The main purpose of the float switch is to ensure correct automatic adjustment and operation of electric pumps in various systems. Practical, reliable and convenient switches are guaranteed to be used in drains and sewers, sewerage systems and water supply systems, where they play the role of not only a control device, but also where they simultaneously perform the functions of a water level sensor, and also protect processing equipment from running idle for a long time. dry run."

Properly integrated into the overall system, this device will permanently monitor the functioning of all communication elements and turn on/off the pump in a timely manner when the specified (or permissible) level of water (or other liquid) in the system nodes changes. Typically, the described device is placed in containers, tanks, tanks, and wells.

Floats on mounting rod

One tank can contain up to several switches, each of which has its own function: one controls the auxiliary pump, another controls the main pump, the third acts as an emergency water level sensor, and the fourth monitors overflow.

In any case, the number of floats is determined by the number of connected pumps, as well as the need for protective devices in the system. Several floats are mounted on a special mounting rod. In its role, you can successfully use a plastic pipe securely fixed in the tank. The float switches are fixed on the rod at a distance from each other so as not to interfere with the work of the neighbor. The cable of each switch is secured using clamps. There are situations when necessity dictates the use of several rods at once for attaching floats. Taking into account operating conditions and project features, the number of float switches required to organize the work of a particular system is determined. There are two types of float switches:

- Lightweight - for a system that controls water supply or water disposal;

- Heavy - designed to control drainage or sewage pumps.

Rotary level switch with paddle

The paddle level switch is the most common method for detecting the level of powder and other bulk materials. This type of relay is also installed on the side of the container from the outside using a flange or mounted on the top of the container on an extension. These devices have a motor that rotates a paddle inside the container. As the height of the material increases, the blade is covered by the material and it stops rotating, the motor is turned off and the relay is activated. When the material level decreases and the paddle is released, the spring starts the motor again and the relay returns to normal.

Level switch series with paddle PLS

is produced by Proximity Control. This series features an integrated magnetic coupling that seals the circuit compartment from the process material, reducing maintenance and increasing reliability. The magnetic drive also creates a non-mechanical sliding grip that prevents damage to the motor and drive mechanism from sudden or excessive load on the blade. A special feature is also the external power-on indication.

Advantages:

This is a low cost technology. The devices are easy to use as there is no need for electronic calibration for applications and they are universal for various applications.

Flaws:

The devices are mechanical and the motor will wear out with use, they will not work with very light materials and the devices must be purchased with the power supply in mind.

Float in the pump device description of the element

Both the sump pump and the submersible float pump operate in conditions where debris can get into the fluid or it can run out. In the first case, solid waste fractions can severely damage the system. In order to avoid this, pumps are equipped with shut-off floats, which are activated when there is no water or when there is a large amount of debris in it.

Pumps can be placed and operated in various containers, wells or wells. Depending on where the unit is used, the functions of the float may differ. However, in all cases, the tasks of floats include:

- Adjusting the operation of the main pump;

- Adjusting the operation of the auxiliary pump and increasing its efficiency;

- Water level alarm;

- Overflow alarm.

A liquid level indicator is required to prevent the pump from running dry. An overflow alarm is necessary to eliminate the possibility of overfilling the tank in which the pump is located. This often leads to a short circuit in the device.

Equipment classification

Float sensors can independently monitor the liquid level or send a signal to the control circuit. According to this principle, they can be divided into two large groups: mechanical and electrical.

Mechanical devices

Mechanical valves include a wide variety of float valves for the water level in the tank. The principle of their operation is that the float is connected to a lever; when the liquid level changes, the float moves this lever up or down, and it, in turn, acts on the valve, which shuts off (opens) the water supply. Such valves can be seen in toilet flush tanks. They are very convenient to use where you need to constantly add water from the central water supply system.

Mechanical sensors have a number of advantages:

- simplicity of design;

- compactness;

- safety;

- autonomy - do not require any sources of electricity;

- reliability;

- cheapness;

- ease of installation and configuration.

