The article talks about one of the most important materials in construction, masonry mesh. Its areas of application are varied, both for its intended purpose and for related purposes, but this does not make its role any less.

All the indicated factors indicate the importance of using masonry mesh for a durable building. Inexpensive, durable, profitable, fast and reliable!

Which masonry mesh is best to use for brickwork?

Brickwork is the most ancient, widespread and reliable method of building walls.

Thanks to new technologies, brickwork is becoming even more advanced and durable. Recently, masonry mesh has been successfully used to strengthen brick structures. Masonry mesh is widely used:

- during the construction of residential buildings and industrial facilities;

- to strengthen load-bearing structures;

- when creating partitions;

- during the construction of brick fences, pillars, etc.

Marking of masonry mesh

Currently, manufacturers offer a wide range of metal meshes, and therefore choosing the appropriate option is not an easy task.

Before purchasing masonry mesh, we recommend that you read the markings on the roll. Knowing what this or that parameter means, you can choose the best option for your case.

What indicators affect the quality of the mesh?

Firstly, this is the weight of the roll . This is the most important criterion. The more weight, the better the quality of the product. Compare this parameter on different rolls offered by the seller.

Secondly, look at the specified wire diameter . According to GOST, it must be more than 3 mm.

In addition, the label indicates the cell size, mesh (sheet) size, method of production of the product, etc.

For example, let’s look at what the marking “Welded mesh 50x50x3 (1.5x50)” means:

- welded - a method of manufacturing a product;

- 50x50 mm – cell size;

- 3 mm – wire thickness;

- 1.5 m – mesh width;

- 50 m – roll length.

If the wire is galvanized, the thickness of the zinc layer should be indicated on the label. Sometimes, with a very small layer (for example, only 10 g/m2), the mesh is passed off as an expensive and high-quality product. Thus, the seller is trying to mislead buyers.

Scope of application

Once you understand the markings, you can choose the appropriate mesh option for a specific application:

- For private construction, a wire mesh with a diameter of 3 mm is suitable;

- For the construction of residential buildings - 4 mm;

- For the construction of industrial facilities - 5 mm.

Masonry mesh up to 600 mm wide is intended for reinforcing walls, more than 600 mm – for reinforcing floors and other surfaces. Also, consider the size of the cells. The smaller it is, the stronger the mesh.

Summarize. High-quality masonry mesh is made from wire with a diameter of 3-5 mm. When choosing a mesh, take into account its technical characteristics and purpose (mesh size, presence of galvanization, etc.)

produces masonry mesh in strict accordance with its own specifications. We value our reputation and offer our customers only proven, high-quality products.

Buy products from reliable manufacturers, and then the structure you build will be strong and durable!

Choose quality building materials

setkaplast.ru presents to your attention a wide range of meshes for various purposes. Each visitor to our online masonry store will be able to select the appropriate masonry mesh. Masonry using mesh is the only right solution if you are interested in:

- reducing work completion time,

- construction of a construction project that will fully comply with modern high standards,

- ensuring a high level of comfort of the construction site and its maximum service life,

- reducing construction costs.

Metal mesh for reinforcement and masonry

Prices for masonry mesh

- Mesh 50x50 Vr1 neozinc.

- Mesh 50x50 Vr1 galvanized.

- Mesh 50x100 Vr1

- Mesh 100x100x3

- Mesh 100x100x4

- Mesh 100x100x5

Types of mesh for masonry

Masonry mesh is used in the construction industry to reinforce brick walls and concrete products. In this case, the main task of strengthening the entire structure is solved. Masonry mesh is:

- steel

- basalt

- fiberglass

Metal masonry mesh

At APEX METAL you will buy metal masonry mesh. The main material for the manufacture of mesh is galvanized and non-galvanized wire BP1. The most common cell size is 50x50 mm, with a wire diameter of 3 to 5 mm:

| Cell size, mm | Theoretical weight of 1 m2, kg |

| Mesh 50x50x3 | 2,22 |

| Mesh 50x50x4 | 3,86 |

| Mesh 50x50x5 | 5,92 |

In addition, depending on the scope of application, mesh of other sizes is used - 50x100, 100x100 mm:

| Cell size, mm | Theoretical weight of 1 m2, kg |

| Mesh 50x100x3 | 1,66 |

| Mesh 50x100x4 | 2,96 |

| Mesh 100x100x3 | 1,13 |

| Mesh 100x100x4 | 2,00 |

| Mesh 100x100x5 | 3,10 |

The dimensions of welded masonry mesh are standardized and regulated by GOST 23279-85. You can find out the cost using the links above in the “Prices for masonry mesh” block or in the “Welded mesh” section of the Catalog.

