To work with wood, you need to use high-quality tools. This is especially true for procedures related to drilling material. When choosing a suitable tool, take into account the type of wood and the diameter of the required holes. It’s easy to buy a good wood drill; there is a wide range of them on the construction market.

Types of wood drills

Modern models of electric drills are sold with a set of additional elements. One of the most important components of the tool is wood drills, which vary in shape and size. Sometimes the standard set is not enough to carry out complex types of work. In this case, you will have to purchase certain types of wood drills. The main parameter by which the products in question are classified are design features.

Feather drill for wood

The devices have two cutters on the sides. Their central part is shaped like a feather. Main features of the product:

- The presence of a sharp tip in the center of the pen.

- Perform sharpening with an inclination to the right side.

- Making a drill bit for wood in a certain ratio of the length and width of the cutting edge.

- The presence of a tail section shaped like a hexagon.

Sharpening of feather drills is carried out exactly according to the sample. The main thing is that its central part remains sharp. Drilling wood using feather drills should be carried out at high speed (200-500 rpm). The smaller the hole, the faster the tool must rotate. When using the drill in question, it is better to use tools with adjustable power levels.

Screw drill for wood

Another name for the device is shredder. The working section of a screw drill is shaped like a screw. Due to the unusual shape of the product, builders will not have to remove shavings from the wood. Advantages of a screw drill:

- Long working part. The maximum parameter is 600 mm, but in construction work a 450 mm screw-type wood drill is more often used.

- Possibility of making holes in thick and durable materials with high quality.

- The wide range of device diameters offered on the market is from 3 to 52 mm.

- There are two types of tips: conical and with special cutters.

It is recommended to install screw drills on electric drills. All work using them is carried out at low tool speeds. The smaller the diameter of the product, the shorter its working part should be. When working with screw drills, do not allow them to bend. Only in this case will it be possible to obtain even holes corresponding to the required dimensions.

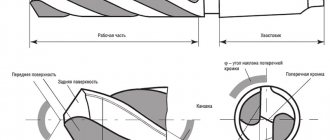

Twist drill bit for wood

The devices are most often used when performing home construction work. In appearance, they are similar to what a screw-type wood drill looks like. The work of the drill occurs from the influence of pressure and rotation. The main advantages of a spiral drill include:

- No significant mechanical forces on the drill from workers. To obtain an accurate and even hole, they will only need to accurately guide the drill and control the power of the tool.

- The presence of a point at the end, which prevents the drill from sliding off the surface being processed.

Twist drills are inserted into an electric drill or hammer drill and give it the necessary rotational force. This type of drill is capable of not only making holes in wooden products, but also expanding holes already existing in the material. Spiral drills are used in the construction industry to work with metal and concrete surfaces.

Forstner drill bit for wood

The product has a number of advantages, due to which it is used when carrying out high-precision work. The devices are most often used in the manufacture of furniture. A forstner drill bit for wood helps to make holes up to 10 cm long and with a diameter from 10 to 60 mm. They are equipped with extensions (up to 300 m) for making deeper holes in wood. The main advantages of a set of forstner drill bits for wood:

- possibility of purchasing drills as a set (5-6 pcs.);

- permissible fixation of the extension;

- the ability to create holes at low drill speeds.

Ballerina drill for wood

The design of the device resembles a compass. The sharp part of the drill is located in the middle, and the cutting part is located at the edges. The ballerina has the widest range of all kinds of holes compared to what wood drills come in. Using a drill, you can make holes in material with a diameter of 30 to 140 mm. When purchasing a ballerina, you must be especially careful, since drills of this type are often counterfeited.

Advantages of the tool:

- possibility of fast processing of sheet blanks;

- drilling of any types of wooden surfaces: chipboard, fiberboard;

- The presence of a punch in the set, with which it is convenient to make marks on the material.

Hole drill bit for wood

The products are also called crowns. The main advantage of the devices is the ability to make holes of large diameters that cannot be made using pen and spiral drills. A core drill bit for wood resembles a ring with teeth in appearance. The main disadvantage of the design is the inability to make deep holes.

