The use of an air pneumatic relay allows you to automate the filling of the compressor receiver with compressed gas. The operator of equipment with a pressure switch does not need to monitor the process, trying to fix the limit parameters. As a result, engine damage is prevented. Significant results, right?

If you are planning to purchase a pressure switch for your compressor, then you have come to the right place. Here you will find a vast amount of extremely useful information about the principles of operation of the device, its configuration and connection methods.

We have described in detail the existing types of pneumatic relays. They provided options for connecting to a household and industrial network with extremely clear diagrams. We looked at typical breakdowns and ways to prevent them. The information and useful tips we provide are supplemented with graphic, photo and video applications.

Operating principle of a pressure switch

The name of the relay is determined by its purpose - controlling a piston compressor to maintain the required atmospheric pressure in the receiver. It is rarely found on a screw type device responsible for compressing and supplying air.

I take into account the magnitude of the pressing force in pneumatic automation; the device acts on the voltage line, closing or opening it. Thus, insufficient pressure in the compressor starts the motor, and when the required level is reached, it turns it off.

This standard operating principle, based on connecting a normal closed loop to a circuit, is used to control the motor.

The design of all ejectors contains a cylinder containing air at a certain pressure. Reducing it requires turning on the engine to replenish the supply. If the situation is the opposite and an excess is detected, the supply is stopped so that the container does not burst. These processes are controlled by a pressure switch

Modifications with the opposite operating algorithm are also presented: when reaching minimum values in the compression circuit, the pressure switch turns off the electric motor, and at maximum values it activates. Here the system operates in a normally open loop.

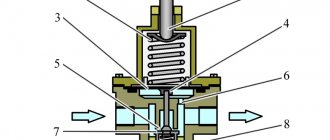

The operating system is made up of spring mechanisms with varying degrees of rigidity, reproducing the response to fluctuations in the air pressure unit.

During operation, the indicators formed as a result of the elastic force of tension or compression of the springs and the pressure of the atmosphere pressed by the device are compared. Any changes automatically activate the action of the spiral and the relay unit connects or disconnects the electricity supply line.

However, it is worth considering that the design of the review model does not provide for regulatory influence. Exceptional impact on the engine. In this case, the user has the opportunity to set a peak value, upon reaching which the spring will fire.

Relay design and circuit

Compressor relays are divided into two types: normally open and normally closed. The former turn on the compressor when the air pressure exceeds, and the latter - when the pressure drops below a certain level.

The actuating element of the pressure switch is springs, whose compression force changes through a special screw. Typically, the compression force of the springs is set at up to 6 atmospheres, as indicated in the user manual. Since the rigidity and flexibility of spring-type elements depend on the ambient temperature, all designs of compressor pressure switches are designed to operate in the range from -5 to +80 degrees.

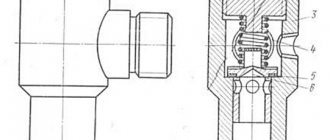

There are two required subassemblies of such a relay: an unloading valve and a mechanical type switch. The first one is connected to the air supply line located between the receiver and the compressor. It is used to control the electric motor. When the compressor drive is turned off, such a valve will release 2 atmospheres of compressed air into the environment, relieving the moving elements of the compressor from excess force. This force must be developed when the compressor is turned on again. This prevents the engine from overloading its torque limit. When starting an unloaded engine, the valve closes without undue load on the drive.

Features of the pressure switch

The mechanical switch has a “stand by” function. This prevents accidental starting of the engine. When the button is pressed, the drive is turned on and the compressor runs automatically. At the moment of shutdown, the compressor engine will not start working even if there is a small amount of atmosphere in the pressure-type pneumatic network.

Increased work safety is ensured by equipping industrial pressure switch designs with a safety valve in the form of a valve. It is very useful in case of unexpected engine stop, piston failure or other emergency situation.

Sometimes the pressure switch housing has a thermal relay inside to check the current strength in the primary network. If this parameter begins to increase, then to prevent overheating and subsequent breakdown in the windings, such a relay will turn off the engine.