How is reinforcement carried out?

The mesh is laid on every 4-5 rows of bricks. The mass of the wall acts on the reinforcing wire, causing it to clamp and work with the masonry as a single whole structure. The need for the masonry reinforcement procedure increases significantly if ventilation holes must be made between the facing brick and the wall.

Reinforcement with masonry mesh is divided into two types:

- longitudinal

- transverse

In the case of transverse reinforcement, the rods absorb transverse tensile loads associated with compression of the masonry. As a result, the mesh prevents the destruction of bricks subjected to tension or bending, thus increasing the load-bearing capacity of the wall.

Areas of application

Metal mesh for masonry from APEX METAL is used for the following purposes:

- plastering works

- fencing of scaffolding, building facades, construction areas

- arrangement of drainage of horizontal terraces, walls

- reinforcement of gypsum panels

- reinforcement of concrete, facades, floors, walls, arches

- reinforcement of reinforced concrete products, structures

- identification of underground communications

- pavement reinforcement

- mechanical protection of pipeline lining

- laying heating pipes when installing heated floors

Corrosion protection

The main method of corrosion protection is the hot-dip galvanizing method.

The mesh can also be supplied in non-galvanized form. But in this case, in order to provide anti-corrosion protection, the brickwork mesh is covered with a layer of mortar, which protects the steel from contact with the atmosphere.

Production technology

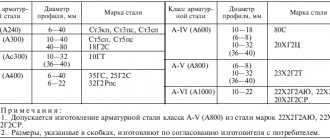

Masonry welded mesh is made by resistance spot welding from mutually perpendicular rows of rods with a diameter of 3 - 5 mm. For the production of such products, cold-drawn reinforcing wire of class BP-I is used from low-carbon steel grades with unlimited weldability and high ductility.

Also in the production process, reinforcing bars of classes A-1, A500C, B500C can be used.

Composite reinforcing mesh

Composite reinforcing mesh is a multicomponent material made from composite reinforcing bars that intersect each other to form cells of various shapes.

Unlike metal mesh for reinforcement, composite mesh practically does not allow heat to pass through and does not form “cold bridges ” in concrete. Therefore, at present, the question of using this particular material in construction is becoming increasingly relevant. The reduction in heat loss when laying composite mesh reaches 34%, which significantly reduces the cost of heating the building. Also, when using composite meshes, it is possible to reduce the concrete layer by almost half without compromising the strength of the object.

Technical characteristics largely depend on the production method of the composite mesh:

- With plastic fastenings at the intersections of reinforcing strands. This type of assembly was developed in Russia and is the most productive and reliable.

- Tying reinforcement with a special thread . Developed abroad, the disadvantage is that the fastening does not withstand shifts when used diagonally.

- Tying the harnesses manually with plastic clamps : a more labor-intensive and least productive process.

Types of composite mesh for reinforcement

- from basalt fiber;

- fiberglass ; _

- made of carbon fiber.

On top, this type of mesh is impregnated with a special polymer composition.

All types of composite mesh for reinforcement have a number of advantages:

- light weight compared to metal;

- absolute immunity to aggressive chemicals;

- durability;

- low price;

- ease of installation and maintenance.

Released in two forms: in the form of a canvas and in separate rods up to 6 m long. The profile of the composite mesh rods comes with notches, like on metal reinforcement, and also with a quartz coating, which results in good adhesion to the concrete mixture.

Basalt reinforcing mesh

Basalt is a volcanic rock formed from magma. Basalt-based reinforcing mesh is made by weaving threads from roving (basalt fiber) impregnated with polymer or bitumen.

Used for laying on cement, adhesive or lime mortar, as an alternative to metal reinforcing mesh. It is used for screeding floors, reinforcing large foam blocks and gas silicate blocks, walls made of non-standard bricks, sealing thin horizontal masonry joints and waterproofing swimming pools, as well as for reinforcing road surfaces of highways (road basalt geogrid), compacting dirt roads, runways (extends service life of the asphalt concrete pavement, while saving on the use of materials by reducing the thickness of the pavement by up to 20%)

Supplied in rolls of 50 m².

Basalt reinforcing mesh

Advantages of basalt reinforcing mesh:

- not subject to corrosion;

- conducts heat poorly (thermal conductivity 0.46 W/m²)

- relative elongation no more than 4%;

- tensile density 4840 MPa (stronger than steel wire of comparable size);

- elastic, impact-resistant, moisture-resistant;

- environmentally friendly material;

- frost-resistant (min operating temperature -260°C);

- fire resistant (max operating temperature +600°C);

- roll length up to 50 linear meters;

- high adhesion;

- the thickness of the mesh fibers is no more than 1.3 mm;

- does not create magnetic fields;

- 6-7 times lighter than metal mesh (from 270g/m²);

- compatible with any additives in concrete mortar;

- In terms of electrical conductivity, it is a dielectric.

