Hands from the right place | 03/24/2016

Each of us came across this simple tool in labor lessons; everyone remembers how difficult it was to cut pieces of sheet metal with heavy, indestructible Soviet metal scissors. But time does not stand still; when we go to the nearest construction tools supermarket, we will see a huge number of varieties of those same simple metal scissors. Lever, curly, right and left, with or without insulating handles, there are even professional hand-held metal snips that cost the same as a decent set of tools. And so as not to get confused, let's figure it all out!

What are metal scissors

From the name it becomes clear for what purposes the devices in question are intended. Like regular scissors, metal cutting devices are designed only for working with sheet materials. It is impossible to cut pipes, angles and profiles with metal cutting devices, since they are not designed for this, and simply will not cope with this task.

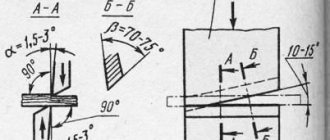

Structurally, hand-held metal scissors consist of handles and cutting knives. The mobility of the knives is ensured by the mounting bracket. The sharpening angle of cutting knives is 60-75 degrees. This sharpening angle ensures high performance with minimal effort. The large sharpening angle means that the tool can be used for cutting hard metal sheets. The knives in relation to the handle are located at an angle of 7 to 12 degrees.

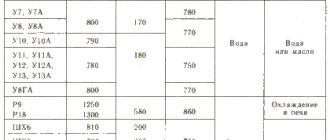

The knives of the tools in question are made of alloy (chrome-vanadium) or tool steel, which has a positive effect not only on the quality of the cut, but also on the service life. When the blades on knives become dull, they can be sharpened. The tool handles are covered with plastic, rubber or silicone material for ease of work.

This is interesting!

Many people use hand-held metal shears to cut thin sheet metal, such as galvanized sheets or corrugated sheets, and do not know that there are different types of such tools. Depending on the task at hand, it is necessary to select the appropriate type of tool.

The best hydraulic shears

At construction sites and in auto repair shops you can often find hydraulic shears. They are used for cutting through reinforcement or bolts. High force on the cutting edges is supplied thanks to a hydraulic drive. The following tool has proven itself well among domestic users.

KVT BRG-12

Rating: 4.9

A safe and effective tool for cutting reinforcement, rods or bolts are the hydraulic shears KVT BRG-12. The Russian development allows you to bite pieces with a diameter of 4 to 12 mm. The hydraulic drive creates a powerful force (5000 kg), and the sharp blades instantly dig into the metal structure. Experts note the high hardness of the cutting jaws (52...54 HRC); they are easily removed for sharpening or replacement. The working head is C-shaped, to return the closed blades to their original position, a pressure relief valve is installed. There is a plastic case for storage and transportation. The weight of the tool is 2.3 kg.

Owners of a hydraulic bolt cutter are satisfied with its durability and safety, affordable price and simplicity of design. They call the narrow scope of application a disadvantage.

Advantages

- strength;

- safety;

- ease of operation;

- practical case.

Flaws

- narrow specialization.

Types of tools

Before you buy hand scissors for cutting thin sheet material, you need to understand their types. To carry out the relevant work on processing sheet steel, you need to take the appropriate tool, which will allow you to achieve the necessary results. What are the devices in question or their types, we will find out further.

- A straight cutting tool is the simplest type of device, which is designed for cutting large circles and straight cutting of material

- Mechanical with curved blades - used for cutting holes, as well as for obtaining cuts of different shapes

- Finger blades with thin blades - used to produce cuts of various shapes. The blades on finger scissors have different positions relative to each other. It follows that tools are divided into left and right, and depending on the task at hand, it is necessary to use the appropriate type of device

- Chair saws - used for cutting thick sheet steel. They cope with steel thicknesses up to 2-3 mm. When cutting thick sheet steel, effort must be made, so the design of the devices has a special bend. This bend is necessary in order to hook the tool to the workbench, thereby ensuring that the upper handle is pressed with high force, increasing the cutting force

- Power - another type of device for cutting sheet metal with a thickness of 2.5 mm. Power mechanical scissors consist of two levers, which are fixed using a hinged bracket. Power tool models come with replaceable discs and blades that can be used to cut metal rods up to 8 mm thick

- Lever scissors are professional models of scissors that are attached to a workbench. The design of such devices is such that one blade is movable and the other is fixed. The movable blade is driven by a handle on the tool. They are used for cutting aluminum, steel, copper, brass, etc. The maximum thickness of steel reaches 4 mm, and brass, copper and aluminum up to 8 mm

All types of scissors are divided into professional and amateur. They differ not only in price, but also in quality. Professional models are made from high-quality materials, so they are intended for constant use. They have a long service life and are 2 times cheaper than amateur ones. Amateur ones are intended for infrequent use, since low-grade types of steel are used for their manufacture.

