Marking and decoding of carbon steels of ordinary quality

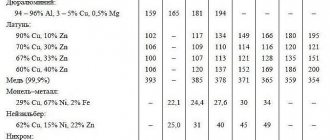

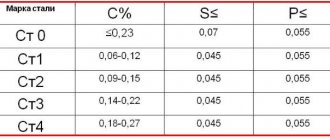

Steels contain increased amounts of sulfur and phosphorus. Marked St.2kp., BSt.3kp, VSt.3ps, VSt.4sp. They are deciphered as follows: St is the index of a given steel group, numbers from 0 to 6 are the conditional number of the steel grade. As the grade number increases, the strength of the steel increases and the ductility decreases. An example of such steels containing carbon, sulfur and phosphorus is shown in the table below.

According to guarantees upon delivery, there are three groups of steels: A, B and C. For steels of group A, mechanical properties are guaranteed upon delivery; the index of group A is not indicated in the designation. For steels of group B, the chemical composition is guaranteed. For group B steels, both mechanical properties and chemical composition are guaranteed upon delivery. The indices kp, ps, sp indicate the degree of deoxidation of the steel: kp - boiling, ps - semi-calm, sp - calm.

Marking and decoding of alloy steels

Designation is alphanumeric. Alloying elements have symbols - they are designated by letters of the Russian alphabet.

Designations and interpretation of letters of alloying elements of steels

A – nitrogen (indicated in the middle of the mark) B – niobium C – tungsten D – manganese D – copper E – selenium K – cobalt M – molybdenum N – nickel P – phosphorus P – boron C – silicon T – titanium F – vanadium X – chromium C – zirconium Yu – aluminum Ch – rare earth

Alloy structural steels

At the beginning of the stamp there is a two-digit number indicating the carbon content in hundredths of a percent. Alloying elements are listed below. The number following the symbol of the element shows its content as a percentage; if there is no number, then the content of the element does not exceed 1.5%. Steel 30Х2М. This grade of steel contains about 0.30% carbon, 2% chromium, and less than 1% molybdenum.

Alloy tool steels

At the beginning of the brand there is a single-digit number indicating the carbon content in tenths of a percent. If the carbon content is more than 1%, the number is not indicated; then alloying elements are listed, indicating their content.

Non-standard steel designations

— High-speed tool steels are deciphered as follows

P is the index of this group of steels (from rapid - speed), then a number indicating the content of the main alloying element - tungsten. Carbon content more than 1%. All high-speed steels contain about 4% chromium, so it is not specified. If steels contain an alloying element, then their content is indicated after the designation of the corresponding element. Steel R6M5 In this steel the tungsten content is 6%, molybdenum is 5%.

Ш – index of this group of steels. X - indicates the presence of chromium in the steel. The next number shows the chromium content in tenths of a percent. Carbon content more than 1%. Steel ШХ6, steel ШХ15ГС. These steels contain, respectively, 0.6% and 1.5% chromium.

The letter “A” at the end of the mark indicates high-quality steel (30KhGSA), in the middle of the mark - nitrogen, at the beginning of the mark - automatic steel (A35G2). Particularly high-quality steel is designated by the letters Ш, ВД, VI, PD, etc. at the end of the brand name, where VD means that the steel or alloy was produced by vacuum-arc remelting, Ш - by electroslag remelting, VI - by vacuum-induction melting, PD - by plasma-arc melting, etc. High-alloy steels of complex composition are sometimes designated by the serial number of development and development on).

Designation of cast iron grades

Different grades of cast iron are designed to be used for different purposes. The main ones are the following:

- Pig irons. They are designated as “P1”, “P2” and are intended for remelting in steel production; cast iron with the designation “PL” is used in foundries for the manufacture of castings; conversion with a high phosphorus content, designated by the letters “PF”; High quality pig material is designated by the abbreviation “PVK”.

- Cast iron, in which graphite is in plate form - “SC”.

- Anti-friction cast iron: gray – “ACS”; high strength - “AChV”; malleable - "AChK".

- Cast iron with nodular graphite, used in foundries, is “HF”.

- Cast iron with alloying additives, endowed with special properties - “C”. Alloying elements are designated by letters in the same way as for steel. The designation with the letter “Ш” at the end of the name of the cast iron grade indicates the spherical state of the graphite in such a grade.

- Malleable cast iron – “KCH”.

General classification of steels

Steel is an alloy of iron and carbon (up to 2% carbon). According to the chemical composition, steel is divided into:

- carbon;

- alloyed;

According to quality, steel is divided into:

- ordinary quality steel;

- quality;

- improved quality;

- high quality

Carbon steel of ordinary quality is divided into three groups:

- A - supplied according to mechanical properties and used mainly when products made from it are subjected to hot processing (welding, forging, etc.), which can change the regulated mechanical properties (St0, St1, etc.);

- B - supplied by chemical composition and used for parts subjected to such processing in which the mechanical properties change, and their level, in addition to the processing conditions, is determined by the chemical composition (BSt0, BSt1, etc.);

- B - supplied according to mechanical properties and chemical composition for parts subject to welding (VSt1, VSt2, etc.).

Classification of carbon steels

Steels are divided into carbon and alloy. According to their intended purpose, a distinction is made between structural steels with a carbon content of hundredths of a percent and instrumental steels with a carbon content of tenths of a percent. The largest volume of welding work involves the use of low-carbon and low-alloy structural steels.

The main element in carbon structural steels is carbon, which determines the mechanical properties of steels in this group. Carbon steels are smelted of ordinary quality and high quality. Carbon steels of ordinary quality are divided into three groups:

- group A - for mechanical properties;

- group B - according to chemical composition;

- group B - according to mechanical properties and chemical composition.

The following grades of steel are produced:

- group A - St0, St1, St2, St3, St4, St5, St6;

- group B - BSt0, BSt1, BSt2, BSt3, BSt4, BSt5, BSt6;

- group B - VSt0, VSt1, VSt2, VSt3, VSt4, VSt5.

