Kickback valve

Carrying out gas-flame work involves the risk of flame backlash. If the ignition has penetrated the burner (cutter), it moves through the gas channels at tremendous speed. That is, a backstroke is a situation in which the gas begins to burn in the direction opposite to its outflow and the rate of its combustion is higher than the speed of its outflow.

The consequences of such a negative development of events can be varied:

• equipment failure • rupture of hoses, reducers, cylinders with acetylene or propane • human casualties!

Causes of kickback

What leads to such a fatal situation:

• incorrect ignition – incorrect adjustment of oxygen and combustible gas, flame strength; • too much heating of the mouthpiece and the tube onto which it is screwed, which leads to self-ignition of the gas mixture even before it leaves the burner; • debris accumulates in the mouthpiece; if it clogs the hole at its end, the gas pressure at the outlet will increase; • closing the outlet of the mouthpiece by touching the part also interferes with the normal release of gas into the environment. • if the oxygen cylinder runs out or the injector is clogged, etc. – that is, everything that affects oxygen pressure, a sharp change in its value

External signs:

• a sharp bang, but the flame continues to burn (weak flame, incorrect setting); • cotton when combustion stops, smoke comes out of the mouthpiece.

For what reasons does it occur?

The specifics of the occurrence of a reverse shock have been studied quite well. During laboratory studies, experts identified the main causes of the dangerous phenomenon:

- improper adjustment of oxygen and gas supply; • severe overheating of the burner; • incorrect selection of proportions of the combustible mixture; • contamination of the working mouthpiece; • low pressure inside the oxygen cylinder; • contamination of the injection system; • overcooling of the gear unit; • mechanical shutdown of the flame on the mouthpiece.

Among the main reasons is a sharp increase in oxygen supply, when the pressure significantly exceeds the throughput characteristics of the burner itself. Also, a similar effect can occur due to low pressure inside the cylinder or due to a gas leak.

To avoid consequences, you must consider the following recommendations:

- check connections using soap solution; • follow the rules for working with the burner; • move cylinders on a trolley; • avoid impacts of cylinders; • protect cylinders from sparks and fire; • ensure high-quality ventilation; • separate cylinders; • prevent oil or grease from entering the cylinder valve; • do not work with metal without a mixture of oxygen impurities; • store spare cylinders separately.

Additionally, the regulations for inspecting cylinders must be observed.

Kickback protection - valve

Installing a kickback valve will save your life and protect your equipment from damage and destruction.

It works as follows: the flow of flame penetrating the burner (cutter) or sleeves is immediately extinguished by a fire extinguisher. The counterflow of propane, acetylene or oxygen is stopped by a shut-off spring. The process is blocked by a cermet insert sintered from powder.

There are two types of them:

• for oxygen • and for flammable gas.

They always come in pairs. They are installed on a gearbox or burner (cutter) and withstand at least one hundred reverse flame impulses coming one after another.

Add a comment Cancel reply

You must be logged in to post a comment.

Is it worth BUYING, reviews from welders:

- Welding transformer PATRIOT 200AC 102.00 RUR

- Charger GreenWorks G24C RUB 2,490.00

- Voltage stabilizer PRORAB DVR 1000 2597.22 RUR

- Stabilizer Resanta ASN-2000 N/1-C Lux 3610.00 ₽

- Voltage stabilizer Stavr SN-2000 3920.00 RUR

- Welding machine BauMaster AW-79161 3990.00 RUR

- Hitachi AB17 charger RUB 4,076.87

Hello! The situation when a cutting torch fires is called backfire or countercurrent, and in most cases its occurrence depends on the experience and qualifications of the welder. A propane cutter slams when the gas combustion area moves inside the burner and hoses for various reasons. That is, the rate of combustion of gases turns out to be greater than the rate of their outflow from the cylinders.

Most likely, the propane cutter is firing for one of the following reasons:

- The pressure of propane and oxygen during ignition is incorrectly adjusted.

- The nozzle or torch barrel is overheated. This leads to premature self-ignition of the mixture still inside.

- The flow area of the cutter nozzle has decreased due to mechanical contamination.

