If temperature control works great on nichrome, then you may be puzzled by the question of the price of this material. If you want to save money on delays, then the problem arises - where to get nichrome without buying it in a store. Let's try to figure out this problem and help beginners in this difficult matter.

So, let's look at what nichrome wire actually is:

- differs from kanthal in its lower resistivity;

- The box mod delivers high performance power;

- does not contain iron, therefore it does not corrode and lasts much longer;

- conducts heat well. Thus, the coil heats up faster and cools down faster.

Obviously, nichrome is sold in vape shops. 1 meter of such wire is very expensive. When this option does not suit you, you can find nichrome on radio markets. They still exist, but the likelihood that you will be able to find it there is very small.

However, this issue can be solved, you just need to know where to go. Also in this matter, a regular soldering iron or a faulty device that you can stumble upon in a closet or garage will help you out. If you were unable to find a soldering iron, then you can buy it at the Fix Price store, where everything is sold at the same price. The price of a soldering iron there will be only $1.

Expert opinion

It-Technology, Electrical power and electronics specialist

Ask questions to the “Specialist for modernization of energy generation systems”

How to identify nichrome wire at home? Even if the customer lives in a remote locality where the supplier’s organization is not located, you can request delivery, choosing the most convenient of the proposed options. Ask, I'm in touch!

Distinctive characteristics

Among the most popular electrical products on the market is nichrome wire.

The resistivity of this component of electric heating technology is extremely high, which allows it to have a wide demand. An important feature of the metal is its resistance to high-temperature oxidation under normal and aggressive conditions. Chrome plays a key role here

The element forms a corresponding oxide film on the surface, which performs a protective function. It is also responsible for the corresponding dark color of the material, which is replaced by a characteristic white-gray when the oxidized layer is mechanically removed.

It is worth noting that direct contact with acids still destroys it, even more than corrosion-resistant tungsten.

The two-component alloy has no magnetic characteristics. They arise for its multicomponent modifications, but have weakened indicators.

Nichrome wire is rigid and does not lend itself to simple force.

We systematize information on how to identify nichrome wire, mainly how to distinguish it from externally similar materials:

- White is the color of new metal, dark is the color of previously worked metal.

- Negative or minimal magnetism.

- Rigidity.

- Destruction by acids, resistance to oxidation under the influence of high temperatures.

How to determine nichrome?

Nichrome, as a slightly silver or white material, is not easy to recognize. In addition, it often has a dark gray tint associated with an oxide (oxidizing) film.

However, it is possible to determine the appearance of the material by the following characteristics:

- dark green film on the surface;

- turning the wire into a spiral after heating.

The last sign indicates the high resistance of nichrome to deformation.

ATTENTION . The mode of alternating long-term and short-term use of the thread will help maintain the quality characteristics of nichrome wire.

How to identify nichrome wire at home

Nichrome wire is a popular material that has already taken its place as a “traditional” one among many similar products. It is obtained thanks to an alloy of nickel and chromium.

If you are also looking for such an option, then simply enter nichrome wire to buy into your search query and then look through all the proposed products.

What is nichrome

It is worth noting that such an alloy contains a large concentration of chemical elements, which ensures strength and resistance to electrical influences.

Why is nichrome in demand in various fields? Here are some features of this material:

- sustainability. The product does not rust and has excellent corrosion resistance, which cannot be said about other types of metals;

- cannot be deformed. Nichrome wires retain their properties under any influence;

- elasticity. The material can be given various shapes.

Nichrome wires are used in various fields. The product is used for the manufacture of machines and devices for wood processing.

Wire has found wide application in the creation of ordinary household heaters.

There is a certain classification of nichrome products, which is necessary if they are used in various systems. For example, marking C indicates that the product is used for the manufacture of various elements characterized by resistance.

The letter H on the wire indicates that the material is used to create heating systems.

The article number of the heating element means that nichrome wire is used in the manufacture of electrical options. Most often these are heating systems.

How to distinguish

During purchase, it is quite difficult for some buyers to distinguish nichrome wire from other products. Most often the material is confused with tungsten.

To avoid such questions, you can use the following tips:

- corrosion resistance. Nichrome has less resistance, so when exposed to an acidic environment, the wire may change color;

- heating. When exposed to high temperatures, tungsten can be deformed;

- appearance. Nichrome wire differs significantly in color.