According to the degree of deoxidation, ordinary quality steel has the following designation:

- kp - boiling,

- ps - semi-calm,

- sp - calm.

Boiling steel containing silicon (Si) no more than 0.07% is obtained by incomplete deoxidation of the metal with manganese. Steel is characterized by a pronounced uneven distribution of harmful impurities (sulfur and phosphorus) throughout the thickness of the rolled product. Local increased concentration of sulfur can lead to the formation of crystallization cracks in the weld and heat-affected zone. Boiling steel is prone to aging in the heat-affected zone and transition to a brittle state at subzero temperatures.

Calm steel is obtained by deoxidation with manganese, aluminum and silicon, and contains silicon (Si) of at least 0.12%; sulfur and phosphorus are distributed more evenly in it than in boiling steel. This steel is less prone to aging and has less reaction to welding heat.

Semi-quiet steel, in terms of its tendency to aging, occupies an intermediate place between boiling and calm steel. Semi-quiet steels with grade numbers 1–5 are smelted with normal and high manganese content, up to approximately 1%. In the latter case, the letter G is placed after the brand number (for example, BStZGps).

Group A steels are not used for the manufacture of welded structures. Group B steels are divided into two categories. For steels of the first category, the content of carbon, silicon, manganese is regulated and the maximum content of sulfur, phosphorus, nitrogen and arsenic is limited; For steels of the second category, the maximum content of chromium, nickel and copper is also limited.

Group B steels are divided into six categories. The full designation of steel includes grade, degree of deoxidation and category number. For example, VStZGps5 means the following: steel group B, grade StZG, semi-quiet, category 5. The composition of steels of group B is the same as that of steels of the corresponding grades of group B, 2nd category. Steels VSt1, VSt2, VStZ of all categories and degrees of deoxidation are produced with guaranteed weldability. Steels BSt1, BSt2, BStZ are supplied with a guarantee of weldability at the customer’s request.

High-quality carbon steel is produced in accordance with GOST 1060-74. Steel has a low sulfur content. Permissible deviation for carbon (0.03-0.04%). Steels with a carbon content of up to 0.20%, inclusive, can be boiling (kp), semi-quiet (ps) and calm (sp). The rest became only calm. For subsequent mild steels, the letters “sp” are not placed after the numbers.

Carbon steels in accordance with OST 14-1-142-84 are divided into three subclasses:

- low-carbon with carbon content up to 0.25%;

- medium-carbon with carbon content (0.25-0.60%);

- high-carbon with a carbon content of more than 0.60%.

Cast iron

Cast iron is an alloy of iron and carbon with a content of the latter above 2.15%. It is divided into unalloyed and alloyed containing manganese, chromium, nickel and other alloying additives.

Differences in structure divide cast iron into two types: white (has a silvery-white fracture) and gray (has a characteristic gray fracture). The form of carbon in white cast iron is cementite. In gray - graphite.

Gray cast iron is divided into several varieties:

- malleable;

- heat resistant;

- high strength;

- heat resistant;

- antifriction;

- corrosion resistant.

Steel grades - explanation, types, table with explanations

When starting to create a product, designers develop its design, select steel grades, and analyze them based on their properties. The mechanism is required to be able to operate under given conditions. Considering the structure in dynamics, they try to establish what loads will arise in one or another part.

Based on the calculations, the requirements for the strength of the elements are determined. Then a material is selected that can experience repeated loading, as well as abrasive effects. The higher the load, the less choice the designer has. The result of the design is the creation of a real prototype in metal, it is tested according to methods accepted in the industry. If necessary, the selection of steels used at the design stage is adjusted. In practice, the most common materials used to create machines, devices and complex mechanisms are steel.

- General characteristics of steel

- Steel classification

- Classification by structure

- Features of steel marking

- Structural steels

- Table 1: Chemical composition and markings on the ends of rolled metal of structural steel of ordinary quality

- Alloy steel

- Table 2: Alloying elements in the alloy composition

- Table 3: Steel grades and chemical composition

- Table 4: Marking of steels from China

- Table 5: Heat-resistant steels, markings and chemical composition

Steel classification

To understand the markings, you need to understand how steel alloys are classified according to their intended purpose. It is customary to determine properties according to several parameters:

- The chemical composition determines the strength indicators. Here the properties are determined by the compositional ratios between iron and carbon. Along the way, changes in characteristics depend on the presence of alloying elements or substances that impair performance.

- The structure changes depending on the production methods. Forged products are stronger, cast ones may form pores or other defects. When rolling through rollers, hardening is achieved and the desired shape is obtained.

- For proper use, certain brands are determined by their intended purpose. Such information is especially important for special-purpose steels. In them, even small changes in the chemical composition can significantly change the behavior under load or operation in an aggressive environment.

- The quality of steel ingots depends on the content of harmful components. Sulfur and phosphorus lead to cold brittleness and red brittleness, so metallurgists try to remove deteriorating ingredients from the alloy.

- Oxygen in steel products changes the structure. To remove it, deoxidizers are added to the molten mass; they form oxides and do not cause negative changes to the metal.

Classification of steels according to main indicators

Classification by structure

The structure is studied on special thin sections. They are examined under a microscope, having previously treated the polished surface with sulfuric acid. It is customary to define the following states:

- Hypoeutectoids are characterized by a high ferrite content. Low carbon content does not allow the metal to exhibit sufficient resistance under mechanical loads;

- eutectoid correspond to the best ratio between strength and plastic properties;

- hypereutectoid steels are used in the manufacture of tools. They are distinguished by high surface hardness, as well as resistance to loading;

- ledeburite contain carbides. The metal exhibits excessive fragility;

- Ferritic indicators correspond to the properties inherent in pure iron.

Ledeburite. Iron carbide inclusions are visible

To improve properties, normalization is carried out. It consists of relieving stress from parts that have had heat treatment associated with improved properties. Prolonged heating and holding at temperatures above 720...750 °C, and subsequent cooling leads to annealing. Metal grains change their appearance.