Best lever shears

Lever shears can handle a large volume of metal cutting work. They boast a simple and reliable design, compactness and versatility. Although in this category there is also a highly specialized tool.

Enkor Korvet-575

Rating: 4.9

To quickly and efficiently cut rectangular segments in sheet metal, lever cutting shears have been developed in Russia. The 30-kilogram tool has a wide base, thanks to which the product behaves steadily during operation. Experts appreciated the high force (3000 kg) on the rod. As a result, the cutting size reaches overall dimensions of 125x125 mm with a maximum steel sheet thickness of 1.5 mm. The manufacturer managed to prevent the hand from slipping due to a special coating of the handle. The asset of the tool should be ease of use, reliability and durability.

Domestic users have no complaints about the quality of workmanship. They consider the design simple and durable. The only disadvantage is the limited scope of application.

Advantages

- high force on the rod;

- simple design;

- comfortable handle;

- quality production.

Flaws

- narrow scope of application.

Manual models of metal scissors and their manufacture

The manufacturing process of hand scissors involves the use of two options:

- Forging

- Casting

Models differ in price. Forged devices are much more expensive than cast ones, but they are much more reliable and durable. To make the blade durable, it is subjected to additional heat treatment. Hardening the cutting part prevents dulling of the cutting part, so it is extremely rare to sharpen this type of tool. After sharpening, the blades will dull much faster.

Cast scissors are suitable for farming, they are inexpensive and do an excellent job. With frequent use of scissors, the blade quickly becomes dull, so they need periodic sharpening. This tool can only cut thin sheet steel up to 2 mm.

This is interesting!

The hinge mechanism on hand scissors consists of two parts, which is done specifically to double the applied physical force.

Manufacturers also produce lever products that are made from two different materials. The cutting part is made of high-quality material, which increases their service life. The handles of such devices are made of ordinary steel, which has a positive effect on the cost of the tool. Using lever shears allows you to cut metal without much effort.

When purchasing hand scissors, you need to consider the placement of the knives. They are straight, as well as left and right. Straight ones are designed for smooth cutting, as well as cutting out large round shapes. As for the left and right shapes of the blades, here you need to know the following:

- Left - used to make cuts in the left direction. The left scissors should be used primarily while holding them in the right hand. When working with a tool with left-handed blades, the left side of the blades enters from below

- Right - used when it is necessary to bend to the right side. When working, you should hold such a tool in your left hand. When cutting with scissors, the right side goes under the sheet from below, which allows you to make an even cut

To make it easier to distinguish them, manufacturers paint the handles in different colors. The right scissors are painted green, and the left scissors are painted red. When using hand-held cutting devices, everyone has encountered the fact that when cutting a long sheet, the plane becomes bent and bent. This usually happens when using scissors with a symmetrical arrangement of knives. To prevent creases from forming, when cutting a long sheet of steel, you need to use a tool with asymmetrical knives.

This is interesting!

Instruments with asymmetrical knives are extremely rare on sale.

The reason for such low popularity is their high cost. However, in order to make an even and neat cut, it is recommended to buy just such metal scissors with asymmetrical blades. What can be cut with hand metal scissors:

- Galvanized steel

- Corrugated sheet

- Metal tiles

- Sheet metal

- Steel mesh

- Linoleum

- Rubber

- Ruberoid

The advantage of hand-held metal shears is that they cost 10 times less than power tools.

The best rebar shears (bolt cutters)

Large pliers can be called reinforcement shears. Their scope of application is limited to cutting rolled metal (wire, rods, squares, hexagons). A distinctive feature of bolt cutters is their long handles, which create the force necessary for cutting. The following models fall into this category.

KNIPEX KN-7182950

Rating: 4.9

A professional tool for cutting metal wire, fittings, and rods are the German KNIPEX KN-7182950 scissors. Thanks to the high strength of the working part and the long handles, the bolt cutter allows you to work with both soft workpieces with a thickness of 11 mm and hard material (6 mm). To make the cutting head, the manufacturer used chrome vanadium steel, which was forged and oil hardened. The swivel joint is made of tool steel. Comfortable operation with long handles is ensured by a combination of hard plastic and elastic inserts. Experts liked the 12-step adjustment and corrosion resistance of the tool.

Professionals are satisfied with the technical parameters of the scissors, reliability and durability. The downside is the high price.

Advantages

- high-quality manufacturing;

- versatility;

- corrosion resistance;

- comfortable handles.