But these sensors have one significant drawback: they can control only one (upper) level, which depends on the installation location, and regulate it, if possible, then within very small limits. On sale, such a valve may be called a “float valve for containers.”

Electrical sensors

An electric liquid level sensor (float) differs from a mechanical one in that it itself does not shut off the water. The float, moving when the amount of liquid changes, affects the electrical contacts that are included in the control circuit. Based on these signals, the automatic control system makes a decision on the need for certain actions. In the simplest case, such a sensor has a float. This float acts on the contact through which the pump is turned on.

Reed switches are most often used as contacts. A reed switch is a sealed glass bulb with contacts inside. Switching of these contacts occurs under the influence of a magnetic field. Reed switches are miniature in size and can be easily placed inside a thin tube made of non-magnetic material (plastic, aluminum). A float with a magnet moves freely along the tube under the influence of liquid, and when it approaches, the contacts are activated. This entire system is installed vertically in the tank. By changing the position of the reed switch inside the tube, you can adjust the moment the automation operates.

https://youtube.com/watch?v=HFM-k0jItxM

If you need to monitor the upper level in the tank, then the sensor is installed at the top. As soon as the level drops below the set level, the contact closes and the pump turns on. The water will begin to increase, and when the water level reaches the upper limit, the float will return to its original state and the pump will turn off. However, in practice such a scheme cannot be used. The fact is that the sensor is triggered by the slightest change in the level, after which the pump turns on, the level rises, and the pump turns off. If the water flow from the tank is less than the supply, a situation arises when the pump constantly turns on and off, and it quickly overheats and fails.

Therefore, water level sensors for pump control work differently. There are at least two contacts in the container. One is responsible for the upper level; it turns off the pump. The second determines the position of the lower level, upon reaching which the pump turns on. Thus, the number of starts is significantly reduced, which ensures reliable operation of the entire system. If the level difference is small, then it is convenient to use a tube with two reed switches inside and one float that connects them. If the difference is more than a meter, two separate sensors are used, installed at the required heights.

Despite their more complex design and the need for a control circuit, electric float sensors allow fully automated liquid level control.

If you connect light bulbs through such sensors, they can be used to visually monitor the amount of liquid in the tank.

Instruments for measuring the level of bulk materials

Measuring the level of bulk media in containers of various shapes and volumes when automating technological processes in the food industry is a more complex task than monitoring the level of liquid media. This is due to the fact that bulk materials, when filling and emptying containers, do not have a horizontal surface, but form slopes as a result of friction and some adhesion between the particles of the bulk material. The pressure of bulk media on the bottom and walls of the container is not proportional to the height of the level, since Pascal’s law does not apply to bulk materials. Most bulk materials (especially salt, sugar, flour and the like) lose their flowability during storage, i.e. have caking properties. In addition, they can stick to the surfaces of containers and sensing elements of level transducers, which, combined with caking, leads to materials hanging on inclined and, in some cases, vertical planes. The abrasiveness of some bulk materials (grain, salt, etc.) causes increased wear of level sensors installed in bins, and lump materials can cause mechanical damage. A number of bulk materials (flour, salt, concentrated feed, sulfur, etc.) form suspended, flammable, and under certain conditions, explosive dust in containers. Therefore, electric level gauges can only be used in explosion-proof versions.

The variety of measurement conditions and characteristics of bulk media determines a large range of instruments for measuring the level of bulk materials: mechanical, contact-mechanical and float-type, hydrostatic and electrical, ultrasonic, etc. It should be noted that a number of the above discussed devices for measuring the level of liquid media can be successfully used for measuring level of bulk materials. However, commercially produced devices for monitoring the level of bulk materials do not provide solutions to the entire variety of problems that arise when implementing automated process control systems in the food industry.

Float maintenance and repair

Subject to the operating rules, the float to turn on the pump will work for a long time and properly. If the element is used in conditions of working with clean water, then it does not require special maintenance. If the float is used when working with dirty water and a large amount of solid fractions, then it, like the entire system, must be washed under running clean water. This must be done at least once a month. This will prevent the part from sticking to the pressure pipe or pump.

