Today we will talk about how to glue silicone. Since this product is quite capricious, you need to choose the right adhesive composition for it. As part of the publication, we will analyze in detail what means you can use so that it is not only effective, but also budget-friendly.

Glue for repairing silicone products Source fastbox.su

Basic properties of silicone

Silicone is a soft synthetic material that is obtained by synthesizing polymers. It is quite practical, relatively durable and elastic. Such raw materials are used in various fields due to significant advantages, including:

- resistance to high temperatures and temperature changes;

- presence of water-repellent properties;

- plastic;

- resistance to various types of deformation and minor mechanical stress;

- elementary processing and disinfection;

- complete resistance to oxidation.

How to choose the right glue for silicone

The question often arises of how to glue silicone if a product made from it breaks at home. It is important to choose the right adhesive composition here. We'll talk about the criteria in this section. First of all, they make a choice based on operating conditions:

- Universal. The most optimal adhesive option, which is suitable for joining at home and outdoors. Typically, such products are used to seal cracks or eliminate defects during repair work. This composition will retain its properties even with dramatic changes in temperature.

- For outdoor work. This option is ideally used outdoors or on products that require strong hardening. These are the properties that the composition for street work has. The adhesive composition performs well in air.

- Sealants. This is another special group of polymer adhesives. Such compositions can withstand exposure to moisture and various types of liquids. Under proper processing conditions, the connection with such glue will be long-lasting and waterproof.

- Automotive. This adhesive composition is also called a “liquid gasket”. It copes with the tasks of gluing various gaskets when repairing car engines and chassis. It is not recommended for use in domestic conditions due to toxicity and unsafety.

- Sanitary. Another composition for gluing silicone rubber, and it can be classified as a type of sealant. It is used for gluing flexible polymers, as well as for processing seams in bathrooms and other rooms exposed to high levels of humidity.

- High temperature. This is a convenient composition that can now be found in every owner. Sold in the form of special sticks of different lengths, placed in a heat gun and melted by heating, after which it perfectly glues not only silicone, but also many other products.

Glue brands for silicone Source alibaba.com

Brief introduction to the topic

Based on the type of origin, silicones can be classified as organosilicon compounds. The properties of adhesive compositions will depend on the structure and component composition. Due to its excellent adhesion to various surfaces and low cost, silicone adhesive is popular in the construction field.

Its main advantages are:

Resistance to light, moisture and temperature changes.- Elastic structure in various operating conditions.

- High strength of polymers after 100% drying.

Silicone-based glue is available in a wide range, and therefore finding a product on sale for a certain type of work is not difficult. Such compositions are valued for their excellent sealing properties, quick drying and versatility of use. Thanks to the addition of modifying components, adhesive compositions acquire important technical characteristics.

Compound

Silicone is a durable polymer compound of organosilicon type components with a high molecular weight structure. Chemicals have a liquid-viscous texture that is visually similar to resin. The basis of silicone-type adhesive is formed by synthetic rubber - an artificial substance that occupies half of the composition of the polymer compound. Some manufacturers may make adhesives and sealants from silicone grades. The fundamental difference between them is that glue is used for strong fixation, and sealant is used to obtain a waterproof layer. The products have similar properties and compositions.

Silicone glue contains:

- The rubber base of the chemical type polymer will act as the basis of the adhesive joint.

- The strength enhancer will affect the viscosity of the substance, and will also give the required characteristics after drying.

- The plasticizer for improving the plasticity properties of the glue mass is made on the basis of silicone.

- The primer will ensure high adhesive properties of the product and adhesion to all materials.

- The vulcanizer will be responsible for the speed at which the glue dries and gives it a rubber-like structure.

- Coloring pigments are not included in all silicone products; white, black and colored dyes will mask seams and cracks.

- Fine-grained fillers (glass and quartz dust, sand) improve the adhesive properties and strength of silicone.

- Fungicidal type additives have antiseptic characteristics and also prevent the appearance of fungi and mold.

Manufacturers add catalysts to accelerate curing, as well as extenders, to some adhesive compositions. Adhesive sealants are usually produced in the form of one-component formulations for household use, and for professional work two-component substances are used.