Complete set of compressor automation unit

The relay design is a small-sized block equipped with receiving pipes, a sensing element (spring) and a membrane. Mandatory subassemblies include an unloading valve and a mechanical switch.

The pressure switch sensing unit is made up of a spring mechanism, the compression force of which is changed by a screw. According to the factory standardized settings, the elasticity coefficient is set to a pressure in the pneumatic chain of 4-6 at, as reported in the instructions for the device.

Inexpensive models of ejectors are not always equipped with relay automation since such devices are mounted on the receiver. However, during long-term operation, to eliminate the problem of overheating of engine elements, it makes sense to install a pressure switch

The degree of rigidity and flexibility of the spring elements is subject to the temperature of the environment, therefore absolutely all models of industrial devices are designed for stable operation in an environment from -5 to +80 ºC.

The reservoir membrane is connected to the relay switch. During movement, it turns the pressure switch on and off.

The unloading unit is connected to the air supply line, which allows excess pressure to be released into the atmosphere from the piston compartment. This relieves the moving parts of the compressor from excessive force.

The unloading element is located between the ejector check valve and the compression block. If the motor drive stops working, the unloading section is activated, through which excess pressure (up to 2 atm) is released from the piston compartment.

With further start or acceleration of the electric motor, a pressure is created that closes the valve. This prevents overloading of the drive and simplifies starting the device in switched off mode.

There is an unloading system with a time interval of activation. The mechanism remains in the open position when the engine starts for a specified period. This range is enough for the engine to achieve maximum torque.

A mechanical switch is required to start and stop the automatic system options. As a rule, it has two positions: “on.” and "off". The first mode turns on the drive and the compressor operates according to the established automatic principle. The second one prevents accidental starting of the engine, even when the pressure in the pneumatic system is low.

Shut-off valves allow you to avoid emergency situations when elements of the control circuit fail, for example, a breakdown of the piston unit or a sudden stop of the motor

Safety in industrial structures must be at a high level. For these purposes, the compressor regulator is equipped with a safety valve. This ensures system protection in case of incorrect relay operation.

In emergency situations, when the pressure level is higher than the permissible norm, and the telepressostat does not work, the safety unit comes into operation and vents the air. Safety valves in heating systems operate according to a similar scheme, the operating principles and devices of which are described in the article we recommend.

Optionally, a thermal relay can be used as additional protective equipment in the review device. With its help, the strength of the supply current is monitored for timely disconnection from the network when parameters increase.

To avoid burnout of the motor windings, the power is turned off. The nominal values are set using a special control device.

Design and principle of operation of the automation unit

To maintain the pressure in the receiver at a certain level, most air compressors have an automation unit, a pressure switch.

This piece of equipment turns the engine on and off at the right time, preventing the compression level in the storage tank from being exceeded or too low.

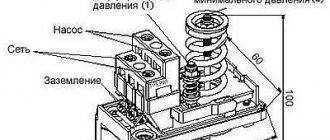

The pressure switch for the compressor is a unit containing the following elements.

- Terminals. Designed for connecting electrical cables to relays.

- Springs. Installed on adjusting screws. The pressure level in the receiver depends on the force of their compression.

- Membrane. It is installed under the spring and compresses it under the action of compressed air.

- Power button. Designed to start and force stop the unit.

- Connection flanges. Their number can be from 1 to 3. The flanges are designed for connecting the compressor start relay to the receiver, as well as for connecting a safety valve with a pressure gauge to them.

In addition, automation for the compressor may have additions.

- Unloading valve. Designed to relieve pressure after a forced stop of the engine, which makes it easier to restart.

- Thermal relay. This sensor protects the motor windings from overheating by limiting the current.

- Time relay. Installed on compressors with a three-phase motor. The relay turns off the starting capacitor a few seconds after the engine starts.

