There are often situations at home when you need to squeeze objects with great force. Here are a few of them:

- Squeezing juice from grapes, fruits and vegetables;

- Pressing or removing silent blocks, bearings and bushings;

- Molding of products using a matrix;

- Bending of durable metal parts;

- Straightening curved objects;

- This list has no end.

These actions require press. The most popular version is hydraulic. The liquid is not squeezed out, so it is enough to equip a hydraulic cartridge for extrusion - stamping, and you can develop almost unlimited force.

These lamps are quite compact. For example, the figure shows a machine less than one meter high that produces a force of up to 10 tons. And it is controlled manually.

Such a press can be purchased at a hardware store, but the price is quite high. If you look closely at the design, you can see that the power element is very similar to a regular car bottle lift. Therefore, you can do it yourself.

Design and diagram of a manual hydraulic pump

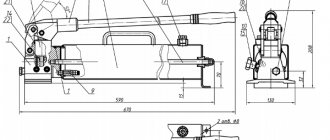

Diagram of a hydraulic hand pump

The manual hydraulic pump consists of two main parts, the pumping unit (1) and the hydraulic tank (2). They are connected to each other by a pin (3). You need to fill the liquid through the hole, having first unscrewed the plug that closes it (4). The handle (6) with the lever (7) drives the plunger (8) of the first and second stages, made as one part. The pumping unit has a two-stage structure. Stage number one, with reduced pressure and higher productivity, serves to accelerate the movement of the hydraulic cylinder plunger. Stage number two, at high pressure and lower capacity, serves to obtain the operating force of the actuator. Overload protection is provided by a safety valve (9). Pressure is released and hydraulic fluid is extracted from the cylinder cavity into the tank using a screw (10).

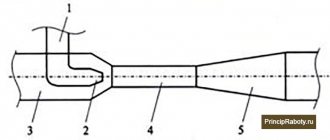

Drawing and concept of a jack press

Power elements are made of steel with a thickness of at least 15 mm or from steel profiles. As vertical struts, you can use a dowel, angle, profile pipe or the same channel. It is preferable to use a threaded rod, as it allows you to quickly adjust the size of the working area.

It is this diagram that we will take as the basis for understanding the design.

Two threaded rods (4) at the bottom (5) and at the top are screwed into the base (7) with a thickness of 20 mm, which allows you to adjust the height of the upper platform.

The pins (4) are made of a steel wheel with a diameter of 30 mm. The upper thread is cut based on the lifting height of the jack rod with a small margin.

The hydraulic jack (6) is installed on the base.

Popular: Homemade pipe bender how to make at home

It would be advisable to fix it there. The bracket is removable to use the lift for its intended purpose.

The lower platform (3) moves vertically on pins.

If the metal thickness is insufficient, the holes can be reinforced with sleeves to prevent tipping. The upper feed platform (1) is bolted with reinforced nuts (2), which are used to adjust the height of the working area.

As a result, the following power structure is created:

This is by no means an axiom; the formula can be anything, especially. Drawings will be developed depending on the availability of material and the type of hydraulic jack used.

The operating principle is as follows: dies (sleeves, punches) or other devices are installed on the platforms, between which the workpiece will change its shape. The jack is lifted in the traditional way - a force equal to the lifting capacity of the jack acts between the platforms.

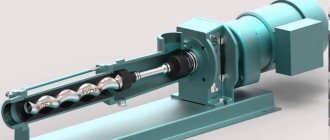

In industrial construction, a separate hydraulic cylinder and a hydraulic pump are connected to each other by a supply line. This is convenient because it makes the design compact, and the use of a manual pressure pumping system is more convenient.

Working principle of a manual hydraulic pump

Before starting to work with any pump, be sure to inspect the tool and if cracks and chips are found on the surface, do not use it. It is important to check whether the high pressure hose is tightly connected to the hand pump.

Work algorithm:

- We connect the pump to the hydraulic system with a quick-release coupling;

- Turn the valve all the way clockwise.

- Using progressive movements, pump the pump handle up and down. As a result, oil is pumped into the system from the pump. At the same time, pressure builds up in the system, and the piston of the hydraulic tool moves, into which we pump oil.

- In a situation where the working piston of the system into which oil is poured reaches its final position, increased pressure will be created in the system, as a result it will be impossible to pump oil. Then it is necessary to stop the pump to avoid failure of the device.

