Hook bender. Strip bending. Bending bracket. These are all names of a tool that can be used to bend a metal strip or gutter holder.

You can buy an industrial prototype of a bending bracket for 3-5 thousand rubles. and higher. For those who do not want to spend money on factory tools, we offer options for inexpensive homemade strip benders.

Homemade tool for bending hooks for a drainage system

I installed a drainage system on awnings. To do this, I bought metal holders for the gutter, which are made of good steel. First I bent the hooks in a vice. Inconvenient. Do not really clamp the workpiece. I started looking for a tool for bending strips to attach the drain. Prices start from 1500 rubles. and more expensive. I thought about it and made my own bracket bender for bending the metal gutter holders.

Instructions for making a hook bender for a drainage system:

A homemade bracket for a drain is made as follows:

The paint on the bracket is cracking a little where it bends, but the quality of the hook doesn't compare to bending a metal strip with a vice.

Hook bender for drain holders - description, scope and reviews + Video and Photo

Hook bender for gutter holders - description, scope. For flawless roof installation, you should not use improvised means, but only special roofing tools, and also do not neglect roof installation technology. Typically, most of those who do not have sufficient experience use grinders with abrasives to cut metal tiles, which often only damage the polymer coating, which leads to corrosion and burnout of the metal.

These negative consequences in total shorten the service life of the roofing material. To avoid such situations, you should use a number of special roofing tools, but in particular this applies to a hook bender.

Description, principle of operation

This tool is massive and is used to bend the hook on which the drain will be installed. Please note that when using a vice or any other improvised means that are not intended for this, you take a risk and can not only get a bend where it is not necessary, but also completely ruin the product. The principle of operation is simple - using the adjusting bolt installed in the tool, you can adjust the bending depth.

When using a hook bender, you will be able to create perfect, identical bends on any number of hooks. Due to this, the drain gutter will be placed on the hooks at right angles, which means that water will not pour out in different directions, as happens with improper installation.

Advantages:

- Identical bend angles for all brackets on the roof.

- Installation speed.

- There is no risk of damage to the brackets.

- You can make bends on the roof or scaffolding.

Do it yourself

You can buy a real industrial hook bender for 3,000 to 5,000 rubles, and sometimes even more. If you only need this tool once, and you don’t want to spend a lot of money, we suggest making a hook bender yourself.

Manufacturing instructions:

- Take a corner or channel. The wall thickness must be at least 0.6 cm.

- Using an angle grinder, cut a slot in the workpiece, the length of which should be equal to the width of the bracket. The width of the slot should be the same as the thickness of the hook.

- Take a profile pipe whose inner wall width is greater than the width of the bracket.

- Mark the desired bend location on the gutter brackets.

- Insert the holder into the profile pipe and select a wooden block so that it fits tightly inside the pipe.

The required bend angle should be limited by the height of the corner (stop) that is welded to the channel. When bending, the bracket will jam the block that is inserted into the profile pipe, so after that you should knock out one block with another on the back side of the pipe.

As you can see, you can save money and make a disposable tool from available materials. Such a hook bender will help you do everything no worse than with a factory tool, but unlike it, it will not cost you anything.

Do-it-yourself bracket bender is not inferior to the factory one

I needed a bracket bender for work. A factory tool for bending gutter holders costs about 5,000 rubles. I looked at pictures on the Internet and repeated the design.

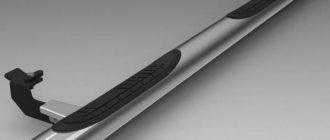

The device of the bracket bender is clearly understood from the photo below.

Tool at work.

According to the user, he bent many gutter hooks using a homemade bracket bender, and the homemade product showed only its best side.

Three of the most budget homemade hook benders for drainage

Hook bender. Strip bending. Bending bracket. These are all names of a tool that can be used to bend a metal strip or gutter holder.

You can buy an industrial prototype of a bending bracket for 3-5 thousand rubles. and higher. For those who do not want to spend money on factory tools, we offer options for inexpensive homemade strip benders.

Homemade tool for bending hooks for a drainage system

I installed a drainage system on awnings. To do this, I bought metal holders for the gutter, which are made of good steel. First I bent the hooks in a vice. Inconvenient. Do not really clamp the workpiece. I started looking for a tool for bending strips to attach the drain. Prices start from 1500 rubles. and more expensive. I thought about it and made my own bracket bender for bending the metal gutter holders.

Instructions for making a hook bender for a drainage system:

A homemade bracket for a drain is made as follows:

The paint on the bracket is cracking a little where it bends, but the quality of the hook doesn't compare to bending a metal strip with a vice.

How to position the brackets correctly?

At this stage, you will have a completely expected question: how are gutters attached to the roof itself? Hooks for them are mounted to the front board, windshield, to the eaves overhang or directly to the rafters.