Also, “cold” processing methods are not used to create the product, which cannot be said about other metals. Most often, during manufacturing, it is rolled into coils, which is quite convenient to use.

An option for “mining” nichrome wire is in this video:

Nichrome from used products or purchased, but not in demand, ends up through non-ferrous metal collection points for recycling.

Nichrome in any form is purchased by both small outlets and reputable companies; the price also varies.

Let's consider what nichrome and its scrap are, how much they pay for 1 kg of this alloy and why.

Properties and applications of nichrome

An alloy of nickel and chromium in a ratio of 80 to 20, obtained in 1905, thanks to its technical properties, has found application in many devices and products. Despite the high cost of the resulting material, obvious benefits were observed due to the durability and trouble-free operation of the devices.

The percentage ratio of nickel-chromium was selected experimentally and solved the set goal: to achieve properties of the metal that were not provided by any of those used in technology at that time.

Advantageous characteristics of nichrome:

plasticity (an important property in the production of nichrome products); heat resistance; low expansion coefficient when exposed to high temperatures; does not create a significant electromagnetic field when using products in electrical appliances: high current resistance (the main parameter for use in electric heating devices); small specific gravity.

Currently, the alloy composition may vary. Supplements may be added from:

The main brands of nichrome are X20N80 and X15N60.

Products made from nickel-containing alloy:

- ribbon;

- rod;

- wire;

- certain types of fasteners;

- parts for operating devices under conditions of sudden and repeated temperature changes and (or) in an aggressive environment.

Heater production

Firstly, nichrome has become an advanced material in the manufacture of heating devices. Various types of tubular and spiral electric heaters are made using nichrome wire.

It is usually used as a core. This is very economical and practical; nichrome is not very expensive and is an extremely durable material.

Wire for heaters is made with an emphasis on nickel, since it determines the ductility of the overall mixture. The greater the proportion of nickel content, the higher this parameter of the wire.

Useful tips Connection diagrams Principles of operation of devices Main concepts Meters from Energomer Precautions Incandescent lamps Video instructions for the master Testing with a multimeter

Tungsten wire and its features

Basic properties of tungsten

Tungsten is a refractory metal that is used in the manufacture of heat-resistant alloys. It has a high density, its density reaches 19.3 g/cm3. Tungsten begins to melt at 3395°C and boils at 5500°C, while its evaporation rate is low. As for the electrical conductivity of this metal, it is approximately 1/3 of the value of the same parameter for copper. Tungsten is brittle at low temperatures and also has low oxidation resistance. This metal can be processed by pre-heating it. Externally, tungsten is similar to steel.

Tungsten wire production

The most popular long products made from tungsten are wire. It is produced in accordance with GOST 25501-82. Tungsten wire is a semi-finished product, the cross-section of which remains constant along its entire length. It is made by pressing or drawing.

Since tungsten has low technological plasticity, to increase this property it is heated, which in no way affects the strength of the material, which still remains high. Only after such procedures can wire be obtained by any method of processing under pressure. Supplied in coils or coils.

Powder metallurgy methods are often used to produce tungsten blanks, which makes it possible to improve some of the quality and properties of tungsten. A shtabik is a semi-finished product from which wire is made. It is first heated, and then a special rotary forging machine is used to carry out the forging. This is how tungsten rods are obtained, the diameter of which is 2-3 mm. Wire is obtained from them by drawing in a heated state. The diameter of the resulting long rolled metal is represented by a number of standard values up to 0.3 mm.

Scope of application of tungsten wire

The electrical and electronics industries are the main consumers of pure tungsten. The metal is indispensable in cases where low vapor pressure is required at operating temperatures up to 2500 °C. Tungsten wire is a material for heating elements of furnaces operating in a hydrogen, neutral or vacuum environment, heating up to 3000 °C. Thermocouples are made from this grade of metal. For their manufacture, tungsten-rhenium wire with a rhenium content of 5 and 20% (VR 5/20, VR5/20, VR5/VR20) is used.

More information about the use of tungsten wire grades VA, VM, VRN, VT-7, VT-10, VT-15 can be found by reading GOST 18903-73.

Examples of where you can get nichrome alloy

There are several ways to get nichrome. Each of them differs in the ease of obtaining and the quality of the material, but it is worth considering all possible options.