Flaws

- high price.

KRAFTOOL 1-23290-060

Rating: 4.8

The winning bolt cutter KRAFTOOL 1-23290-060 is slightly inferior in grip size (10 mm). The tool is an example of successful cooperation between German developers and a Japanese manufacturer. Experts highly appreciated the reliability and durability of the model. The working part is made of alloy steel; the jaws can be adjusted to the diameter of the workpiece using special screws. To create powerful force, the handles are equipped with a double lever. The special feature of the scissors is the red paint on the working part, which is a pre-sale seal. A comfortable grip is ensured by rubber pads on the handles. The asset of the tool should be its compactness (600 mm) and low weight (2.56 kg).

It has not yet been possible to find reviews from domestic consumers in RuNet. The bolt cutter deserves the attention of not only professionals, but also home craftsmen.

Advantages

- reliability;

- grip adjustment;

- comfortable handles;

- compactness.

Flaws

- no reviews.

Ridgid S18

Rating: 4.7

Thanks to the use of high-quality materials, the American manufacturer Ridgid managed to create durable S18 rebar shears. They are capable of working with bar metal with a diameter of up to 9.5 mm (non-ferrous metals and steel with a hardness of up to 15 HRC). The thickness of a wire spring or stainless steel (42 HRC) is limited to 6.4 mm. Experts noted the cam mechanism, which ensures the level position of the jaws. The cutting elements are made of alloy steel that has been hardened. The model differs from its competitors in its lightness (1.5 kg) and compact dimensions (485 mm).

On thematic forums, reinforcing shears are praised for their high-quality manufacturing, neat edges, and reliability of the tool. Disadvantages include high price and rapid fatigue during prolonged use.

Advantages

- high-quality manufacturing;

- cam mechanism;

- wear-resistant sponges;

- compactness and lightness.

Flaws

- high price;

- short handles.

Sturm 1280201

Rating: 4.7

The budget bolt cutter Sturm 1280201 is designed for cutting wire, rods, nails and other metal products with a hardness of up to 40 HRC. The maximum diameter of the workpiece should not exceed 10 mm. The tool looks quite impressive; with a length of 600 mm, it weighs 2.39 kg. The manufacturer used chrome vanadium steel to make the jaws; plastic linings on the handles provide a comfortable grip. The presence of an adjusting bolt allows you to adjust the travel of the handles to suit your physical capabilities. The tool is supplied in cardboard packaging and plastic film.

Users are satisfied with the affordable price and build quality, ease of use and presentable appearance. The disadvantages include the low hardness of the sponges.

Advantages

- high-quality assembly;

- presentable appearance;

- decent diameter of workpieces;

- ease of use.

Flaws

- low hardness of sponges.

Zubr 23313-045

Rating: 4.7

The most affordable bolt cutter in the category was the Zubr 23313-045 model. Experts liked the eccentric mechanism; it precisely regulates the fit of the jaws to each other. Using the tool, you can cut through metal with a hardness of up to 40 HRC and a thickness of up to 8 mm. The bolt cutter works best with wire rods up to 6 mm in diameter. As hardness and thickness increase, a lot of physical effort must be exerted to bite. The cutting parts are made of tool steel, hardened to 55-60 units. The assets of the scissors include a forged connector and ergonomic handles with plastic linings. The tool combines compactness (450 mm) and lightness (1.5 kg).

In reviews, users praise the tool for its low price, sharp, wear-resistant jaws, compactness and lightness. But its scope is limited.

Advantages

- low price;

- compactness and lightness;

- wear-resistant sponges;

- reliability.

Electric scissors for fast and precise cutting of sheet material

Accuracy and accuracy of cutting with hand scissors is ensured only by choosing the right tool. In addition to manual scissors, manufacturers also produce electric scissors. The power tool does not require any physical effort to cut sheet material, since the electric motor is responsible for this action. There are two types of electric metal shears:

- Punching or die-cutting - structurally they have no resemblance to manual ones

- Knife - similar to hand tools, and their work is ensured by the mobility of one blade

Die-cut

received this name due to their operating principle. They are used for cutting sheets of corrugated sheets and metal tiles. The advantage of such devices is their ease of use and operational efficiency. When cutting through a steel sheet, sparks do not occur, and the roof covering does not deform. That is why it is recommended to abandon the use of an angle grinder when cutting thin-sheet material, replacing it with manual or electric scissors, or even better, buy an attachment for a drill for cutting metal.

Electric cutting scissors can not only cut straight, but also cut out various curly patterns. If you plan to cut a shape in the center of the sheet, then first you need to drill a hole and then install the cutting edge of the scissors into it. They work on the principle of a hole punch, and a movable mechanism—a punch—is responsible for punching through steel. When piercing steel, the knife moves very quickly, so the possibility of deformation and bending of the sheet is excluded.

