- Setting up a gas reducer using various methods

- 1. Gearbox adjustment: what is needed for adjustment?

- 2. Gearbox adjustment methods

Due to rising gasoline prices, many car owners began to equip their “iron horses” with gas equipment (LPG) in order to somehow save their finances. However, along with the new equipment, new troubles also appeared - its maintenance and configuration. Therefore, today we decided to address the problem of adjusting the gas reducer. After all, this must be done not only immediately after installing the LPG on the car, but also during the operation of this system. The longer the mileage of the LPG and the period of its operation, the more necessary this adjustment becomes. The fact is that over time, the rubber elements of gas equipment - valves and membranes - can change their properties, which, in turn, leads to excessive gas consumption. Of course, such consequences can occur only after 3-4 years of operation (this is approximately 100,000 km), but you should prepare for this in advance.

Gearbox adjustment: what is needed for adjustment?

Before you begin to get acquainted with the basic methods by which the gearbox is configured, you need to become more familiar with this device and its main characteristics. After all, it is the gas reducer that plays the most important role in the normal functioning of gas equipment. What is its main task? It is thanks to this unit that the driver of a car with gas equipment can reduce the gas pressure that comes from the cylinder. At its core, this is a rather primitive pressure regulator, which allows you to autonomously maintain the same pressure indicator.

As we already noted in our introduction, gearbox adjustment is necessary during the installation of a new gas equipment on a car, as well as after its long-term operation. But in addition to these factors, the need for the frequency of adjustment and the specifics of performing this task is also associated with:

— generation of gas-cylinder equipment and, accordingly, the gas reducer itself;

— the number of regulators that are on the gas reducer;

- the fuel system on which the car engine runs - gasoline or diesel.

The gas reducer contains membranes that can freeze at low temperatures. For this reason, the gearbox must be connected to the automotive cooling system. If we talk about the operation of this gas equipment element in general, it is important to note the following point: it is impossible to start the gearbox simultaneously with the engine. First you need to wait until the engine temperature rises to 30-50°C, and after that you can put the gas reducer into operation.

The design of a conventional gas reducer is also simple. In particular, this device consists of the following parts:

— separate chambers, the number of which may vary depending on the type of gearbox (from 1 to 3);

— idle channel;

- a regulatory system that controls the supply of gas from cylinders to the combustion chamber of the engine.

But on modern gas equipment you can find two types of gearboxes. They have a number of very important differences between themselves, which, in particular, has a significant impact on the process of setting them up. Let's look at the features of each of them:

1. Vacuum reducer. To put such a gearbox into operation, you must perform a number of mandatory actions:

— put the switch in the “Gas-Petrol” position;

— turn the key in the ignition;

When the first two instructions are followed, the required amount of gas is pumped into the intake manifold, which will then allow you to start the engine without any problems and hit the road. The same is ensured by the operation of the starter.

2. Electronic device of the gas reducer. It turns on only when the switch is in the “Gas” position. Similar to the vacuum reducer, we turn on the ignition and give the starter the opportunity to work a little until the required amount of gas collects in the intake manifold and the device itself warms up to the desired temperature.

To properly configure the gas reducer, you need to understand absolutely everything about its settings. Thus, a large number of propane-type reducers are characterized by two regulators, although there are a small number of models with one. But methane analogues, on the contrary, almost always have only one regulator. It is the correct setting of the gas reducer regulator that is the main problem for car owners.

Why are two regulators installed on gearboxes? The first of these is the idle air control. In the process of setting up the device, we will need to screw it all the way. But the bottom one is the sensitivity regulator . It is he who presses the gearbox membrane. Having become familiar with this device in more detail, you can proceed directly to the setup procedure.

Starting a car engine with HBO in winter

In winter, in severe frosts, it can be difficult to start a car even on gasoline, but on gas it becomes a problem. After all, the coolant in the engine is cold and it is simply not possible to warm the gearbox. In this case, the engine is started on gasoline. To do this, during installation, an electromagnetic valve is installed on the gas line; it operates only when the ignition is turned on.

To switch the engine from gasoline to gas, a three-position button is installed in the car interior, which has three operating positions “petrol - neutral - gas”.

- In the first position, gasoline is supplied, the gas is turned off.

- In the second position, both gas and gasoline are turned off.

- In the third position, the gas supply is turned on and gasoline is turned off.