- The torch nozzle has touched the workpiece or the cut surface.

- The mixing chamber injector is incorrectly adjusted.

- The oxygen has run out or for some reason its pressure has sharply decreased. For example, the mixing chamber injector is clogged.

A kickback is dangerous due to possible destruction of the cutter, gearboxes, joints, rupture of hoses and explosion. This is a very dangerous situation and must be avoided by all means possible.

If a backflow occurs, you should quickly close the flammable gas valve, then the oxygen valve, and cool the cutter. After cooling, you need to clean the injector, mixing chamber and mouthpieces, tighten everything and check the cutter for leaks.

To avoid kickback, we recommend using DONMET 142 or Donmet 300 cutters. Due to the patented design of the mixing unit, they are highly safe when cutting and resistant to kickback. If you already have a cutter from another manufacturer, we recommend using Donmet check valves OBK and OBG or fire-preventing valves KOK and KOG. They are installed directly on the torch separately for oxygen and fuel gas.

Read also: Convector circuit on a PWM controller

If you still cannot eliminate these pops, contact our consultants by phone +7.

Gas cutting seems to be a simpler process than gas welding work, and therefore even a person who does not have special skills can cope with it. For this reason, almost any of us can master working with a cutting torch. The main thing here is to understand the essence of gas cutting technology. In modern conditions, propane cutters are increasingly used. Working with them requires the use of both propane and oxygen, since the combination of such substances provides the maximum combustion temperature.

Fire protection valves: purpose, design and installation options

Any work with flammable gas (oxygen, acetylene, propane) carries the risk of a backfire. To protect equipment from damage and people from physical injury, fire-stop valves , which simultaneously serve as a flame-extinguishing element and a check valve.

Advantages and disadvantages

Cutting metal with propane has a number of advantages , among which are the following:

- Gas cutting is in demand in situations where there is a need to cut metal of considerable thickness or create products according to templates that require the production of a curved cut that cannot be made with a grinder. You also cannot do without a gas cutter even when faced with the task of cutting out a disk from thick metal or making a blind hole of 20-50 mm.

- A gas cutter is a very easy-to-use tool and is lightweight. All home craftsmen who have experience working with gasoline models are aware of the inconveniences associated with large weight, size and noise. In addition to the fact that vibration creates significant inconvenience, the operator is forced to provide serious pressure during operation. Gas models seem to be a more attractive alternative due to the absence of all the above-mentioned disadvantages.

- Using metal cutting with gas allows you to speed up the work by 2 times, which cannot be done using a device equipped with a gasoline engine.

- Among most gases, including gasoline, propane has a lower price. For this reason, it is better suited for carrying out a significant amount of work, for example, if there is a task of cutting steel into scrap metal.

- When using propane cutting, it is possible to create a narrower cut edge than when working with acetylene cutters. At the same time, the method under consideration allows you to create a cleaner cut than what can be done using gasoline torches or a grinder.

Among the disadvantages that propane cutters have, only one should be highlighted: they can be used only for a limited range of types of metals . They are suitable for cutting exclusively low and medium carbon steels, as well as ductile cast iron.

Features of use

Such tools are not suitable for cutting high-carbon steels for the reason that they have a fairly high melting point, which is almost the same as the flame temperature. This leads to the fact that instead of the release of scale, which looks like a column of sparks, from the back side of the sheet, it mixes with the molten metal along the edges of the cut. As a result, oxygen cannot reach the thickness of the metal, which is why it fails to burn through the material.

Difficulties when cutting cast iron are created by the shape of the grains , as well as the graphite between them. True, this does not apply to malleable cast iron. It is impossible to solve the problem if you have to deal with aluminum, copper and their alloys.

It is important to dwell on the following point: the category of low-carbon steels is represented by grades from 08 to 20G, medium-carbon steels - grades from 30 to 50G2. A characteristic feature of carbon steel grades is the presence of the letter U in front of their names.

How it manifests itself

The backlash of the flame is most often observed in the form of a sharp bang, after which the following occurs:

— the burner flame goes out and black smoke comes out of the mouthpiece;

— the flame does not disappear, but there may be several pops. Mainly due to incorrect equipment settings or low power of gas supplied to the burner;

— flame extinction as a consequence of excessively long manipulations with the oxidizing flame.