Ordering material

Nichrome, kanthal, nickel, and wire of some other alloys are sold in wholesale stores. The assortment provided by wholesalers is very large; you can order wire of any desired alloy of any cross-section and thickness. Relevant information about available stores can be found by calling the city's information service, or using an Internet search.

Even if the customer lives in a remote locality where the supplier’s organization is not located, you can request delivery, choosing the most convenient of the proposed options.

The caveat is that you will have to pay a considerable amount for delivery, and intermediaries send orders in large quantities and are unlikely to agree to supply a couple of meters of material.

Shopping in stores

Probably the most adequate option of all possible for those who require high-quality wire of a certain cross-section, especially when only a few meters of material are required.

Purchasing also has its options:

Sources of nichrome scrap

Modern heating equipment (household and industrial) contains products made of nichrome. High resistance resistors

, including

ballast ones

, are often made of this alloy.

A thrifty owner, before throwing away a device that cannot be repaired, will disassemble it and sort it by type of recyclable material. Then he will receive monetary compensation for his efforts.

A burnt-out radiator can be returned without disassembling it. In this case, it will be accepted at the price of regular scrap metal. But it also contains non-ferrous metals, albeit in small quantities.

In case of separate delivery

components,

the amount due will look much nicer

.

In addition to privately owned equipment that allows you to extract nichrome parts and wire, there are other sources.

The most attractive - warehouses with surplus goods

. It is not always possible to sell unclaimed items as products. The solution is to hand over it as non-ferrous metal.

When product certificates have been preserved and the batch is large (in weight terms), nichrome will be accepted on the most favorable terms.

Money from the delivery of recovered nichrome products will not be superfluous.

During reconstruction

or

re-profiling of production

you can hand over

:

- ovens;

- CNC machines (plastic molding);

- other electrical devices.

If you are involved in the collection and delivery of ferrous metal, then it will be useful for you to know. Don't know where to find non-ferrous metals? Read this. Not sure which metal detector model to choose? Check out our overview of popular models

Features of wire reception

metals, taking wire

, usually pay for it at a reduced rate. With nichrome wire the situation is the opposite.

This type of waste is often more expensive

, how:

- tape trimmings;

- canvases;

- monolithic parts.

Maximum

wire

in coils

. Even scraps of burnt out coils can be returned at a very reasonable cost.

Selling scrap as an additional source of income

In the house and garage, you won’t earn much from your own nichrome reserves. But everyone has neighbors who are ready to give away spoiled household appliances for a modest reward or even for nothing, subject to self-delivery or self-pickup.

All you have to do is:

- Equip a site for dismantling.

- Get the necessary tools

.

A few extra thousand rubles a month will not be superfluous.

Application

The quality always justifies the cost. The same applies to nichrome alloy. Wire and tapes made from this material are widely used in areas where any other metals could not replace them. High electrical resistance, oxidation resistance, high-quality mechanical characteristics, including for aggressive environments, high-temperature operating conditions - all this allows it to be used in various fields.

In industry:

- Thermocouples of metallurgical electric heating furnaces.

- Structural elements for induction metal smelting equipment.

- Industrial ventilation dryers.

- Parts of boilers and heat exchangers.

- Electrical production: resistors and rheostats.

- Some electrodes for welding.

- Single-core and multi-core electrical wires.

It is the main structural element for all modern household appliances:

- Heating elements in electric kettles, boilers, boilers, heaters.

- Heating elements in hair dryers, curling irons, irons.

- Automotive spark plugs and heating systems.

- E-Sigs.

Perhaps the price is the only drawback of the nichrome material. Two-component nickel-chrome wire will be more expensive. The iron content and the reduction in the amount of nickel, in turn, dictate a lower cost, but do not provide the same opportunities as X20N80. The choice depends on technical needs.