- In order to lower the pressure in the system, you need to slowly turn the valve all the way counterclockwise. As a result, oil from the system will flow back into the pump. This occurs due to the return of the piston to its original position.

- After finishing pumping oil, you should inspect the hydraulic system for oil leaks, and you should also inspect the pump. If leaks are found, they should be corrected immediately.

Manufacturing process

When the drawing of your future hydraulic press is ready, and all the necessary materials, tools, equipment and components are available, we proceed directly to manufacturing. The first thing to do is to cut all the metal, guided by the dimensions indicated in the drawing.

One of the drawing options for making a press

Now you need to make the base of the press, for which prepared square pipes are welded together, and a steel plate is welded onto the rectangle formed from them. Then the side and top parts of the frame are welded together, carefully ensuring that the resulting U-shaped structure is smooth and has strictly right angles in the joints. Now the resulting structure should be welded to the base and we can assume that the frame for your hydraulic press is ready.

The next element that you will need to make for the press is a movable platform. To make it, you can use a channel, square or rectangular pipe. A piece of pipe is welded in the central part of the platform, which will serve as a socket for the head of the jack rod. To make guides for the working platform, you will need two steel strips, the length of which must correspond to the width of the press frame along its outer contour.

A variant of the press design with a movable lower platform, which is fixed with bolts

The strips are attached to the sides of the mobile platform using bolted connections, having previously brought it inside the frame. A removable stop is made using the same scheme, but holes are drilled in its guide strips opposite the frame posts to fix it at the desired height. The process of making a hydraulic press with your own hands is completed by installing tension springs and the jack itself. Such a hydraulic press is also convenient because you can always remove the jack from it (for example, if you need to use it to repair a car).

Appearance of a finished homemade press

One of the fairly economical variations of a hydraulic press, made with your own hands in your garage using simple devices, welding, a jack and channels.

Malfunctions and their elimination

- The manual hydraulic pump does not supply pressure. The main reasons for this behavior may be the lack of hydraulic fluid in the tank or the drain valve is not closed. In any case, it is worth checking these versions; if the tap is still closed and there is liquid, then perhaps the reason is that the suction or discharge valve is clogged. Then you will have to disassemble and wash the hydraulic pump valves.

- Oil (hydraulic fluid) is leaking in the gap located between the body and the plunger. In this case, it is highly likely that the O-rings are worn out or damaged. It is recommended to replace them immediately to prevent failure.

- Does not produce the performance specified in the data sheet. Most likely the filter element of the manual hydraulic pump is clogged. It is recommended to thoroughly rinse the filter element.

- Does not develop the pressure specified in the technical data sheet. The safety valve is not adjusted correctly. You need to set the safety valve to the pressure indicated in the data sheet.

Culinary uses of a jack press

At the first stage, an accurate drawing is made, which should include all design elements. Their operational and technical characteristics are taken into account - overall dimensions, steel thickness, load capacity.

Before this, you need to choose the optimal set of tools and consumables. To process and weld metal structures, you will need a welding machine, a powerful drill, and a set of bolts and nuts. Blanks for a manual hydraulic press can be formed using a self-generator or an angle grinder. In order to secure the unit, holes will need to be made in its base.

Recommendations for assembling the machine:

Frame. The frame consists of 6 channels. The connection is made in two ways: welding and mechanically using screws;

auxiliary table. The optimal design is to install two channels with a gap between them;

How to choose the right hydraulic manual pump?

Choice

Three main selection factors:

1. The hydraulic pump tank must be larger than the hydraulic cylinder capacity.

2. Manual hydraulic pumps come in two types: single-acting and double-acting, pay attention to this parameter.

3. The pressure level should match what you need for work. Select a hydraulic pump with a pressure equal to or greater than the maximum pressure of the hydraulic cylinder.

AM devices

This high-pressure pump for pneumatics (12 volts) is in great demand today. First of all, a high-quality plunger mechanism deserves attention. The maximum permissible pump temperature is 45 degrees. If you believe the reviews of experts, the model’s rod rarely deforms. The model is perfect for air rifles of the KR202 series. The pushers come with an adapter.

Jumpers are used at the bottom of the rack. The footrests are provided with a small width. The handle is standardly used with side covers, and they are made of plastic. The hose in the standard kit is used with a diameter of 0.4 cm. The stand is used with a round cross-section. The upper valve of the device is made of cast iron. The pump weighs quite a lot, but it is stable and is not afraid of heavy loads. You can buy this pump at a price of 18,900 rubles.

Is it worth making a manual hydraulic pump yourself?