This combination is needed to manage the transition from gasoline to gas. When the engine is started on gasoline and it has warmed up, the switch is switched to the “neutral” position, at this time the gasoline remaining in the carburetor burns out and only after that is switched to the “gas” position.

Adjustment and repair of Lovato gas reducer

In gas-cylinder equipment, the gearbox is given the greatest importance among all components. Its task: to provide the driver with the opportunity to reduce the pressure coming from the cylinder. Repair, namely adjustment, on a car gearbox involves working with one or two regulators: this is the main difference.

In principle, a gas reducer is a primitive pressure regulator designed to independently maintain a standard pressure value based on fuel consumption. As practice shows, the device supports it with minor fluctuations. The pressure decreases slightly with increasing gas flow. This is not a very significant point, but requires attention.

Manufacturer's offer

Lovato gearbox

The Lovato gearbox design is characterized by versatility, simplicity and reliability. For Turkish artisanal producers, the manufacturer is a role model. Almost all generations of Turkish gearboxes have adopted the design of a flattened “drum”, at the ends of which there are two stamped covers. belongs to a family-type enterprise that was founded in the post-war period in conditions of acute fuel shortages. In modern conditions, Lovato is one of the leaders in the global gas cylinder system market. Repair, namely adjustment, of Lovato analogues depends on the following factors:

- mechanism generation;

- number of regulators;

- fuel system.

Manufacturer product range:

- Lovato propane vacuum reducer for 90 and 140 kW. The device is intended for 1st generation LPG systems on carburetor-type cars with a power of up to 123 horsepower. The reducer is intended exclusively for conversion to propane.

- Lovato electronic propane reducer 90, 140, 170 kW. The device is intended for 1st, 2nd and 3rd generation HBO systems on cars of injection, mono-injection and carburetor types with engine power up to 123 horsepower. The reducer is designed for propane-butane.

- Lovato methane gearbox. The 2nd generation device is used for converting cars and buses to methane fuel.

Gear settings

Repair, namely adjustment, of the gearbox requires orientation in its settings. Propane analogues usually have two regulators, but there are also one. Methane type gearboxes are almost always characterized by one regulator. In their management, these settings are the most problematic.

Repair for the gas generation of gearboxes with one unique setting involves manipulation exclusively with the pressure of the transmitted gas. Vehicle owners with particular enthusiasm prefer to “tighten up” the pressure themselves

Having set the only correct and, what is very important, true pressure value, the fuel reducer alone will make it possible to limit gas consumption at operating power due to an element called the greed screw

Repair has some difficulties when the screw is in the “closed” position. To maintain idle speed in this case, it is necessary to increase the pressure, the process of which involves:

- Checking the gearbox before tuning, namely, whether the “greed screw” is open.

- After the previous stage has been completed, adjustment work can begin.

Lovato gearbox design

Adjustment process

The Lovato gas regulator itself is presented in the form of a screw compressing a spring. In order to install it, you should consider:

- when tightening, the gas supply will be reduced by the reducer;

- when unscrewing, it will grow.

Sometimes screws are found with left-hand threads, most often they are right-hand threads. This moment depends on the designer’s imagination of the manufacturer. To simplify this task slightly, it is necessary to take into account: with any rotation it is characterized by the above characteristics of changes in gas pressure.

Adjusting the idle speed on vehicles is explained by the degree of engine shaking. His calm work indicates that the gearbox repair was carried out competently and efficiently.

So, start the engine and hold the throttle open. Then we smoothly release it and slow down until the power unit stalls. At the same time, do not forget the condition: the gas reducer of the car engine must continue to work. For “dummies”, an explanation: the engine will not stall completely if you start twisting the throttle valve in an arbitrary direction. If worse motor performance is observed, you will have to change the direction of rotation of the gearbox and restore its stable operation.

Instructions for replacing the regulator

Two-stage gearboxes are connected to the vapor extraction valve using a threaded fitting and a union nut. The type of thread at the reducer inlet depends on the type of thread at the valve outlet.

If the nature of the connection was not taken into account at the time of purchase, an appropriate adapter will be required. The device is connected to the gas hose through a threaded outlet on the reducer, using an adapter or a union nut.

To replace the stabilization device, you will need a gas wrench. If the connection is rusty, then to remove the gearbox you will need two adjustable gas wrenches.