When choosing nichrome products, it is important to use information about the chemical composition of the brand of interest, its electrical conductivity and resistance, physical characteristics of diameter, cross-section, length

It is important to be interested in documentation of compliance, as well as to be able to visually distinguish the alloy from its “competitors”. Correctly selected material is the key to the reliability of equipment and technology for its use.

| 1. Approximate purpose of nichrome and fechral alloys. |

| 2. Chemical composition of nichrome and fechral alloys. |

| 3. Physical properties of nichrome and fechral alloys. |

| 4. Correction factors for calculating changes in electrical resistance depending on temperature. |

| 5. The difference between the electrical resistance of R20 and that regulated by the standard. |

| 6.1 Cross-sectional area, weight, length and electrical resistance of nichrome and fechral depending on the diameter of wire X20N80, X20N80-N, X23Yu5T, GS SY. |

| 6.2 Cross-sectional area, weight, length and electrical resistance of nichrome and fechral depending on the diameter of the wire X20N80, X15N60, XN70Yu. |

| 7. Sectional area, weight, length and electrical resistance of nichrome and fechral depending on the size of the tape and strip X20N80, X20N80-N, X23Yu5T, GS SY. |

| 8. Approximate service life of heating elements made of nichrome and fechral Kh20N80-N, Kh15N60-N, KhN70Yu-N, KhN20YUS, Kh23Yu5, Kh15Yu5. |

Calibrated precision chromium-nickel alloys (nichrome) have high electrical resistance and high operating temperature, are stable when working in an oxidizing environment, and, depending on the grade of nichrome, are also stable when working in a vacuum, in an atmosphere of nitrogen, ammonia, and hydrogen.

The range of application of cold-drawn nichrome wire and cold-rolled nichrome tape is very wide. The main area of application of nichrome alloys is the manufacture of heating elements for electric furnaces for various purposes, for industrial and household electric heating devices, for industrial and household water and air heating systems.

In addition, rolled nichrome is used: - for the manufacture of critical parts operating in a vacuum; — for the manufacture of resistors and connectors in electronic products; — for the manufacture of electrodes, meshes, conveyor belts and structures for glass-ceramic and other industries; - in many other industries where heat-generating and heat-resistant elements are required.

Prices

The company's assortment includes PARTAL, Russian nichrome, high quality.

The current price for nichrome, including VAT, in the form of wire, tape and thread is indicated on the page - Price of nichrome

To buy nichrome from us - place an order according to your needs on the page - Ask a Question

Don't look for where to buy nichrome. The PARTAL company provides not only detailed information about materials, but also a high-quality product available in the online store. Shipping throughout Russia.

Heat capacity, linear expansion, density and thermal conductivity of nichrome

The table presents the following physical properties of nichrome: specific heat at 25°C, average coefficient of thermal linear expansion in the temperature range from 20 to 1000°C and density of nichrome at 25°C.

It should be noted that the considered grades of nichrome have similar values of physical properties. The density of nichrome is in the range of 8200...8660 kg/m 3 and increases with increasing nickel content in the alloy. The coefficient of thermal linear expansion of nichrome at 20...1000°C has the value (17...18)·10 -6 deg -1. The specific heat capacity of nichrome, depending on the brand, is 440...460 J/(kg deg).

Specific heat capacity, linear expansion and density of nichrome

| Nichrome brand | C, J/(kg deg) | α·10 6 , deg -1 | ρ, kg/m 3 |

| Nichrome (10%Cr + 90%Ni) | 460 | 18 | 8660 |

| Х15Н60 | 460 | 17 | 8200 |

| Х20Н80-Н | 440 | 18 | 8400 |

| Nikrothal 80 | 460 | 17,2 | 8300 |

The thermal conductivity of nichrome is similar in value to the thermal conductivity of stainless steel. The table shows data on the thermal conductivity of the considered alloys at various temperatures in the range from 0 to 600°C.

The thermal conductivity of nichrome increases when heated. With increasing nickel content in the alloy, its thermal conductivity coefficient increases. For example, an alloy containing 10% Cr and 90% Ni has the highest thermal conductivity of the alloys considered, equal to 17.4 W/(m deg) at 20°C.

Characteristics of nichrome and its application

The alloy consists of 50−80% nickel and 15−24% chromium with a small amount of additives in the form of aluminum, manganese and chromium. Alloying with rare earth components is possible to increase service life.

Cr20Ni80 is the most common type of material, and wire made from this alloy is the most popular. In second place are stripe and ribbon, and the least popular is the leaf shape.

Depending on the grade of the alloy, it has the following physical characteristics:

- Melting point 1100 - 1400 °C, operating temperature 800−1100 °C.

- Specific resistance depending on the alloy = 1.05−1.4 Ohmxmm²/meter.