- Safety valve. If the relay malfunctions and the compression level in the receiver rises to critical values, then in order to avoid an accident, the safety valve will operate, releasing the air.

- Gearbox. Pressure gauges are installed on this element to measure air pressure. The reducer allows you to set the required level of compression of the air entering the hose.

The operating principle of the pressure switch is as follows. After the compressor engine starts, the pressure in the receiver begins to increase. Since the air pressure regulator is connected to the receiver, the compressed air from it enters the membrane relay unit. The membrane bends upward under the influence of air and compresses the spring. The spring, compressing, activates the switch, which opens the contacts, after which the engine of the unit stops. When the compression level in the receiver decreases, the membrane installed in the pressure regulator bends down. At the same time, the spring opens, and the switch closes the contacts, after which the engine starts.

Types of pressure switch devices

There are only two variations in the design of the automatic compressor unit. The determination is made based on their operating principle. In the first version, the mechanism turns off the electric motor when the established limits of the air mass pressure level in the pneumatic network are exceeded. These devices are called normally open.

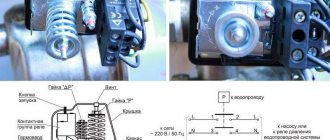

Schematic structure of a membrane pressure switch: 1 – pressure converter; 2 and 3 – contacts; 4 – piston; 5 – spring; 6 – membrane; 7 – threaded connection

Another model with the opposite principle - turns on the engine if a drop in pressure is detected below the permissible level. Devices of this type are called normally closed.

Structure of pneumatic relay symbols

The marking of the air pressure switch indicates the entire optional set of the device, design features, including information about the factory settings for the pressure differential.

Condor's production models offer a wide range of pressure control equipment. The MDR series is aimed at using ejectors of various powers

Let us examine the designations in more detail using the example of devices for air ejectors RDK – (*) (****) – (*)/(*):

- RDK – series of relays for compressors;

- (*) – number of threaded ports: 1 – one port with 1/4”NPT internal thread; 4 – four connectors;

- (****) - type of housing design: T10P - version 10 with a “lever” switch; T10K – “button” switch; T18P – execution 18 with a “switch” switch; T19P - 19 s;

- (*) – factory settings of the threshold response: 1 – 4…6 bar; 2 – 6…8 bar; 3 – 8…10 bar;

- (*) – diameter of the unloading valve: the absence of a symbol means a standardized parameter of 6 mm; 6.5 mm – 6.5 mm.

The difference between the minimum and maximum pressure thresholds is set by the manufacturer and, as a rule, has a value of 2 bar.

However, it is also possible to manually adjust the range of two values – maximum and minimum, but only downward.

The specifics of setting up pressure switches for pumping stations are outlined in the following article, the contents of which we recommend that you familiarize yourself with.

Connection and setup

The general diagram of the compressor installation shows that the pressure switch is located between the unload valve and the secondary control circuit. Most often, a pressure switch for a compressor has four threaded heads, one of which connects the device to the receiver, and the other connects a pressure gauge to monitor readings. The third can be fitted with a safety valve, and the last has a quarter-inch threaded plug in the thread. With a free connector, the user can install a control pressure gauge at his discretion.

The pressure switch is connected according to the following sequence:

- The device is connected to the unloading valve of the receiver.

- Install a control pressure gauge or plug.

- The engine control circuits are connected to the contacts.

- If there are fluctuations in the voltage network, then the connection is made through a surge filter, including when the contact power is greater than that available for the motor load current.

- If there is a need for this, the relay is adjusted through the adjustment screws to the required air pressure.

The connection is accompanied by checking that the voltage in the network matches the factory settings of the pressure switch. For example, a three-phase network of 380 Volts requires the use of a three-contact group, and for 220 Volts a two-phase group must be used.

The adjustment is made when the receiver is at least two-thirds full. The relay is disconnected from the network, the top cover is removed and the compression of the two springs is changed. The operating pressure limit is determined by an adjusting screw with an axis of larger diameter. On the board next to it there is a pressure mark in the form of the letter P and an indication of the direction of rotation of the screw, with the help of which the specified parameter is changed. The second screw helps set the required difference ΔP and has an indicator in which direction it rotates.