Characteristics and description of silicone

As a result of chemical synthesis for polymers, elastic type silicone is obtained. There are several types of material: liquids, elastomers and resins. The most common type is rubber-like silicone, which has been widely used since the middle of the last century. The main characteristics of silicone include the following:

- Safety - the materials contain no toxic substances, because they are harmless to humans, animals and even the environment.

- Wide range of operating temperatures - the ability to maintain shape and quality at extreme temperatures will expand the range of applications.

- High degree of elasticity - even with prolonged use, the material will remain flexible and will not crack or crumble.

- Resistance to water - silicone products can be used in places where there is frequent contact with liquids, and even directly in an aquatic environment.

- Inertness to microbes - the influence of parasites is not able to affect the appearance and structure of silicone. Moreover, disinfection can be easily carried out if necessary.

Suitable brands of adhesives for silicone

Silicone rubber adhesive can be produced by different manufacturers. The highest quality products are listed in this section.

- Klebfix. A popular adhesive for silicone products, which ideally glues not only silicone objects, but also aluminum alloy. The finished connection is quite strong and tear-resistant.

- Permabond. Another equally functional material. It is used to join silicone with heterogeneous gaps, as well as other difficult-to-join objects. The composition can be applied in an automated way, especially if there is a need for gluing large objects.

- Valmexinsc38. Product with increased strength, produced in Germany. Provides reliable connection of latex, natural silicone and even PVC-based items. After hardening, seams made with glue of this brand are not destroyed by water. The hardening time is three minutes.

- Cosmofen CA 12. High-quality glue that can be used to glue silicone and other components. Sold in a package with a special dispenser. This composition is consumed economically and is stored for a long time.

For reliability, before using each brand of glue, it is necessary to prepare the product that needs repair. You can find out all the details in the section below.

Silicone adhesive related to universal sealants Source au.ru

Glue Basics

There are a number of requirements that must be observed when working with glue for silicone restoration:

- be sure to degrease the surfaces before applying glue; standard alcohol, white spirit, or acetone are suitable for this;

- apply carefully, use a small amount of glue, as the residue can harden on the surface and ruin the appearance of the silicone item;

- gluing should be performed by tightly pressing the two parts to each other and additionally holding them in this position for several seconds;

- Carry out silicone repairs only in a well-ventilated area at a temperature of at least 25 degrees;

Do not allow direct contact of the skin of your hands with the adhesive composition, as the latter can cause serious burns.

If you follow all the recommendations listed, you will eventually get a strong connection without harm to your own health.

Silicone kitchen mat can be easily repaired using food grade glue Source allbuyshop.ru

What products can be glued

If you follow the standard rules, you will be able to glue any product, including a watch strap, children's toys, construction components (seals, bushings), and medical tubes. The result of the repair directly depends on a number of factors, including the current condition of the product, the degree of damage, the adhesive solution used and the accuracy of the work.

See also

Characteristics and rules for choosing glue for polyethylene foam, review of popular brands

The process of simple gluing using the example of a silicone toy at home

The entire gluing process will take place in several steps, but first of all, it is important to prepare the product so that the seam is strong enough.

- First, take two pieces of torn silicone and rinse them thoroughly. To do this, fill a small container with water and rinse the fragments thoroughly, removing any dirt, if any.

- Next, drain the water and prepare a soap solution and rinse the silicone in it again. Now leave the item to dry completely on a napkin. It is important that there are no lint left on the product.

- After complete drying, take a painting or stationery knife and a lighter. It is desirable that the blade be thin enough. Warm it thoroughly over an open fire. Then lean the two parts of the silicone toy against both sides.

- The two fragments will be securely fastened to each other. The toy will turn out to be one whole.

Silicone toy repaired by heating Source vova.com.tw

This method has two main disadvantages: firstly, it is only suitable for gluing miniature products, and secondly, the finished seam will not be very smooth and unesthetic.

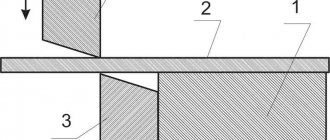

Step-by-step instructions for gluing silicone and metal

In certain cases, the question may even arise as to how to glue silicone to metal. For this purpose, any type of silicone or cinacrylate composition is used. The gluing work is performed according to the following algorithm:

- Take the silicone part and thoroughly degrease the part that will stick.

- Next, treat the metal surface with alcohol or acetone, after cleaning the area with fine sandpaper. Ideally, remove the paint layer if there is any.