- Thermal conductivity coefficient = 11.3W/(mxK)

Nichrome has a number of advantages over wires made of other alloys:

Nichrome is used in most devices, such as:

As you can see, nichrome has good physical properties and is not subject to corrosion, which extends its service life compared to other types of similar materials used for the same purposes. The scope of its use in everyday life is also vast, so the question is often asked - where can you get nichrome thread. Most common options for obtaining nichrome will be listed below.

Which devices contain nichrome wire?

Nichrome wire is not such a hard-to-find material as it might seem at first glance. Some stores charge quite an impressive price for it. However, there is no need to spend money when you can get the material completely free or for pennies.

Nichrome wire is a component of all heating elements of household appliances. A regular electric kettle contains about one and a half meters of such wire; it can also be found in old models of irons, which contain about 2 meters of nichrome. If you have a non-working fan heater, you can also remove nichrome wire from it. It is quite easy to get it out of faulty toasters and hair dryers. Nichrome can be removed from the heating element in the washbasin. You need to carefully open the tenu with a grinder and clean the wire from the white insulation.

A minimum investment will be required if you purchase the cheapest soldering iron for 50 rubles. There is a wire with a cross-section of 0.1 mm and a length of about 2 meters. In this case, the wire with the plug and other parts are also a bonus, so we can assume that the nichrome wire was received practically for nothing. Among budget purchases, it is worth noting spirals for open-type tiles, which can be selected with different sections.

There is a fairly simple way to determine that nichrome is used in the device. You need to check the wire with a magnet. Kanthal, similar to nichrome, is magnetic, unlike nichrome.

Usually, at home, such wire is very convenient for cutting foam and polystyrene. To do this as quickly and efficiently as possible, you can build a simple cutter, the main part of which will be a hot nichrome string. To do this, you need to prepare a step-down transformer, a lining made of some pipe with a thickness of at least 2 cm, and the thickness of the foam plastic should also be at least 2 cm. You also need springs for tensioning the string and the nichrome wire itself. As a base, you can take a tabletop, board or sheet of corrugated board. For shaped cutting of foam plastic, you will need a cutter made of fairly thick wire, which will be attached to an insulated handle.

Modern technology places serious demands on the compliance of its constituent materials with real operating conditions. One of the high-tech alloys is nichrome. The wire and devices containing it are resistant to aggressive operating conditions.

Nichrome from a soldering iron

Disassemble the soldering iron and find the same nichrome wire. We actually found one, but it was very thin. You can find out the cross-section of the wire by winding 10 turns of thread tightly pressed together around a pencil. Our turns took 1 mm.

This means that the cross-section of our thread is 0.1 mm. You can buy a lot of such cheap soldering irons, but the nichrome spiral in them may differ in length. Disassembling a household soldering iron to obtain nichrome is a really working scheme. But what to do if you don’t have a soldering iron?

A similar spiral is found in hair dryers. Different models have nichrome threads of different diameters, but they are definitely there. Nichrome can be found in a heater built on the principle of a fan. This option will be slightly more expensive than the previous one.

And finally, the most difficult way is to get this metal out of an electric stove with an open spiral. Today we told you that nichrome winding is not such an expensive undertaking. If you decide to find a thread in a soldering iron, then it can reach 2.5 m. This will turn out to be far from 1 winding.

What kind of lighting do you prefer?

Built-in Chandelier

Brand nomenclature

Existing brands differ in composition and represent a range of nichrome alloys. Wire has a wide range of uses, which is determined by the individual properties of each.

- Group 1 – resistor material: X20N80, X20N73YUM-VI, N80HYUD-VI, X15N60.

- Group 2 – metal for heating elements for household and industrial use with increased heat resistance characteristics: Kh20N80-N-VI, Kh15N60-N, KhN70Yu-N, Kh20N80-N, KhN20YUS.

- Group 3 – for work at temperatures up to 900˚С: Н50К10, Х25Н20.

In this case, the diameter of the nichrome wire of the first group is 0.009-0.4 mm, and for the second - 0.2-7.5 mm.

“Relatives” are kanthals or fechrals - alloys of chromium, aluminum and iron. They are also characterized by high electrical resistance, heat resistance in the range of 1250-1400˚C, but less reliability, although low cost (X23Yu5, X13Yu4, X23Yu5T, X27Yu5T, X15Yu5).

Factors affecting the cost of scrap

Why does the price of nichrome vary significantly between different receivers? What does it depend on? Is it possible to get maximum benefit by studying the market and preparing your existing nichrome waste accordingly?