Replacement or repair of a gas reducer is often carried out in winter, when the formed condensate freezes at the junction of the valve and reducer. To prevent such problems, it is necessary to provide electric heating at the installation stage of the gas system.

To replace the gas reducer, you must perform the following sequence of work:

- Shut off the gas supply using the valve located on the gas vapor extraction valve.

- Unscrew the metal hose.

- Unscrew the union nut connecting the valve and stabilizer.

- Remove the gearbox with connecting hose.

- If the stabilizer cannot be repaired, then it is necessary to twist the bellows hose.

- After ice cleaning, repair or replacement, the regulator should be screwed to the complex valve using a nut.

- If the device was disconnected from the supply line, it is necessary to connect the gas hose step by step, first to the reducer, then to the main line.

- After fixing the connections, you can turn on the gas supply.

When starting fuel into the system, after replacing the fittings, it is necessary to check the output pressure; it must be within acceptable limits and be suitable for operation of the heater, stove or boiler.

With correct installation and normal operating conditions, the regulator, as a rule, lasts at least 10 years.

For high-strength sealing of threaded connections, it is recommended to use blue anaerobic sealant. The material should not be used at low temperatures due to the increased polymerization time, but if you treat the joints in the summer, you can achieve 100% sealing.

You can diagnose problems with the stabilizer using a level gauge and pressure gauge on the tank. If the devices show that there is enough gas, but there are interruptions in the network, then one of the problems with the gearbox is to blame.

In this case, the device can be disassembled and dried. This will help solve the problem, but temporarily. If you install a new gearbox and ensure the device is protected from moisture, you can forget about interruptions in the system.

In order to avoid possible problems with the gearbox in the future, it is also important to take care of the correct installation of the gas tank on the site. You can read about how to do this correctly here

Required materials and tools

To approach the matter correctly, you need to stock up on the necessary details in advance:

- USB adapter/chip;

- cable;

- connector (connection block);

- soldering iron and soldering materials;

- heat shrink tube of different diameters;

- insulating tape;

- multimeter or test light;

- side cutters (nippers).

If you have an unnecessary cord, for example from an old mobile phone that has a board marked PL2303, you can make this cord from it.

But we will make it simpler; online stores already have an almost ready-made solution at an affordable price. In particular, on Aliexpress (Aliexpress), you can buy an adapter for 4th generation HBO (TTL module PL2303) and all the necessary elements for assembling the cord.

It is worth noting here that such a wire (made in China) is not intended for too frequent use. In addition, due to its length (1 meter), it will not be convenient to use on all cars. But for private use it will work well.

It is best to purchase a copper wire with three cores, a soft, shielded wire at any electrical store. The length is 2-2.5 m. It is quite enough for convenient setting up of HBO directly from the car interior.

The chip will fit from a VAZ-2110 fuel pump.

Features of gear systems

It would seem that the structure of the LPG gearbox is quite simple, and there are no difficulties in understanding the principles of its operation. So why is this unit arousing keen interest among motorists? Perhaps the main reason for close attention to gear systems installed on gas equipment lies in the features they have. To be more precise, there are only two of them:

- “Frozenness” of the gearbox. Probably every motorist has heard at least once that gearbox equipment for gas equipment often freezes. Is it true? And this phenomenon is connected with the fact that gas compressed to 16 or, as in the case of methane, 100-200 atmospheres, actively evaporates and loses pressure to 1.8-2 atmospheres, which is accompanied by the intake of energy (heat) from the environment. As a result, the gearbox freezes, sometimes to such an extent that it simply ceases to efficiently perform its main functions. To neutralize such a sensitive feature of gas “carburetors,” it is recommended to install them close to heating elements and, in winter, to warm up the car not on gas, but on gasoline;

- Types of equipment used. By the way, HBO gearboxes can be either vacuum, which are used on carburetor engines, or electronic, used on injection engines. How it needs to be configured depends on the configuration of the selected equipment. If, in the case of adjusting a gearbox with a vacuum operating principle, you will have to use all the skills of setting up carburetors, “shamanizing” the adjusting screws, then when using an electronic unit, it is enough to adjust its operation by using a special program on a computer connected to the LPG control unit. Of course, both tuning options are good, but the best way to adjust electronic gearboxes is definitely the best one. So, for example, on electronic systems it is possible to flexibly adjust the pressure in the chambers, which is simply unrealistic in the case of “vacuum systems”.