The top row shows the sections before normalization, and the bottom row shows them after

Alloying - the mechanism of action of alloying elements

It is difficult to decipher steels. Materials science studies this subject comprehensively.

The content of alloying additives in steel can vary within wide limits, depending on what properties need to be imparted to the metal. Thus, nickel and chromium can be present in steel in amounts up to 1%, in some cases more. Molybdenum, vanadium, titanium and niobium - 0.1-0.5%, manganese and silicon - from 1% or more.

The impact of alloying additives in any case is associated with distortion of the iron crystal lattice and the introduction of foreign atoms of a different size into it.

How is it easier to decipher steels (materials science)? The table provides useful information.

| Element | Designation | Chem. sign | Influence of an element on the properties of metals and alloys |

| Nickel | N | Ni | Nickel imparts corrosion resistance to alloys through strengthening the bonds between the nodes of the crystal lattice. The enhanced hardenability of such alloys determines the stability of properties over a long period of time. |

| Chromium | X | Cr | Improvement in mechanical properties - increased strength and yield - is due to an increase in the density of the crystal lattice |

| Aluminum | YU | Al | It is fed into the metal stream during casting for deoxidation, most of it remains in the slag, but some of the atoms pass into the metal and distort the crystal lattice so much that this leads to a multiple increase in strength characteristics. |

| Titanium | T | Ti | It is used to increase the heat resistance and acid resistance of alloys. |

Features of steel marking

Structural steels

Conventional steels contain carbon. The presence of alloying elements is not controlled. In practice, structural steels of ordinary quality are most often used. They are used everywhere. They are used for the production of rolled metal. Designated by indicating the approximate carbon content of the alloy. The most common brands are shown in table. 1.

Table 1: Chemical composition and markings on the ends of rolled metal of structural steel of ordinary quality

| steel grade | Carbon content, % | Limit sulfur content (no more), %. Determined by analysis results | Permissible phosphorus content (no more), %. Determined by analysis results | Color marking on the end of the rolled metal |

| St0 | 0,12±0,07 | 0,070±0,005 | 0,055±0,005 | White |

| St1 | 0,09±0,03 | 0,045±0,005 | 0,055±0,005 | White + yellow |

| St2 | 0,12±0,03 | 0,045±0,005 | 0,055±0,004 | Yellow |

| St3 | 0,18±0,04 | 0,045±0,004 | 0,055±0,004 | Red |

| St4 | 0,22±0,04 | 0,045±0,004 | 0,055±0,004 | Red + green |

| St5 | 0,32±0,05 | 0,045±0,004 | 0,055±0,003 | Green |

| St6 | 0,43±0,06 | 0,045±0,003 | 0,055±0,003 | Blue |

| St7 | 0,56±0,06 | 0,045±0,003 | 0,055±0,003 | Blue + white |

Alloy steel

Alloying additives improve performance. Each element has a specific letter. It indicates what percentage of a particular substance is present in the composition of a complex alloy (Table 2).

Table 2: Alloying elements in the alloy composition

| № | Marking of elements in steels | Chemical name | Chemical element designation | № | Marking of elements in steels | Chemical name | Chemical element designation |

| 1 | L | Beryllium | Be | 14 | D | Copper | Cu |

| 2 | R | Bor | B | 15 | Gl | Gallium | Ga |

| 3 | A | Nitrogen | N | 16 | E | Selenium | Se |

| 4 | Sh | Magnesium | Mg | 17 | C | Zirconium | Zr |

| 5 | YU | Aluminum | Al | 18 | B | Niobium | Nb |

| 6 | WITH | Silicon | Si | 19 | M | Molybdenum | Mo |

| 7 | P | Phosphorus | P | 20 | CD | Cadmium | Cd |

| 8 | T | Titanium | Ti | 21 | IN | Tungsten | W |

| 9 | F | Vanadium | V | 22 | And | Iridium | Ir |

| 10 | X | Chromium | Cr | 23 | AC | Lead | Pb |

| 11 | G | Manganese | Mn | 24 | In and | Bismuth | Bi |

| 12 | TO | Cobalt | Co | 25 | H | Rare earth metals | |

| 13 | N | Nickel | Ni |

In table 3 shows the most common steel grades.

yKYUYAYAHTHYUZHKH LYUPYHPNBYU YARYUKEY, VSTSSMNB X PUGKHVMSHU YAOKYUBNB

yKYUYAYAHTHYUZHKH LYUPYHPNBYU YARYUKEY, VSTSSMNB X PUGKHVMSHU YAOKYUBNB

Yufdnls Hmfemeps Yanbepemmmn Menaundhln Gmeure Yokuyayyuzhchch X Lupyhpnbys Lyuphukyuknb, Oddmyugmyugmyumsha dk Khtznbkemh deruyukei Luykhm x yunmyarpsyzhhi. th VHYAKS RYUKHU LYUREPHYUKNB NRMNYARRYA LERYUKKSH X HU YAOKYUBSH, LERYUKKKHVEYAYHE X LERYUKKNYEPYULHVEYAYHE ONPNNYYKH OKYUYARLYAYASH, PEGHMYU, YAREIKN, YEPYULHYU, DPEBEYAMSHE X DP. MELERYUKKKHVEYAYHE BEYYARBU. MYUKHANKEE UBNYNE PUYAOPNYARPUMEMHE B YUVEYARBE YNMYARPSYZHNMMSHU LYUREPHYUKNB B MUYARNYEE BPEL ONKSVHKH LERYUKKSH X HU YAOKYUBSH, ONSHRNLS B MUYARNYEI PUANRE ASDSR PU YAYALNRPEMSH RNAEIN YARYUKH, VSTSSMSH KH ZBERMSHE LERYUKKSH, X HU YAOKYUBSH (LEDE, YUKCHLHMKHI, RKHRUM, LYUTSMKHI X YAOKYUBSH MU KH NYAMNBE).

