, which creates additional conditions for the formation of sparks. Preventive cleaning of the commutator with sandpaper and removing dirt between the plates will keep it clean.

Brushes not installed correctly

If the brushes are deviated from the norm towards the commutator surface, a significantly larger amount of graphite dust is generated during operation. Misaligned brushes must be corrected.

Poor contact between brushes and commutator

The electric motor spends part of its operating time in overheating mode. Under such conditions, carbon deposits form on the collector. Poor contact leads to increased brush sparking and even more carbon deposits.

You need to use fine-grain sandpaper to clean the surface of the commutator. To increase the stripping effect, use a screwdriver. Clamp the engine rotor into the chuck and remove carbon deposits with sandpaper at low speeds. Afterwards you need to finally polish it on a felt wheel.

Mechanical problems

Mechanical reasons are caused by non-compliance with the requirements of design and technological documentation. Most mechanical causes can be eliminated by turning the manifold on a lathe. Refer this repair operation to a qualified technician. Here are some types of faults that may indicate a breakdown:

- The surface of the collector is uneven;

- The shaft runout exceeds the value specified in the technical documentation;

- Individual collector plates protrude beyond a common level for all;

- Insulation protrusion (mica);

- The brushes in the brush holders move with jamming;

- On the contrary, the brushes are inserted into the brush holders with a large gap, which creates vibration during operation;

- The brush holders are installed far from the commutator;

- Uneven tension of the springs, resulting in a difference in the pressure applied to the brushes.

Why do brushes spark in an electric motor, what does this phenomenon lead to and how can it be eliminated.

Topic: what to do if the brushes in an electric motor spark strongly.

So, from the beginning I will say that the sparking itself during the operation of collector electric machines is normal, only it should be very small, barely noticeable to the eye. It’s not normal when the electric motor is running and sparks fly out from its brushes - that’s bad. The very phenomenon of spark formation is associated with intermittent electrical contact that occurs during the rotation of the armature, at the moment of mechanical transition of the brush from one contact, on the commutator, to another. At this time, the circuit breaks and the current flowing through the armature coils ends its passage with a spark, a small arc discharge. Therefore, the greater the power and current in the circuit, the more noticeable the spark will be. But besides this, there are other factors that contribute to an increase in spark.

You should also pay attention to the condition of the gaps between the contacts on the collector. It often happens that they are clogged with graphite dust, which is a conductor with a certain resistance

Naturally, if these gaps are dirty, then you also put them in order (clean them with a sharp tool). Don’t forget to check the condition of the brushes, their performance, clamping force, and freedom of vertical movement. If problems are identified with the brushes, be sure to fix them. Please note that when replacing graphite brushes, you should take into account that they are different. In this case, try to find exactly the same type as the old ones.

The armature should be checked in an alternating electromagnetic field. If there are short-circuited turns, then in such a field the armature will begin to rattle, since induced currents will begin to form in it. To do this, you can make a homemade device from a power transformer, first making a wedge-shaped cutout on its core, into which you need to insert an armature for testing.

PS

Since this is important, I repeat once again - increased spark formation during operation of the electric motor affects its service life. In this case, strong carbon deposits quickly appear on the contacts of the collector, which after a while will damage the electrical equipment.

It is better to eliminate the sparks immediately than to replace the entire armature later.

How to fix and what to do if the vacuum cleaner motor brushes spark

If the household unit begins to work worse, and standard cleaning of blockages does not bring results, it is necessary, first of all, to disassemble the engine. What to do if the vacuum cleaner motor sparks depends on the type of problem.

How to replace worn brushes

Most often, the vacuum cleaner engine sparks in the area of the brushes precisely because of the natural wear of the latter. Although modern models have special capacitors that slow down abrasion, sooner or later contact between the elements leads to unpleasant problems.

Worn parts need to be replaced. To remove them, you need to remove the back cover of the vacuum cleaner, find the brush holders and pull the latches with your hands or a screwdriver. Then all that remains is to purchase exactly the same elements.

Old brushes can wear down to the springs

In order not to make a mistake with your choice, you can go to the store with the old removed parts and, with the help of a consultant, buy similar ones. Then they are installed in the old place, secured with latches and the vacuum cleaner is assembled in the reverse order.

How to eliminate poor contact of new brushes

If the vacuum cleaner is completely new, or the brushes have recently been replaced, and the motor still sparks, the reason may be a poor fit to the commutator. The problem can be solved quite simply. The engine compartment is opened, the engine is removed and the protective casing is removed from it.