To speed up the adjustment process , in some cases the adjusting screw is pulled out, which changes the upper pressure level. Control is carried out according to the readings of the pressure gauge on the pressure regulator for the compressor.

Air relay connection diagrams

The compressor pressure switch is manufactured for connection to electrical circuits of different loads. In accordance with the rating of the power supply line, the appropriate model of the relay unit is selected.

Option #1: to a network with a nominal value of 220 V

If the drive motor is a single-phase device, then a 220 V relay with two groups of contacts is installed.

To work with a single-phase load, manufacturers recommend equipping the unit using models of the RDK series: xT10R-x; xT10K-x; xT19P-x, since these devices have two contact groups

Option #2: to a three-phase network with a voltage of 380 V

For a three-phase load of a 380 V circuit, one of the options can be used: a modification of the relay for 220 V or 380 V, with three contact lines, to simultaneously disconnect all three phases.

Both methods have different schemes. Let's consider the first option:

To operate in a three-phase electrical circuit, a pressure switch RDK-xT18P-x is used. This model is equipped with three contacts and facilitates simultaneous switching of all phases

By choosing the second method, power is supplied from one phase (zero) and in this case the relay rating should be 220 V. For more details, see the following diagram:

It is allowed to use telepressostats of the RDK series: xT10R-x, xT10K-x and xT19P-x with a three-phase load, however, the use of such a circuit requires incomplete disconnection from the supply network. More specifically, one phase will be permanently connected to the load

After connecting to the power supply, you need to understand the additional capabilities provided in the air blocks for ejectors.

Installation of relays and auxiliary elements

In some modifications of pressure switches, you can find additional equipment in the form of flange connections, through which additional equipment is connected. These are basically three-way parts, with a ¼-inch diameter.

By means of several flange connectors, additional elements can be introduced into the system: safety valve, pressure gauge and other necessary mechanisms

To put the device into operation, it must be connected to the receiver. Installation consists of the following steps:

- The device is connected to the compressor through the main outlet.

- A pressure gauge is connected to the device with flanges. There may also be other auxiliary mechanisms that require activation: a safety or unloading valve.

- Channels that are not used for connection must be closed with plugs.

- Next, according to the electrical diagram, the relay is connected to the contacts of the motor control circuit.

Motors with low power can be connected directly; in other cases, additional installation of an electromagnetic starter of appropriate power is required.

Before moving on to setting the threshold response parameters, it is worth paying attention to the operating conditions. First, adjustments are made under pressure. Secondly, the electrical supply to the engine must be cut off.

How to connect and configure a pressure switch?

In the general circuit diagram of a compressor installation, the pressure switch is located between the unloader valve and the secondary engine control circuit. Typically the pressure switch is equipped with four threaded heads. One of them is intended for connecting the device to the receiver, and the second is for connecting a control pressure gauge. One of the remaining connectors can be used to install a safety valve, and the remaining one can be fitted with a regular ¼-inch threaded plug. The presence of a free connector allows you to install the control pressure gauge in a place convenient for the user.

The pressure switch is connected in the following sequence:

- Connect the device to the unloading valve of the receiver.

- Install a control pressure gauge (if it is not necessary, then the threaded inlet is also plugged).

- Connect the terminals of the electric motor control circuit to the contacts (taking into account the selected connection diagram - to normally open or normally closed contacts). When the voltage in the network fluctuates, the connection is made not directly, but through a surge protector. This is also required when the power for which the contacts are designed exceeds the motor load current.

- If necessary, use the adjusting screws to adjust the relay to the required compressed air pressure values.

When connecting, you need to check whether the network voltage corresponds to the factory settings of the compressor pressure switch.