- Take Cosmofen CA 12 glue and apply a few drops to one of the components, then in the correct application, press the parts against each other, holding for 5-10 seconds.

- If there are still parts that are not glued, you can add a few more drops of glue and finally fix the two fragments together.

After the gluing process is completed, the product can be used for its intended purpose without worrying about damage to its integrity.

Cyanoacrylate adhesive for gluing metal with silicone Source ali-fa.ru

If lubricant is not available

Using silicone grease is an ideal and correct option for installing a sewer pipe. And its absence would be a direct indication for the cessation of assembly work in any other country. Our craftsmen find simple and affordable substitutes, which also facilitate installation and do not harm the rubber seal. What can be used to connect sewer lines in the absence of lubricant?

- any animal or vegetable fat. It could even be vegetable oil, which can be found in any home;

- moisturizing creams, if, of course, you don’t mind;

- soap solution;

- liquid detergent.

What is better not to use when joining a pipe?

- solvent;

- WD-40;

- adhesive seals.

These substances can damage the rubber rings. Even wd-40, beloved by all motorists, contains a solvent (white spirit), therefore, it can lead to rapid wear of rubber. And joining with adhesives will make it difficult to repair and dismantle the pipe in the event of an accident.

Today on the street you can see many cars with tinted windows. Why do they do this? For every driver, his car is no less important than his home; no one wants his personal space to be watched. While ordinary curtains will work in an apartment, you won’t be able to hang them in a car.

A good option would be silicone tinting - reviews of which say that it is inexpensive and brings good results. In addition to insulating the interior space, tinted windows also perform protective functions and protect the interior from overheating.

People decide to tint based on different goals. The main thing is to hide the interior space of the vehicle. This will allow you to spend time comfortably even in a traffic jam, when all participants in such a “movement” are trying to look at each other out of boredom. You can also leave personal and expensive things in the car, which bad people won’t stare at while coming up with a cunning plan for theft.

Another purpose of tinting is the appearance of the car. With darkened windows it looks expensive and respectable.

Why choose removable tint?

A removable tint option appeared on the car market and it immediately gained popularity. If you glue and remove the film correctly, it will last a long time. In addition, the cost of gluing work and the price of the material itself are affordable for a simple car owner.

Good to know

When deciding how to glue silicone to silicone, the following situations may arise:

- silicone is real and there is absolute confidence in this. In this case, you can use formulations for their intended purpose. The only thing you have to consider is whether the adhesive is suitable for exterior or interior use;

- if you are not completely sure that the plastic polymer is real, then it is best to abandon expensive professional glue. In such a situation, you can limit yourself to the usual composition for linoleum.

It is impossible to check how high quality and genuine silicone rubber is. Unless you purchase the product directly from the manufacturer.

Repair of silicone baits is carried out using special adhesives with high adhesion Source fishlovlya.ru

On a note! Food grade silicone is odorless and does not emit toxic substances. Therefore, for kitchen items you need to choose the appropriate type of glue. But such a model will not be cheap.

Advice from professionals

- Carefully study the labels on sealant containers from manufacturers. You can find a lot of useful information on it: what kind of work the composition is intended for, under what conditions it can be used, how the seam will react to temperature changes, etc.

- Sealants must be used strictly for their intended purposes, otherwise the applied composition will soon collapse.

- It is easier and more convenient to apply sealant using a special mounting gun.

- If the sealing compound sticks to the rubber spatula (during installation), the tool can be slightly moistened with soapy water.

- Often sealant, especially the first time, is applied carelessly. It is not recommended to wipe off excess immediately. It is better to wait until the seam has dried, then carefully cut off the sealant using a knife or spatula and remove unnecessary glue from the surface.

When choosing, you should decide what type of sealant for plastic is needed: waterproof, UV-resistant, durable, or most importantly, it should be colored. It is necessary to provide for everything where, how and under what conditions it will be used. And from this you can purchase the necessary sealing composition for a plastic surface, which will last for a long time.

Features of repairing silicone baits

There is nothing complicated in restoring silicone baits. You can glue partial or complete tears using a special glue that is odorless. But deep injuries or punctures are healed using open fire: lighters or candles.

The repair process is similar to that described above using the example of a toy. Also, with the help of an open fire, you can completely melt a damaged fishing product, and if you have a special mold, cast a completely new piece.