Included in the alloy is an expensive raw material. In its pure form it is present only in meteorites

.

Recycling nichrome is economically beneficial. The higher the nickel content in the sample, the higher the acceptance cost. For each percentage, on average, from 3 to 5 rubles

.

An increase or decrease in the price of nickel on the stock exchange responds, albeit not instantly, to the assessment of secondary nichrome.

Demand for raw materials in a specific region.

The more enterprises that consume nichrome scrap, the higher the purchase cost. In large industrial cities, the price per kilogram of alloy is higher (up to three times) than in the outback.

The type of nichrome being handed over also affects the cost.

Let us highlight the following types

nichrome scrap:

- wire;

- ribbon;

- rod;

- scrap of unknown origin at first glance.

At points where the assessment is carried out for each type separately, the maximum assessment is for new wire with a thickness of 3 mm or more

.

Let's move on to the numbers:

The table shows approximate scrap prices per 1 kilogram for the most expensive brand of nichrome. For brand Х15Н60

prices are 20% lower.

The price of nichrome scrap per 1 kg in small points is lower than the cost indicated in the table, by approximately 20-25%

.

Nichrome brands

Alloy grades are established by state standards GOST 10994-74, GOST 12766.1-90 and GOST 8803-89. The most popular alloy grades are: X20N80 and X15N60.

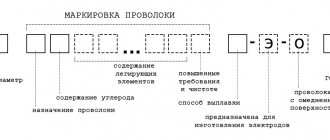

Explanation of nichrome alloy markings using the example of X20N80:

- X – Cr content;

- 20 – value in %;

- Н – Ni content;

- 80- in%.

The designation may contain additional letters, for example, for the X15N60-VI alloy, the letters “VI” indicate that the alloy was made using vacuum induction melting. For the X15N60-N alloy, the letter “N” indicates that it contains zirconium to increase the reliability and durability of the heater at maximum operating temperatures.

Other designations for alloy products:

- H - used for heating elements with a thickness greater than 0.2 mm;

- C - wire can be used as a resistance element in mechanical designs;

- Heating element - thread is used for dry type electric heaters.

Admission conditions and restrictions

When choosing a point for delivery of nichrome raw materials, you should pay attention to some information about the conditions for receiving a particular point.

The seller must pay attention

for the following points:

- The maximum declared value refers to an alloy in which the nickel content approaches 80%

, and scrap in its pure form (without dirt or chemical residues). - Is there a limit on the weight of the batch

(some have a minimum weight, for example, 500 kg). They will, of course, accept less, but the price will be reduced. - What method is used to check the nickel content in raw materials ().

Production

Nichrome wire is produced using pressure processing, namely, the technological operation of drawing. It is carried out without additional heating of the workpieces; accordingly, the product is cold-drawn.

Nichrome wire is supplied in a soft state, for which it is annealed. In some cases, the surface is etched. Mechanical processing, which includes turning, grinding and other operations, is not performed due to the small size of the workpieces. Product dimensions, mechanical properties, delivery condition, electrical resistance, as well as maximum operating temperatures are regulated by GOST 12766.1-90 and GOST 8803-89 standards.It is worth noting that a semi-finished product of round cross-section with small diameters is usually called nichrome thread. The standards do not contain such a semi-finished product in their descriptions, but among specialists this term is used quite often.

Purpose

The use of nichrome wire in various fields of activity is due to its advantages. In instrument making it is used as a unit of resistors, rheostats, and heaters. Cables and ropes are produced from large-diameter blanks.

Many household appliances (toaster, soldering iron, iron) contain nichrome. In medicine, nichrome threads are used in plastic surgery and intracavitary interventions.

- Diamond cutters for stone: options, features, how to choose

LLC GC "TransStroyKomplekt" is a reliable supplier of cast iron products in Russia

Features of diamond blades for wet cutting

The clever “Kulibins” manage to design wood cutters and burning devices from nichrome rods.

Peculiarities

First of all, it should be noted that the high popularity of the heating cable is due to its impressive efficiency. It converts almost all electrical energy into heat, allowing you to minimize losses and achieve optimal consumption of available resources.

If we single out situations for which underfloor heating is considered the best solution, then their list will look like this:

- use of cold coatings (optionally, ceramic tiles);

- high level of humidity in rooms (most often these are bathrooms);

- inability to connect to central heating (relevant for dressing rooms and hallways, as well as insulated loggias and balconies);

- the need to heat suburban real estate.