For example, in a three-phase network with a voltage of 380 V, the relay must have a three-contact group (two phases + zero), and for a voltage of 220 V - a two-contact group. The adjustment is made when the receiver is at least two-thirds full. To perform this operation, the relay is disconnected from the power supply, and, by removing the top cover, the compression of the two springs is changed. The adjusting screw, on which the axis of the larger diameter spring is mounted, is responsible for the upper limit of the working pressure. On the board next to it, the generally accepted pressure symbol (P - pressure) is usually indicated, and the direction of rotation of the screw by which this pressure is reduced or increased is also indicated. The second, smaller adjustment screw is responsible for setting the required pressure range (difference). It is marked with the symbol ΔР, and is also equipped with an indicator of the direction of rotation.

To reduce setup time, in some designs the adjusting screw for changing the upper pressure limit is moved outside the pressure switch housing. The result is monitored using the pressure gauge readings.

Adjustment and commissioning process

Factory set parameters do not always meet consumer requirements. In most cases, this is due to insufficient compression force at the highest point of disassembly.

The operating range of the pressure switch may also not be suitable. In this case, independent adjustment of the actuator will be relevant.

Standard factory settings: upper limit 2.8 atmospheres, lower limit 1.4 bar. The parameters are monitored visually using a pressure gauge included in the standard pressure switch kit. New models, for example, Italtecnica, have a transparent body and are equipped with a compression scale indicator directly on the relay

To begin setting the operating compression value, you will need to inspect the engraved plate, which indicates the parameters of the electric motor and compressor.

We only need the largest value that the device produces. This indicator indicates the maximum pressure force that can be set on the relay for the correct operation of the entire pneumatic system.

If you set the specified value (in the figure 4.2 atm), then taking into account all factors - differences in power supply, exhaustion of the service life of parts, etc. - the compressor may not reach the maximum pressure, and accordingly it will not turn off.

In this mode, the working elements of the equipment will begin to overheat, then deform and eventually melt.

The maximum ejector value must be taken into account when determining the maximum relay value. This indicator should be less than the rated pressure of the compressor. In this case, all elements of the system will work uninterruptedly

For reliable operation without shutdowns, it is necessary to set the highest shutdown pressure on the relay, which does not reach the nominal value engraved on the compressor, namely 0.4-0.5 atm lower. According to our example - 3.7-3.8 atm.

The pressure limits at which the compressor is turned on/off are regulated by a single bolt. In order not to make a mistake with the choice of direction for increasing/decreasing, arrows are placed on the metal base

Having determined the level that will be set, it is necessary to remove the relay housing. Under it there are two adjusting elements - a small and a large nut (in Figure 1.3).

Nearby there are arrow indicators for the direction in which the twists will be made - thereby compressing and unclenching the spring mechanism (2.4).

A large screw clamp and spring are provided to control compression settings. When twisted clockwise, the spiral compresses - the compressor switch-off pressure increases. Reverse adjustment - weakens, and accordingly, the pressure level for shutdown decreases.

It is worth remembering: by increasing the shutdown compression strength, we are changing the factory settings, which were set taking into account the regulatory requirements for the operation of the equipment. Before making adjustments, check the technical documentation of the device so as not to exceed the limits stated by the manufacturer

When reproducing settings, the receiver must be at least 2/3 full.

Having understood the purpose of the elements, let's proceed:

- To ensure the proper level of safety, we turn off the power supply.

- Changing the compression level of the springs is done by turning the nut several turns in the required direction. On the board, near the large-diameter adjusting screw, according to the standards, there is a symbol in Latin letters P (Pressure), a smaller one - ΔР.

- The adjustment process is monitored visually on a pressure gauge.

For convenience, some manufacturers place the adjusting fittings for changing the nominal value on the surface of the device body.

Adjusting the compressor pressure

As mentioned above, after creating a certain level of air compression in the receiver, the pressure switch turns off the unit’s engine. Conversely, when the pressure drops to the switching limit, the relay starts the engine again.