Digitronic control unit MAXI 2

For four cylinder engines, Digitronic has developed the MAXI 2 control unit. This line is designed to reduce installation and calibration time.

The basis of the unit is a thirty-two-bit processor with the possibility of upgrading. Such a unit can be quickly installed thanks to a small number of wires and a sealed compact housing. Calibration is carried out through functions located on two panels, which eliminates the problem of switching between tabs. There is a separate button with a buzzer, which is connected using three wires.

The software capabilities of the unit include displaying engine operating parameters on an oscilloscope, a gasoline injection time map in 2D format, functions for correcting gas pressure and temperature with corresponding maps, heating gas injectors, setting the maximum load on the gas mixture, changing the time for opening and closing injectors, as well as the flow through them, and much more.

The MAXI 2 unit is compatible with almost forty manufacturers of gas injectors, including AEB, Hana, Valtek, Rail, Matrix. Functional and software characteristics have made Digitronic MAXI 2 one of the most popular on the Russian market.

VAZ 2107 on propane, what air filter to install and how often to change it?

In principle, there is no big difference in air filters, so you can install any one. The main thing is that it is advisable to set up gas equipment with a new air filter. There is also a peculiarity in the operation of a propane engine: gas consumption and engine power depend on the throughput of the air filter. The first sign that you need to change the air filter is that the engine starts to slow down and consumes more gas, which means that the filter is clogged and does not allow the required amount of air to pass through. At this point, it is advisable to replace the air filter.

Interestingly, the gas can be adjusted for any air filter, even a clogged one, using the settings described in the article above.

Operating principle of the stabilization device

Modern pressure reducers for gas tanks operate on the reverse action principle. The gas coming from the inlet rod tends to close the pressure reducing valve.

The adjusting screw compresses the main spring and when air leaves the working chamber, the flexible membrane pushes the transfer disk with the pin up. At this moment, the pin compresses the return spring, moving the reducing valve away from the seat, and the gas enters the working chamber.

Two-stage gearboxes are less susceptible to freezing, so such devices must be installed on gas tanks in regions where extremely low air temperatures are observed

After the substance moves into the low-pressure chamber, gas exits into the system. As a result, the spring relaxes, the transfer disk and pin lift the valve, gas from the upper chamber enters the low pressure chamber, and the process repeats.

When the gas release decreases, the pressure in the chamber will increase, the spring will take the “closed” position, the valve will lower into the seat, and the gas supply to the reducer and low pressure chamber will stop.

To stabilize the gas pressure in the gas tank, two-stage reducers are used. The fuel in such regulators, before entering the outlet fitting, goes through two stages of reduction.

To increase the life of the gearbox, it is necessary to minimize the contact of the membrane and other elements with moisture. To do this, at the installation stage, decorative or standard protection is installed above the tankTwo stages of the reducer provide maximum stability of the output pressure, so they are safer during operation.

In addition, two-stage devices are resistant to freezing, so they provide a continuous supply of gas in summer and winter. If the gearbox is still frozen, we recommend reading our other article, where we described in detail how to fix this problem. Read on for more details.

Which system should you choose?

There are several leading LPG manufacturers in the world, one of which is Lovato. The equipment has a fairly high build quality, as well as high performance indicators. A particular advantage is the electronic control unit, which calculates all readings with excellent accuracy and very rarely fails. You can also note the compactness of this installation, in comparison, for example, with BRC equipment. It is worth choosing LPG for a specific type of gas, that is, either for liquefied propane or for compressed compressed methane. By the way, when using propane, gasoline injectors can be used, since the density and consistency of the gas is close to gasoline. When working with compressed gas, it is necessary to use special gas injectors.

Errors in setting up HBO 2 on the injector

1. Mismatch between engine power injectors. The injector jets must correspond to the outgoing pressure of the gearbox and the characteristics of the motor. If the 2nd generation LPG injectors do not have time to supply gas, there will be a loss of power and a lean mixture. The problem is solved by replacing the injectors or boring the jets. The injectors are placed as close to the intake manifold as possible. 2. Incorrect adjustment of gearbox screws. Setting up the 2nd generation LPG on the injector is carried out at different engine speeds, including idle. Consequences of incorrect settings:

- automatic switching to gasoline at rpm 2500-3000 at a rate of 4000;

- gas consumption is increased by 15-20% compared to gasoline (enriched mixture);

- Normal idling and loss of power when accelerating.

