Calculation according to SNiP

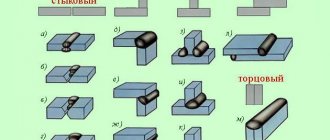

Before moving on to the calculations, first, you need to decide how the structure will be assembled in the future, using welded or bolted connections. Based on these data, all that remains is to choose one or another type of rolled metal. In this case, it is desirable, and in some cases necessary, to take into account the requirements of SNiP, since for each type of metal structures there are certain standards.

In most cases, general-purpose rolled metal is used in construction, namely: T-beams and I-beams, pipes of various types of profiles (circle, square, rectangle), angles, channels. Special products obtained by rolling are also used - I-beams, profile sheets

Classification is carried out according to the following characteristics: shape, dimensions, weight of a certain unit of length, permissible errors in dimensions and geometry, and even method of transportation. It is important to know that all rolled metal products are manufactured in accordance with GOST or, in rare cases, in accordance with the technical specifications of the enterprise. The calculation of metal structures in relation to the economics of rolled products is carried out separately; there are special formulas for this, and we will start from this stage.

Design and calculation of steel frame (structures)

Calculations completed by KM include in general:

- The study of initial data, which mainly includes: determination of wind and snow areas, geological conditions and operating conditions. In rare cases, determination of a seismic zone.

- Specifying a calculation model for the operation of the entire structural system: — Select a design scheme: frame, frame-braced, braced; — set rigid and hinged nodes; — Determination of eccentricities (rigid inserts).

- Collection of loads on the frame: - Vertical loads - own weight; — Horizontal loads — wind, crane braking; — Combinations of loads from cranes; — Dynamic loads; — Seismic loads.

- Construction of a design scheme in a specialized program (assignment of stiffnesses, hinges, rigid inserts, connections, types of finite elements...) and assignment of design characteristics (steel grade, working condition coefficient, design lengths, maximum flexibility, bed coefficient...

- Preliminary calculation for the purpose of selecting sections, their corresponding purpose.

- The final calculation of the frame, which includes determining: the safety factors of the elements and the system, checking the permissible movements of the system, as well as the forces in the frame nodes.

- Calculation of nodes based on a combination of forces (column base, joint of truss elements, joints of beams, bolted connections and welding...).

- Analysis of other frame elements that are not included in the calculation model of the program, such as purlins, half-timbered posts, wind crossbars, staircase structures.

- Checking connections for stability and strength.

- Preparation of a report for the customer or examination.

Separate calculation of steel structures

- Calculation of the steel structure of a truss truss includes: Clarification of the design diagram (work of connections). Determination of nodal loads, calculation of forces in elements, checking deflection. Next is the calculation of the nodes: grid junctions, checking the strength of the flange and support connections.

- Steel crane beam: Load collection depending on the crane design. An important point is the operating conditions of the workshop, if the work is in 3 shifts, then it is necessary to take into account fatigue failure. And the most interesting thing is checking the stability of the upper section chord for class 1 beams. Here, such beams must, as one of the options, be unfastened from the plane.

- Floor beams are a simple calculation option - there are almost no problems here - checking strength, deflection and support unit.

Calculation of metal structures in relation to efficiency

There is a misconception that the smaller the dimensions and weight of the rolled metal, the more profitable the design will be from it. It is clear that thinner corners will withstand less load and this is true for any metal materials. Therefore, quite a lot of basic criteria for determining the efficiency of a product, be it an I-beam or a channel, are used. In particular, the ordinary and plastic moment of resistance (W and Wп, respectively), the moment of inertia I, the radius of gyration i and the shear resistance of the cross section Cc. It is based on all these parameters that the most advantageous form of the product is determined.

Photo from open sources, is for illustrative purposes only

In most cases, it is logical to use a value such as the specific cross-sectional area of the profile, which is denoted as Aw and is determined by the formula:

Аw = А/W2/3.

A is the cross-sectional area of the profile, or, in other words, a given amount of material;

W – moment of resistance equal to unity.

Comparing various structural elements, while having indicators N = N1, which can express any of the material characteristics (W, Wп, I, I or Cc), we still do not always get identical profiles. In this regard, it is necessary to carry out calculations of metal structures using the formula for determining the relative efficiency of one material relative to another:

Δ = (F/F1 – 1). 100%

F and F1 can mean the mass or cost of a specific unit of length or the entire rolled metal product, as well as the cross-sectional area.