Important! By default, relays, both single-phase devices and units operating from a 380 V network, already have factory settings. The difference between the lower and upper engine start threshold does not exceed 2 bar. It is not recommended for the user to change this value.

But often situations that arise force you to change the factory settings of the pressure switch and adjust the pressure in the compressor at your discretion. You can only change the lower switching threshold, since after changing the upper switching threshold upward, the air will be released by the safety valve.

Read also: Resanta sai 250pn scheme

Pressure adjustment in the compressor is carried out as follows.

- Turn on the unit and record the pressure gauge readings at which the engine turns on and off.

- Be sure to disconnect the device from the power supply and remove the cover from the pressure switch.

- After removing the cover, you will see 2 bolts with springs. The large bolt is often designated by the letter “P” with the signs “-” and “+” and is responsible for the upper pressure, upon reaching which the device will be turned off. To increase the level of air compression, turn the regulator towards the “+” sign, and to decrease it, turn towards the “-” sign. First, it is recommended to make half a turn with the screw in the desired direction, then turn on the compressor and check the degree of pressure increase or decrease using a pressure gauge. Record at what indicators of the device the engine will turn off.

- Using a small screw you can adjust the difference between the on and off thresholds. As mentioned above, it is not recommended that this interval exceed 2 bars. The longer the interval, the less often the device’s engine will start. In addition, the pressure drop in the system will be significant. Setting the on-off threshold difference is done in the same way as setting the upper on-off threshold.

In addition, you need to configure the gearbox if it is installed in the system. It is necessary to set the compression level on the gearbox to a level that corresponds to the operating pressure of the pneumatic tool or equipment connected to the system.

Finished compressors are delivered to customers with factory settings. Developers optimize the operating mode of the unit to extend its life, increase productivity and simplify maintenance. Sometimes it is necessary to decide how to configure a compressor so that it meets operating conditions that differ from conventionally standard ones. Manufacturers allow some changes, describing in the instructions exactly which settings can be adjusted.

Possible malfunctions of the device

Several malfunctions characteristic of pressure switches are noted. In most cases, they are simply replaced with new devices. However, there are minor problems that you can fix yourself without the help of a repairman.

If the cause of the malfunction was determined to be a pressure switch, the technician will insist on replacing the device. All service actions for cleaning and replacing contacts will cost the user more than purchasing and installing a new device

The most common malfunction is characterized by air leakage from the relay when the receiver is turned on. In this case, the culprit may be the start valve. It is enough to replace the gasket and the problem will be eliminated.

Frequent starting of the compressor indicates loosening and displacement of the adjusting bolts. Here you will need to double-check the threshold for turning on and off the relay and adjust them according to the instructions in the previous section.

Troubleshooting methods

A more difficult problem lies ahead if the compressor does not work. There may be several sources. Let's consider one of them - melting of the pressure switch contacts due to erosion arising from electrical sparks.

Burning of the contact group occurs due to electric spark erosion, which is formed as a result of the opening of the contacts. However, it is not always possible to replace elements - some modifications are no longer available for sale

To eliminate this type of malfunction, you can use one of the following methods: clean the surface, which extends the service life by at least 3 months, or repair it by replacing the contacts in the terminal clamps.

Step-by-step instructions for the second option:

- Bleed all air from the receiver and turn off the power to the ejector. Remove the pressure switch.

- Having removed the protective housing, disconnect the wiring connected to the group of contacts.

- Using a screwdriver, you need to remove the terminal with contacts and drill out the burnt lines from it.

- You can replace the wire with copper wire. It is necessary to select it taking into account the diameter of the hole, since it must fit tightly into the seat. It is inserted into the hole and pressed on both sides.

- Similar actions are performed with the remaining burnt lines.

- After the contact group is assembled, it is mounted in its original place and the pressure switch cover is screwed on.

The compressor relay operates in difficult conditions, subject to wear and failure.

Although the repair is not cost-effective, those familiar with the device can perform the repair themselves. However, the option of replacing it with a new device still remains profitable.