Adjustment of the 2nd generation LPG on the injector is carried out on a stand; garage adjustment is dangerous.

3. The ECU cells are incorrectly configured. To eliminate the appearance of the Check signal, a clear selection of coefficients for the fuel map is necessary. Correctly setting up gas equipment involves adjusting the emulator of the injector until it fully matches its operation on gasoline.

Summarize. HBO 2nd generation is an outdated type of equipment, which is installed only on carburetor systems and single injection. Most errors on the classic 4-cylinder injector are associated with a setting error. And if in the 2nd generation the LPG setting on the injector is manual, then in the 4th generation the electronics are responsible for the accuracy of the settings. It also automatically adjusts changes in the injection system at different engine speeds, bringing gas consumption closer to the minimum possible limits. You can buy 4th generation HBO in Kharkov for 400 euros. The difference of 200 euros between generations pays off in 5-6 thousand km and it is worth it to drive comfortably without worries about problems with valves and pistons.

Service station KOSTA GAS is a service station that is the official representative of AEB in Ukraine. The company is a certified importer of Italian PRIDE by AEB kits of any configuration. The service station sells and installs kits for almost all types of cars, sets up LPG in Kharkov and Kyiv, sells components: you can buy LPG propane and methane cylinders, injectors, reducers, sensors, multivalves, lines and much more. Always qualified assistance and information support throughout the entire partner network of service stations (15 cities of Ukraine) and engine insurance is free for every client!

KOSTA GAS - the best Italian LPG for Ukraine!

Adjusting the gearbox on carburetor and injection cars.

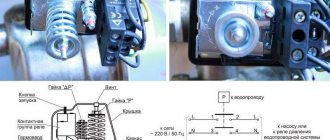

Adjusting the electronic gearbox

There are two main adjustments on the electronic reducer-evaporator (hereinafter referred to as the “reducer”): the pressure in the second stage of idle speed, number 2 in the figure, and the amount of gas passing through the idle channel in the figure, number 1. The engine must be started on gasoline and warmed up to operating temperature, the idle speed should be set to 950-1000 rpm. Turn off the gasoline supply and run out of gasoline. Initial adjustment position: dispenser turned to maximum

(maximum cross-section of the gas supply channel, if the dispenser is two-section with separate adjustment by chambers,

then the first chamber is at maximum, the second at minimum), screw the idle speed screw number 2 on the gearbox all the way, and then unscrew it 5 turns, screw number 1 all the way.

Idle speed setting

Start the car on gas and use the choke to set the speed to 1700-2000 rpm. Now, in several steps, gradually remove the choke and, turning the idle speed screw number 2, find the maximum speed.

(this means that screw number 2 should be turned until the speed stops increasing as soon as it stops increasing!!)

how to set up a methane gearbox - search on DRIVE2

Setting up HBO-4 instructions for dummies

• Reducer

⇒ The working pressure after auto-calibration will automatically be set at the level at which

the adjustment

. Minimum pressure is the gas pressure below which the system will automatically switch the car to gasoline.

Setting up a methane gas system - Community “Repair and Operation. »

Communities › Repair and Operation of Gas Equipment › Blog › Settings

LPG

methane

.

If I configure

According to the instructions, driving on gas is not fun.

So the pressure at the output of the reducer

1.3 and all the screws in

the gearbox

are tightened all the way.

Stuck speed or correct setting of 2nd generation LPG.

This is what an incorrect recommendation for setting up

the gearbox

: If the engine capacity is up to 2 liters, then screw the xx screw all the way, and adjust

the gearbox

using the sensitivity screw, i.e. changing the elasticity of the membrane spring.

Adjusting XX on methane - Community “Repair. »

We have a VAZ 2107, an OZONE carburetor, a lower spacer, a gearbox

OMWL R89E So here’s a question about adjustment, I can’t find the answer anywhere on how to properly adjust

the gearbox

. Now screw 1 (small) is tightened all the way, and screw 2 (larger) is unscrewed somewhere in the middle.

Difficulties in translating the instructions for the tomasetto at04 gearbox (methane).