Another remarkable feature of floors equipped with a heating cable is the ability to install them under a variety of types of coverings. It’s enough just to get acquainted with the principle of operation and arrangement of such heating systems, as well as with their main varieties.

How to verify nichrome

You may have a thought while winding up your coil. What if the metal you got is not nichrome at all. How can you distinguish it from other metals? There is one simple and reliable way to determine. Take a magnet and use it to check your thread. For your information, kanthal will immediately be attracted to it, but nichrome will not care about the magnetic field. Good luck with your experiments.

How and where did you find your nichrome winding?

How to solder nichrome

You can solder a nichrome spiral in the following ways:

Heating of the winding in the form of thin copper wire.

Use of lapis (silver nitrogen).

The use of special solders and acid-containing fluxes.

The first method is the simplest and most accessible, but it is only suitable for connecting high-resistance conductors with a thickness of no more than 0.5 mm. It is best to take copper wire for winding with a thickness of 0.1 mm. Heating is done using a gas burner, but you can also use a regular turbo lighter. The copper wire heats up red hot and sticks to the nichrome, creating electrical contact at the atomic level. The soldering method using lapis is used to strengthen the contact of mechanical twisting if the operating temperature of the heating element in the device does not exceed 200 °C (silver nitrate fusion limit). The substance is applied to the twist when it is heated by electric current. The most reliable results are obtained by soldering using special solders and fluxes. The oxide film that forms on the surface of chromium-nickel spirals is the main obstacle to high-quality tinning. In industrial production conditions, to solve this problem, it is advisable to use vacuum chambers, or neutral gas environments. At home, acid-containing fluxes are used:

A mixture of petroleum jelly, glycerin and zinc chloride.

Factory-made fluxes, type F-38N PET.

The surfaces to be joined are cleaned of the oxide film, degreased and coated with fluxes using a soldering iron. After this, preliminary tinning and soldering are carried out using POS 40/50/61 solders.

Where to find nichrome wire

So, let's look at what nichrome wire actually is:

- differs from kanthal in its lower resistivity;

- The box mod delivers high performance power;

- does not contain iron, therefore it does not corrode and lasts much longer;

- conducts heat well. Thus, the coil heats up faster and cools down faster.

Read also: How to tin aluminum at home

Obviously, nichrome is sold in vape shops. 1 meter of such wire is very expensive. When this option does not suit you, you can find nichrome on radio markets. They still exist, but the likelihood that you will be able to find it there is very small.

However, this issue can be solved, you just need to know where to go. Also in this matter, a regular soldering iron or a faulty device that you can stumble upon in a closet or garage will help you out. If you were unable to find a soldering iron, then you can buy it at the Fix Price store, where everything is sold at the same price. The price of a soldering iron there will be only $1.

Advice from professionals

Experts consider the first switch-on to be one of the most significant moments on which the performance of the system being installed depends. Its algorithm is presented below:

- First day. The temperature controller is set to 20°C.

- Next 3 days. The temperature increases by 2°C every day.

- Fifth day. The heated floor is ready for full use.

If the installed equipment does not heat, then first of all the owner of the premises needs to check whether the cable is broken using a multimeter

When measuring resistance using this device, it is important to consider that it should not deviate by more than 5% from the values declared by the manufacturer. If there are serious discrepancies, there is only one solution left - to find damage or a break, “armed” with a device for searching for hidden wiring in the walls. Having found the problem area, you can begin to repair it (it is better not to solder, but to use a coupling that provides the most reliable connection)

Having found the problem area, you can begin to repair it (it is better not to solder, but to use a coupling that provides the most reliable connection).

Another common cause of underfloor heating malfunction is the temperature regulator, or more precisely, loosening of the contacts of its terminal block. To repair the device, just remove its front cover and carefully tighten the screw connections.

In conclusion, it remains to add that experts do not advise saving on the cost of purchased products. A cheap cable can quickly become unusable, which is explained by its low service life. Considering this circumstance, it is better to buy high-quality products from the top ones with the best reviews. Having made such a choice, there is no doubt that warmth and comfort in your home will be ensured, and for a very long time.

To see the difference between a heating cable and a heating mat, see the following video.

Scope of application in industry and at home

Nichrome products are used in places that require high-quality metal. Particularly in demand in industrial production.

