- home

- Differences between seamless pipe and electric welded pipe

Seamless pipe

- one-piece metal structure without types of joints. There are several ways to make such structures:

- forging;

- pressing;

- rolling;

- drawing.

The product has increased strength, which is why it is often used in complex structures exposed to different environments. Products without a welded seam are divided into 2 classes:

- hot rolled;

- cold rolled.

Both products are made from the same grades of steel. The difference is that cold rolling helps to achieve better metal surface quality, as well as accuracy in geometry parameters. Hot rolled steel has higher productivity and the price of the final product will be lower.

Due to the high reliability of seamless products, solid rolled metal can be used in complex areas and machine construction industries. In particular, hot-rolled pipes are used in industrial applications. This type of rental is used when the loads on the product greatly exceed the permissible level for the welded type.

Electric welded pipe

- a sample with one seam running along the entire length, made of rolled sheets or strips by molding or welding.

Rolled metal is divided into 4 types:

- straight-seam;

- spiral seam;

- water and gas pipeline;

- profile.

1. Straight seam type is made from metal strips welded at opposite ends, and formed by electric arc or high frequency welding.

2. Large diameter spiral weld type is produced by submerged arc welding.

3. In the production of water-gas electric-welded pipe samples, carbon steel is used as a raw material.

4. Profile products using the electric welding method are manufactured using various metals or alloys, as well as polymer materials.

The method of manufacturing electric-welded pipes is hot-rolled or cold-rolled.

This type has received a wide range of applications: construction, manufacturing of furniture, fences, cars, manufacturing of oil and gas pipelines, pipelines, and other economic/industrial areas.

Product standardization

The difference here is due to different types of GOSTs, where VGP pipes are regulated by state standard No. 3262-75, and the second option No. 10705-80 and No. 10704-91. It is thanks to these instructions that the purpose of the product can already be found in the documents regarding the product item.

Moreover, each such collection of requirements allows us to make the product better and give the owner a longer service life.

Comparison of straight-seam and spiral-seam pipes

Rolled pipe with a straight seam is cheaper because it is easier to manufacture. It is universal in use. It is used in heating systems, water supply, sewerage, as support structures, etc. Available in different types, differing in diameter and wall thickness. You can buy electric welded pipes inexpensively on our website.

Spiral welded pipes are more expensive, but they are also stronger. The products have large diameters, which allows them to be used for laying pipelines.

Dimensions and technical characteristics

The main similarity between the pipes here is one and it lies in the outer diameter. The remaining components of VGP and ESV pipes are completely different, down to the diameter of the passage hole.

The range of VGP products is very limited and mainly commercial units are presented with a thickness of 2 to 5.5 millimeters, and an outer diameter of up to 165 mm. At the same time, electric-welded pipes can provide up to 1420 millimeters in diameter - it is extremely important for them to withstand powerful pressure relative to themselves.

Scope of application of electric-welded pipes

The quality for which electric-welded pipe is especially valued is its exceptional versatility of use. This primarily concerns round products, which are successfully used by industrial enterprises and construction organizations, as well as in the installation of pipelines, furniture production and the creation of interiors for modern residential and commercial premises. In addition, electric welded pipe is often used as a consumable material for the production of various products.

How widespread pipes of this type are can be judged by the fact that they are found almost everywhere: fencing of buildings and territories, stair railings, awnings, canopies and public transport stops, street benches, etc. The high quality of steel pipes is evident. straight-seam electric welded, evidenced by the fact that they are successfully used for the installation of pipelines through which chemically aggressive liquids and media heated to high temperatures are transported.

Production, materials and assembly method

Although at first it seems that both types of equipment are made according to the same principle with the same materials, namely carbon steel, the varieties with the abbreviations SP, PS, KP, and so on are best suited for water and gas pipes. ES variations use hard steel grades that are resistant to even maximum mechanical stress.

The products are similar in manufacturing technology - VGP pipes are formed from sheet metal by welding, with the addition of a reinforced weld. A similar technique works with electric welded structures.

Straight or spiral?