Fastenings are installed on rafter legs when there is no front board as such or it is important to leave it untouched for a certain aesthetic effect. But, if the roof is already ready, then the only rational option is to attach the fasteners to the front board:

Sometimes fasteners for the drainage system have to be installed directly to the roof sheathing. For this purpose, special elongated clamps are used, which are fixed at two points. The brackets are attached to the rafters (through the sheathing) only after being pre-bent.

Often home craftsmen try to save money and place the brackets too far from each other, although the distance between the fasteners should not exceed 60 meters. If this rule is not followed, over time the gutters will become deformed and gradually damaged under the pressure of the weight of water, ice and snow.

It is also important to guess the location of the brackets so that they are not too low or too high relative to the edge of the roof. If the hooks are located lower than necessary, rainwater from them will not flow well into the gutter, it will splash and streaks will appear on the facade.

Sometimes such an installation error even leads to breakage and breakage of the fastener itself. It is correct if the gutter protrudes slightly beyond the edge, at least half its width. If the drain is installed too high, then the mechanical pressure on it and its fastenings will be many times greater than normal, and the drainage system itself will have to bear the load of melting snow.

After completing the installation of the fastener, it is important to correctly install and align each hook:

Please also keep in mind that when installing metal tiles, an anti-condensation film with an allowance is also used:

Do-it-yourself bracket bender is not inferior to the factory one

I needed a bracket bender for work. A factory tool for bending gutter holders costs about 5,000 rubles. I looked at pictures on the Internet and repeated the design.

Homemade bracket bender

The device of the bracket bender is clearly understood from the photo below.

Tool at work.

Homemade hook bender in five minutes and three kopecks

And this is the most budget-friendly and simplest version of a bending bracket, which was made by a portal user with the nickname Avalex.

To make the tool you needed:

Tool at work.

There is a topic on the portal that tells how to make an arched profile bender without a lathe.

On the topic of homemade tools, we recommend the articles: How to modify a garden wheelbarrow for transporting heavy loads and make a sawing table for a circular saw and a cyclone from a vacuum cleaner, DIY mini-forge: the most budget option and How to make your own device for bending reinforcement.

The video shows how to set up a workshop and the necessary set of tools for a self-builder.

Source

How to fix the gutter yourself?

When installing any drainage system, it is extremely important to take into account the thermal movement of the gutter and its structural elements, which, depending on the material of manufacture, work differently in tension and contraction.

According to the rules, the only movable such element should be a hinged complaint, which is mounted without additional gluing - only on a latch. Moreover, modern manufacturers take care of this by making a special, so-called expansion mark inside the gutter, which helps to assemble in accordance with the air temperature at the time of installation.

Here's how to properly attach a gutter directly to an eaves overhang:

Types of sheet benders

There are three types of sheet metal bending machines:

For bending sheet metal

To obtain radial bending of a metal sheet

All these devices are classified as sheet bending machines. The easiest way to make one with your own hands is the unit of the first group, a little more difficult - the third (rollers for sheet metal). So we’ll talk about them - from how to make a sheet bending machine with your own hands.

Simple manual

Shaped metal parts cost a lot of money. Even more than corrugated sheeting or metal tiles, therefore it makes sense to make a simple machine for bending sheet metal, and with its help make as many corners, ebbs and other similar parts as you need, and exclusively to your own dimensions.

If you're worried about appearance, you shouldn't be. On sale today there is sheet metal not only galvanized, but also painted. In all designs, the sheet is fixed tightly, so that when working it does not slide on the table, which means that the paint does not rub off or get scratched. It is also not damaged in places of bending. So the products will look quite decent. If you try, they will look even better than what they sell on the market.

Powerful sheet bending machine from brands

This sheet bending machine will require a flat surface (table), preferably metal, three corners with a shelf width of at least 45 mm, and a metal thickness of at least 3 mm. If you plan to bend long workpieces (more than a meter), it is advisable to take wider shelves and thicker metal. You can use brands, but this is for bending metal sheets of large thickness and length.

You will also need metal door hinges (two pieces), two large diameter screws (10-20 mm), wings on them, and a spring. You will also need a welding machine - weld the hinges and make holes (or a drill with a metal drill bit).

Where is edge bender used?

The device has found application in many areas of industry. In particular, it can be used to form seams in roofing iron, air ducts, and prepare product edges for welded joints. Today, car repair is given one of the first places in the use of the device, since cars are becoming the most popular among the population every year.

The principle of operation of the device is simple, it is enough to set the required width of the edge bending, then, between two rollers rotating towards each other, place the section of metal being processed and a bend will gradually form with translational movements. Therefore, doing the edge bending yourself will not be difficult. A mechanical hole puncher-edge bender allows you to make holes with a higher degree of quality than when drilling with a drill.

Sheet metal rollers or roller bender

This type of sheet bending machine can have three types of drive:

They make rollers for sheet metal with manual or electric drive with their own hands. Manual ones have 3 shafts, electric ones can have 3-4, but usually there are also three.

