Interesting ideas, implemented by the skillful hands of summer residents, transform outdated items into extraordinary creations needed in the household. Products made from old car wheels have become notable for making at home. They are used to make stoves, smokehouses, animal feeders and many other necessary things for the garden and home. But the most popular among owners are the oven and grill for barbecue.

Types of barbecue designs made from disks

Based on the principle of operation, a grill made from a truck disk is similar to a homemade one made from a cylinder or barrel. It is used in the following variations:

- grill on skewers or grill;

- barbecue with a lid to preserve the juiciness of the meat;

- hob for a pot, frying pan, cauldron or kettle;

- hot smokehouse.

The simplest design is a barbecue. It can be made from one car wheel without additional work. The shape of the wheel itself is a ready-made container. They simply put logs or coals in it and light a fire.

If you use two car wheels and carry out welding work, the product already performs several functions. Complex oven models maintain heat perfectly. Even heating ensures uniform cooking.

For smoking, the grill is equipped with a smoke exhaust. The oven is covered with a lid, which allows the wood to smolder, releasing smoke, thereby smoking the food.

Products made from 2-3 car wheels do not need legs. In this case, the height of the structure is already ideal.

A short excursion into history

This word comes from the Azerbaijani or Turkish manqal - brazier. There are similar words in Arabic, Persian, Georgian, and Armenian. It was a bowl made of copper with wide horizontal brims. For ease of carrying, it was equipped with two handles and was covered with a lid in the shape of a hemisphere. For stability, supports were placed from below. Somewhat later, skewers from the Syrian peak appeared, and the self-name shashlik came from the Tatar shishlyk - fried on a spit. Now it has firmly taken its place in the national cuisine of many peoples of the world.

What kind of discs can be used to make a barbecue?

Finding unnecessary wheels will not be a problem. A grill made from a KamAZ disk is considered the most durable. The thickness of the metal from which it is made will allow the product to be used for up to 40 years.

Motorists consider the wheels from a minibus to be the most acceptable and affordable. A product made from this material will last up to 20 years.

Comment! Experts believe that the thickness of the steel of a car wheel does not so much affect the service life of the barbecue as it depends on the type of fuel. When using coal, steel burns faster.

Many summer residents with skillful hands began to use the idea of using car wheels for barbecues. Some craftsmen make not only useful and multifunctional, but also very decorative things.

What about in a city apartment?

If you want to treat yourself to a barbecue at home. There is no need to cook it on the balcony like the hero of one famous film. Just make a sealed box with an infrared heater from an electric oven grill. Place the handles of the skewers outside and make sure that the food does not burn; turn it over in a timely manner. The most delicious kebab is guaranteed without leaving the kitchen.

These are not all ideas about devices for preparing shish kebabs and barbecues. Based on this article and examples from the Internet, you can always come up with something more original.

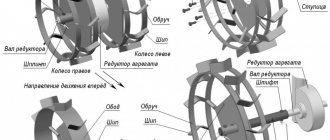

Drawings of barbecues made from disks

Before making a barbecue stove from car wheels, a diagram of the future design is drawn onto paper. Before this, information about the functionality of the product is collected:

- comfortable height;

- the need for a hob for a cauldron, kettle or pot;

- the need for a chimney;

- presence of a cover.

In reality, craftsmen do without a diagram, simply study the variety of finished products or come up with their own version. Some designs are very simple, the wheel is disassembled, cleaned of dirt and rust, covered with heat-resistant paint and installed on legs. If necessary, they make a mobile grill from car wheels, this allows you to install a stove to a convenient place

Combined design

From the pros: do-it-yourself grill from a gas cylinder

There is another version of the furnace, in which, in addition to car rims, a steel pipe with a diameter equal to the diameter of the rims is used. It is this that is installed between two disks, and holes are made in it for the firebox and door installation. The design is obtained with a high firebox.

It should be noted that this option is no different from the ones described above in terms of design features. This stove simply makes it possible to expand the combustion zone, increasing the power of the unit itself. Like previous models, such stoves can be horizontal or vertical.

The only thing you need to pay attention to is two points:

- The thickness of the pipe walls should not be less than 6 mm.