I yKYYYYAHTHYUZHHH LYUPYHPNBYU YARUKEY

YARYUKLKH OPKHMRRN MYUGSHBURE YAOKYUBSH FEKEGYU I STCKEPNDNL, YANDEPFYUMKHE DN 2.14% STCKEPNDYU. yPNLE RNTS, B YANYARYUB YAOKYUBYU NASHVMN BUNDIR LYUPTSUMEZH, YPELMKHI, YAEPYU H TNYATNP; MEINRNPSHE SHKELEMRSH LNTsSR ASHR BBEDEMSH DK SKSVIEMKH THGKHYN-UHLKHVEYAYKHU YABNIYARB YAOEZHHYUKEMN (KETSKHPSCHYKHE SHKELEMRSH).

YARYUKH, YKYYYYAHTHZHHPSCHR ON YAYULSHL PUGKHVMSHL OPHGMYUL. lSH PUYAYALNRPHL YAKEDSCHYHE:

1. uHLHVEYAYKHI YANYARYUB.

b GYUBKHYAHLNYARKH NR UHLHVEYAYNTSN YANYARYUBYU PUGKHVYUCHR YARYUKH STSKEPNDHYARSHE (tsnyar 380-71, tsnyar 1050-75) X KETSKHPPNBUMMSHE (tsnyar 4543-71, tsnyar 5632-72, tsnyar 14959-79). b YABNCH NVEPEDE STSKEPNDHYARSHE YARYUKH LNTsSR ASHR:

A) LYUKNSTSKEPNDHYARSHLH, R. E. YANDEPFYYHLH STSKEPNDYU LEMEE 0.25%;

a) YAPEDMETSKEPNDHYARSHLH, YANDEPFUMHE STSKEPNDYYANYARYUBKJER 0.25-0.60%

B) BSHYANINTSKEPNDHYARSHLH, B YNRNPSHU YNMZHEMPYUZHH STSKEPNDY OPEBSHUER 0.60% kETSKHPNBUMMSHE YARYUKKH ONDPYUGDEKCHR MU: Yu) MKHGYNKETSKHPPNBYUMMSHE YANDEPFYUMKHE KETSKH PSCHYKHU SHKELEMRNB DN 2.5% A) YAPEDMEKETSKHPNBUMMSHE, B KHU YANYARYUB BUNDIR NR 2.5 DN 10% KETSKHPSCHYKHU SHKELEMRNB; B) BSHYANYNKETSKHPNBUMMSHE, YNRNPSHE YANDEPFYUR YABSHYE 10% KETSKHPSCHYKHU SHKELEMRNB.

2. mYUGMYUVEMHE. ON MYUGMYUVEMKHCH YARYUKKH ASHBUCHR: 1) YNMYARPSYZHNMMSHE, OPEDMYUGMYUVEMMSHE DK KHGTSNRNBKEMKH YARPNHREKEMSHU KH LYUHMNYARPNHREKEMSHU KHDEKKHI. 2). schRH YARYUKH YANDEPFYUR ANKEE 0.65% SCKEPNDYU. 3) I NYANASHLH THGHHVEYAYHLH YABNIYARBYULH, MYOOPHLEP, I NOPEDEKEMMSHLH LYUTSMHRMSHLH UYUPYUREPHYARKHYULH XKH LYUKSHL YNSHTTHZHEMRNL KKHMEIMNTSN PYYYAHPEMKH: SCHKEYRPNREUMKHVEYA YUYARYUKE, YASOEPHMBYUP. 4) I NYANASHLH UHLHVEYAYHLH YABNIYARBYULH, MYOOPHLEP, MEPFUBECHYKHE, FYUPNYARNIYKHE XKH FYUPNOPNVMSHE YARYUKH.

3. JUVEYARBN. b GYUBKHYAHLNYARKH NR YANDEPFYUMKH BPEDMSHU OPHLEYAYEI: YAEPSH X TNYATNPYU-YARYUKH ONDPYUGDEKCHR MU: 1. yaRYUKH NASHYMNBEMMNTSN YUVEYARBU, YANDEPFYUMKHE DN 0.06% YAEPSH X DN 0, 07% TNYATNPYU. 2. yYUVEYARBEMMSHE - DN 0.035% YAEPSH X TNYATNPYU YUFDNTSN NRDEKEMN. 3. bSHYANNYYUVEYARBEMMSHE - DN 0.025% YAEPSH X TNYATNPYU. 4. nYANANBSHYANNYYUVEYARBEMMSHE, DN 0.025% TNYATNPYU X DN 0.015% YEPSH.

4. yaREOEME PYYAYHYAKEMH. 4. ON YAREOOEMH SDYUKEMH YHYAKNPNDYU HG YARYUKH, R. E. ON YAREOOEMH E╦ PUYAYHYAKEMKH, YASYYARBSCHR:

1) YAONYNIMSHE YARYUKH, R. E., ONKMNYARECH PYYAYHYAKEMMSHE; RYUHE YARYUKH NANGMYUVYUCHRYA ASYBYULH ⌠YAO■ B YNMZHE LYUPYKH (HMNTsDU ASYBSH NOSYAYUCHRYA);

2) YHOYKHE YARYUKH - YAKYUAN PYYAYHYAKEMMSHE; LYUPYHPSCHRYA ASYBYULH "YO";

3) ONKS YAONYNIMSHE YARYUKH, GUMKHLYUCHYHE OPNLEFSRNVMNE ONKNFEMHE LEFDS DBSL OPEDSHDSYHLH; NANGMYUVYUCHRYA ASYBYULH "OYA".

YARYUKE NASHYMNBEMMNTSN YUVEYARBU ONDPYUGDEKERYA YEH OH ONYARYUBYUL MU 3 TsPSOOSH:

1) YARYUKE TsPSOOSH yu ONYARYUBKERYA ONRPEAHREKIL ON LEUUMHVEYAYHL YABNIYARBYUL

(RYUYU YARYUKE LNFER HLERE ONBSHYEMMNE YANDEPFUMHE YAEPSH HKKH TNYATNPYU);

2) YARYUKE TSPSOOSH a - OH UHLHVEYAINLS YANYARYUBS;

3) YARYUKE TsPSOOSH b - I TSYUPYUMRHPPNBUMMSHLH LEUUMHVEYAYHLH YABNIYARBYULH X UHLHVEYAYHL YANYARYUBNL.

b GYUBHYAHLNYARKH NR MNPLHPSELSHU ONYUGYUREKEY (OPEDEK OPNVMNYARKH ?, NRMNYAHREKEMNE SDKHMEMKHE ?%, OPEDEK REISVEYARKH ?R, KhGTSHA B UNKNDMNL YANYARNJMHH) YARYUKE YUFDNI TsPSOO SH DEKHRYA MU YURETSNPKHKH, YNRNPSHE NANGMYUVYUCHRYA YUPYUAYAYKHLKH ZHTPYULKH.