Advantages of crowns:

- carrying out work not only with wood, but also with plastic and drywall;

- formation of an even cut with a smooth inner surface;

- absence of noise and dust when drilling.

Wood router bit

Using the device, not only round, but also shaped holes are made. Drills are used by workers for complex processing of wooden surfaces. Holes of round diameter can be expanded using a milling drill to the required sizes and shapes. The tail part of the drill has the shape of a cylinder. Less common are wood drills with triangular, square and hexagonal tips.

The device also has significant disadvantages. One of them is the need to use powerful drills with a built-in cooling system. The rotation speed of the tool should be 1500 rpm. Some types of cutters are designed to work at low speeds, so the presence of power adjustment functions in the tool will be mandatory.

Flexible wood drill

The devices are designed for processing hard-to-reach surfaces. There are often situations when it is impossible to reach the canvas in a straight line. In such cases, builders use one of the non-standard types of wood drills - a flexible drill. The term itself does not have a completely correct name. It is the shaft for transmitting torque that is flexible, not the drill itself.

Advantages of the device:

- ability to work in cramped conditions;

- drilling any type of wood;

- elimination of drill slippage due to the self-centering tip;

Disadvantages of a flexible drill:

- impossibility of drilling holes of large diameter;

- work only at low drill speeds;

- bending the shaft to a certain level.

Drill with countersink for wood

If builders need to hide the heads of self-tapping screws, they first use a thin and then a thick drill. The procedure can be completed in one step if you use a countersink drill bit for wood. It allows you to make holes of the desired size in order to mask the connecting elements. Products with countersinks are more often used in the furniture industry for screwing in confirmatory screws.

Design features of the drill option under consideration:

- fastening in the body of a drill with a diameter of 4 mm, which can be changed if necessary;

- the presence in the set of a hexagon with which the clamping screw is released;

- presence of a depth limiter.

Long wood drills

The design of drills of this type largely depends on the diameter indicators. It is impossible to purchase both a long and thin drill on the market. The smaller the diameter of the drill, the shorter it will be. This prevents possible damage to the device during work. It is necessary to correlate the dimensions of the drill and the capabilities of the tool used when drilling holes in the material.

The disadvantage of a wood drill is that the long product is heavy. Experienced builders use low-speed mixer tools when working with such structures. For conventional drills, miniature products are selected. Drilling holes with such a drill will require a lot of effort. Giant drills are used only in non-standard situations.

Rating of drill manufacturers

| Nomination | place | manufacturer | rating |

| Rating of drill manufacturers | 1 | Haisser | 4.9 |

| 2 | Bosch | 4.9 | |

| 3 | Metabo | 4.8 | |

| 4 | DeWALT | 4.8 | |

| 5 | AEG | 4.7 | |

| 6 | Makita | 4.7 | |

| 7 | DIAGER | 4.7 | |

| 8 | VIRA | 4.6 | |

| 9 | Ryobi | 4.6 | |

| 10 | Zubr | 4.5 | |

| 11 | SIBRTECH | 4.5 | |

| 12 | Ineterskol | 4.5 | |

| 13 | Tulamash | 4.4 | |

| 14 | Inforce | 4.4 | |

| 15 | Anchor | 4.3 |

Understanding how to choose a drill, let’s move on to the rating, which has collected the best manufacturers based on the characteristics of their products and reviews from craftsmen. Experts analyzed the range of products, types of steel used, service life and practical experience of users, which helped to distinguish the companies in that order.

Haisser

Rating: 4.9

We gave first place in the ranking to a German manufacturer, known for its products not only in Europe and the CIS, but also in the USA. The company has production facilities at home and in China, so the quality of products, unfortunately, varies. But German drills are distinguished by sharp sharpening and a long service life. In terms of price, they occupy the middle place, which is what most users like in the reviews. The products are produced in two series: “Medium TN” and “Long TM”. The first line presents models with lengths from 3.4 to 15 cm, and the second from 5.6 to 20.5 cm. Products are sold both individually and in whole sets. The priority direction of drilling is metal.

