The operation of pumps is controlled using various devices, and one of the most common is a water level float switch. It can simultaneously perform the task of a water level sensor and be an actuator for controlling the pump. Floats for the pump are placed in containers.

One tank can accommodate several such switches, and they can solve different problems:

- Monitor the operation of the main pump.

- Serve as an overflow sensor.

- Ensure the operation of the auxiliary pump.

- Serve as an emergency level sensor.

With the help of such devices, the pumping apparatus is protected from the “dry running” mode. When filling different tanks, this element protects them from overflowing. Float switches for pumps come in light and heavy sizes. The former are more often used in drainage and water supply systems; the second - in drainage, rain and fecal wastewater. In stores, devices are sold with a cable length of 2, 3, 5, 10 m.

Device design

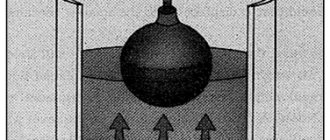

The floating plastic switch housing contains an electrical switch and a lever that moves the switch contacts. There is also a steel ball that adjusts the position of the lever when the float position changes. of three wires is connected to the switch , the first of which is common, and the rest are connected to the normally closed and open contact of the device.

The circuit is completed by the black and blue wires when the float is in the down position. When you move it to the top position, the brown and black wires become the closing contacts. The wire that does not provide connection to the device must be insulated.

It is important that the supply cable has moisture-proof properties; the plastic box must be sealed. The cable outlet is sealed using a mechanical seal, and it also has a special device that eliminates mechanical stress in the cable. The insulated cable gland cavity contains a polymer resin that prevents water from entering.

The chemical properties and heat resistance of the housing and cable sheath, made using thermoplastic rubber, determine the switch’s ability to withstand interaction with the following aggressive substances:

- uric acid;

- alcohols;

- fecal water;

- gasoline;

- other things.

Due to the lack of pores on plastic cases, dirt appears on them. Because of this, sand, paper and other solids slide off, and the float remains buoyant.

Characteristics of the water level control sensor:

- Maximum switching current, A;

- Mains voltage, V - 220±10%;

- 10A - for active loads (starters, lamps, switches, heating elements, etc.);

- 8A - for reactive load (compressors, pumps, fans, etc.);

- Operating temperature range: 0−60°C;

- Protection: IP 68.

Types of drainage sewer pumps for a private home

Every owner of a private home sooner or later faces the problem of choosing a pump for a sewage system. Let's consider their main types and criteria for their selection.

Sewage pumps

Pumps for sewerage of a private house are drainage and fecal.

- Drainage pumps are used to pump contaminated water from the sewer system of a house, swimming pools, or flooded rooms. Such waters contain relatively large solid particles (50 mm or more): sand, stones, etc., but are free of organic or fibrous inclusions;

- Fecal pumps are designed for pumping out liquids of high viscosity, with organic, silty and fibrous inclusions, and food waste. Fecal pumps have a design feature - the presence of a grinding device for such particles. Solid inorganic particles can break the shredder blades.

Since drainage plants do not have a grinding system, they are more compact and their cost is lower.

Areas of use

Drainage sewer pumps can be used to pump out liquid:

- storage wells or storm drains of a private house, the problem of pumping is especially relevant in the spring, during melting snow or heavy rains;

- overflow well reservoirs (septic tanks);

- in basements, basements and other rooms in a private house in case of flooding (rising groundwater or as a result of a break in the water supply pipes of the house);

- in pools or wells, decorative ponds for water replacement.

- watering, car washing;

- pumping water through sewer drainage pipes if they do not have the required slope.

Types of sewage pumps

Based on their location during pumping, drainage and sewage installations are divided into 2 types.

- Surface sewage pumps. During operation, they are placed on the surface of the earth, and a water intake hose is lowered into the pumped well. In this case, enhanced protection of the housing and electrical wiring is not required. Usually a special platform and light shelter are arranged for the units. This deprives them of mobility, although compact copies are also available for sale. Disadvantages of this type: high level of noise and vibration during operation, the possibility of overheating during pumping. The pumps are equipped with automatic devices: liquid level control and automatic switching on and off. Difficulties arise when using it in winter. They are characterized by relatively low productivity and low water pressure. The advantages include their low cost, reliability and long service life.

