04/29/2020 Author: VT-METALL

Issues discussed in the material:

- Main types of metal structures

- Stages of manufacturing metal structures

- About assembly as an important part of metal structures manufacturing technology

- Technologies for combating corrosion in the manufacture of metal structures

- About quality control of metal structures manufacturing

- Features of installation of metal structures

The technology of manufacturing metal structures is a rather complex process containing several stages. At each of them, all work must be completed perfectly - and the point here is not only, or even so much, in the possible claims of the customer.

Metal structures are now used everywhere: in industry, the energy sector, and construction. On their basis, residential buildings and administrative buildings, various kinds of warehouses and sports complexes are erected. Therefore, people’s lives literally depend on how accurately the technology for producing metal structures is followed.

Main types of metal structures

The scope of application of metal structures is varied both in terms of the purpose of the buildings and in the level of complexity of the objects being built. They are widely used in the construction of warehouses, car washes and service stations, industrial and agricultural complexes, granaries, etc. Given the wide range of areas of use, a clear classification of metal structures is required in accordance with specific criteria.

One of these criteria is the manufacturing technology of metal structures and the method of their assembly. So, they distinguish:

- bolted (screw) – assembly is carried out using hardware;

- riveted - assembly using rivets;

- forged - combining structural elements by forging;

- welded - connecting parts by welding;

- stamped – production of seamless metal structures by stamping rolled metal;

- combined - combining several methods of manufacturing and assembling metal structures: for example, welded-bolted, welded-cast, etc.

By type of use of metal structures there are:

- Collapsible, when the structure can be assembled directly on site and disassembled if necessary. This technology for manufacturing metal structures allows them to be reused.

- Solid cast (stationary), when a stationary structure is created for long-term operation. Such metal structures cannot be dismantled.

- Transformable - this option is reminiscent of prefabricated structures, but in this case, metal structures of various configurations and sizes can be created from the same set of elements.

According to their purpose, metal structures can be divided into two types: load-bearing and enclosing. The first includes the frames of parts that provide the rigidity and stability of the entire structure and its technical configuration. The second type includes a complex of parts (sandwich panels and facade panels, fences, gate systems, etc.) that perform a protective function.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

Technologies for the manufacture of metal structures are also classified according to the material from which they are made. For these purposes, metal alloys are used: aluminum, steel, titanium, cast iron, etc. or their compounds.

Prices for welding work

Today, metal structures are actively used in construction. Therefore, the question of the price of welding for work when installing metal structures is very important for many.

| Name | Unit | Price |

| Prefabricated hangar | m 2 | from 6,000 rub. |

| Prefabricated warehouse | m 2 | from 6,000 rub. |

| Manufacturing of metal structures | T | from 65,000 rub. |

| Hangars made of metal structures | m 2 | from 6,000 rub. |

| Prefabricated buildings made of metal structures | m 2 | from 9,500 rub. |

| Construction from metal structures | m 2 | from 6,000 rub. |

| Buildings made of metal structures | m 2 | from 9,500 rub. |

| Public building structures | kg | 65,000 - 75,000 rub. |

| Structures of industrial buildings (including crane tracks) | kg | 70,000 - 85,000 rub. |

| Agricultural building structures | kg | 62,000 - 75,000 rub. |

| Supports, platforms, stairs, grillages, auxiliary structures | kg | 85,000 - 115,000 rub. |