The last option is the most dangerous. It can be accompanied not only by micro- and macro-ruptures of the hose and burner, but can also provoke an explosion of cylinders.

Why does flame backlash occur? Main reasons

Several factors can provoke this phenomenon, which include:

— incorrect selection of gas mixture;

— low power of the supplied gas flow;

— the mouthpiece or replaceable burner tip overheats greatly;

— the consequence of metal splashes sticking to the mouthpiece;

— the burner accidentally touched the part and the outlet was blocked;

— the air in the oxygen cylinder has run out.

Options for solving the problem

- The oxygen valve on the burner is closed, and then the supply of flammable gas is turned off.

- The pressure level in the cylinders and the regulator parameters are checked.

- We wait until the burner cools down, after which we clean it if necessary.

- In case of strong pops, we additionally inspect the hose, regulator, and cylinder.

- If everything is fine, we re-ignite the flame and check how everything works.

Additionally, devices that block the reverse gas flow can also be installed. These include safety valves connected between the torch/torch and the source of flammable gas.

The valves are hydraulic (filled with water) and dry (fire arresters (filled with metal-ceramic powder with a fine-porous structure).

Small valves are mounted between the burner and the hoses, and larger ones are installed at the outlets of the regulators. Don't forget to keep the valves working - they require regular maintenance. Thus, having implemented all changes to the equipment, a flashback of the flame will be unlikely. One solution to the problem may be more advanced plasma cutting. It is not only more productive and versatile, but also safer.

source

Necessary equipment

As with any other work, even before you start cutting metal with gas, you should prepare the necessary equipment:

- Cylinder with propane and oxygen - 1 pc.;

- High pressure hoses;

- Cutter;

- A mouthpiece that must have certain dimensions.

A prerequisite is the presence of a reducer on all cylinders, with which you can adjust the gas supply. It should be remembered that the propane tank has a reverse thread, which is why it will not be possible to screw an additional reducer onto it.

In general, gas equipment for cutting metal has a similar design, regardless of the manufacturer. There are three valves in the design

- the first provides propane supply;

- the second valve allows you to change the oxygen supply;

- The last one is the cutting oxygen valve.

Read also: DIY wooden organizer drawings

Oxygen valves are usually marked with blue markings, while propane valves are usually marked with red or yellow markings.

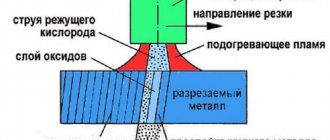

Metal cutting is ensured by a jet of hot flame acting on the metal, which is created using a cutter. When it is turned on, propane and oxygen are mixed in a special mixing chamber, which leads to the appearance of a flammable mixture.

Using a propane cutter, you can cut metal whose thickness does not exceed 300 mm . The detailed installation is completed with elements that are mostly replaceable. For this reason, if one or another part fails, it will not be difficult for the operator to carry out repairs directly at the workplace.

Particular care should be taken when choosing a mouthpiece. The key parameter to pay attention to is the thickness of the metal. If you have to deal with an object that includes elements of different thicknesses ranging from 6 to 300 mm, then you will have to prepare mouthpieces with internal numbers from 1 to 2, and external numbers from 1 to 5.

Consequences of a negative phenomenon

The backlash often breaks supply hoses, reducers and even the cylinder itself. This effect disables gas equipment. However, the most dangerous consequences are injuries and casualties among people. To prevent the effect from occurring, experts recommend using fire suppression valves - proven equipment that prevents backburning and completely extinguishes the flame.

It is also recommended to follow safety precautions. After all, it will be much more expensive to compensate for the damage after a cylinder rupture.

Preparing for work

Even before starting gas cutting, it is necessary to inspect the device to make sure that the propane cutter is in working condition. Next you need to perform the following operations:

- Preparing the cutting machine begins with connecting the hoses to it. Even before attaching the hose, it is purged with gas - this will remove debris and dirt from it.