It is necessary to polish the vacuum cleaner brushes with the finest abrasive.

It is necessary to go over the installed brushes with sandpaper to eliminate the smallest roughness. You can also use abrasive sandpaper to treat the collector plates if they have scratches. The smoother the contacting surfaces are, the less likely it is that the vacuum cleaner will start sparking.

How to change the angle of the brushes

If the brushes are skewed relative to the commutator after prolonged use of the vacuum cleaner, sparks will occur when the engine operates. To resolve the problem you must:

- remove the motor from the vacuum cleaner;

- visually determine how correctly the brushes are positioned relative to the commutator axis;

- Use a screwdriver to tighten the two screws securing the brush holder to align the elements.

In old vacuum cleaners, you need to carefully examine the condition of the connecting nodes between the collector and brushes. If traces of corrosion and even cracks are visible on them, such elements must be replaced with new ones.

When the axis is knocked down, the brushes begin to contact the commutator loosely

How to clean dirt

Coal dust and the resulting carbon impair the friction between the brushes and commutator and cause the engine to spark. The problem can be resolved by regular cleaning. The motor is removed from the unit and the casing is removed, after which the brushes are disconnected and access to the commutator is opened. If dirt is noticeable on the surface of the parts, they are treated with fine sandpaper until completely clean.

Plaque accumulates on the brushes and commutator, so when cleaning they are additionally degreased with alcohol. Tip! During operation, you should pay attention to the rotor contacts. If graphite dust and dirt have also accumulated between them, it must be carefully cleaned out.

How to eliminate a short circuit in the winding

Sometimes replacing brushes and other actions do not produce any results, and the vacuum cleaner continues to spark strongly. Usually the problem is an interturn short circuit of the commutator. There are two ways out of the situation - you need to either completely change the winding or replace the unit’s motor.

When a short circuit occurs, noticeable blackening appears on the collector plates

Rewinding an armature requires some experience and specialized knowledge in electrical engineering. Therefore, it is easier to send the engine for service or immediately purchase a new engine. This will be expensive, but buying just an anchor usually doesn't make sense. Its price is about 80% of the cost of the entire motor.

Prevention

The problem of sparking grinder brushes can be prevented by taking preventive measures:

Read also: Severus Snape (biography)

- follow the operating rules;

- regularly change the lubricant in the gearbox and bearing sections, reducing mechanical and thermal loads (factory lubricant must be replaced before starting any work);

- promptly replace bearings while maintaining the structural integrity of the armature shaft;

- install a new set of brushes before the old ones start sparking.

If you notice that the brushes spark and burn, you should immediately check the tool or contact a specialist. The lack of timely diagnostics of angle grinders leads to the fact that the sparking brush block ultimately breaks the entire power tool.

You will learn how to replace faulty brushes in an angle grinder in the following video.

Care and proper operation of the grinder

To make the grinder work for a long time, follow the rules:

- Monitor the integrity of the insulation of the wire and plug. Don't remove your protection.

Lubricate and clean the entire tool.

After turning off the grinder, wait until the circle stops rotating, then place it on the ground. When the engine stops, the tool, through the ventilation holes, sucks in, along with the air flow, particles of earth and other hard fractions that hit the motor windings. As a result, a break or short circuit occurs.

Try not to use an angle grinder outside in the winter. While you are running, the engine gets hot. The air is icy. As a result, condensation forms. Moisture is harmful to the engine. Always use the circles recommended by the tool manufacturer. If the angle grinder is 180 mm, do not put more than 200 mm there. The larger the circle, the lower the revolutions should be. You will have to remove the protection, and the speed will be exceeded. Vibrations and vibrations will increase. As a result, the circle will break into pieces. This is not only fraught with serious injuries. The gearbox bearing breaks and the gears wear out.

Post Views: 10

What are they made from?

Brushes for grinders and other power tools are made from different materials, but the main ones are coal and graphite. This material has a low coefficient of friction and also has increased abrasion resistance. To improve contact, various impurities are added to the composition of graphite or carbon during the manufacture of brushes. Depending on the impurities used, the following types of brushes are distinguished:

- Coal

- Copper plated

- Carbon-graphite

- Graphite

- Copper-coal

- Copper-graphite

The composition of the main part affects not only the service life or wear, but also such a parameter as signs of sparking. The amount of brush sparking depends on the composition from which they are made

When purchasing them, you need to pay attention to the composition, and not purchase equipment of unknown origin and questionable quality.

