Industrial brushes are consumable tools for processing various surfaces using a pile of twisted or straight wire. Such devices are called wire brushes and cord brushes . In addition, they are called brushing brushes, brushing brushes, roughening brushes, abrasive brushes.

Manufacturers offer a wide range of brushes designed for use in everyday life, at work, and in industry. Brushes are in high demand , so they are sold everywhere. However, choosing the best option is not always easy. To do this, you need to have complete information about the types of brushes, individual characteristics, and features of each type. The most common classification is the division into the following groups:

- brushes for grinders, among which metal and wire brushes stand out;

- brushes for drills, the popular types of which are disc and cup brushes;

- hand brushes.

A separate article is devoted to each type of cord brush; this publication is dedicated to hand tools. The current information presented here will help you choose the best solution.

Varieties

Brushes for metal surfaces are divided into separate groups. Depending on the scope of application, there are:

- hand brushes for metal;

- specialized attachments for power tools (for example, for a drill).

Hand tools are divided by size. Options:

- width - 1–5 cm;

- height - 5 cm;

- length - 15–35 cm.

Separation by pile material:

- Brass, stainless steel. Used for surfaces made of the same material as the pile.

- Nylon. This material is suitable for working with plastic or wood.

- Metal. Suitable for working with metals.

Nylon brushes are often used to apply patterns to the surface of wood. After application, the wooden surfaces are covered with paint or varnish.

A separate division concerns the number of rows of pile. There can be from 1 to 6. Metal brushes can be divided into separate groups according to the material of the handle:

- Plastic - durable, strong. The polymer is not afraid of moisture. The instrument has indentations for holding in the hand.

- Wooden - you can make them yourself. Wood is stronger than plastic. To prevent it from being destroyed by moisture, the wood must be coated with a layer of paint or varnish.

Can be used as an attachment for the following tools:

- Drills. This is a special equipment with a pin for fastening in a drill chuck.

- Bulgarians. These are grinding discs of different grain sizes or metal attachments.

Equipment for an angle grinder (Photo: Instagram / osbornrus)

Types of iron brushes for metal: steel, brass

The wide range of functions performed by cord brushes makes them in demand among craftsmen of various qualifications. Therefore, manufacturers offer a wide range of brushes. Next, the main types of tools with metal bristles are reviewed and analyzed . For more detailed information about each type, it is recommended that you read other publications referenced in the article.

It is important to know that metal brushes include tools made from the following materials:

- steel: alloy, carbon, stainless, brass;

- alloys: brass.

In addition, it is worth remembering this important nuance. Often metal (or, more precisely, steel) brushes are called iron brushes. But this is not entirely true, since nothing is produced from pure iron. Alloys of iron and carbon are used to manufacture metal products. Depending on the amount of the second element, the result is either strong and brittle cast iron, or soft or ductile steel. In publications on our website, when we talk about iron brushes, we mean devices with steel bristles.

Reference. Brushes are included in the All-Russian Product Classification (OKPD) and are a separate group.

For an angle grinder

Metal brushes for grinders, also called attachments, are a universal solution. With their help, it is possible to carry out various processing operations.

Cup brush for angle grinders with bristles made of twisted metal wire. Photo MATRIX

The product is equipped with a special hole designed for attaching the brush to an angle grinder.

Important! The dimensions of the nozzle and the parameters of the unit must match. This also includes the rotation speed of the angle grinder.

Cord brushes for grinders (link to article about them) have different shapes and sizes.

For drill

Metal brushes for drills have some design features compared to attachments for grinders. Such products are equipped with a pin-type fastening , which is placed in a chuck (like a drill) and secured.

Flat brush for drill with metal twisted bristles. Photo MATRIX

Using a tool with such an attachment, you can grind, polish, and clean metal, concrete, stone, wood and other surfaces. Brushes for drills (link to an article about them) have more compact sizes (diameter) than attachments for grinders.

For screwdriver

Another popular type of attachment is screwdriver brushes. This type of device is often combined into one category with cord brushes for drills. Depending on the shape of the chosen brush, the performer has the opportunity to process various products.