- Submersible sewage pumps. As the name suggests, they are designed to be submersible in water. On the one hand, this solves the problem of cooling the pump, on the other hand, it requires good sealing of the installation. The pump body is made of stainless, impact-resistant materials, the electrical cable has multi-layer insulation. They also have an automatic on/off system (usually a float type). They have good pressure, they are mobile, universal (can be used both for wells and in basements). Due to the fact that submersible pumps are located in the water, they do not make noise and do not freeze.

Criterias of choice

Formula for calculating the required installation pressure:

N is the water pressure produced by the pump, in meters of water column;

H – maximum depth of immersion of the unit or lowering of the water intake hose;

L is the length of the horizontal pipeline from the pumping point to the waste water discharge point.

- For submersible pumps, the instructions indicate the maximum immersion depth; for surface pumps, the maximum depth of lowering the water intake hose.

- Productivity (liters per unit of time - hour or minute) should not be less than the capacity of the sewer system in the house, in order to avoid flooding.

- The installation has an acceptable level of solid impurities.

- The units must be equipped with automation systems and various protections: from overheating, short circuit, etc.

- The presence of valve devices to prevent reverse flow of liquid.

- The housing material must be impact resistant. Thus, submersible pumps must have a housing protection degree of at least IP 68.

The ergonomics of the unit, the presence of handles for carrying, and the convenient location of the pipes are important.

It is better to opt for installations from well-known companies. Purchasing a low-quality unit leads to its rapid wear and breakdown.

Advantages of the device

Among the advantages of a float switch, the first thing to highlight is that this device can serve as a regular sensor for determining the water level in a tank. It performs this task regardless of the purpose of using the container and its volume. This device will make the operation of the pump more convenient and simplify control of the functions of domestic and industrial water supply systems. Sometimes it can be used to successfully drain fluid.

The switch can be an element as part of the equipment during the construction of sewer communications. Simplicity and efficiency have ensured its widespread use in a variety of systems where it is necessary to control water levels. The ability to protect pumping systems in dry running mode is not the only advantage of the devices. With their help, you can prevent situations where water overflows in containers.

Selection rules

When purchasing a liquid level sensor in a tank, you need to take into account several factors; if they are observed, the device will work correctly and reliably. First of all, you need to determine the type of liquid medium and its density, the level of danger to humans. What matters is the material used to make the container and its volume—the operating principle of the selected sensor depends on these parameters.

The next point that you need to pay attention to is the purpose of the device; it will be used to control the minimum and maximum liquid levels or to constantly monitor the filling of the tank. When choosing industrial sensors, the number of criteria can be expanded; for household alarms and level meters, it is enough to take into account the volume of the tank and the type of device

At home, home-made devices are used - they work no worse than factory models

When choosing industrial sensors, the number of criteria can be expanded; for household alarms and level meters, it is enough to take into account the volume of the tank and the type of device. At home, home-made devices are used - they work no worse than factory models.

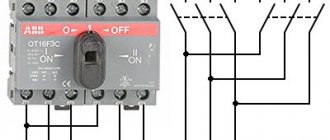

Float switch installation

Devices can be installed in different ways. Before installation, you should make sure that the rated current required to operate the pump is less than the maximum permissible value given in the technical characteristics of this type of float. Among the known installation methods, the simplest is to place it in a tank, which involves the use of a device with a cable and a special sinker supplied with the device.

With this installation, the sinker is fixed on the cable, and then the length of the free-running arm is experimentally calculated. Using a latch, the sinker is secured to the cable, and then the cable is firmly fixed to the outside of the tank. The switch is then connected to the pump, and the device can be used for its intended purpose.

The float mounting option, which involves the use of a supply cable, can only be used when there is no risk of the main device getting caught or hanging in the tank itself and when there is only one float in it.

Sometimes several floats are installed. They are mounted on a rod, the role of which is often played by fragments of a plastic pipe, which is firmly fixed in the tank. Then floats are installed on the pipe, which must be correctly positioned, adjusted, and spaced along the length of the rod so as not to create difficulties for work.

The cables coming from the floats are connected to the rod using clamps. When choosing the number of float switches, pay attention to the number of pumps or the type and number of safety devices and control panels. Sometimes the problem of ensuring the operation of switches can be solved by using several rods. When determining installation schemes, their quantities and locations, each time take into account the features of the place of their installation or check with the project.

Equipment classification

Float sensors can independently monitor the liquid level or send a signal to the control circuit. According to this principle, they can be divided into two large groups: mechanical and electrical.