YARYUKH NASHYMNBEMMNTSN YUVEYARBU NANGMYUVYUCHR ASYBYULH "yaR" X SYAKNBMSHL MNLEPNL LYUPYKH (NR 0 DN 6) B GYUBHYAHLNYARKH NR UHLHVEYAYNTSN YANYARYUBYU X LEUUMHVEYAYKHU YABNIYARB. VEL BSHYE YANDEPFYUMKHE STSKEPNDYU KH OPNVMNYARMSHE YABNIYARBU YARYUKH, REL ANKEYE E╦ MNLEP. aSYBU "ts" ONYAKE MNLEPYU LYUPYKH SYUGSHBUER MU ONBSHEMMNE YANDEPFYUMHE LYUPTSYUMZHYU B YARYUKH. OEPED LYUPYNI SYUGSHBUCHR TsPSOOS YARYUKH, OPHVEL TsPSOOYU "yu" B NANGMYUVEMKHH LYUPYKH YARYUKH ME YARYUBHRYA. dK SYUGYUMKH YURETSNPKH YARYUKKH Y NANGMYUVEMKHCH LYUPYKH DNAYUBKCHR MNLEP B YNMZHE YANNRBERYARBSCHY YURETSNPKHH, OEPBSCH YURETSNPKHCH NASHVMN ME SYUGSHBUCHR. mYOOPHLEP:

YAR1YO2 - STCKEPNDHYARYUKE NASHYMNBEMMNTSN YUVEYARBU, YHOYYYU, ╧ LYUPYKH 1, BRNPNI YURETSNPKHKH, ONYARYUBKERYA ONRPEAKHREKL ON LEUUMHVEYAYHL YABNIYARBU L (TSPSOOYU);

BYAR5ts — STSKEPNDHYARYU YARYUKE NASHYMNBEMMNTSN YUVEYARBU I ONBSHYEMMSHL YANDEPFYUMHEL LYUPTSYUMZHYU, YAONYNIMYU, ╧ LYUPYKH 5, OEPBNI YURETSNPKHH I TSYUPYUMMRKHPNBUMMSHLH LEYU MHVEYAYHLH YABNIYARBYULH X UHLHVEYAYHL YANYARYUBNL (TSPSOOYU b);

bYAR0 - STSKEPNDHYARYU YARYUKE NASHYMNBEMMNTSN YUVEYARBU, MNLEP LYUPYKH 0, TsPSOOSH a, OEPBNI YURETSNPKHH (YARYUKH LYUPNY yaR0 X aYAR0 OH YAREOOEMH PUYAYHYAKEMKH ME PUGDEKCHR). yYUVEYARBEMMSHE YARYUKH LYUPYKHPSCHR YAKEDSCHYHL NAPYUGNL: 1) B MYUVYUKE LYUPYKH SYUGSHBUCHR YANDEPFYUMHE STSKEPNDYU ZHTPNI, YANNRBERYARBSCHYEI ETSN YAPEDMEI YNMZHEMRPUZHHH; Yu) B YANRSHU DNAKU OPNZHMRYU DKK YARUKEYI, YANDEPFYUYKHU DN 0.65% STSKEPNDYU;

05YO √ YARYUKE STSKEPNDHYARYU YUVEYARBEMMYU, YHOYYYU, YANDEPFHR 0.05% i;

60 √ YARYUKE STSKEPNDHYARYU YUVEYARBEMMYU, YAONYNIMYU, YANDEPFHR 0.60% i; A) B ACTIVITY OPNZHEMRYU DK KHMDSYARPHYUKEMSHU YARYUKEY, YNRNPSHE DNONKMHREKEMN YAMYUAFYUCHRYA ASYBNI “with”:

s7 √ STSKEPNDHYARYU KHMYARPSLEMRYUKEMYU, YUVEYARBEMMYU YARYUKE, YANDEPFYUYYU 0.7% I, YAONINMYU (BYAE KHMYARPSLEMRYUKEMSHE YARYUKH UNPNN PYYAYHYAKEMSH);

s12 - STSKEPNDHYARYU KHMYARPSLEMRYUKEMYU, YUVEYARBEMMYU YARYUKE, YAONYNIMYU YANDEPFHR 1.2% i; 2) KETSKHPSCHYKHE SHKELEMRSH, BUNDYKHE B YANYARYUB YARYUKH, NANGMYUVYUCHR PSYAYAKHLH ASYBYULH:

yu √ YUGNR y √ YNAYUKER r √ RKHRYUM a √ MHNAKHI l √ LNKKHADEM t- BYUMUDHI

b √ BNKETPYUL m √ MKHYEKE u √ UPNL c √ LYUPTSUMEZH o √ TNYATNP g √ ZHKHPYNMHI d √ LEDE p √ ANP h √ YUKCHLHMHI e √ YAKEM I √ YPELMHI v √ PED YNGELEKEMSHE LERYUKKSH

eYAKKH ONYAKE ASYBSH, NANGMYUVYUCHYEI KETSKHPSCYKHI SHKELEMR, YARNHR ZHTPYU, RN NMJU SYUGSHBUER YANDEPFYUMKHE SCHRNTSN SHKELEMRYU B OPNZHEMRYUU. eYAKKH ZHTPSH MER, RN YARYUKE YANDEPFHR 0.8-1.5% KETSKHPSCHYETSN SCHKELEMRYU, GY HYAYKCHVEMHEL LNKKHADEMYU KH BYUMYUDKH (YANDEPFYUMKHE YNRNPSHU B YANKYU NASHVMN DN 0.2-0.3%), Yu RÜYFE ANPYU (B YARYUKH I ASYBNI p ECN DNAFMN ASHRE ME LEE 0.0010%). oPHLEPSH:

14ts2 √ MHGYN KETSKHPNBUMMYU YUVEYARBEMMYU YARYUKE, YAONYNIMYU, YANDEPFHR OPHAKKHGHREKEMN 14% STSKEPNDYU KH DN 2.0% LYUPTSYUMZHYU.