Oddly enough, welded pipes are a rather “young” type of metal product. The first samples of welded (more precisely, forged) pipes appeared less than 200 years ago - in 1824. And only at the beginning of the 20th century did they begin to use the so-called. “furnace” welding, in which the hot edges of the pipe are held together by compressing them with rollers.

It was only with the advent of electric welding that seam pipes were divided into straight-seam and spiral-seam.

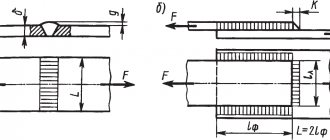

The name “straight seam” speaks for itself: this method of making pipes is due to the fact that a steel strip - strip - is heated until the metal becomes plastic and passed through two rows of rolls that roll the metal “into a tube” - so that all that remains is to connect its edges electric welding.

This is a fairly simple and cheap technology, but some problems arise when using it, namely:

— for the manufacture of pipes of different diameters, blank strips of different widths will be needed.

— the transition to the production of pipes of a different diameter will require re-equipping the entire production line with new parts (primarily rolls).

— when the workpiece cools, stresses will arise in the weld, which will significantly reduce its strength.

- if such a pipe still cannot withstand the pressure supplied through it, then its rupture will occur precisely along the seam and along the entire length of the pipe section, which will create additional problems when eliminating the accident.

Another option for producing welded pipes is to join steel strips using a spiral weld. With this technological option, the seam itself turns out to be much longer than with a straight-seam connection, but a number of advantages appear:

— when manufacturing a spiral-welded pipe, there is no need to use blank strips of clearly defined sizes; the pipe can be welded from metal strip of any width

— changing the diameter of the produced pipes can be done using a simple readjustment of the production line; It will be enough to simply change the feed angle of the tape.

— when welding a pipe from a metal strip, it is not necessary to strongly heat the entire metal strip; this reduces the possibility of changes in the properties of the metal during heating and cooling and reduces the possibility of internal stress in it.

— during spiral welding, the resulting seam itself becomes an element that gives additional strength to the structure

- if such a seam still does not hold up and diverges, then it diverges not “alongwise”, but “obliquely”, which reduces the size of the section of pipe that will have to be replaced.

Pros and cons of products

For a better understanding, let's present the pros and cons in the form of lists. So, the advantages of VGP structures are as follows:

- Protection from biological and chemical irritants;

- Increased strength;

- Ease.

The only disadvantage that can be noted is the increased conductivity of the metal to electricity.

ES pipes are inferior here in all respects:

- Susceptibility to corrosion.

- Reduced strength.

- Narrowly focused specialization - when such pipes are used in the wrong place, they quickly become unusable.

But even so, these products have increased resistance to mechanical stress and are chemically inert, and therefore, with the proper approach, they can serve the owner for many decades.

Manufacturing technology

The technological process by which electric-welded pipes are manufactured includes a number of operations. It is complex, labor-intensive, and therefore time-consuming. In order for the electric-welded pipe to acquire a finished look, it is rolled from a strip, that is, a strip of alloy steel. It is pre-manufactured using either hot or cold deformation.

To produce reliable, durable products of different diameters, in most cases radio frequency welding is used, which allows metal to be joined at a fairly high speed. With this welding method, high voltage currents are passed through the rolled workpiece, which contribute to the rapid heating of the edges. In order to form a reliable seam in place of the heated and already melted edges, they are pressed against each other under high pressure. To make a workpiece of the required diameter from a steel strip (strip), special crimping machines are used.

The technology used to produce straight- and spiral-welded electric-welded pipes allows not only to obtain reliable products, but also to ensure their attractive appearance. The weld seam is almost invisible on the products.

Conclusion

Welded pipelines are used in the development of various utility networks, complex innovative systems and the construction of buildings. When compared with all-metal similarities, they have low weight, lower cost and less significant discrepancies in thickness. Welded pipe can be designated according to a variety of parameters, but its zoning by direction is considered the most common. In accordance with this, structural, pipeline and main products are distinguished. The first of them are used for construction, the second - in the development of utility networks and innovative systems, the third - in gas and oil pipelines. In the production of welded rolled products, furnace welding technologies, electric welding are used, and shielding gas welding is also used. The first method is considered quite popular, because it is the least expensive and makes it possible to produce thin-walled products. The highest quality connection is guaranteed by welding in shielding gas

Moreover, it is considered the most expensive method. You can find out additional information on this topic by watching the video in this publication.