Our experts singled out this manufacturer as the best because it produces a lot of drills with a cross-shaped cutting edge. Thanks to this design, the equipment easily “bites” into the material even without punching and does not move during the initial rotation. Also, the working part of the tool is always thinner than the shank, therefore it is less susceptible to wear when the drill falls into the chuck and continues to rotate.

Advantages

- fracture resistance;

- precise sharpening - can be used immediately;

- cross-shaped point on many drills for self-centering;

- reinforced rod;

- full range of drills for ceramics, cast iron, plastics, alloy steel.

Flaws

- the cost is more expensive than analogues;

- range for hand tools only;

- Victory tips on drills round off quite quickly;

- It is difficult to buy products made in Germany.

How to distinguish drills for wood and metal?

The easiest way to determine the purpose of a drill is to consider the method of sharpening it. Drills designed for wood have a center point. It prevents the tool from sliding off the surface. The peak is presented in the form of a pin or an acute angle. In models for metal processing, there is no such element.

Drills for metal and wood, the differences between which are visible visually, also have different angles. For the latter material, this figure is 90°; when working with steel, drills with a large inclination are used. Universal products have an angle of 120°. Wood is less dense than metal. When working with it, cheap gray drills are used. For drilling metal, choose products of a golden or black hue.

Which drill is better

Equipment is a consumable material and is consumed in large quantities. Hundreds of domestic and foreign companies produce instruments. In construction stores you can find products from concerns with an impeccable reputation and nameless products that do not have quality certificates. It’s not difficult to figure out which drill to use to drill concrete and metal; it’s more difficult to make a choice in favor of a specific brand. The decision made determines how many tools are needed to complete the work.

Taking into account the specifics of the tasks performed, the VyborExperta.ru team recommends the following products:

- Matrix 72357 95 – for working with sheet metal in the home workshop;

- Practice 774-474 – for bolted connections when assembling metal structures;

- Fit 36429 – for working with confirmants;

- Stayer 2944 – universal “ballerina” for holes of different diameters;

- Metabo Forstner 627594000 – for blind holes in chipboard and wood;

- Enkor 9365 – will help installers when laying electrical wiring;

- Bosch Promoline 2.607.019.435 is the best set for metal work.

Using this tool will increase profitability, increase productivity, and reduce costs for consumables. This is the best equipment, the benefits of which will be appreciated by home craftsmen and professionals.

How to choose a wood drill?

There are many types of products on sale. They differ not only in appearance, but also in purpose. When choosing a suitable drill, pay attention to several nuances:

- Product material

. It is best if the drill is made of metal alloys. They are characterized by a long service life and wear resistance. - No marriage

. When purchasing a device, you need to pay attention to its appearance. There should be no cracks or irregularities on the surface. Such a drill will leave defective holes, especially when using a wood router bit. - Parts color

. High-quality structures are coated with a chemical oxide that has a bright yellow tint. This set of wood drills can be used to make holes in hard materials: ash, cedar.

Best Drill Sets

In home workshops and industrial plants, drills of different sizes and diameters are required. Manufacturers produce sets for such cases, equipped with equipment of different diameters with shanks of the same type. The tool is of stable quality, and convenient packaging makes storage simple and convenient.

Bosch Promoline 2.607.019.435

The German set of metal drills contains 19 pieces of tools, with a diameter from 1 to 10 mm. A step of 0.5 mm allows you to select equipment with high accuracy. All products are made of hard alloy steel, which has undergone additional heat treatment. The sharpening angle ensures high quality drilling; the tool copes well with carbon steel, aluminum and other metals.

The cylindrical shank allows use with chucks of electric drills and small drilling machines. The set is supplied in a convenient box with an informative stand, where each drill diameter is labeled.

Advantages:

- Ideal geometry;

- Durability;

- High strength;

- Low price for its category;

- Small box size.

Flaws:

- Not detected.