Manual: five-row, small and others

Hand brushes are independent tools for work . Their operation does not require any additional equipment. The criteria for classifying metal cord brushes are:

- number of rows: from one to six:

Hand wire brush. Photo VseInstruments.ru

- material from which the body is made: plastic, plastic, wood, combined models are in demand;

Manual four-row metal brush TM Cobalt with a plastic body. Photo VseInstruments.ru

- size: standard and small hand brushes.

Hand brush with metal bristles and wooden handle, standard size. Photo STAYER MASTER

You can learn more about manual metal brushes here.

Harness

Brushes of this type are products whose pile is twisted into strands . The bristles are characterized by increased hardness and cruelty. Wire brushes allow you to perform particularly complex cleaning work, remove stubborn dirt and solve labor-intensive tasks. Wire cord brushes have a self-sharpening effect.

Radial brush for angle grinders with bristles made of twisted steel wire. Photo Practice

Round

There are a variety of types of attachments for power tools. One of the main criteria for classification is the shape of the product.

Cup metal brush for drill. Photo VseInstruments.ru

Despite the large number of models, all types of cord brushes: cup, conical, radial, disk - have a round configuration. It is important to remember that this statement does not apply to hand tools, which have completely different shapes.

Disk

Disc cord brushes (along with cup-shaped ones) are the most common. They allow processing of surfaces located in narrow and hard-to-reach places.

Disc brush for drill with bristles made of twisted steel brass-plated wire, diameter 100 m. Trademark DEXX. Photo Instrumentomania

Selection principles

When buying a brush, you need to pay attention to several factors:

- material and number of rows of pile;

- handle shape (straight or bent);

- body material;

- handle length.

Before buying a tool, it is recommended to hold it in your hands and check how comfortable it is.

Advantages

Advantages:

- if the handle is iron, the tool will last for many years;

- using a brush you can clean out various dirt;

- accessories for power tools allow you to clean metal surfaces from scale and clean welding seams;

- Using a metal brush, you can brush wood.

It takes a lot of effort to clean serious stains without power tools.

Manufacturers and cost

There are a huge number of manufacturers of hand tools for stripping metal products. Several popular companies stand out from them:

- Anchor;

- TOPEX;

- ATAKA;

- Sparta;

- K.W.B.

The cost of the tool depends on the material of the handle and pile. The average price of hand brushes is 300 rubles.

Different types of brushes (Photo: Instagram / osbornrus)

Functions of manual brushes

Brushes are an effective mechanism for processing various materials: metal, wood, glass, plastic, concrete, and can act as an alternative to abrasive wheels.

Special hand brushes of different types. Photo by Lesmann

Brushes are used to clean surfaces from old paint and varnish, tarnish, rust, welding scale and slag. In addition, using this tool you can:

- polishing;

- grinding;

- deburring,

- smoothing out roughness;

- identifying and emphasizing texture;

- roughening;

- grinding down sharp corners.

Exploitation

The hand tool is easy to use. You don't need to follow any rules. After each use, it is enough to clean the lint and metal surfaces from chips, rust, and dirt.

To effectively use accessories for power tools, you need to learn how to properly clamp them in an angle grinder or drill. It is important to check how firmly the fastenings are held. It is recommended to carry out a trial run of the power tool. When cleaning metal surfaces with equipment for an angle grinder or drill, you need to set the number of revolutions correctly. Metal lint cannot be used to clean the front sides. It will leave a lot of scratches that will need to be corrected and polished. You can remove scratches with polish or fine sandpaper.

Before using the equipment or hand brush, you should carefully inspect it. If the pile is bent to one side, you need to straighten it. To do this, you need to focus and lightly tap the bends with a hammer. If there is not enough lint, it is recommended to replace the brush with a new one.

To clean a metal surface from dirt, plaque, scale, and rust, you can use various tools. The simplest, most affordable option is a brush. If you have a power tool (grinder, drill, screwdriver), you can buy special equipment. Learning to use a brush is easy. You don't need any additional skills to do this.