Methods for manufacturing welded pipes

Rolled pipe products with a seam are manufactured by cold or hot deformation. Hot-formed pipes have a thicker wall due to the nature of the process used. This gives them additional strength. The cost of such products is higher than that of cold-formed ones. Therefore, they are used in areas where increased strength is important: on main heat pipelines or in gas systems. Cold-formed pipes have a wider range of applications.

Before purchasing rolled metal pipes, it is important to determine the selection criteria and purpose of use. Thanks to new technological solutions, the scope of application of electric welded pipes is becoming much wider. Already, pipelines are being laid even in unfavorable places: swamps, permafrost, acidic soils.

Advantages of welded pipe material

Rolled pipes created by welding have important positive qualities. Let us explain them in detail:

- Cost-effective - the latest technologies make it possible to make the most reliable welded joints. Thanks to them, a pipe created by welding is in no way inferior to all-metal samples. This makes it possible to install it where previously only seamless products could be used. This leads to big savings because the cost of prefabricated products is much less than their cast substitutes;

- Low weight - welded structures, when compared with all-metal samples, have much thinner walls, which greatly reduces the weight of the product. As a result, the process of transporting and future installation of components becomes easier. After all, this will require less participation of equipment and people;

- Smaller deviations in thickness - this can be explained by the fact that welded products are created from steel based on a sheet, which is considered the same along its entire length. The clarity of the shapes makes the process of installing the welded product easier.

Which option to choose

The main difference between welded and seamless pipes is the maximum permissible pressure. According to state standard 10705, sutures can withstand up to 160 atm. GOST for seamless pipes contains a maximum value of 200 atm. At the same time, the standard for communications in a multi-story building is 16 atmospheres. In private houses - only 2-3 atm. This explains the main difference in the use of welded and seamless pipes. In most cases, there is simply no point in spending money on more expensive all-metal products.

Types of seam pipes and standards for them

There are three main types of these products:

- structural;

- pipeline;

- main pipes.

Their short characteristics are demonstrated as a table.

Type of pipe Characteristics Structural Made in accordance with the requirements of GOST No. 10704-91, and also GOST No. 10705-80, except for hydrotest indicators. In this case, they are not significant, because this type of product is not used for the transportation of liquids and gases. The welded welded pipe according to GOST 10704 91 is made from steel grades St2, St3 or St10, St20. Pipeline Unlike the previous type, for these products compliance with hydraulic pressure indicators is considered very important. After all, this product itself is used for the manufacture of pipelines through which various liquids and gases move. Thanks to this, it is calibrated at a pressure of 30 to 60 kgf/cm2. Depending on the required strength, these products are made from steel grades St2, St3, or St10, St20. Main pipes intended for main gas and oil pipelines are made in accordance with GOST 2095-85. They have a diameter of 159 millimeters or more. They must be subjected to hydraulic tests in accordance with GOST No. 3845-75. The steel grades used are St10, St20, and also 09G2S and 17G1S.

Advice! It is preferable to buy goods made from St10 and St20 steel, because these grades of material are considered the highest quality.

Where is this material applicable?

- Thanks to a reasonable price/quality combination, electric welded products surround us everywhere . They form the basis of all plumbing and gas systems existing at the moment. In addition, almost all household appliances, from a vacuum cleaner to a sports trainer or even a car, necessarily have electric-welded pipes in their design.

- A special place in production is occupied by metal electric-welded structures developed for construction needs . Along with traditional reinforced concrete, not a single serious modern construction project can do without square and rectangular profiled welded pipes. They often form the basis of the frame of any modern high-rise building.

- All modern pavilions and various kinds of exhibition halls are made from such structures . In urban markets, any trade tent or stall is based on lightweight welded frames. No modern greenhouse in the country is conceivable without a strong frame made of profiled welded metal structures.

- Each of us sat at a desk at school, at an office table or on chairs in a city cafe; currently, the frames of all such furniture are made from welded hollow lightweight structures.

Welded structures for furniture.