Uv. Owners of cars with LPG, I am asking you for help. Even though I know it's on methane

Not many people travel here, but I still count on practical advice. After all, as the sage Quintilian said in ancient Rome, “It’s never too late to learn,” that’s exactly what I decided to do.

setting up methane gas system — Daewoo Lanos, 1.5 l., 2010

Review from the owner of Daewoo Lanos - refueling. Hello friends! who set it up

Do-it-yourself

gearbox

on the second generation

of methane

?

can you tell me how to set it

to the minimum flow rate,

the settings

, I seem to have turned it to minimum, but the flow rate is rushing...

Methane pressure at the reducer - Community.

Greetings comrades! What are your opinions on methane

on

the gearbox

for Euro 4 installations?

Modernization of gas equipment (METHANE + PROPANE) - Nissan Maxima QX.

Then we secured the gearbox

under the hood (also not a simple matter, since I decided to leave the propane equipment and there is limited space under the hood).

I am very pleased with the result of the installation... After setup

gas computer for

methane

and tuning the schedule turned out to be excellent.

We adjust the ejector gas pump with Lovato gearboxes and its copies.

Italian electronic gearbox

Lovato evaporator and its exact copy of the Turkish Atiker with two adjustment screws.

If the gearbox

vacuum type, this screw is missing.

Start the car on gasoline, warm up the gearbox

and only then switch to GAS.

Adjusting the Tomasetto AT07 gas system on the injector - Lada 21099.

to adjust

on the gearbox , but on the pipe from

the gearbox

to the manifold there is an important regulator - the greed screw.

Gearbox manufacturer

advises

setting

it at 3000 rpm. But I’ll add why at these particular speeds.

Setting up OMVL - Community "Repair and Operation of Gas Equipment".

(502 rack) Gearbox

: Unfortunately, Alaska. So, before any gas adjustment, we connect the scanner and look at the gasoline

Improved customization

It takes a long time and only on gasoline, i.e. You won’t be able to switch to gas from the button at any time until the map is assembled.

gas regulation theory

These gearboxes

one adjustment screw.

The so-called combined idle/sensitivity regulator. How to configure

such

a gearbox

. As in the previous method, start the car on gas (or on gasoline with subsequent transfer) and adjust the idle speed.

HBO adjustment — Mazda 626, 2.0 l., 1993

Electrical diagram of the gearbox

is already

configured

and does not require any intervention.

If the gearbox

requires

adjustment

, then it can be done by following these rules: 1. Fully tighten the idle speed adjustment screw.

Instructions for installing and configuring Tomasetto Achille AT-04 CNG.

Gearbox

Tomasetto AT-04 (

methane

) Methane

reducer

model AT-04 is an electronic methane pressure regulator with 3 levels of pressure reduction for traditional systems.

There are 3 types of these gearboxes

depending on the power of the car engine.

Tomasetto Features of adjustment and configuration or Euro gas equipment.

If the gearbox

requires

adjustment

, it can be done by following these rules: 1. Fully tighten the idle speed adjustment screw.

2. Stop the engine and disconnect the gas pipe. Then connect the reducer

and the gas valve with a temporary wire.

LOVATO LPG equipment

*All prices are for original equipment recommended by the manufacturer and certified in accordance with the requirements of the Russian Federation. The basic cost for installing gas equipment with Russian-made gas cylinders and excluding additional services is indicated.

| Gas cylinder capacity/car model | Prices for installing gas equipment 4th generation (gas injection) in rubles. | ||

| car with 4 cylinders | car with 6 cylinders | car with 8 cylinders | |

| 50-65 l, cylindrical | 29 500 | 46 600 | 51 000 |

| 80-100 l, cylindrical | 30 600 | 47 700 | 51 700 |

| 42-53 l, toroidal | 30 500 | 47 900 | 51 900 |

| 75-95 l, toroidal | 34 200 | 52 000 | 55 000 |

| Installation of an FSI direct injection system | |||

| from 48 900 | from 72 000 | from 83 000 |

https://www.youtube.com/watch?v=ytadvertiseru

The following are discussed separately:

- Installing a filling device in the gas tank hatch;

- Installation of EURO multivalve;

- Additional cylinder;

- Additional gearbox;

- Valve lubrication systems.

What are the advantages of gas

Many people ask why install HBO at all? After all, in fact, you have to drive with a gas cylinder in the car. This is oh so dangerous.