- The oxygen hose must be connected to a fitting with a right-hand thread; a nipple and a nut are used for this purpose. As for the hose through which propane will flow, it is attached to a fitting with a left-hand thread. Before connecting the hose with gas, it is imperative to find out whether there is suction in the cutter channels. This problem can be solved by connecting an oxygen hose to the oxygen fitting, making sure that the gas fitting remains free.

- Next, you will need to set the oxygen supply level to 5 atmospheres, after which you need to open the valves that regulate the flow of gas and oxygen. Touch the loose fitting with your finger - this way you will know that there is an air leak. If it is missing, you will have to clean the injector and blow out the cutter channels.

- After this, you need to make sure that the detachable connections are airtight. If a leak can be detected, it is eliminated by tightening the nuts or replacing the seals. You should also make sure that the fastenings of the gas reducers are sufficiently tight and whether the pressure gauges are in working condition.

How fire shutoff valves work

Structurally, the fire safety shutter consists of:

- metal case;

- locking spool;

- springs;

- flame retardant element.

The spring-loaded spool is capable of passing oxygen (acetylene, propane) only in the forward direction. When the gas leaves the cylinder, due to excess pressure, it overcomes the force of the spring and creates a gap between the seat and the spool, through which it enters the cutter. In the event of an inverse impact, the spool is pressed against the seat and, thus, cuts off the gas supply to the working area.

Let's get started

First, you need to move the oxygen reducer to the position corresponding to 5 atmospheres, the gas reducer to 0.5 . You also need to make sure that each valve is in the closed position.

After that, you need to take a propane torch and open the propane slightly, and then light it. The cutter nozzle must be positioned so that it rests on the metal, after which you need to slowly open the oxygen control. Next, you should adjust these valves one by one, thereby ensuring the required flame supply force. During such a setup, you need to sequentially open gas, oxygen, gas, oxygen.

When choosing the flame strength, you need to focus on the thickness of the metal. As the thickness of the sheet increases, the strength of the flame will have to increase, which will lead to an increase in the consumption of oxygen and propane. After adjusting the flame strength, you can start cutting metal. The nozzle must be held in relation to the edge of the metal so that it is removed from the object being cut at a distance of 5 mm, and it itself must be located at an angle of 90 degrees. In some cases, it may be necessary to cut through the sheet or product in the center . In this case, the starting point is chosen to be the place from which the cut will go.

The essence of the procedure is to heat the top edge to a temperature of 1000-1300 degrees Celsius. The exact temperature is determined taking into account the metal. In practice, such work will look like the surface appears to be “wet.” The heating itself will take no more than 10 seconds. After waiting for the metal to ignite, you need to open the cutting oxygen valve, after which a powerful, narrowly directed jet will begin to flow.

Cutting Features

When opening the valve of a propane cutter, do not rush. In this case, the ignition of oxygen will occur naturally as a result of interaction with the heated metal. By acting this way, you will eliminate the risk of a flashback of the flame, during which you may see a pop. It is necessary to slowly guide the oxygen stream strictly parallel to the given line. Here it is important not to make a mistake with the angle of inclination.

Read also: How to use a hand plane

First, it is maintained at 90 degrees, after which it is necessary to create a slight deviation of 5-6 degrees in the direction opposite to the movement of the cutter. If you have to deal with metal whose thickness is more than 95 mm, then it is allowed to increase the deviation to 70 degrees. After the cut in the metal reaches 15-20 mm, the angle of inclination begins to increase to 20-30 degrees.

What to do in case of persistent backfire?

In the event of a persistent backfire, you must first close the oxygen valve of the gas supply tube. This must be done as quickly as possible. Sustained shock is the result of improper handling and/or poor maintenance of the tube. Before re-igniting the burner, it is necessary to cool the gas supply tube. Under no circumstances should you continue welding or cutting without thoroughly checking the equipment and handling procedures.

Penetrating flashback occurs only as a result of improper operation, poor maintenance of the gas supply tube or incorrect setting of the operating pressure.

Incomplete flame penetration can easily occur if the flame passage port is dirty or damaged (see separate article on gas tube maintenance). To prevent penetrating flashback and the danger associated with it, a special device (fuse) and non-return valves should be installed in the welding machine.