In addition to cutting (or mortise) scissors, there are also knife scissors

. They are also called sheet or spline. They are very similar to manual ones, only they consist of movable and stationary knives. The movable blade moves due to an electric drive, making reciprocating movements. They are suitable not only for making straight cuts, but also for curved ones.

During operation, such scissors do not create waste, but they have a drawback - they jam the corrugated sheets. It is recommended to use them exclusively for cutting smooth sheet materials such as galvanized sheets, tin, etc. During operation, only the movable cutting knife becomes dull, which must be sharpened and replaced when worn.

Sheet shears have one fixed blade and the other a movable one. Slotted ones differ from them in that they have two fixed knives at the bottom and one movable one at the top. When using spline tools, chips are formed, the size of which does not exceed a few millimeters. The shavings are rounded when working with scissors and go to the side. You can work with a spline tool not only on the smooth surface of sheet materials, but also on corrugated sheets and metal tiles.

Cutting pneumatic tool

Pneumatic shears are easy to use. Structurally, they consist of movable and fixed blades. The movable blade can perform straight and curved cuts. Chips are formed during operation, but the sheet is not deformed, and the edges of the workpiece do not require further processing. Pneumatic tools are lighter, more convenient and faster to use than electric ones.

Professionals whose work constantly involves metal cutting usually have a large set of tools at their disposal. And for craftsmen who do not need to resort to these operations often, the choice of tool should depend on what work needs to be performed. Sometimes homemade lever shears are even used to cut thin sheet metal.

Why do you need guillotine shears?

There is another type of scissors, which also belongs to the group of hand tools. They're called

guillotine, which consist of a frame, as well as a fixed knife and a movable blade. Due to their design, they are also called tabletop or stationary. To cut sheet material, it is necessary to place the sheet on the knife according to preliminary markings. The sheet is cut by lowering the cutting blade.

This type of tool is suitable exclusively for cutting in a straight direction. They are not suitable for circular cutting, so you should choose a tool depending on its purpose. Guillotine shears are used in industry when large volumes of work are performed. Manufacturers also produce hydraulic guillotine tools for cutting pipes, profiles and other compact non-sheet materials.

Electrical appliance

Electric tools make metal cutting easier and faster. There are two types of electric scissors: nibblers and knife scissors . Nibblers or nibblers are used when cutting profiled metal and are used as shears for metal tiles. They do not jam the material being cut and do not spark during operation.

The punching tool can also make cuts in the center of the sheet. To do this, a hole is first made in the workpiece, and from there the cutting edges begin cutting. This tool is called poisson shears because the cutting is done with a moving poisson. Nibblers for cutting metal tiles can also be used as an attachment for an electric drill.

How to choose scissors for cutting metal

Choosing a tool is the most important undertaking, since the purchase determines the ability not only to do the job, but also to do it efficiently. Every craftsman should have a pair of metal scissors in his arsenal. The prices for these devices vary, so you should choose depending on the tasks at hand. If you need to cut reinforcement, it is better to choose hydraulic guillotine shears, and for cutting galvanized sheets, ordinary ones with straight blades are suitable.

Which scissors to choose for the job depends on the technological tasks, so you need to focus on the following parameters:

- The location of the blades is left and right. Depends on what types of cuts you plan to make

- The shape of the blades is straight and curved. Scissors with straight blades are convenient for cutting in a straight direction, and curved blades can be used to make curved and shaped cuts.

- The capabilities of the tool depend on the material from which the device is made. They are cast, forged, and mixed

This is interesting!

Often, a decrease in the performance of scissors occurs not due to dulling of the blades, but due to a violation of the distance between the knives. The distance increases due to the loosening of the hinge joint under heavy loads. To improve the quality of metal cutting, the tool must be periodically adjusted.

Working with hand scissors is not difficult if you choose them correctly for certain jobs. Once you try a power tool in action, you probably won’t want to go back to hand tools. The only advantage of manual devices is that they are not expensive, so it is worth buying them so that you can use them at any time to cut thin-sheet materials. The video below explains in detail how to use the tool in question correctly.

To summarize, it should be noted that the devices in question are manufactured according to the relevant standards GOST 7210-75. To choose the best scissors, you don’t need to look for a rating of the best, since price is an indicator of quality. However, if you do not choose the right tool for the appropriate type of work, then even high quality and high price will not help.