| Silos and bunkers | kg | 65,000 - 120,000 rub. |

| Tanks and pressure vessels | kg | 80,000 - 150,000 rub. |

| Embedded products | kg | 50,000 - 150,000 rub. |

| Steel trusses | T | from 20,000 rub. |

| Columns | T | from 20,000 rub. |

| Building frames and structures | T | from 42,000 rub. |

| Containers for liquids and bulk materials | T | from 63,000 rub. |

| Metal shelving | T | from 5,000 rub. |

| Walling | linear meter | from 1,500 rub. |

| Gate frames | linear meter | from 1,000 rub. |

| Pipeline supports | T | from 53,000 rub. |

| Frames for stairs | linear meter | from 1,000 rub. |

| Roller conveyors | units | from 13,000 rub. |

| Overpasses | units | from 6,500 rub. |

| Bunks for semi-trailers | units | from 18,500 rub. |

| Bicycle parking | units | from 1,500 rub. |

| Steel formwork for foundation | units | from 4500 rub. |

| Wheel chocks for parking lots | units | from 1,000 rub. |

| Canopies and canopies | units | from 30,000 rub. |

| Metal pallets | units | from 3,500 rub. |

| KMD development | ||

| Buildings and structures up to 30 tons | kg | 1,500 - 3,000 rub. |

| Buildings and structures 30-300 tons | kg | 1,000 - 1,200 rub. |

| Buildings and structures from 300 tons | kg | 800 - 1,000 rub. |

| Installation | ||

| Installation of metal structures | T | from 17,500 rub. |

| Manufacturing and installation of metal structures | T | from 65,000 rub. |

| Installation of fences and fences | linear m. | from 950 rub. |

| Installation of building cladding with corrugated sheets | m 2 | from 300 - 400 rub. |

| Installation of building cladding with sandwich panels | m 2 | from 400 - 900 rub. |

| Installation of shaped elements | linear m. | from 180 rub. |

| Gate installation | PC. | from 13,500 rub. |

| Construction of a reinforced concrete slab | m 3 | from 3,500 rub. |

| Construction of the floor slab | m 3 | from 3,700 rub. |

| Foundation work | m 3 | under contract |

| Cleaning of metal structures | ||

| Surface preparation degree St2 according to ISO 8501-1 | kg | 1,000 rub. |

| Surface preparation grade Sa2 according to ISO 8501-1 | kg | 2,500 - 4,000 rub. |

Stages of manufacturing metal structures

The technology for manufacturing metal structures at a plant from sheet, profile, long or shaped steel includes:

- Element design. The future product must be made taking into account the type of its mechanical loads, the scope and features of operation, and the specifics of connecting parts in the finished structure. At the same stage, the material for manufacturing the element is determined.

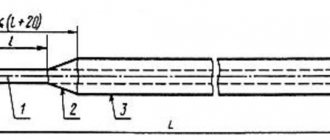

- Blank . At this stage, the weight of the future part is determined and quality is checked. If necessary, it is given the desired configuration using chopping, cutting (mechanical or thermal) or other methods and tools.

- Processing future parts . The technology for manufacturing metal structures from profiled metal products involves giving the workpiece a designed shape by bending, grinding, drilling, joining sheets into cards and processing joint seams, etc.

- Assembly of the structure . The elements are fastened in accordance with the drawings by welding or by mechanized assembly. We will look at this stage in more detail later in this article.

- Coating metal structures with anti-corrosion agents.

- Finished structures are labeled, packaged and quality checked.

- Products that have passed the previous stages are delivered to the site . They are installed here.

Project development

All work on the creation of metal structures begins with a technical specification, which the customer transfers to the contractor.

- The terms of reference must include:

- dimensions of the building for which the frame will be made;

- building layout;

- characteristics of the soil on which the building will be located.

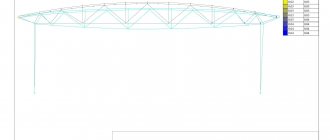

It is also necessary to calculate the impact of wind and precipitation on the future structure. Based on this data, designers create a structure layout diagram, identifying the parts that will experience maximum loads. Then a specification of the metal is carried out, which indicates the requirements for its grade, properties, manufacturing technology and other parameters that will allow the structure to perform its functions. Having summarized all the data, taking into account the requirements of norms and regulations, engineers make drawings of future structures.

Assembly as an important part of metal structures manufacturing technology

As noted above, the technology for manufacturing metal structures includes several stages. Assembly is by no means the least important. It can be produced by welding, gluing and using bolts or rivets.

Let's take a closer look at each of the methods.

- Welding is performed by actively heating the material until the edges of the elements begin to melt along the joint line (welding edge). When using an electric arc welding machine, the electrode melts - it is this that ensures the adhesion of the parts. In addition to electric arc welding, gas welding (using inert gases) or spot welding can be used (when the parts to be joined are pressed as tightly as possible to each other, and an electric pulse is passed through the joint line).

- Gluing is performed using special adhesive compositions that allow parts to be soldered together at the molecular level. Today, this technology for manufacturing metal structures is considered one of the most reliable.

- Assembly using bolts and rivets refers to mechanical methods of connecting structural parts. Rivets are most often used in cases where the object is expected to be subject to vibration during operation. Nuts and bolts are not suitable in this case, since their fastenings may become loose under the dynamic movement of the structure.