Mechanical devices

Mechanical valves include a wide variety of float valves for the water level in the tank. The principle of their operation is that the float is connected to a lever; when the liquid level changes, the float moves this lever up or down, and it, in turn, acts on the valve, which shuts off (opens) the water supply. Such valves can be seen in toilet flush tanks. They are very convenient to use where you need to constantly add water from the central water supply system.

Mechanical sensors have a number of advantages:

- simplicity of design;

- compactness;

- safety;

- autonomy - do not require any sources of electricity;

- reliability;

- cheapness;

- ease of installation and configuration.

But these sensors have one significant drawback: they can control only one (upper) level, which depends on the installation location, and regulate it, if possible, then within very small limits. On sale, such a valve may be called a “float valve for containers.”

Electrical sensors

An electric liquid level sensor (float) differs from a mechanical one in that it itself does not shut off the water. The float, moving when the amount of liquid changes, affects the electrical contacts that are included in the control circuit. Based on these signals, the automatic control system makes a decision on the need for certain actions. In the simplest case, such a sensor has a float. This float acts on the contact through which the pump is turned on.

Reed switches are most often used as contacts. A reed switch is a sealed glass bulb with contacts inside. Switching of these contacts occurs under the influence of a magnetic field. Reed switches are miniature in size and can be easily placed inside a thin tube made of non-magnetic material (plastic, aluminum). A float with a magnet moves freely along the tube under the influence of liquid, and when it approaches, the contacts are activated. This entire system is installed vertically in the tank. By changing the position of the reed switch inside the tube, you can adjust the moment the automation operates.

https://youtube.com/watch?v=HFM-k0jItxM

If you need to monitor the upper level in the tank, then the sensor is installed at the top. As soon as the level drops below the set level, the contact closes and the pump turns on. The water will begin to increase, and when the water level reaches the upper limit, the float will return to its original state and the pump will turn off. However, in practice such a scheme cannot be used. The fact is that the sensor is triggered by the slightest change in the level, after which the pump turns on, the level rises, and the pump turns off. If the water flow from the tank is less than the supply, a situation arises when the pump constantly turns on and off, and it quickly overheats and fails.

Therefore, water level sensors for pump control work differently. There are at least two contacts in the container. One is responsible for the upper level; it turns off the pump. The second determines the position of the lower level, upon reaching which the pump turns on. Thus, the number of starts is significantly reduced, which ensures reliable operation of the entire system. If the level difference is small, then it is convenient to use a tube with two reed switches inside and one float that connects them. If the difference is more than a meter, two separate sensors are used, installed at the required heights.

Despite their more complex design and the need for a control circuit, electric float sensors allow fully automated liquid level control.

If you connect light bulbs through such sensors, they can be used to visually monitor the amount of liquid in the tank.

Principle of operation

Depending on the operation scheme of the float switch, the operating principle of the device also changes.

Water supply system, filling and emptying the tank . When the float operates according to this scheme, at the moment of ascent it de-energizes the pump that supplies water to the tank. When the float is on the surface, it gives a signal to turn on the automatic water supply station. The station can only be turned off when the device is immersed to the bottom when the container is empty.

Sewage system . The fecal pumping equipment is switched on when the main control device is raised. The pumping unit turns on when it sinks to the bottom. One float is capable of servicing two pumps at the same time: the first can supply water to the container if the float is in its lower position, the second pump is inactive at this time. When the float is at the top, the second pump is turned on, pumping out water. During this time the feed pump is inactive. This scheme is quite effective, as it eliminates problems with the regular delivery of water when filling the container.

How to set up a float?

Almost every user can adjust the float to turn on the pump. This allows you to set the required immersion depth and set the water level settings at which the equipment will turn on and off.

The easiest way to set it up is by piping the pump while simultaneously fixing the float at the required level next to the housing. You can use steel wire for this. The switch should be fixed tightly, but it should be possible for it to be pulled out from under the cable if necessary.

Operation, repair, maintenance

Compliance with the rules for operating floats will ensure their long-term operation. When the float is included in the water supply and sanitation system, you should not waste time on its maintenance. If the device controls the operation of sewer or fecal pits, it is recommended to clean the float and pump from contaminants at least once a month with a stream of water supplied under pressure. This will prevent the float from sticking or sticking to the discharge pipe or pump. A broken float switch is replaced, and the replacement is carried out by specialists from service centers.

When it is necessary to provide drinking water or remove contaminated wastewater, special devices are used together with pumps, in particular, a float switch. Since the device prevents dry-running, the service life of the pump is increased. A lot of energy is also saved, because, thanks to the float switch, the pump is activated only when necessary.