Calculator for calculating prefabricated buildings

Prefabricated buildings have become widespread due to the relative cheapness of solutions, high reliability, functionality, and energy efficiency. Correct calculation of the main parameters of the water treatment plant and determination of the optimal layout makes it possible to reduce costs by an average of 10-15%. Therefore, before proceeding directly to the design, preliminary calculations of the price of prefabricated buildings are carried out. This makes it possible to focus on the cost of construction and, if necessary, make certain adjustments to the plans

Calculation of the cost of metal structures

The cost of the structure consists not only of the prices of materials, but also taking into account the labor intensity of assembly and the cost of transporting rolled metal. The easiest way to determine the cost-effectiveness of choosing a particular hot-rolled profile is by the manufacturing method. Because the most accessible and inexpensive are products obtained by hot rolling, long and profile products, and sheet materials.

Photo from open sources, is for illustrative purposes only

From these same products, bent profiles and corrugated hardware are subsequently produced by cold rolling, which are naturally more expensive than conventional steel sheets. The exception to cheapness is seamless pipes, which are much more affordable than electric welded pipes.

Electric-welded pipes are made by long-term cold profiling from sheets of metal obtained by hot rolling. Seams are produced using high-frequency currents that form a corona arc at the end of the electrode. This method produces not only electric-welded pipes, but also closed profiles of rectangular sections. The latter are somewhat more expensive if they are made by changing the shape of bent-welded pipes with a round cross-section.

When calculating metal structures, it is better to focus on Belarusian standards due to the fact that they have fairly high requirements and are not inferior to foreign ones. Remember, to correctly design buildings and structures made of steel, you need to have the skills to collect loads, calculate forces, and determine normal and shear stresses.

How to calculate the load on a profile pipe

When choosing a profile pipe for load-bearing structures on their own, the customer understands the importance of accurate calculations of parameters and load. In this article we will try to figure out whether it is worth saving on calculations.

With the arrival of summer, the construction season begins for companies, owners of cottages and summer cottages. Someone is building a gazebo, greenhouse or fence, other people are re-roofing or building a bathhouse. And when the customer has a question about load-bearing structures, more often the choice is made on a profile pipe due to its low cost and bending strength with low weight.

What load acts on the profile pipe?

Another question is how to calculate the dimensions of a profile pipe so as to get by with “little expense” and buy a pipe suitable for the load. For the manufacture of railings, fences, greenhouses, you can do without calculations. But if you are building a canopy, roofing, canopy, you cannot do without serious load calculations.

Every material resists external loads, and steel is no exception. When the load on the profile pipe does not exceed the permissible values, the structure will bend, but will withstand the load. If the weight of the load is removed, the profile will return to its original position. If the permissible load values are exceeded, the pipe becomes deformed and remains that way forever, or breaks at the bend.

To eliminate negative consequences, when calculating a profile pipe, consider:

- dimensions and cross-section (square or rectangular);

- structural stress;

- steel strength;

- types of possible loads.

Classification of loads on a profile pipe

According to SP 20.13330.2011, the following types of loads are distinguished by duration of action:

- constant, the weight and pressure of which does not change over time (the weight of parts of the building, soil, etc.);

- temporary long-term (weight of stairs, boilers in a cottage, plasterboard partitions);

- short-term (snow and wind, weight of people, furniture, transport, etc.);

- special (earthquakes, explosions, car impact, etc.).

For example, you are building a canopy in the courtyard and using a profile pipe as a supporting structure. Then, when calculating the pipe, take into account possible loads:

- canopy material;

- snow weight;

- strong wind;

- possible collision of a car with a support during unsuccessful parking in the yard.

To do this, use SP 20.13330.2011 “Loads and impacts”. It contains maps and rules necessary to correctly calculate the profile load.

Calculation diagrams of the load on a profile pipe

In addition to the types and types of load on the profiles, when calculating the pipe, the types of supports and the nature of the load distribution are taken into account. The calculator calculates using only 6 types of calculation schemes.

Maximum loads on profile pipe

Some readers wonder: “Why do such complex calculations if I need to weld a porch railing?” In such cases, there is no need for complex calculations taking into account the nuances, since you can resort to ready-made solutions (Tables 1, 2).

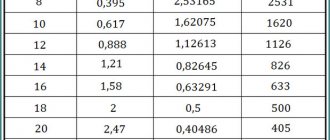

Table 1. Load for a square profile pipe Profile dimensions, mm Maximum load, kg taking into account the span length 1 meter 2 meters 3 meters 4 meters 5 meters 6 meters Pipe 40x40x2 Pipe 40x40x3 Pipe 50x50x2 Pipe 50x50x3 Pipe 60x60x2 Pipe 60x60x3 Pipe 80x80x3 Pipe 100x100x3 Pipe 100x100x4 Pipe 120x120x4 Pipe 140x140x4