This machine needs a good solid foundation. This could be a separate bed or some kind of workbench or table. The basis of the structure is rolls. They are made the same size. The two lower ones are installed permanently, the upper one is movable, so that in the lower position it is located between the rollers. By changing the distance between the lower rollers and the upper one, the radius of curvature changes.

The machine is set in motion using a handle attached to one of the shafts. Then the torque is transmitted to other rollers through sprockets. They are selected so that the rotation speed is the same.

How to install a heating cable in a drain?

In order to protect the newly installed drain from being broken by ice during the first cold weather, today a cable heating system is being installed. It is an electrical cable that is stretched along the entire perimeter of the roof. It operates in temperatures from 0 to minus 15 degrees, and even in the presence of ice and water on the roof.

Such cables are equipped with a temperature main sensor. They are installed along the edges of the roof on the south side, and such sensors regulate the on/off switching of the cable system.

So, any gutter is always subjected to constant loads during its service. Especially if in your area it rains, snows and there are strong winds quite often. In addition, ultraviolet radiation and wind-blown debris have a destructive effect on the drain. And therefore, even a well-installed drainage system always needs to be looked after!

Homemade tool for bending hooks for a drainage system

alp_rnd User FORUMHOUSE

I installed a drainage system on awnings. To do this, I bought metal holders for the gutter, which are made of good steel. First I bent the hooks in a vice. Inconvenient. Do not really clamp the workpiece. I started looking for a tool for bending strips to attach the drain. Prices start from 1500 rubles. and more expensive. I thought about it and made my own bracket bender for bending the metal gutter holders.

Instructions for making a hook bender for a drainage system:

The required bend angle of the bracket is limited by the height of the stop (angle) welded to the channel.

A homemade bracket for a drain is made as follows:

When bending, the bracket jams the block inserted into the profile pipe, so then we knock out the block with another block from the opposite end of the pipe.

The paint on the bracket is cracking a little where it bends, but the quality of the hook doesn't compare to bending a metal strip with a vice.

Hook bender for drain holders - description, scope and reviews + Video and Photo

Hook bender for gutter holders - description, scope. For flawless roof installation, you should not use improvised means, but only special roofing tools, and also do not neglect roof installation technology. Typically, most of those who do not have sufficient experience use grinders with abrasives to cut metal tiles, which often only damage the polymer coating, which leads to corrosion and burnout of the metal.

These negative consequences in total shorten the service life of the roofing material. To avoid such situations, you should use a number of special roofing tools, but in particular this applies to a hook bender.

Description, principle of operation

This tool is massive and is used to bend the hook on which the drain will be installed. Please note that when using a vice or any other improvised means that are not intended for this, you take a risk and can not only get a bend where it is not necessary, but also completely ruin the product. The principle of operation is simple - using the adjusting bolt installed in the tool, you can adjust the bending depth.

When using a hook bender, you will be able to create perfect, identical bends on any number of hooks. Due to this, the drain gutter will be placed on the hooks at right angles, which means that water will not pour out in different directions, as happens with improper installation.

Advantages:

- Identical bend angles for all brackets on the roof.

- Installation speed.

- There is no risk of damage to the brackets.

- You can make bends on the roof or scaffolding.

Do it yourself

You can buy a real industrial hook bender for 3,000 to 5,000 rubles, and sometimes even more. If you only need this tool once, and you don’t want to spend a lot of money, we suggest making a hook bender yourself.

Manufacturing instructions:

- Take a corner or channel. The wall thickness must be at least 0.6 cm.

- Using an angle grinder, cut a slot in the workpiece, the length of which should be equal to the width of the bracket. The width of the slot should be the same as the thickness of the hook.

- Take a profile pipe whose inner wall width is greater than the width of the bracket.

- Mark the desired bend location on the gutter brackets.

- Insert the holder into the profile pipe and select a wooden block so that it fits tightly inside the pipe.

The required bend angle should be limited by the height of the corner (stop) that is welded to the channel. When bending, the bracket will jam the block that is inserted into the profile pipe, so after that you should knock out one block with another on the back side of the pipe.

As you can see, you can save money and make a disposable tool from available materials. Such a hook bender will help you do everything no worse than with a factory tool, but unlike it, it will not cost you anything.

Do-it-yourself bracket bender is not inferior to the factory one

Alex Nk FORUMHOUSE user

I needed a bracket bender for work. A factory tool for bending gutter holders costs about 5,000 rubles. I looked at pictures on the Internet and repeated the design.

A factory-made bracket bender that can be purchased at a hardware store. Homemade bracket bender

The device of the bracket bender is clearly understood from the photo below.

Such a tool can be made by any home craftsman who owns an angle grinder and an inverter welding machine.

Tool at work.

According to the user, he bent many gutter hooks using a homemade bracket bender, and the homemade product showed only its best side.