- Welding of discs and pipes is carried out according to the rules described above.

Manufacturing methods

It’s not difficult to make a barbecue with your own hands from car rims. Before performing work, the discs are cleaned of dirt and rust with a grinder. The parts of the product are attached using a welding machine.

No welding

The simplest design of a homemade barbecue made from a car wheel does not require welding. The workpiece is cleaned, painted with heat-resistant paint and a tripod is installed using metal screws. If there are too many holes in the bottom of a car wheel, find a suitable piece of metal and make patches from it. The patches are also secured with self-tapping screws or welded.

With welding

You can make a barbecue from stamped car wheel rims using a welding machine. The hole in the bottom is closed with a piece of metal of suitable size, secured by welding.

At the top part, the bottom is sawed off and the two parts are connected to each other using a welding machine. If necessary, additional holes are drilled with an electric drill. Structures can supply:

- door and latch;

- legs;

- lid;

- grate;

- chimney;

- firebox (grid).

Potbelly stove for a bath

This stove is suitable for use in small spaces, for example, in a bathhouse or garage. To make it, you need wheels from a KrAZ-255B type truck. You can use wheels from UAZ or GAZelle.

A stove made from car disks perfectly performs the function of a sauna stove and will be portable. To make it you will need:

- a metal sheet;

- disks;

- pipes with a diameter from 100 to 150 mm;

- a short pipe with a diameter of 76 mm.

The hardest part is removing the inside.

The metal of the disk is quite thick, so it is better to use a gas cutter. You can do this with an angle grinder, but the work will take longer. The discs are hermetically joined and welded together with a strong seam. The rear part of the resulting housing is covered with sheet metal, and the chimney pipe is welded to it. A damper is installed inside the pipe to regulate draft.

If the stove has air supply regulation, then a damper in the chimney is not necessary. Simply insert a pipe with a damper into the door. The damper axis is spring-loaded.

A plate is placed inside the firebox, which will divide the space into two parts. The secondary chamber with a welded chimney pipe will be located on top.

Such a furnace can be of any diameter and length . Orientation in space - vertical or horizontal. The Buleryan design is taken as a basis.

What tools and materials will be needed

To build a barbecue from machine disks, you need to prepare tools and materials:

- rims from car wheels;

- welding machine or drill (if the structure is not supposed to be welded);

- welding electrodes:

- protective clothing, mask and gloves;

- pieces of metal for patches on the bottom (if the holes are too large);

- Bulgarian;

- metal profile with a cross section of 2-3 cm for legs, length 1.5-2.4 m (the length depends on the number of legs and the height of the structure).

Additionally you will need a hammer, screwdriver, drill, screws, level, file, pliers

Potbelly stove for the garage: a thorough approach

In the example under consideration, the firebox consists of 3 old disks, plus one for the ash pan and another one for smoke removal, which increases heat transfer.

Stages of work:

- We weld the disks together, having previously cut off the core in the first three, except for the top one;

- We weld 4 legs from metal corners;

- we cut a hole and make a door to size from pieces of metal;

- to seal the firebox, we insert an asbestos thread along the contour;

- cover the top of the 4th disk with metal;

- add a 5th disk at the bottom and make a hole in it to collect ash and a blower, completely cover the bottom with a metal sheet;

- make a hole on the side of the 4th disk and weld a pipe to remove smoke;

- After polishing, it can be painted with heat-resistant paint.

In the example, the pipe has an angle of 90º, which, according to experts, will cause frequent clogging with soot. It is more practical to make an angle of 45 or 27º.

How to make a barbecue from car rims with your own hands

A simple design option is made from one piece. More functional barbecue models are made from two disks. Work order:

- A disc is removed from a car wheel. Using a grinder or a metal brush, it is cleaned and painted with heat-resistant paint. Cut off the excess inner part, leaving only a pot-shaped container. The central hole is sealed with a metal patch, welded in several places

- Legs with a height of 40-60 cm are attached to the bottom. The optimal height of the legs, according to experts, is 40-45 cm, which results in the most stable structure

How to make a barbecue grill from a wheel disk with your own hands

The simplest design of a barbecue made from car wheels on three legs. The product will require:

- disk;

- three legs made of metal profile 40-60 cm long;

- metal sheet 20*20 cm for patching;

- Bulgarian;

- welding machine;

- electrodes.