If water gets inside the float, its contacts burn, or the integrity of the cable insulation is damaged, all faulty elements must be replaced, since they cannot be repaired. If the electronic float itself is completely out of order, then it must be changed at special service centers.

Diaphragm level switches

The oldest and simplest technology is the use of diaphragm relays. These relays are mounted on the outside of the tank using a flange, or mounted on the top of the tank as a pipe hanger. The relay turns on when the height of the material in the container increases and it begins to put pressure on the diaphragm. When the material level decreases, the relay diaphragm returns to its normal position.

A series of diaphragm level switches are produced by Proximity Control under the Ultra Mag brand™

. This series has a patented feature of magnetically sealing the circuit compartment from process material, reducing maintenance, improving sensitivity and making the device highly reliable.

Advantages:

The devices are flush mounted and do not have a sensor protruding into the container. With other types of sensors, the sensor or blade can be easily broken. This device is very well suited for use with heavy, flowing and large particle size materials. They also do not require calibration.

Flaws:

These devices are pressure sensitive; Thus, pressure vessels must use a breathable diaphragm or vent. It should also be taken into account that these devices are mechanical and have a diaphragm, which wears out when used for a long time.

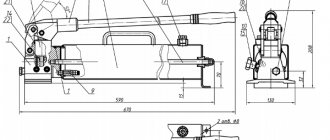

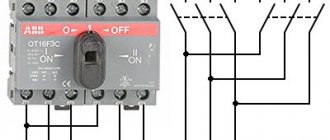

How to connect a float switch to a pump

Installation of the float can be done in different ways. Before installation, make sure that the current consumed by the pump is less than the maximum permissible current specified in the system operating manual.

The easiest way to install a float is to install it in a container using a cable and a special sinker, which is included with the unit. Installation of the float is carried out according to the following algorithm:

- First, the sinker must be put on the cable and the free play of the float must be determined;

- After this, the sinker must be secured to the cable using a latch;

- Next you will need to fix the cable on the outside of the container.

After installing the element, you should connect the float switch to the pump. Before setting up the float, you need to carefully study the diagrams that come with the device.

Once connected, you will need to check if the system is working. To do this, start the pump and wait a couple of hours. If the device pumps out water stably, it means that the installation and connection were carried out correctly.

Float switch in action

Before connecting a newly purchased float switch to a pump, it is advisable to ensure that their technical characteristics are compatible. An elementary way to set up the operation of a switch for electric pumps is inside a water tank.

Serial connection diagram for float switch:

- A special sinker (from the kit) is attached to the float cable.

- The cable is securely fixed at the edge of the tank.

- The amplitude of the free movement of the float switch is adjusted to set the highest and lowest levels at which the float switch will operate.

- The float switch is connected to the pump last.

The main functions performed by a float switch:

- The float connected to the pump that performs the task of filling the tank will turn off when ascending and connect when it reaches the bottom mark.

- For an automatic station: switching on when the upper liquid level mark is reached and switching off at the lower mark (reaching the bottom of the container).

- Valves or valves with a servo drive: the switch will give a signal to close when it is in the upper position (full capacity) and will open the way for water when it reaches the lower position.

- Control room: monitoring of excess and shortage of water.

It is possible to connect two pumping devices to one float: the function of the first pump is to fill the tank when the float is located at the bottom, the mission of the second is to pump out water when it is at the top. The scheme is effective only if there is an uninterrupted supply of water to the tank. Some options for connecting switches to prevent pumps from running dry.

Capacitive level switches

Capacitive level switches are very suitable for use with a wide range of applications, as they can be used for liquids, powders and other bulk materials. This type of relay can be mounted in any position and the sensor can be shortened or lengthened to suit almost any measurement required. Capacitive level switches determine the material level by changing the capacitance of the sensor resulting from the movement of dielectric materials between the sensor and the reference ground level, for example the wall of a tank. As the height of the material increases and it comes into contact with the sensor, the capacitance of the sensor changes from the normally calibrated state and the relay is activated. When the material level decreases, the sensor again senses a change in capacitance and the relay returns to normal.