Required components to prevent kickback

- non-return valve that prevents the reverse flow of gases;

- filter for extinguishing the front part of the backlash flame;

- cut-off, operating under the influence of temperature, to shut off the gas in case of fire (when the temperature rises to 100°C);

- pressure cut-off to stop the gas supply in the event of a backfire (activated by the pressure shock generated at the front of the backfire);

- excess pressure relief valve in the event of a backfire or incorrect setting of the operating pressure, which. prevents hose rupture

Nuances of metal cutting

When cutting metal, it is important to maintain the required speed . Its selection is carried out visually, for which the speed of scattering of sparks is assessed.

If the speed turns out to be optimal, then the stream of sparks will fly out at an angle of about 88-90 degrees relative to the surface being cut. In a situation where the flow of sparks tends to be in the direction opposite to the movement of the cutter, we can conclude that the cutting speed is set too low. In some cases, the stream of sparks is emitted at an angle of less than 85 degrees. This is a clue that the current cutting speed is too high.

When cutting with gas, it is important to take into account such a parameter as the thickness of the metal. If it is more than 60 mm, then it is advisable to place the sheets at such an angle that the slag easily moves to the side.

If you have to work with metal that has a significant thickness, then a special approach must be used. It is unacceptable to move the cutter until the metal is cut to its full thickness. As cutting is completed, it is important to gradually reduce the advance speed and maintain the torch angle 10-15 degrees higher . The cutting procedure itself should be carried out in such a way that there are no significant pauses during it. If it happened that you had to stop at a certain area, then you do not need to return to cutting at the point at which the work was interrupted. It starts all over again, and a new starting point is chosen.

After finishing cutting, you need to turn off the supply of cutting oxygen, after which the same is done with the regulating oxygen. The final action should be to turn off the propane.

How to cut with a gas cutter (technology)

We gradually increase the oxygen stream, which ignites the molten metal. If a violent process begins and the steel catches fire, then you can gradually increase the oxygen pressure (until the fire cuts through the material). If the reaction has not started (the metal is not heated), then oxygen should be added and heated.

We started cutting the metal and slowly moved along the cutting line. All processing products are blown away to the rear of the cutting area. If this flow slows down or returns, then reduce the cutting speed or stop and warm up the material.

Useful video on how to work

Watch video tutorials on cutting with propane and a torch:

Surface and figure cutting

In some situations, it may be necessary to create a relief on the surface by cutting a groove into the sheet. If you decide to use a similar cutting method, then the heating of the metal will be provided not only by one flame of the cutter . Molten slag will also make a contribution. Becoming liquid, it will spread over the entire surface, which will lead to heating of the lower layers of the metal.

The first step in performing surface cutting is heating the selected area to the ignition temperature. After you start supplying cutting oxygen, you will create a metal combustion zone, and thanks to the uniform movement of the cutter, the cutting line will receive a clean edge. The operation itself must be performed in such a way that the cutter is at an angle of 70-80 degrees with respect to the sheet. When cutting oxygen begins to flow, the cutter is positioned so that it forms an angle of 17-45 degrees .

To create grooves of suitable sizes, it is necessary to change the cutting speed: to obtain greater depth, the speed is increased, and for less depth, it is reduced. To create greater depth, the angle of the mouthpiece must be increased, cutting must be done at a slower pace, and the oxygen pressure will also have to be increased. The width of the groove can be influenced by using the correct diameter of the cutting oxygen jet. It should be borne in mind that the difference between the depth of the groove and its width should reach 6 times. Moreover, the latter should have the advantage. Otherwise, you may encounter such an unpleasant phenomenon as the appearance of sunsets on the surface .

Tags: torch, welding

Comments 51

In some cases there is no need to drill out anything!, it is adjusted by unscrewing it 1.5-2.5 turns. Unscrew the gas hose, unscrew the injector two turns, open the gas valve and supply oxygen with your finger, plug the gas fitting onto the burners, it sucks air into itself quite strongly, try turning it down half a turn and adding more until you get the strongest air leak. The burner operates by suction of oxygen gas. After this, check for leaks and put it in water.

I unscrewed (adjusted) the injector, nothing helps