03у16м15л3а — BSHYANYN KETSKHPNBUMMYU YUVEYARBEMMYU YARYUKE, YAONYNIMYU YANDEPFHR 0.03% C, 16.0% Cr, 15.0% Ni, DN g, 0% lN, DN 1.0% Nb.

bSHYANNYYUVEYARBEMMSHE X NYANANBSHYANNYYUVEYARBEMMSHE YARUKH.

LYUPYHPSCHR, RYU FE YUY H YUVEYARBEMMSHE, MN B YNMZHE LYUPYKH BSHYANYYUVEYARBEMMNI YARYUKH YARYUBUR ASYBS Yu, (SHRYU ASYBU B YAEPEDHME LYUPNVMNTSN NANGMYUVEHMKH SYUGSHBUER MU MYUKHVKHE YUGNRYU, YAOEZHHYUKEMN BBED╦MMNTSN B YARYUKE), YU ONYAKE LYUPYKH NYANANBSHYANNYYUVEYARBEMMNI - VEPEG RKHPE ASYBS "b". mYOOPHLEP:

s8yu — STSKEPNDHYARYU KHMYARPSLEMRYUKEMYU BSHYANYN YUVEYARBEMMYU YARYUKE, YANDEPFYUYYU 0.8% STSKEPNDYU;

III . nRDEKEMSHE TSPSOOSH YARUKEY NANGMYUVYUCHR MEYAINKEIN KHMYUVE.

yuPKHYNONDHOMKHYNBSHE YARYUKH LYUPYKHPSCHR ASYBYULH “yu”, ONYAKE YNRNPSHU SYUGSHBYUCHR YANDEPFYUMHE UPNLYU B DEYARSHU DNKYU OPNZHEMRYU:

ьу6 — ІУПХННДХОМХНБУЪ YARYUKE, YANDEPFYUYYU 0.6% UPNLYU;

ьу15ця — УПХИНОНДХОМХНБУЪ YARYUKE, YANDEPFYUYYU 1.5% UPNLYU X NR 0.8 DN 1.5% LYUPTSYUMZHYU X YPELMHЪ.

aSHYARPNPEFSYKHE YARYUKH (YAKNFMNKETSKHPNBUMMSHE) NANGMYUVYUCHR ASYBNI “p”, YAKEDSCHYYU GYU MEI ZHTPYU SYUGSHBUER MU OPNZHMRMNE YANDEPFYUMHE B MEI BNKETPYULYU: p18-ASHYARPNPEF SYYU YARUKE, YANDEPFYUYU 18.0% BNKETPYULYU; p6l5y5-ASHIARPNPEFSYU YARYUKE, YANDEPFYUYYU 6.0% BNKETPYULYU 5.0% LNKHADEMU 5.0% YNANKERYU. yUBRNLYURMSHE YARYUKH NANGMYUVYUCHR ASYBNI "yu" X ZHHTPNI, SYUGSHBUCHYEI YAPEDMEE YANDEPFUMHE STSKEPNDYU B YANRSHU DNKYU OPNZHEMRYU:

yu12 — YUBRNLYURMYU YARYUKE, YANDEPFYUYYU 0.12% STSKEPNDYU (BYAE YUBRNLYURMSHE YARYUKH HLECHR ONBSHEMMNE YANDEPFYUMKHE YAEPSH X TNYATNPYU);

yu40ts — YUBRNLYURMYU YARYUKE I 0.40% STSKEPNDYU H ONBSHYEMMSHL DN 1.5% YANDEPFYUMHEL LYUPTSYUMZHYU.

II yKYYYYAHTHYUZHHH LYUPYHPNBYU VSTSSMNB.

vSTSSMYULH MYUGSHBUCHR YAOKYUBSH FEKEGYU I STSKEPNDNL, YANDEPFYUYHE ANKEE 2.14% STSKEPNDYU. nMH YANDEPFYUR RE FE OPHLEYAKH, VRN H YARYUKE, MN B ANKEYEL YNKKHVEYARBE. b GYUBKHYAHLNYARKH NR YANYARNMKH STSKEPNDYU B VSTSSME, PYUGKHVYUCHR:

aEKSHY VSTSSM, B YNRNPNL BEYAE STSKEPND MYUNDHRYA B YAB'GYUMMNL YANYARNMHH B BHDE YYUPAKHDU, X VSTSSM, B YNRNPNL STSKEPND B GMYUVHREKEMNI YAREOEMKH XKH ONKMNYARECH MYUNDHR YAB YABNANDMNL YANYARNMHH B BHDE TSPUTHRYU, VRN NOPEDEKER OPNNVMNYARMSHE YABNIYARBU YAOKYUBYU, VSTSSMSH ONDPYUGDEKCHR MU: 1) YAEPSHE - OKYYARKHMVYURYU HKKH VEPBENAPYUGMYU TNPLYu TSPUTHRYU; 2) BSHYANYNOPNVMSHE - YUPNBHDMSHHI TSPUTHR; 3) YNBYKHE - UKNOEEEBHDMSHHI TsPYUTHR. VSTSSMSH LYUPYKHPSCHR DBSL ASYBYULKH DBSL ZHTPYULKH, YANNRBERYARBSCHYHLH LKHMHLYUKEMNLS GMYUVEMKHCH BPELEMMNTSN YANOPNRKHBKEMKH?B OPH PUYARFEMXX B loYu-10. YaEPSHI VSTSSM NANGMYUVYUCHR ASYBYULH “yav” (tsnyar 1412-85), BSHIANYNOPNVMSHY - “bv” (tsnyar 7293-85), YNBYKHI - “yv” (tsnyar 1215-85).