In fact, when it comes to professional installation of equipment in accordance with all safety standards and requirements, a gas cylinder is no more dangerous than a tank of gasoline or diesel fuel.

The cost of installation and the purchase of equipment itself is impressive if you want a truly high-quality device from famous brands. Therefore, it’s worth thinking about it, reading reviews and deciding for yourself whether you need gas.

I will tell you my personal opinion. It is important to install an LPG because the car is actively used. The same working Gazelle, which travels several tens of thousands of kilometers annually, will fully justify the costs and will save the owner money when compared with gasoline or diesel.

HBO allows you to save money only if the car is constantly in motion. I don’t see the point in spending 2-4 thousand dollars on modifications if the car spends 80% of its time in the garage and drives no more than 10-20 kilometers a day. It will take more than one year to recoup the costs of installing gas equipment.

So the main advantage is savings at gas stations. But it is conditional, as you understand.

Propane butane or methane

Another pressing question is what type of gas is best used for LPG? The answer is clear - propane-butane.

Yes, there are installations where the use of gas equipment is provided. If we take purely operational characteristics, then methane is not inferior to propane-butane.

We recommend: How to test a car battery for performance

There is only one problem - lack of infrastructure. Finding a gas station with methane gas even in a large city is quite difficult. The majority of gas stations specialize in propane-butane. That's the whole trick of choice.

HBO adjustment 2nd generation

After successfully installing a 2nd generation LPG on a car, and passing a test to ensure the functionality of its components and the absence of leaks of the propane-butane mixture (detected by “soaking” the connections or using a gas analyzer), the time comes for the need to adjust the equipment for further successful operation. The HBO adjustment is carried out sequentially in several steps, let's take a closer look.

Adjusting the 2nd generation HBO consists of several simple steps:

- Adjusting the sensitivity of the gearbox.

- Adjusting the propane-butane mixture dispenser.

- Adjusting the idle speed when operating on a propane-butane mixture.

- Delay in the operation of the automatic shutdown when switching the operation of the car engine from gasoline to a gas mixture for carburetor cars. Or the number of revolutions at which the engine will switch from running on gasoline to running on a propane-butane mixture, provided that the fuel type switch button is set to the “automatic” position.

Before starting the adjustment, check:

- There is a sufficient level of coolant in the vehicle's expansion tank. If necessary, liquid must be added.

- Check and, if necessary, adjust the operation of a car engine on gasoline.

- Since the engine, when running on a propane-butane mixture, is very sensitive to air filter contamination, the air filter is replaced with a new one or blown out.

- No gas leaks. It is checked mainly by applying soap foam - by washing all gas compounds. If leaks are detected (in such places soap bubbles form from the foam), the connection is disassembled and the leak is eliminated. Then the reassembled connection must be checked again.

- Reliability of fastening of all clamps and nuts.

- Reliability and correct connection and absence of short circuits of all electrical appliances of HBO2 (electric valves, buttons).

- Check the presence of gasoline in the gas tank.

- Fill the cylinder with a propane-butane mixture.

Advantages and disadvantages of HBO 2

Despite some imperfections, 2nd generation gas equipment has its advantages:

suitable for engines with fuel injection and for cars with carburetors; the design of second-generation gas equipment is simple and reliable; easy connection diagram and installation of gas equipment; it is easy to configure and regulate the system; An important advantage is that you can regularly start the engine on gas at an ambient temperature above 10 degrees Celsius.

The advantages of second-generation gas equipment include the low cost of repair kits.

Flaws:

- There is no feedback from the car engine, which leads to unstable operation in some modes (motor elements fail prematurely due to incorrect settings for the mixture quality or ignition timing).

- Increased gas consumption.

- There is a danger of a backfire of the gas mixture in the intake manifold.

- The emission of spent fuel in 2nd generation gas equipment does not comply with Euro-3 standards and higher.

- Slow response to pressing the accelerator pedal.

- The need to constantly adjust the valve clearance to prevent uneven engine operation under heavy loads.

When operating HBO 2, it should be borne in mind that water entering the air intake affects the number of revolutions.

You can’t do business with the 2nd generation of gas equipment today, since new versions of gas equipment have been released, which take into account many of the shortcomings.

What is gas equipment

GBO is gas-cylinder equipment. It is a gas installation that powers the engine instead of conventional fuel. Gas can be of two types - propane or methane. In practice, they differ little (except for the state of aggregation), but in terms of price and storage they still have slight differences.