Types of cord brushes for metal and stainless steel

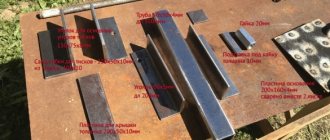

Hand brushes are divided into several types, the criteria being the size of the devices, the material of the bristles and handles, and the number of rows. Detailed information is provided below.

Sizes: mini and more

When talking about the sizes of manual cord brushes, it is customary to indicate the length, height and width of the product. The value of the first indicator varies from 25 to 35 cm. The height of the processing device most often does not exceed 5 cm , the width - no more than 4-5 cm.

A set of hand brushes, consisting of two large and one small. Steel pile, curved extended plastic handle. Photo STAYER MASTER

In addition, performers are offered small (mini) brushes ; their distinguishing feature is the small size of the working part. The handle of such products has dimensions similar to those of standard cord brushes.

Pile material: steel, metal, brass, nylon

The bristles of hand brushes are made from:

- Metal. Such tools are used for grinding, polishing, removing stubborn stains of various types, and grinding off corners on the surface of products made of different materials.

Hand brush TM Cobalt with a wooden handle and metal bristles. Photo VseInstruments.ru

- Nylon. Polymer pile is suitable for working with wood: texturing, roughening, brushing, and is used for finishing.

Hand brush TM FIT with a plastic handle and nylon bristles. Photo 220Volt

- Steel, stainless and brass plated . Steel brushes are suitable for a variety of functions and are designed to work with the appropriate materials and metals. stainless steel bristles are designed to work with products made from similar steel. Brass-plated wire bristles provide delicate handling and are suitable for soft metals.

Hand brush TM MOS with bristles made of brass steel. Photo VseInstruments.ru

By number of rows: one-, two-, three-, four- (4-row), five- (5-row) and six-row (6-row)

An important criterion is the number of rows . The higher this indicator, the better (more thoroughly) the processing is carried out:

- single row;

Manual brass single-row brush TM FIT. Photo Ozon.ru

- double row;

- three-row;

Manual three-row brush. Photo STAYER MASTER

- four-row;

Manual four-row metal brush TM Cobalt. Photo VseInstruments.ru

- five-row;

Manual five-row wire brush with wooden handle. Photo Anchor

- six-row.

Manual six-row brush with a plastic handle TM VIRA. VseInstruments.ru

Brushes with a wooden handle most often have from 4 to 6 rows. A smaller number is typical for plastic models.

Pens

Cord brush handles come in several shapes and are made from different materials.

Material: with plastic, wood, plastic handle

- Plastic brush handles are characterized by mechanical strength and low weight. The handle has small recesses for the convenience of the performer, for a comfortable and reliable grip.

Hand brush with plastic handle and steel bristles. Photo STAYER MASTER

- Plastic handles have high performance characteristics, aesthetic qualities, and durability. The plastic handles are also complemented by small recesses.

Metal hand brush with plastic handle. Photo Anchor

Reference. You often find cord brushes in which the pile is located on a metal or steel bar, and a plastic or plastic handle is put on it. Thus, a combined tool model is obtained.

- Cord brushes with wooden handles, along with plastic tools, are especially popular. Wood is characterized by naturalness, ease of processing and painting. The handles are made of hard wood.

Hand brush with metal bristles and wooden handle. Photo STAYER MASTER

Size: long and standard

The length of the handle is most often approximately equal to the size of the working part. However, there are models with a compact handle . In addition, there are small brushes with an extended handle that are designed for cleaning hard-to-reach areas.

Hand brush with a small handle TM KURS. Photo 220Volt

Configuration: curved and straight

Cord brushes with a straight handle are a typical tool option, suitable for various processing operations. The curved handles of the brushes allow you to comfortably perform work at an angle.

Manual concave brush with a curved plastic handle TM FIT. Photo 220Volt

Sets

Performers who need to process a large number of products made from different materials will need several cord brushes . An excellent solution in this situation is to purchase a set . There are kits that include several devices of the same type . But the most common sets are those containing brushes of different types .

Hand brushes included. Photo VseInstruments.ru