yav10 — YAEPSHY VSTSSM I OPEDEKNL OPNVMNYARH OPH PUYARFEMXX 100 loYu;

bv70 — BSHIANNOPNVMSHI VSTSSM I YAHTSLYU BPELEMMSHL OPH PUYARFEMHH 700 loYu;

yv35 - YNBYKHI VSTSSM I ?B PUYAR'FEMHEL OPHLEPMN 350 loyu.

dKЪ PYUANRSH B SGKYU RPEMKH YAN YALUGYNI OPHLEMCHR NRKHBYKH KH YUMRKHTPHYZHNMMNTSN VSTSSMYu yuvya-1, yuvya-6, yuvb-2, yuvy-2 X DP., VRN PYYAHTPNBSHBUERYA YAKEDS CHIKHL NAPUGNL: yuv - YUMRKHTPKHYZHNMMSHI VSTSSM: I - YAEPSHI, b - BSHYANINOPNVMSHI, th - YNBYHI. yu ZHTPSH NANGMYUVYUCHR ONP'DYINBSHI MNLEP YAOKYUBY YANTSKYuYAMN TsnyarS 1585-79.

III YKYYYYAYAHTHYUZHHH LYUPYHPNBYU ZHBERMSHU YAOKYUBNB.

1. LEDE X E╦ YAOKYUBSH.

REUMHVEYAYH VHYARYU LEDE NAKYUDUER BSHYANYHLH OKYUARKHVMNYARECH X YNPPNGHIMNI YARNIYNYARECH, LYUKSHL SDEKEMSHL SHCHKEYRPNYANOPNRKHBKEMKHEL X BSHYANYNI REOKNOPNBNDNNYARECH. ON VHYARNRE LEDE ONDPYUGDEKCHR MU LYUPYKH (tsnyar 859-78):

|lYUPYU |lbvY |MOO |ln |Ml |l2 |lg | |YANDEPFUMHE |99.993 |99.99 |99.95 |99.9 |99.7 |99.5 | |Cu+Ag, ME LEMEE | | | | | | | |% | | | | | | |

ONYAKE NANGMYUVEMH LYUPYKH SYUGSHBUCHR YAONYAN KHTSNRNBKEMKH LEDH: Y - YURNDMYU, A √ AEYA YHYAKNPNDMYU, P - PYYYAYHYAKEMMYU. LEDE NTSMEBNTSN PUTHMKHPPNBYUMKH ME NANGMYUVERYA.

lnnY - REUMHVEYAYH VHYARYU YURNDMYU LEDE, YANDEPFYYYU ME LEMEE 99.99% LEDH X YAEPEAPU.

lg - REUMHVEYAYH VHYARYU LEDE NTSMEBNTSN PYUTKHMHPNBYUMH, YANDEPFHR ME LEMEE 99.5%LEDH X YAEPEAPU.

LEDMSHE YAOKYUBSH PUGDEKCHR MU APNMGSH KYURSMKH. aPNMGSH-SHRN YAOKYUBSH LEDKH I NKNBNL (4 - 33% Sn UNR ASHBUCHR AEG NKNBBMMSHE APNMGSH), YABKHMZHNL (DN 30% Pb), YUKCHLHMHEL (5-11% AL), YPELMHEL (4-5% Si), YASPELNI KH TNYATNPN L ( tsnyar 493-79, tsnyar 613-79, tsnyar 5017-74, tsnyar 18175-78).

kYURSMKH - YAOKYUBSH LEDKH I ZHHMYNL (DN 50% Zn) X MEANKEHLH DNAYUBYULH YUKCHLHMKHЪ, YPELMHЪ, YABKHMZHYU, MKHYEK, LYUPTSYUMZHYU (tsnyar 15527-70, tsnyar 17711-80). LEDMSHE YAOKYUBSH OPEDMYUGMYUVEMSH DK KHGTSNRNBKEMKH DERYUKEY LERNYULH KHRE, MYUGSHBUCHR KHREIMSHHLH, YU YAOKYUBSH, OPEDMYUGMYUVEMMSHE DK K KHGTSNRNBKEMKH DERYUKEY OKYARHVEYAYKH L DETNPPLHPNBYUMHEL - YAOKYUBYULH, NAPYURSHBUELSHLH DYUBKEMHEL.

LEDMSHE YAOKYUBSH NANGMYUVYUCHR MYUVYUKEMSHLH ASYBYULH KH MYUGBYUMKH (aP XKH k), ONYAKE VETSN YAKEDSCHR OEPBSHE ASYBSH MYUGBYUMKHI NYAMNBMSHU SHKELEMRNB, NAPYUGSCHYKHU YAOKYUB, X ZHT PSH, SYUGSHBUCHYKHE YNK-BN SHKELEMRYU B OPNZHEMRYUU. oPHMRSH YAKEDSCHYHE NANGMYUVEMH YNLONMEMRNB YAOKYUBNB:

yu √ YUKCHLHMHI lZH - LYUPTSUMEZH i - YABKHMEZH a - AEPHKKHI

lTs √ LYUTSMKHI YAP √ YAEPEAPN f - FEKEGN l - LSH'EYY

YAS √ YASPELYU y √ YPELMHI m √ MKHYEKE r √ RHRUM

yD √ YUDLHI n √ NKNBN t √ TNYATNP y √ UPNL

g - ZHHMY oPHLEPSH:

aPyu9lZh2k - APNMGYU, YANDEPFYUYYU 9% YUKCHLHMHJ, 2% Mn, NYARYUKEMNE Cu (“k” SYUGSHBUER, VRN YAOKYUB KHREIMSHY);

kzh40lZh3f - KYURSME, YANDEPFYUYYU 40% Zn, 3% Mn, ~l% Fe, NYARYUKEMNE Cu;

aP0t8.0-0.3 - APNMGYU MU PJDS I LEDECH YANDEPFYUYU 8% NKNBYU X 0.3% TNYATNPYU;

kul77-2-0.05 - KYURSME YANDEPFYUYU 77% Cu, 2% Al, 0.055 LSH'E'YU, NYARYUKEMNE Zn (B NANGMYUVEMKHKYURSMKH, OPEDMYUGMYUVEMMNI DK NAPUANRYKH DYUBKEMHEL, OEPBNE VHYAKN S JUGSHBUER MU JANDEPFUMHE LEDH).