At the moment, hand-made pumps are almost never found. Despite this, you can make a hydraulic pump with your own hands. We will need a steel tank. The body will be made from it. To control the pressure in the tank you need a valve. It needs to be secured at the top with a washer. A lever is installed to control the closing valve. A cast iron pipe may be suitable. Use a pressure gauge to monitor pressure. In the end, you will end up with a device that will not withstand pressure of more than 4 atmospheres. With all this, a homemade hydraulic pump will take up a lot of space and be inconvenient to carry. The disadvantage of homemade hand pumps is their low efficiency; quite a lot of force will be required to activate the pump. Also, homemade devices are very unreliable. And if you take into account all the disadvantages, then spending resources on creating a homemade manual hydraulic pump is very ineffective. That is why they are not common.

Tools and materials

If you are going to make a hydraulic press with your own hands, then you will need the following tools, consumables and equipment:

- welding equipment;

- electrodes;

- metal hacksaw or grinder (angle grinder).

In addition, you will need the following elements that will make up your future garage press: a hydraulic jack, two springs that will pull the movable platform to its original state. If you find an old bridge fungus in your garage left over from a renovation, it can be used as an element of a pulling device for homemade presses with a lower jack. In this case, the fungus is put on the jack rod, the upper part of the springs is attached directly to it, and the lower part is fixed to the frame.

The type and quantity of materials required to build a press greatly depends on the chosen design option.

In order to make a press from a jack, you will need the following rolled metal:

- channels (no less than 8 numbers), rectangular or square pipes (with dimensions no less than 40x40), corners with a shelf width of no less than 50 mm;

- a steel sheet with a thickness of at least 8 mm, which will be used as a reliable foundation for the entire structure;

- a piece of steel strip 10 mm thick - for the manufacture of guides and stiffeners, if necessary;

- a piece of pipe - for making sockets for the head of the jack rod.

Manual hydraulic pumps NRG

NRG hydraulic pumps are very reliable devices and are very common here in Russia as they are produced here. The NRG line of pumps contains devices with distributors. The letter “P” is usually placed at the end of the designation of such instruments. This letter means that the tool can work with double-acting hydraulic devices. Let's consider several models of NRG manual hydraulic pumps:

NRG pumps

- Model nrg-7020R. Creates a maximum pressure of 700 bar. And it has a nominal tank volume of 2 liters. The kit includes a hydraulic distributor that allows you to work with both single- and double-acting devices.

- Model nrg-7007. Also creates a pressure of 700 bar. The nominal tank volume is 0.7 liters. The advantages of this model are the presence of a safety valve, minimal force on the handle, and two stages of oil supply. This tool is designed for single-acting hydraulic tools with a spring return rod.

- Model nrg-67016R. The nominal tank volume is 14 liters. Handle force 55 kg. Pressure maximum 4 MPa. Capacity is 115 cubic cm. Such a device weighs as much as 30 kg and is quite large. Suitable for a small car service.

Crosman pump

This high pressure pump for pneumatics is in great demand. Its maximum overload parameter fluctuates around 5 microns. If you believe the reviews of experts, the device uses a high-quality foot rest. The stand in this case is made with a round cross-section. According to buyers, connecting the model to the cylinder is not difficult. The model fits perfectly for PP series rifles. The top valve in the device is made entirely of stainless steel. The pump rod is very rarely deformed.

The permissible temperature level is at least -20 degrees. The sealing sleeve of the model is located behind the adapter. The bottom valve of the device is designed for low pressure. If we talk about the disadvantages, it is important to note that the model uses small pushers. In some cases the barbell wobbles. The handles are made with plastic linings, and they are erased quickly. The model does not have a drying filter. You can buy the specified pump for air rifles at a price of 14,700 rubles.

Summary, pros and cons of hydraulic hand pumps.

Pros:

- Easy to use;

- Do not require any additional energy source;

- High maintainability;

- Have high mobility;

Minuses:

- Low performance;

- Muscular strength of the operator is needed, therefore, additional load on the operator;

Bottom line, it is reasonable to use a manual hydraulic pump in small workshops and mobile services, where there is no need to pump in large volumes of oil and build up significant pressure. In general, hand pumps are very convenient, and most importantly, they are mobile since they do not depend on any energy sources.

Choosing a quality model

How to choose a high pressure pump for pneumatics? First of all, it is important to consider the power limit parameter. The threshold overload indicator, as a rule, does not exceed 4 microns. The adapter must be made of aluminum. The return spring is about 3.6 cm in diameter.