Hammer 202-921 DR set No21

The universal set includes products for working on concrete and metal. The equipment is made of tool high-speed steel. The tool can be used for processing heat-resistant, carbon, corrosion-resistant steels and alloys. The edge sharpening angle of 135 degrees allows you to drill quickly and efficiently. The diameter is selected to work with the main types of rivets. The short pitch makes selection easier.

The tool for working with concrete has high-quality grinding, which helps create smooth holes and quickly remove construction dust from the hole being formed. Supplied in a convenient case that does not take up much space.

Advantages:

- Low price;

- Reliable fixation in the grooves of the box;

- The equipment can withstand intense loads;

- Stable geometry.

Flaws:

- Sometimes there is displacement of the tips.

Wood drill sharpening

To carry out quality work, experience is required. Therefore, before sharpening a new wood drill, you need to hone your skills on previously used products. An important rule of the procedure is to preserve the original geometric parameters of the drill. Sharpening of drills for wood and other materials should be carried out at the same angle as at the manufacturer's factory.

The drill can be processed manually or using an electric sharpener. In the first case, a mild steel file is used. The procedure begins with tools that have a wide notch pitch. Finishing work on sharpening the drill is carried out using files with a needle file. Attention is paid not only to the cutting edge, but also to its reverse side. Sharpening a drill manually or mechanically is carried out only in good lighting.

Types of drills - main parameters

Type and shape of the working part

1. A screw drill, also called a twist drill, is most often used in everyday life. With this tool, the length of which can reach 27.5 centimeters, you can drill both wood and other materials. Twist drills are produced with a diameter from 0.1 millimeter to 8 centimeters.

2. A flat drill shaped like a feather, hence the second name - feather, used for drilling large and deep holes. Its cutting edge is made in the form of a blade. It can be made in one piece, together with the shank, or it can be attached using a boring bar or a special holder.

3. For deep drilling. If you have to drill a particularly deep hole, the depth of which exceeds 5 drill diameters, use a long drill with 2 screw channels. A special emulsion flows through these channels, cooling the tool during operation. The channels are made either inside the drill or inside tubes soldered to the back of it.

4. Single-sided cutting drill. When the hole being made must have particularly precise dimensions, take a drill designed for cutting with only one side. It has a reference plane, and both cutting edges are on the same side of the central axis of the tool.

5. The ring drill is hollow inside. Due to this design, it drills only a narrow ring in the material. These are the so-called crowns.

6. To make a center hole in the part, use a special drill called a center drill.

Shank design

There are several varieties of the tail section of this instrument. Let's list them. So, the shank is:

- Made in the form of a cylinder;

- made in the shape of a cone;

- faceted, having three, four or six sides;

- SDS type.

Drill making method

The drill can be made of a single piece of metal (with a diameter of no more than 8 millimeters) or an alloy (with a diameter of up to 6 millimeters). In this case, a special steel called “high-speed” is used. Her brands: P9K15, P18 or P9.

If the diameter of the drill is more than 8 millimeters, then it is made by welding. In this case, the part that cuts is made of high-speed steel, and the shank is made of carbon steel.

When it is necessary to drill weak and brittle materials, use a drill equipped with carbide plates. It has grooves that can be straight, beveled or helical.

What shape of hole needs to be machined?

Depending on the task being performed, the purpose of the drills differs. So, according to the shape of the hole, they are divided into the following types:

- Conical;

- square;

- stepped;

- cylindrical.

What are the drills covered with?

1. The cheapest coating is a black oxide film. It protects the tool from rust and also protects it from overheating. The service life of the drill naturally increases.

2. Titanium nitride ceramic coating is very durable. It extends the life of the instrument by no less than 3 times. A drill coated with TiN cannot be sharpened, otherwise all its advantages will come to naught.

3. Drills coated with TiAlN - titanium-aluminum nitride - are of even higher quality and reliability. Moreover, such a drill can operate reliably 5 times longer than an ordinary one.

4. Titanium carbonitride, otherwise TiCN, is considered to be a coating of approximately the same quality.

5. When working with high-hard material, for example, porcelain stoneware or stone, you must use the most durable drills - diamond-coated. They have no equal in strength.