Cons of basalt mesh:

- The material is quite new on the market, so there may be problems finding the required mesh. Like all other building materials, there are also fakes for basalt mesh for reinforcement. It is advisable to make a purchase directly from the manufacturer, having previously studied the issue of this material and familiarized yourself with the presence of a quality certificate.

- Basalt mesh is considered conditionally flexible. Of course, you can bend it, but you won’t be able to fix it at the desired angle; after a while, it will still return to its original form. This fact is a slight disadvantage of this reinforcing mesh compared to metal mesh. At the same time, tension arises in the facing surface with a large number of various protrusions, which can subsequently lead to cracking of the layers.

Cells in a basalt grid can be closed or open.

Use of closed cell basalt reinforcing mesh

- Closed ones are used when laying ceramic blocks with large holes, as well as for asphalt pavement. The closed cell prevents the solution from falling into the block.

- Open - for all other work.

The use of basalt reinforcing mesh significantly reduces the labor intensity of the work, and also eliminates the systematic painting of the surface due to corrosion of the metal reinforcing mesh.

TOP companies producing basalt mesh for reinforcement:

- NEOGRID company, Moscow

- Gridex, Rekstrom-K plant, Kimry, Tver region.

- Nizhny Novgorod

- basfiber, Dubna, Moscow region.

- LIGRIL, Makhina-TST LLC, Republic of Belarus, Mogilev,

- ALLIGATOR GAVIAL, Krasnodar

- "Dorsintek", Ekaterinburg

Fiberglass reinforcement mesh

Fiberglass is a complex thread of glass with a special chemical composition, obtained by extrusion (pushing molten glass through dies). The chemical composition of such threads does not allow them to break, but on the contrary, flexibility and elasticity are acquired. To give additional elasticity and resistance to alkaline environments, the fibers are coated with a polymer.

Fiberglass bundles

Types of fiberglass reinforcing mesh:

- painting – for plastering and puttying interior ceilings and walls, when installing floor waterproofing, when repairing doorways and window slopes, sealing cracks and crevices, and decorative finishing. The density of the painting fiberglass mesh is up to 60g/m². Cell size up to 25x25 mm.

- façade – for plastering the outer walls of a building, over façade insulation, for strengthening the outer layer of putty on the base foundation, as well as for installing self-leveling floors. Density of façade fiberglass mesh is up to 160 g/m². Cell size up to 50x50 mm.

- road - designed for reinforcing the road surface. Cell from 100x100 mm.

The price depends on the purpose of the fiberglass mesh. Thus, a mesh for road work and exterior finishing work will cost many times more than a mesh with a finer mesh for interior work.

Fiberglass wall reinforcement mesh

Advantages of fiberglass mesh

- the coefficient of adhesion to the base increases (recommended when processing OSB sheets, chipboard, plasterboard, glass-magnesium sheets);

- increased elasticity, mechanical strength, flexibility;

- neutral to alkalis;

- non-reactive to sudden temperature changes;

- low price, high availability;

- fireproof;

- not hygroscopic;

- easy to install.

Cons of fiberglass mesh

- The components that make up the fiberglass mesh begin to melt at a temperature of 200 degrees Celsius , so it will not withstand fire exposure (in the event of a fire). The frame with the laying of fiberglass mesh loses strength, but does not ignite, since it is a self-extinguishing material;

- fiberglass mesh has a low modulus of elasticity (low rigidity, 4 times less than metal), therefore, for the strength stability of the base, 4 times more fiberglass reinforcement is used compared to the content of the metal reinforcing mesh.

- Fiberglass mesh cannot be given and fixed into the required shape due to its low ductility.

List of the most popular brands in Russia of manufacturers of mesh for fiberglass reinforcement:

Russian brands:

- OJSC "Novgorod Fiberglass Plant"

- JSC "Sudogodskie plastics"

- OJSC "Tverstekloplastik"

- JSC "Steklonit"

Foreign brands:

- X Glass (Sweden)

- OJSC "Polotsk-Steklovolokno" (Belarus)

- ISOTEX Spa (Italy)

- KARL MAYER MALIMO GmbH (Germany)

Repair specialists are well versed in brands. For example, in Russia, fiberglass mesh produced by the Swiss company X Glass is in great demand for installing plaster finishing layers, and for facade exterior work, the budget mesh produced by Polotsk-Steklovolokno OJSC and the more expensive KARL MAYER MALIMO have proven themselves well.