LPG for a passenger car

There are several types of HBO:

The higher the generation, the more advanced the system (more sensors and electronics are used, everything is calculated more accurately and the operating efficiency is higher). But the generation of HBO is selected depending on the type of engine and it is not always possible to use the 5th generation installation on an old engine.

Carburetor adjustment

Adjusting the carburetor for LPG

Adjusting the LPG is not something very complicated, so anyone who is at least a little familiar with the structure of the car and knows the principle of operation of the gas reducer and engine can do it. It is worth adjusting gas equipment only after adjusting the carburetor.

can be done as follows. First, clean it of external blockages (sand, dust, oil), and also rinse it from the inside. It is worth tidying up or even replacing filters, air and fuel jets, and washing the float chamber and the carburetor itself. Of course, it is not necessary to carry out this procedure if you are in a hurry or cannot do it for some reason, but still, a well-maintained carburetor works much more stable and productive. In general, it is worth carrying out maintenance of this spare part several times a year, preferably with the onset of a new season. After this, you can go directly to adjusting the idle speed.

Start the engine and warm it up to operating temperature (several minutes of idling). There are 2 screws here: quality (usually copper) and quantity (plastic). The first is responsible for the quality of the mixture. By unscrewing, the oxygen content in the mixture drops; by twisting, the mixture becomes richer in fuel. The second screw is responsible for the quality of exhaust gases. Use the quality screw to start adjusting the idle speed. Try to set them almost to maximum. As soon as you feel a harmonious rhythm in the engine, stop. The more you continue to unscrew the screw, the faster the RPM will begin to drop. When the engine idle speed on the carburetor is adjusted, you can begin adjusting the gas pressure reducer.

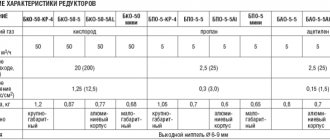

Technical characteristics of propane reducer BPO 5-3

The propane reducer BPO 5-3 is produced by Krass. While maintaining the operating principles common to a propane reducer, it compares favorably with the budget BPO 5-2:

- Weight 0.67 kg.

- Length × Width × Height 164 × 108 × 136mm.

- Operating temperature -15+45˚С.

- Maximum inlet pressure 25 kg/cm3.

- Working pressure, 4 kg/cm3.

- Maximum gas flow 5 m3/hour.

- Connection method W 21.8-14 threads per 1″ LH.

- Working output M16x1.5 LH.

Technical characteristics of propane reducer BPO 5-3

The propane reducer BPO 5-3 produced by Krass is deservedly considered not an amateur, but a professional device.

It should be noted that under the name BPO 5-3 Ridius produces its own propane reducer and is a subsidiary of the Vyritsa Metal Products Plant, however, the characteristics and case materials used by Ridius do not allow their products to be classified as professional.

Purpose of the cylinder propane reducer BPO 5-3

The BPO 5-3 propane reducer is used to reduce, stabilize and control the pressure of domestic gas supplied from standard cylinders to consumers such as welding torches and cutters, heaters and a large number of other types of consumers.

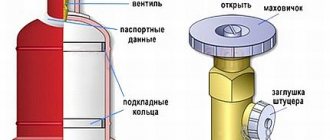

Complete set of propane gas reducer BPO 5-3

- assembled device;

- nipple for connecting hoses with a diameter of 6.3 or 9 mm;

- screw;

- product data sheet;

- packing box.

Complete set of propane gas reducer BPO 5-3

Advantages of the BPO 5-3 cylinder propane reducer

- precise setting of working pressure

- laser printing of parameters on the body

- ergonomic adjustment handwheel

- Manufacturer's barcode on the body simplifies accounting, logistics and order completion for the seller

Design and principle of operation of the propane reducer BPO 5-3

The propane adapter is made according to a single-chamber design, but is distinguished by a larger membrane area, a larger rod stroke and a larger flywheel size. All these design advantages allow you to more accurately set and regulate operating pressure.

The body of the propane reducer is made entirely of brass, which increases strength, reliability and extends service life

Safety precautions when working with propane reducer BPO 5-3

Safety measures also coincide with those for BPO 5-2, however, due to the higher operating pressure, it is necessary to carefully ensure that the permissible parameters are not exceeded - consumers.