Scissors for working with sheet material

Such products are designed to be used for cutting or trimming aluminum, steel and copper plates. A similar type is used by tinsmiths or drywall workers. Often found in the preparation of drainage and ventilation systems. The list contains popular models and their functionality.

Hazet 1961R-1

The most budget-friendly devices are considered to be developments from a brand from Germany. Material of manufacture: steel alloy. This allows you to reliably protect the structure from corrosion and extend its service life. This product is perfect for cutting straight and curved cuts. To prevent your hand from slipping off at some point, there are built-in limiters for the power tool. In addition, for safety, there is also a built-in stop on the drive with the necessary functions. T

The product is brought to the first position due to the fact that it can cut through metal up to 1.8 mm thick. You can also cut reinforced metal up to 1.2 mm thick. In addition to power, there are thick handles that will distribute the entire load. The obvious advantage is good quality and long service life. If treated correctly, they can withstand up to 10 years of use.

Hazet 1961R-1

Advantages:

- Excellent length;

- Convenient location of handles;

- Maximum benefit;

- Cutting metal to a thickness of almost 2 mm.

Flaws:

- There is no reliable safety when the sheet shears are placed in a bent position;

- The handles are not covered with dielectric;

- Best suited for left-handed use.

NWS 070-12-350

This is another German product, but it is produced in the UAE. It is often called the pelican. This is due to the fact that the shape resembles the head of a bird. With it, it is very convenient to cut sheet metal both above and below the surface, and provides the best performance for professionals. The knives are made by pre-hardening and brought to high steel hardness. The length of the tool reaches 35 cm, it can be used either in one hand or in two.

The maximum thickness is 1.2 mm. It is noted that when working with longitudinal cuts, the product has the highest productivity. The invention is distinguished by the fact that it is convenient to use due to the fact that there is a built-in spring for easy spreading of the blade when pressed.

NWS 070-12-350

Advantages:

- The cost for a German device is low;

- Versatility in use;

- An emphasis that will never allow your fingers to get pinched;

- Quick metal cutting.

Flaws:

- You should only work with two hands;

- Sometimes it doesn’t cut into the metal all the way;

- Elegant handle;

- There is no latch when closed.

Kraftool 2325-l

This is another brand in the top manufacturer category that has located its assembly plants in Thailand. The model reaches 26 cm in length and is made of chrome-molybdenum alloy. The maximum metal thickness is 1.5 mm. Many craftsmen praise this device and say that with a cross-section of 0.8 mm, the sharpening will last a long time, even with daily use. Thanks to the complex design, there is no need to apply any additional force to press. And thanks to the high stops, the tool will not slip out even from wet hands. The attachment is secured with bolts and nuts, so the blades can be adjusted. This device was included in the list due to the fact that it is safe and affordable. The knives will be fixed with a bracket. Very often such a device is used for metal tiles and corrugated sheets.

Kraftool 2325-l

Advantages:

- Good equipment;

- The tool is completely ready for use;

- The blades will fit tightly together;

- The handle is comfortable rubber.

Flaws:

- Surface without dielectric;

- The scissors can open wide.

Gross 78327

The fourth place among profile cutting tools still goes to the manufacturer from Germany, which produces in China. The model received the second name “piranha” due to the fact that its appearance is very similar to this predator. But here you can pay attention not only to the appearance, but also to the popularity of the models. The scissors are made of chrome-molybdenum alloy, and the knives have good hardness according to buyers. This device can cut both stainless steel and non-ferrous metals. Very often, according to reviews, buyers like the handle, which fits comfortably in the hand. All connections are bolted, so the scissors can be adjusted at any time. This device received fourth place due to the fact that this model is the most compact and affordable. It is 23 cm in length and is useful for many builders to cut profiles at heights or in awkward positions. At the same time, the scissors can cut metal with a cutting radius of up to 1.5 mm.

Gross 78327

Advantages:

- Good limiters;

- There is a loop for gartering a lace;

- Good strength;

- Small size and weight.

Flaws:

- There are no latches in the closed position;

- The tool is only suitable for short cuts;

- Low productivity.

What materials are electric scissors designed for?

Electric types of tools are most often used for the following materials:

- metallic profile;

- sheet metal;

- plastic;

- various types of roofing material;

- fittings of various diameters.

Such equipment can be used for cutting other metal elements. A distinctive feature of electrical devices is their motor, which provides enough power to cut objects of various thicknesses.

Which scissors are best to use for working with corrugated sheets and metal tiles?

Spline and sheet tools will do an excellent job with various types of corrugated sheets and metal tiles. The electric motor will provide fast and accurate cutting in the required direction.

Hand scissors are also convenient for small amounts of cutting. If you need to process a small area, such tools will be excellent assistants in your work.