To protect hands, workers wear gloves. The face is covered with a welding mask. The procedure for making a barbecue grill:

- The disc is removed from the car wheel. Clean the surface from dirt and rust. The container is painted with heat-resistant paint for metal

- Turn the bottom upside down. A patch is made from a metal sheet in the central hole.

Attention! When carrying out welding work, be sure to wear a protective suit, helmet and gloves. Compliance with safety measures will prevent an accident from occurring.The patch is attached by welding in several places, its purpose is to prevent coal from falling out of the firebox

- The legs are evenly distributed over the surface and welded to the bottom. Three legs 40-60 cm long are made from a metal profile

The simplest design of the grill is ready. If desired, cover the top with a net.

Video instructions for making a barbecue from a car disk:

How to make a barbecue for a cauldron from disks with your own hands

A multifunctional grill is made from a KAMAZ wheel. If you cannot find such a part, use car wheels from a minibus or cars.

Attention! The wheel rim for a barbecue should be made of cast steel, not aluminum alloy.

To work, you will need two car wheels. The procedure for making a barbecue for a cauldron:

- Old car wheels need cleaning. The middle of one disk is cut out. Using a grinding machine, notches are made in several places and knocked out with a hammer.

- The two parts are welded to each other around the circumference. The partition of the second disk is the bottom of the oven. To ensure that the cauldron heats up properly, make a hole for storing firewood. The resulting piece of metal is used as a door. A bolt is attached to the part; it functions as a handle. The hinges are made from nuts that are welded to the container and the door on one side. Using a bolt, screw the door into the nuts. On the resulting container, mark a rectangle (door) in the central part of the structure with a marker and cut it out with a grinder

- The grill is turned upside down. A sheet of metal is applied to the central hole and its size is measured. Cut out the flap and weld it. This is done to prevent the coals from falling out. The legs are welded around the circumference to the bottom at equal distances. Three sections of 80 cm each are cut from the metal profile, but the length may be less

- Two nuts are welded on each side in the upper part. A metal rod 10 mm thick is inserted into the resulting holes. It is bent into a rectangle - these are handles. Before covering the product with heat-resistant metal paint, the grill is heated

How to make a barbecue grill from wheel rims with your own hands

It’s easy to make a barbecue grill from an old car wheel. To do this, follow the instructions:

- The rim of the disc is sawed off, leaving only the bowl. Bolts are attached to the legs so that they are screwed into a nut welded to the base. In order for the legs to be unscrewed, a nut is welded to the metal profile into which they are screwed

- The central hole on the bottom is covered with a metal patch. The patch is made from a sheet of metal; for example, burner plugs from an old gas stove fit perfectly

- The grill is turned over on its legs. To make it function as a grill, a steel grate is added on top. It is measured to size and laid on top of the grill. Using a grinder, cut off the metal mesh according to the markings and strengthen the sidewalls with a metal rod with a diameter of 7-10 mm

Product models

Step-by-step instructions on how to make a metal grill with your own hands

When making barbecues, simple and complex shapes are used. You can make it in the form of such models:

- Simple grill. Coal container - wheel. A fire is lit inside and skewers or a grill are placed on top.

- Double model. Consists of two wheels. Higher than the first option, you can place a cauldron on top.

- Closed oven. It is distinguished by the presence of a door that is tightly closed when smoking products.

- Universal model. Combines all possible functions. Additionally, a chimney can be installed.

The grill can be with or without legs. A simple grill needs a stand, but in double and triple designs, this function is assigned to the lower disk.

The procedure for making a simple grill:

- The old disk is prepared for work: traces of rust and paint, if any, are removed, and the surface is cleaned with a metal brush mounted on a drill or grinder. In general, they give an aesthetic appearance.

- The insides are cut out from one side to form a “cauldron”.

- Holes in the bottom that are too large, through which coals can spill out, are reduced by welding an additional disk made of sheet steel. They should not be closed completely so that air can circulate freely.