Good models use two sealing sleeves. The top valve must be fixed firmly. Separately, when purchasing a device, the foot rest is checked. In some cases it is done with side overlays. The handle should be held firmly in your hands and not dangle to the sides. A high-quality model these days costs about 16 thousand rubles.

Model "Axor"

This high-pressure pump for pneumatics differs from other models by its wide foot rest. This device weighs only 4.6 kg. If you believe customer reviews, problems with the bar rarely occur. The model is suitable for cylinders from almost all well-known manufacturers. The hose is applied at 0.6 meters. The lubricant on the plunger mechanism holds up remarkably well. According to buyers, the stand is made with an excellent protective coating. The device is not afraid of sub-zero temperatures.

However, this pump still has disadvantages. First of all, it is important to note that the buyer may have problems with the pressure gauge. In this case it is used with one scale. It does not have a moisture protection system. If you believe the reviews of experts, the fitting is designed with a small width. This puts a lot of pressure on the spring. The bottom valve of the modification is designed for 4 bar. The pump does not have a drying filter. The protective sleeve is located behind the adapter. The bottom valve is made entirely of aluminum alloy. The price for a pump of this series fluctuates around 15,200 rubles.

Features of Umarex pumps

The design of the high-pressure pump for Umarex pneumatics is similar to the previous model. A model is produced with two adapters. Its leg stand is made of aluminum type. If you believe the reviews of experts, the top valve used is of high quality. It can withstand maximum pressure of 5 bar. The pump stand is used with a round cross-section. The return spring in the device is provided at 2.5 cm.

The plunger mechanism is installed at the bottom of the structure. The pressure gauge is provided with one measurement scale. It is installed near the jumper. The bottom valve of the model is made of cast iron alloy. The overload parameter for a pump of this type is about 3.3 bar. In total, the device uses three sealing sleeves. The model is perfect for air rifles of the PP series.

The hose included in the standard kit is braided. The adapter for it is matched with a clamping ring. The model is not suitable for rifles of the KR202 series. If we talk about the disadvantages, it is important to note the small handle. The device weighs as much as 4.8 kg. The model's stabilization system is of poor quality. You can buy a pump of the presented series for 13,800 rubles.

Model Gehmann

This high-pressure pump for pneumatics is used quite often by professionals. First of all, it is chosen for its compact size. In this case, the pressure gauge is used with two measuring scales. Its protective glass can withstand heavy loads. If you believe the reviews of experts, the bar rarely deforms. The hose included in the standard kit is braided.

In total, the pump has two in-line filters. The plunger mechanism is located at the bottom of the structure. The advance clutch is installed under the upper valve. Its threshold pressure parameter is 4 bar. The sealing sleeve of the model is made of rubber. The stand is used with a round cross-section. The pressure gauge has a moisture protection system. The device is perfect for air rifles of the KR220 series. You can buy the presented pump in a specialized store for 19 thousand rubles.

Less popular manual modifications

In addition to piston models, which have proven themselves well in factory and homemade versions, other devices are also used.

They are less productive, but interesting from the point of view of design and operating principle.

Image gallery

Photo from

Bike pump

Wooden model with flexible stem

Membrane type device

Structure from a sleeve and a wheel

There are factory models that are not practical to make yourself. For example, equipment based on an impeller. Such devices are used in the industrial sector; they are not very convenient for the garden.

In addition, buying a compact metal device that looks like a can twister will cost no more than making it yourself.

None of the considered homemade pump designs suits you? Then we recommend that you look at more homemade options, the production of which we discussed in the next article.

Hatsan devices

These pumps for air rifles are in great demand. However, the devices are not suitable for PP models. The adapter for pumps is used with a jumper. If you believe customer reviews, the hose is installed without problems. The model has three filters in total. The upper valve of the device is made of aluminum alloy. The maximum pressure indicator is 3 bar. In turn, the overbrightness parameter is maximum 6 microns. The plunger mechanism is located at the foot rests. The handle is standardly made with side pads.

The stabilization system is used in the second degree. According to experts, the bar can withstand heavy loads. The spring of the pump is 2.3 cm. The height of the stand is 46 cm. The model's pressure gauge is used with one measurement scale. It has a moisture protection system. The swing valve is of high quality. It keeps the maximum pressure at 2 bar. Pump pushers are used with an expander. You can buy a model on the market for 17 thousand rubles.