The most important condition for the manufacture and release of metal structures (regardless of their type and method of operation) is quality control at each stage of processing.

Technologies for combating corrosion in the manufacture of metal structures

Methods for preventing and eliminating corrosion belong to a separate category of technologies for the manufacture of metal structures, since this step cannot be skipped during operation, repair and maintenance of the facility.

The following methods of combating oxidation and deterioration of metal are distinguished:

- Avoiding contact of metal elements with water. This method is applicable only in cases where there is no restriction on the functionality of the object. The decision to use it must be made on a case-by-case basis.

- Adding to the alloy from which the metal structure is made, chemical elements that are primarily affected by water. Such elements are more resistant to corrosion than metal, which gives the structure as a whole a significant margin of safety.

- Application of water-repellent agents (paint, varnish, epoxy compounds, etc.) to the structure. The presence of a hydrophilic layer prevents direct contact of the metal with water, which protects parts from corrosion. As a rule, such products are applied to already assembled objects.

- Bimetal. This technology for the manufacture of metal structures involves the use of an alloy of two metals as a material, one of which is more vulnerable to corrosion, and the other less (for example, steel and chromium/aluminium/zinc). This measure of protecting the structure from oxidation is applied even at the procurement stage, but the output is a durable part with improved characteristics.

The use of anti-corrosion measures significantly increases the service life of the facility, and timely maintenance of metal structures extends it doubly.

When is welding required?

Welding work allows you to quickly restore parts while maintaining their strength. Many manipulations can be carried out without disassembling and unscrewing threaded connections, which can become sour over time. Using welding, you can quickly restore a part and do not have to wait for a spare part from the store. This is very convenient, because the equipment does not stand idle and quickly returns to work.

Welding work is carried out in the following cases:

- presence of traces of deep corrosion on parts;

- cracks in metal structures, signs of deformation;

- Additional upgrades are being carried out, for example, fasteners for a winch or attachments;

- scheduled repairs are required to eliminate defects in the body or metal structures.

It is better to entrust welding work to professionals - the master will perform high-quality welding without oxide and slag, which allows you to achieve high strength and rigidity of the structure. For additional protection against corrosion, the metal is treated with polymer paint.

Quality control of metal structures manufacturing

Any plant manufacturing metal structures can establish its own rules and enshrine them in internal orders or acts. However, product quality control occurs on the basis of certain regulatory and technical documentation.

VT-metall offers services:

The check involves several stages:

1. Incoming control.

The main and auxiliary materials arriving at the warehouse are assessed for subsequent use in the manufacture of metal structures. Checked:

- accompanying documents;

- appearance of materials;

- metal quality using ultrasound;

- grades, classes and grades of steel, compliance with their geometric characteristics;

- consumables and gases for welding;

- types and brands of corrosion control agents;

- classes of bolts, nuts, etc. materials.

After completion of the examination, its results are entered into a special journal for recording.

Features of installation of metal structures

Metal structures are widely used in construction: in the construction of high-rise buildings, one-story houses with a large area, workshops and other industrial buildings, tanks, technical buildings, etc.

The technology of manufacturing metal structures - in particular their installation - involves a complex set of works on installing parts and equipment and connecting them into a single structure. The object can be presented both in the form of individual parts and in the format of a full-fledged structure.

Since metal structures have the ability to deform, special measures are taken to protect the elements from damage. This is especially important when storing parts, transporting and installing them.

Preparation

A tremendous amount of work will have to be done before installation. It is necessary to provide power supply to the assembly site, bring a crane, install mobile warehouses, rails and much more. If work will take place at a height of more than 5 meters, then railings, cradles and temporary platforms will be installed at the top.

All this is necessary for the safety of workers and those people who will be in the construction area or nearby. After the preparatory work, installation will be carried out faster and without downtime.

At the next stage, it is necessary to carry out slinging, that is, lift the metal structures and install them in the correct position according to the project. Such work is performed by a person who is a slinger by profession. This is quite a traumatic job that can lead to severe injuries and death if it is performed by a non-professional.

In parallel, ground training is carried out. Installation of metal structures begins only after acceptance of the foundation. The accuracy of the construction of the building and its evenness depend on how correctly it is laid.

The surface may have some errors. They are called permissible deviations. But in any case, calculations and measurements are carried out using geodetic equipment. The obtained data must comply with SNiP.