| 709 | 173 | 72 | 35 | 16 | 5 |

| 949 | 231 | 96 | 46 | 21 | 6 |

| 1165 | 286 | 120 | 61 | 31 | 14 |

| 1615 | 396 | 167 | 84 | 43 | 19 |

| 1714 | 422 | 180 | 93 | 50 | 26 |

| 2393 | 589 | 250 | 129 | 69 | 35 |

| 4492 | 1110 | 478 | 252 | 144 | 82 |

| 7473 | 1851 | 803 | 430 | 253 | 152 |

| 9217 | 2283 | 990 | 529 | 310 | 185 |

| 13726 | 3339 | 1484 | 801 | 478 | 296 |

| 19062 | 4736 | 2069 | 1125 | 679 | 429 |

Table 2. Load for a rectangular profile pipe (calculated on the larger side) Profile dimensions, mm Maximum load, kg, taking into account the span length 1 meter 2 meters 3 meters 4 meters 5 meters 6 meters Pipe 50x25x2 Pipe 60x40x3 Pipe 80x40x2 Pipe 80x40x3 Pipe 80x60x3 Pipe 100x50x4 Pipe 120x80x3

| 684 | 167 | 69 | 34 | 16 | 6 |

| 1255 | 308 | 130 | 66 | 35 | 17 |

| 1911 | 471 | 202 | 105 | 58 | 31 |

| 2672 | 658 | 281 | 146 | 81 | 43 |

| 3583 | 884 | 380 | 199 | 112 | 62 |

| 5489 | 1357 | 585 | 309 | 176 | 101 |

| 7854 | 1947 | 846 | 455 | 269 | 164 |

Programs for calculating metal structures

Of course, in modern construction, special programs are used that can help carry out calculations of metal structures; we will discuss some of them below. First of all, it is worth saying that programs can be both desktop and online versions, each of them is good in its own way.

- The Metalcalc online calculator is a fairly convenient and fast resource that will quickly determine the weight and length of rolled metal products. It is important to note that the calculations are performed on the basis of current GOSTs and are characterized by maximum accuracy.

- “Sopromatguru” is an excellent, but, unfortunately, only partially free online version of the program, which is used for calculating beams. Here you can calculate a statically determinate system, determine displacements at nodes and other parameters.

- The Truss desktop program allows you to calculate a flat statically determinate truss and at the same time save the results.

Of course, this is only a small part of the existing programs for calculating metal structures, we just wanted to show their existence and briefly described the capabilities; if desired, all additional information can be found on the Internet.

International online building calculator - WebSteel system

The PC Vesta plant offers a unique online service WebSteel

(calculator of buildings and building structures) for designing and calculating the cost of individual buildings made of light metal structures for further construction anywhere in the world (hangars, warehouses, offices, shops, workshops, farms, etc.) The online service operates 24/7 and allows you to receive an official commercial proposal with free sketches, taking into account the main climatic zones at the construction site (snow, wind and seismic)

Unlike traditional CAD systems, the WebSteel

works in the technological capabilities zone of the PC Vesta plant, which allows a client without technical education to create a unique building project much faster and more conveniently, calculate the budget for the construction of the building as accurately as possible and instantly take into account the basic requirements for the design of such buildings online.

Spend a maximum of 10 minutes entering basic online building parameters, select a construction site on the map in most countries of the world and receive an official online commercial offer! And all this is completely free! If you are satisfied with the construction budget, then feel free to place an order at the PC Vesta plant with an accurate fixation of all prices and terms under the contract!

Order a building calculation Calculate online

Innovative service for calculating cost estimates from PC VESTA

PC VESTA has developed a unique calculator for online calculations of building structures. WebSteel is an innovative service that allows customers from any corner of the world to perform all necessary calculations and be serviced remotely without calling or visiting the factory. It's free, available 24/7/365, and easy to use. It takes into account the maximum number of factors that influence the cost and functionality of the construction project, which qualitatively distinguishes it from conventional online calculators for calculating the construction of a house.

This service is intended for online design of any type of air conditioning plant. To work with it, you just need to enter the initial parameters of the building, after which the system will calculate the parameters and create a 3D model of the new object. WebSteel allows you to service completely remotely, from design to ordering the delivery of metal structures anywhere in the world. All this saves customers time and speeds up the delivery time of prefabricated buildings.

If you have any questions, ask our managers via online chat or by phone.

Calculate building

How it works

Calculations using a free online construction calculator are performed remotely without a call or visit to the metal structures plant. Despite the high functionality of the service, its interface is as simplified as possible, which makes it easy to navigate even for people without special technical knowledge and skills.

To calculate a prefabricated building, you must indicate the following information in the appropriate fields:

- region;

- BVZ dimensions;

- type of construction;

- cladding options;

- type of openings, their parameters and quantity; color of walls, roof, canopy, openings, extensions;

- select additional services.

The system automatically calculates the cost. The user can change the initial parameters by tracking price changes. Such a comparative analysis allows you to select the optimal solutions in terms of functionality and cost. Sketches, technical specifications and ready-made calculations are provided to the customer by email.