Carbon fiber reinforcement mesh

Carbon fiber is produced by pyrolysis (heating to a temperature of about 3000 degrees Celsius) of natural organic fiber. Threads with a diameter of 0.001 mm have a carbon mass fraction of at least 90%, which makes them very durable and resistant to mechanical stress.

Carbon fiber reinforcement mesh

Carbon fiber mesh has similar characteristics to other types of composite mesh and is used in the following areas:

- tunnels, pipelines, sewers, bridges, reservoirs;

- chimneys, columns;

- repair work on historical sites;

- building facades;

- work on sealing thin-walled structures;

- installation of structures in conditions of high humidity.

Available in rolls of 50 meters, width up to 1200 mm. Tensile strength is not less than 2600 MPa, carbon fiber surface density is 150 g/m². Rectangular cells depending on the area of application from 10x20 mm. The weight of a carbon fiber mesh in equal proportions is 10 times less than the weight of a metal mesh for reinforcement.

Due to its high physical and mechanical properties, the use of carbon fiber mesh increases the load-bearing strength of structures without increasing the total weight of the object due to the minimal thickness of the reinforcing layer used.

Brickwork mesh

Description

Brick mesh is used as a reinforcing element in the construction of brick buildings.

Masonry mesh is also widely used in construction and finishing works:

- for reinforcing prefabricated and monolithic reinforced concrete structures and products;

- for reinforcing brickwork;

- for reinforcement when pouring floors, ceilings, foundations;

- for plastering work.

In the production of mesh for brickwork, the contact welding method is used in accordance with GOST 23279-85 from VR-1 wire (GOST 6727-80).

Dimensions of masonry mesh.

For ease of use in brickwork, masonry mesh is produced in the following standard width (according to the options for using the mesh in brickwork):

- mesh 250 mm

- mesh 380 mm

- mesh 510 mm

- mesh 640 mm

- mesh 770 mm

- mesh 1000 mm

To make working with the mesh for brickwork and its transportation more convenient, it is made 2 or 3 m long.

Custom manufacturing according to drawings

The SK LenStroyDetal plant can also produce mesh for brickwork of any type and size depending on the thickness of the reinforced brick wall.

It is possible to produce masonry mesh with cells from 50 to 200 mm with a pitch of 50 mm.

The most convenient length of masonry mesh for transportation by rail containers is 2 m. This length guarantees maximum container loading.

Possible wire diameters: 4 and 5 mm.

The plant also produces galvanized masonry mesh made from wire with a diameter of 4 mm

- home

- News

- Production

- Economy

- Price list

- Where is welded reinforced mesh supplied? LenStroyDetal

- Articles Information on reinforcement

- Tips and tricks

CONSTRUCTION REINFORCEMENT MESH

- Welded mesh

- Brickwork mesh

- Mesh for concrete reinforcement

- Road mesh

- Masonry mesh

- Heavy reinforcement mesh

- Reinforcement frames

- Galvanized mesh

- Wire VR-1 (d=4 and 5 mm) in rods.

- All types of construction reinforcing mesh

Polls

Photo album

New on the site

- Wire VR-1 (d=4 and 5 mm) in rods.

- Invitation to the seminar: “Finished welded reinforcement products for monolithic reinforced concrete buildings - the path to increasing construction efficiency”

- June 12 is a holiday - RUSSIA Day!

- Video material: Reinforcement of vertical load-bearing structures of monolithic reinforced concrete buildings

- Bonava residential complex “Magnifika”

Popular

- Welded mesh

- Brickwork mesh

- Mesh for concrete reinforcement

- Road mesh

- Masonry mesh

- Heavy reinforcement mesh

- Reinforcement frames

- Galvanized mesh

- Wire VR-1 (d=4 and 5 mm) in rods.

- All types of construction reinforcing mesh

- home

- Types of metal mesh and production

- Prices

- Adviсe

- Map

- Contacts

Statistics

JSC SK Lenstroydetal © 2000-2021. Production and sale, construction reinforcing mesh

Polymer reinforcing mesh

The polymer mesh for reinforcement is made from polyurethane (plastic) and polypropylene (refined petroleum product such as Plurima, Armaflex, Syntoflex). Reinforcing polymer meshes do not require fasteners during installation due to their low weight, are moisture resistant, and are not subject to corrosion and rotting. They are absolutely safe from an environmental point of view and are also resistant to minor vibrations.

Operating temperature from -40°С to +100°С.