Capacitive level switch CLS2

is the second generation of devices manufactured by Proximity Control. The series has automatic calibration, universal power supply, protective coating, external switching indication and fail-safe setting.

Advantages:

The devices are non-mechanical and have no wear parts, jamming or breakage. They do not require routine maintenance. This technology is very convenient for coating materials, since the devices are protected from product accumulation on the sensor. They are also useful for pressure vessels where the density of the bulk material may vary.

Flaws:

Devices must be calibrated for a specific application and, if calibration is not performed correctly, surges may occur when different dielectric materials are introduced into the same tank.

The role of alarms in drainage pumps

A drainage pump with a float switch is widely used both in industry and in everyday life. Its scope of use is cleaning wells, removing dirty liquid, etc. In a drainage pump, the float is equipped with the function of turning the drive on and off automatically. The switch is lowered into the wastewater via an extended cable along with a pipe for collecting liquid. The vertical type drain pump kit includes a vertical float switch with the function of pumping liquid out of a confined space. Such a drainage pump can, for example, drain inactive pipelines.

Wilo MS 1

Photo: https://beru.ru

An expensive product intended for professional use where precision is important. The body is made of polypropylene, which has good wear resistance and durability. The outer part is completely smooth, eliminating the chance of contamination. The insulating element is made of high quality.

Float switch WILO MS 1

Advantages:

- efficiency

- high service life

- high quality insulation

- cable length - 10 meters

- universal design

Flaws:

- not detected

Making a float switch with your own hands

To make a part yourself, you will need to prepare:

- Metal ball;

- 2 buildings;

- 2 small magnets;

- Contact plates.

The plates can be made of brass or copper. They must be on different sides of the housing so that the ball between them can make contact. To make the metal strips more springy, they can be placed on a file and beaten with a hammer.

The magnets should lift the ball and hold it at an angle of 65 degrees. The housing itself can be made of any material that does not conduct electricity. Further work looks like this:

- First, wires with a cross-section of no more than 2 mm are soldered to the contacts;

- Next, the wires need to be insulated and placed in the housing;

- It is also necessary to carefully insulate the inside of the case;

- You will need to pour polyurethane foam into the float cavity and insulate the outer side of the housing;

- After this, you need to install loops at the ends of the case and connect the cord.

The manufactured float will last quite a long time, and you will save a lot of money on the purchase of equipment.

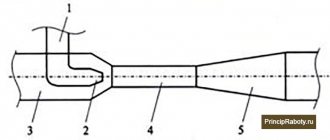

Design and principle of operation of the drainage pump

The design of the drainage pump is quite simple; its main elements are:

Rice. 3 Internal structure of the drainage electric pump

Frame

A typical drainage system has two bodies: external and internal. The internal casing houses the main unit of the device - an electric motor, which is cooled by the water flow washing it, flowing between the casings to the outlet located at the top.

The outer body of the device is equipped with a convenient handle for carrying or hanging in the water column; it also contains an outlet pipe (pipe) to which hoses are connected.

The inner case is made of metal to organize better cooling; the outer case is usually metal (stainless steel) or impact-resistant plastic.

Electric motor

In the internal, completely insulated pump casing, there is an electric motor consisting of a stator with a winding and a rotor, the shaft of which rotates on the upper and lower bearings. Power is supplied to the electric motor using a cable through a sealed input unit; a capacitor is built in for starting.

To lubricate and cool the bearings, special chambers are provided in the lower part of the inner housing, filled with technical oil. There are also O-rings there that prevent water from penetrating into the engine.

Working wheel

The disk-shaped impeller, on which curved blades are placed, is fixed to the motor shaft. The usual material for its manufacture is metal, sometimes it is made of high-strength plastic.

Water intake filter

At the bottom of the pump body there is a stand with legs on which the pump is usually placed. A little higher is a cover with water intake holes (filter), eliminating the possibility of particles with sizes exceeding its technical characteristics from penetrating into the electric pump.