- Legs made of metal rods or profile pipes are welded on the sides. A convenient height is 40−45 cm. The structure must be stable.

- Sharp cuts are cleaned, and a grill is installed on top. Handles are welded for carrying.

Originally posted 2018-04-18 12:24:03.

Decorating the barbecue

To make the product last longer, it is painted with heat-resistant paint. Before painting, the grill is fired. Hardening increases its service life.

There are many options for decorating a barbecue. Using a jack, they make an unusual suspended structure with a lifting mechanism. If necessary, raise the bowl and fry the kebab; in the lowered position, set the cauldron for preparing pilaf or shurpa.

When painting, use protective glasses and gloves, spray paint from a can at a safe distance

A variety of barbecue designs made from machine discs is shown in the photo below. Execution depends on the master. They make movable barbecue structures, attach a spit and grates. They even manage to make a smokehouse and a roasting pan.

Place a cauldron or kettle on the cut middle of the disk; they heat up perfectly

The grill is decorated with forged elements. A spring shock absorber is used as a leg. This continues the theme of car parts.

A twisted metal rod is bent into openwork shapes and attached to the disk

Openwork sinuous legs can give the product an excellent appearance. Such a barbecue will attract the attention of guests on vacation.

The decorative barbecue can be used as an open hearth and admire the play of flames in the evenings

Mobile structures on wheels are quite popular. As soon as the craftsmen do not play with this idea. They install the wheels on a metal rod, build a wooden box for them, there are many options.

A section is prepared from a stainless steel rod with a cross section of 4-7 mm along the diameter of the barbecue and bent into a circle

It has become very fashionable to install a fireplace on the veranda or in a recreation area. The car disk is installed on a pre-prepared site and covered with brick or decorative stone. Fireclay bricks are laid on a flat surface, and a prepared and painted disc is installed on it.

A stone table and wooden benches are installed around the hearth.

The open hearth is made in the form of gabions. This modern exterior decoration is perfect for framing a barbecue.

A metal mesh is welded from a rod with a cross-section of 7-10 mm to hold massive cobblestones

Metal sheets

The traditional manufacturing option is to make a box in accordance with the drawing of the barbecue. The dimensions must be such as to accommodate the required number of skewers. To fix them along the length of the side, slots are made at the top.

There are holes at the bottom for ventilation. The height should be sufficient so that the food does not burn. To make cooking convenient, legs are made. For protection against corrosion and durability, it is advisable to paint it with black heat-resistant paint. It will not stand out against the background of soot.

Advantages and disadvantages of barbecues made from disks

Like any design, a gazelle disk grill has a number of advantages and disadvantages. Product advantages:

- availability of materials;

- the base of the car wheel is made of fire-resistant thick steel, which increases strength;

- the choice of car wheel sizes allows you to make a barbecue of any diameter;

- due to the properties of steel, the furnace has high thermal conductivity and heats up quickly;

- long service life from 20 to 40 years;

- the item is compact, easily fits in the trunk, and can be transported outdoors;

- multifunctional design;

- ease of manufacture.

Along with the advantages, the grill, like any other thing, has a number of disadvantages. These include:

- a low product leads to weak draft and increased smoke;

- very small firebox;

- You can only place 4 skewers, only for a small company.

When to combine with cooking

Instructions on how to make a grill oven:

- We select a suitable project taking into account your wishes;

- we make an additional compartment for the kitchen stove;

- we put a grate in the firebox, be sure to make a ash pan for better draft;

- cover the top with a cap with a chimney;

- We install a hob with burners; when cooking food, the mugs are removed; for better heating of the vessel, you can place a cauldron for pilaf.

Recommendations

Before making a barbecue from rims, they first carefully study ready-made designs, analyze, collect all the best and begin work. When performing work, be sure to follow safety rules. Wear goggles, gloves and protective clothing.

When using a grinder, the disc is directed at a right angle to the object. This rule will prevent it from breaking and scattering fragments.

A barbecue made from a car wheel must be equipped with legs to increase traction and allow smoke to escape better. 2-3-tier products can be installed on a substrate made of heat-resistant brick or stone. The disadvantage of this decision will be weather conditions. Rain or snow will slow down the heating process of the coals.