The price of plastic mesh for reinforcement is much lower than that of metal and composite mesh, so they are considered the most budget option in this area.

Polypropylene mesh for reinforcement

Flaws:

- instability to some alkaline environments;

- can withstand a layer of plaster of no more than 10-15 mm.

Polypropylene mesh "PLURIMA"

The cells are mostly square in shape, for interior work up to 4x4 mm, for facades from 5x5 mm. Suitable for use in gypsum, lime or light cement mortar mixtures. Not suitable for heavy masonry mortars.

Secrets of strengthening brick and block masonry walls with reinforcing mesh?

During the construction of any type of building or structure (including small elements such as stairs or columns), the strength factor is very important. Often quite large loads can affect the load-bearing masonry of brick walls, this leads to cracks and all kinds of destruction.

Reinforcement of brickwork

That is why structures should be strengthened with a reinforcing post or mesh. The purpose of this technology is to make a building or structure of any type stronger, especially half-brick masonry.

1 What are the types of reinforcement?

Reinforcement can be used for laying both horizontal and vertical elements, and is especially important for half-brick masonry. This depends on the direction of the direct load, which acts completely on the entire building structure. After the work is completed, a corresponding work certificate is drawn up.

Why do you need reinforcing mesh?

Application of reinforcing mesh

- to strengthen the foundation, floors, floor screeds;

- for the need to connect non-joining surfaces or apply a layer of plaster on surfaces with poor adhesion (laying plaster on a metal base, on painted walls, foam plastic, wood, etc.)

- for strengthening a thick layer of plaster (more than 20 mm), especially on vertical and ceiling surfaces;

- to prevent premature cracking;

- during finishing finishing processes to avoid small cracks after the plaster has dried;

- to reduce vibration and deformation of finishing layers under mechanical stress.

Strengthening a brick wall with masonry mesh

One of the effective technologies that makes it possible to strengthen the structural elements of buildings is reinforcement. It is used not only when laying foundations, screeds, and constructing floors. Brickwork is also strengthened using reinforcement. For this use:

- Masonry mesh for bricks.

- Straight reinforcing bars.

- Zigzag rods.

Reinforcement prevents the formation of cracks under tensile and bending loads.

Types of brickwork reinforcement

Depending on the specific conditions, reinforcement can be:

- Transverse.

- Longitudinal

- Vertical.

Transverse reinforcement is carried out with pieces of reinforcement or masonry mesh for bricks. To avoid corrosion, it should be immersed in the solution a few millimeters on each side. A mesh made from large diameter rods weakens the masonry because it increases the thickness of the horizontal joint. Every second to fifth row of masonry is reinforced, depending on the results of strength calculations. When using larger size bricks, the mesh is laid more often.

Longitudinal reinforcement is used to strengthen partitions and load-bearing walls to increase their resistance to bending and lateral loads. The mesh is located along the masonry, reinforcing the longitudinal seams. The sheets are sewn together with transverse rods or welding. Vertical reinforcement is used in the construction of brick columns. If the dimensions of the column allow, it can be internal, and if not, external.

produces and sells masonry mesh for bricks of various sizes. It can be purchased at wholesale and retail prices. To do this, leave a request, and the manager will contact you to clarify the details of the order, terms and payment.

- home

- About company

- Catalog

- Online store

- Delivery

- Blog

- Contacts

- Vacancies

- Site Map

- Terms of use

© 2006-2021, Steel mesh. All rights reserved.

What to choose for repair and construction work?

The type and size of the mesh are chosen depending on the masonry material used, the thickness of the walls, as well as the technology and features of the masonry.

In construction, the most common material is hollow brick, as it is much cheaper than ordinary brick and has sufficient strength. For such masonry material, the best option would be a welded mesh with cells measuring 5x5 mm or 10x10 mm. Small cells will prevent the mortar from entering the brick, which will help reduce the cost of consuming binder material. For solid bricks, experts recommend using products with larger cells - from 10x10 mm to 40x40 mm.

Twisted or gabion mesh is better suited for plastering and making cages for keeping animals. For fencing large areas, plastic mesh or woven chain-link mesh is used, which is also widely used for sifting construction sand and rock. For reinforcing complex architectural structures, carrying out interior finishing work, filtering liquids, and sorting crushed abrasives, it is advisable to use woven stainless steel mesh. When reconstructing and repairing buildings, façade mesh will serve as an excellent material. It is also used as fencing for construction sites, pits, and road sections where repair work is taking place.

Any welded or polymer mesh can be ordered at. Products are presented in a wide range of standard sizes and prices. It has high quality characteristics and meets all GOST requirements.