This is interesting! The design of the brushes contains a ceramic tip, which performs one of the important tasks. When the graphite layer is abraded to the limit, the tip begins to contact the copper lamellas of the commutator. Ceramics do not conduct electricity, so when the brushes wear out, the grinder will work intermittently or will not turn on at all until the devices are replaced.

Strong sparking on angle grinder brushes

Having mentioned Robert Ivanovich Bosch), I had a high-power machine for a reason, which is difficult to hold in the palm of my hand during normal starting

Than just 1.5 kW soft start you don’t need to throw it away. The brushes on the grinder sparkle. If it's covered, replace it. We tried the grinder Interskol. It's scary, it breaks out of your hands. If you don't look at him in the forehead, he'll hit you with a disk. Strong sparking on the brushes of the angle grinder. Good evening everyone. In order not to create an extra topic, I decided to ask for advice here. The situation is this: we have an interskal of two hundred thirty mm at two thousand three hundred W. The soft start is kind of mind-boggling, but it works quite correctly, but this is the picture. You press the button, at the first moment there is a sharp jerk, and then it starts as if with a soft start. Guys, can this be cured? in case and sell, then how. By and large, keep silent about the fact that there are some hellish problems due to this, but, you know, the situation is not good. PS The grinder is about three years old, it was used in professional conditions: for a long time, for a long time, and sometimes with heavy (but not prohibitive) loads.

Post edited by Devil666: twelve July two thousand fourteen. 22:13

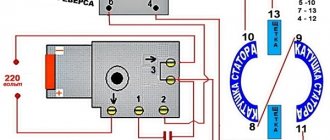

Strong sparking on the brushes of the angle grinder, guys, question: angle grinder one hundred and twenty-five arsenal threw out the speed controller, now how to connect the stator

Attached images

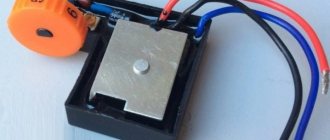

Devil666, Conder is outliving his own skill, very similar. the capacitor needs to be changed

Strong sparking on angle grinder brushes

From my experience. After replacing the brushes, running for a minute after LATR with increasing voltage (from minimum to about one hundred and fifty volts), everything seemed to be normal. After a minute (I think the brushes got used to it at least a little), I began to increase the voltage higher. After 170-180 volts, a circular fire began. And with low voltage (with slow rotation), the rotation was smooth and uniform. Something doesn't fit. When I loosened the springs of the brushes a little, the fire disappeared.

How to understand that you need to change the brushes

Many people change brushes only after they notice strong sparking from the tool, as well as the appearance of a burning smell. Many craftsmen are not stopped even by these signs, and they continue to use the tool until it stops turning on. When is it necessary to change carbon brushes so as not to damage the structure of the power tool? There are the following signs for this:

- Strong sparking - if signs of strong sparking appear, then it is necessary to disassemble the tool and inspect the consumables. Sparking is the first sign that consumables need to be replaced.

- The appearance of a burning smell - if the smell of soot is heard when using the tool, it is recommended to disassemble the grinder and replace the graphite brushes

- When the wear of the main part is over 30% -40%. However, it is almost impossible to determine their initial length, unless you measure it before installing the elements

- When signs such as jerking or “growling” of the power tool appear

Devices are also subject to replacement if they have uneven wear and do not correspond to quality.

This is interesting!

It is not recommended to buy copper-plated brushes for a home grinder, as they will quickly damage the armature commutator due to the high copper content in the composition.

Copper-plated elements can be used on grinders that have a special coating on the collector plates. https://youtube.com/watch?v=Wt0n_ECSwvE%3F

What are they made from?

Brushes for grinders and other power tools are made from different materials, but the main ones are coal and graphite. This material has a low coefficient of friction and also has increased abrasion resistance. To improve contact, various impurities are added to the composition of graphite or carbon during the manufacture of brushes. Depending on the impurities used, the following types of brushes are distinguished:

- Coal

- Copper plated

- Carbon-graphite

- Graphite

- Copper-coal

- Copper-graphite

The composition of the main part affects not only the service life or wear, but also such a parameter as signs of sparking. The amount of brush sparking depends on the composition from which they are made

When purchasing them, you need to pay attention to the composition, and not purchase equipment of unknown origin and questionable quality.

This is interesting! The design of the brushes contains a ceramic tip, which performs one of the important tasks. When the graphite layer is abraded to the limit, the tip begins to contact the copper lamellas of the commutator. Ceramics do not conduct electricity, so when the brushes wear out, the grinder will work intermittently or will not turn on at all until the devices are replaced.