In industrial production

Metal products occupy one of the first places in the market of industrial and household electrical equipment. It has found wide application in industrial sectors using electric heating furnaces, roasting and drying furnaces, furnaces heated to high temperatures, and devices with thermal effects. It is used in welding machines, household heaters and heating systems for car windows and rear-view mirrors, in resistors, resistance units and rheostats as a heating or resistor element. As noted above, the material is widely used among home craftsmen.

In the household

In the domestic sphere it is used for cutting foam and polystyrene. Cutting these materials at home is quite problematic. There are several ways. Often a knife is used for these purposes, from which the material begins to crumble.

Home craftsmen know how to cut polystyrene foam at home so that it does not crumble. For this you will need nichrome wire. It is needed in order to make a machine whose cutting tool is a heated string. With its help, you can cut foam plastic and make products from it with your own hands.

To cut polystyrene foam at home, you can design a simple machine with a vertical or horizontal arrangement of the cutting tool

How to make a foam cutter with your own hands

Making a machine is not difficult. To do this you will need:

- a step-down transformer;

- lining made of pipe (pipe at least 20 mm thick, foam thickness at least 2 cm);

- springs for string tension;

- metal string.

To make a tabletop you will need a table, a board and a sheet of corrugated sheeting.

The simplest version of a foam cutting machine that you can make yourself

You can make a step-down transformer yourself from transformer iron. You will need to make a rheostat to select the current value. To do this, you can take a spiral from an electric stove, first stretching it into a string. The winding frame is constructed from an asbestos-cement or ceramic pipe 15-20 mm thick and about 80 mm long.

For shaped cutting, a thermal cutter made from a piece of nichrome wire is used. It is secured to a handle made of insulating material. A homemade cutter for foam plastic copes well with the task, including shaped cutting of material. The device allows you to make indentations, cut out cavities, and work with foam plastic the way a sculptor works with clay.

A foam cutter can be compared to a sculptor's tool when working with clay.

With the help of homemade devices in which nichrome wire is used, you can not only cut foam plastic, but also burn wood. It can also be used in homemade household heaters, welding machines, and heating systems for car windows and rear-view mirrors.

What is nichrome

Nichrome is the general name for a number of alloys that contain 55-78% nickel, 15-23% chromium, as well as aluminum, titanium, molybdenum, and iron. The range includes wire, strip, hot-rolled steel. The latter is supplied in the form of individual rods or coils.

A description of nichrome wire would not be complete without mentioning the cross-sectional shape. It can be round, oval, square, multifaceted. The most common configuration is a circle.

Soldering Features

The features of nichrome soldering are as follows:

- Use of tin-lead materials POS 50 and POS 1 for solder.

- Careful preparation of flux.

- Proper processing of the working surface.

Before soldering, the working surface is cleaned with sandpaper and treated with cotton wool soaked in an alcohol solution of copper chloride. Next, apply flux and begin the process.

When tinning nichrome with copper leads, it is better to use 2-3 g of citric acid. This is enough to service one wire. To remove acid, the wire must be placed on rosin, dipped, and a soldering iron is used for further work.

ATTENTION TO THOSE WHO WANT TO REGISTER ON THE FORUM. Problem activating your account? Write to (ignel(gav)mail.ru, ICQ 50389649), indicating your nickname and the address from which you registered. Don’t forget to look at the forum rules

Ignorance of the rules does not exempt you from responsibility! Don't forget to look at the TB Section. Knowing the rules can save lives. Have questions about using the forum? Look for answers in the FAQ (FAQ). There is a lot of useful information there. Looking for interesting materials? Guide to master classes from our forum members

- Artisan »

- Our works »

- We make it ourselves (Moderator: AndyAB) »

- Topic: How to distinguish nichrome wire by eye?

Author Topic: How to distinguish nichrome wire by eye? (Read 31354 times)

0 Users and 1 Guest are viewing this topic.

Among precision alloys subject to large temperature changes, nichrome occupies a special place. Due to its high heat resistance, its use is more justified in the manufacture of heating devices and key components of furnace equipment. The working material in this case is nichrome wire of a certain grade. Each of them differs in the percentage of various alloying additives, which allows, based on design performance indicators, to make a choice in favor of one or another sample, depending on its main quality characteristics, the main of which is the resistance of the nichrome wire.