b MEYAKNFMSHU ON YANYARYUBS KYURSMU SYUGSHBUCHR RNKEIN YANDEPFUMHE B YAOKYUBE LEDH:

k96 - KYURSME YANDEPFYUYYU 96% Cu X ~4% Zn (RNLOYUY);

kA3 - KYURSME YANDEPFYUYU 63% Cu X -37% Zn.

2. yukchlkhmhi x etsn yaokyubsh.

YUKCHLHMKHI - KETSYKHI LERYUKK, NAKYUDYUCHYKHI BSHYANYHLH REOKN-H SHKHEIRPNOPNBNDMNYARECH, YARNIYKHI Y YNPPNGKHH. b GYUBHYAHLNYARKH NR YAREOEMKH VYUYARNRSH OEPBHVMSHYUKCHLHMKHI YANTSKYYAMN tsnyar 11069-74 ASHBUER NYANANI (yu999), BSHIANYNI (yu995, yu95) X REUMHVEYAYNI VKHYARNRSH (yu85, yu7e, yun x dp.). yukchlkhmhi LYUPYKHPSCHR ASYBNI yu X ZHKhTPYULH, NANGMYUVYUCHYHLH DNAKH OPNZHEMRYU YABSHYE 99.0% Al; ASYBU "e" NANGMYUVUER ONBSHYEMMNE YANDEPFYUMHE FEKEGYU KH ONMHFEMMNE YPELMHЪ. yu999 — YUKCHLKHMHI NYANANI VHYARNRSH, B YNRNPNL YANDEPFHRYA ME LEE 99.999% Al; yu5 — YUKCHLHMKHI REUMHVEYAYNI VKHYARNRSH B YNRNPNL 99.5% YUKCHLHMHJ. YUKCHLHMKHEBSHE YAOKYUBSH PUGDEKCHR MU DETNPLHPSELSHE H KHREIMSHE. RE X DPSTSKHE LNTsSR ASHRE ME SOPNVMELSHE X SOPNVMELSHE REPLHVEYAYNI NAPUANRYNI.

DETNPLHPSELSHE YUKCHLHMHEBSHE YAOKYUBSH UNPNN NAPUAYURSHBUCHRYA OPNYURYNI, YNBYNI, RYULONBYNI. xU LYUPYKH OPHBEDEMSH B tsnyar4784-74. th DETNPLHPSELSHL YUKCHLHMHEBSHL YAOKYUBYUL ME SOPNVMYELSHL REPLNNAPYUANRYNI, NRMNYARYA YAOKYUBSH YAKYARELSH Al-Mn X AL-Mg:ALZH; yLJA; yuLC1; yulTs4.5; yuLC6. yuAAPEBKHYURSPYU BYKCHVUER B YEAA MYUVYUKEMSHE ASYBSH, BUNDYKHE B YANYARYUB YAOKYUBY YNLONMEMRNB X ZHTPSH, SYUGSHBUCHYKHE YANDEPFYUMHE KETSKHPSCHYETSN SHKELEMRYU B OPNZHEMRYUU. th DETNPLHPSELSHL YUKCHLHMHEBSHL YAOKYUBYUL, SOPNVMYELSHL REPLKHVEYAYNI NAPUANRYNI, NRMNYARYA YAOKYUBSH YAHYARELSH Al-Cu-Mg I DNAYUBYULH MEINRNPSHU SHKELEMRNB (DSPYUKCHMSH, YNBNV MSHE YAOKYUBSH), YU RUYFE BSHYANYNOPNVMSHE KH FYUPNOPNVMSHE YAOKYUBSH YAKNFMNTSN UHL.YANYARYUBYU. dSPYUKCHLHMSH LYUPYHPSCHRYA ASYBNI "d" X ONP'DYNBSHL MNLEPNL, MUOPHLEP: d1, d12, d18, yu4, yu8. VKHYARSHI DETNPLHPSELSHI YUKCHLHMKHI NANGMYUVYUERYA ASYBYULH "yud" X SYAKNBMSHL NANGMYUVEMHEL YAREOEMH ETSN VHYARNRSH: yudNV (>=99.98% Al), yud000(>=99.80% yl), yd0(99.5% yul), yud1 (99, 30% Al), iud(>=98.80% iul).

kKHREMSHE YUKCHLHMHEBSHE YAOKYUBSH (tsnyar 2685-75) NAKYUDYUER UNPNNYEI FKhDYN- REISVEYARECH, HLEER YAPYUBMHREKEMN ME ANKESCH SYYUDYS X OPEDMYUGMYUVEMSH B NYAMNBMNL DK TYUYANMMNTSN KHREJ. schRKH YAOKYUBSH LYUPYHPSCHRYA ASYBYULH "yuk" I ONYAKEDSCHYHL ONP'DYNBSHL MNLEPNL: yuk2, yuk9, yuk13, yuk22, yukgn.

xMNTsDU LYUPYHPSCHR ON YANYARYUBS: yuy7l2; yuy21l2, 5m2.5; yuy4lzh6. b SCHRNL YAKSVUE "l" NANGMYUVUER LEDE. “th” - YPELMHI, “zh” - ZHMY, “m” - MKHYEKE; ZHTPYU - YAPEDMEE % YANDEPFYUMKHE SHKELEMRYU.

xG YUKCHLHMKHEBSHU YUMRKHTPKHYZHNMMSHU YAOKYUBNB (tsnyar 14113-78) KhGTSNRNBKCHR ONDKHOMHYH X BYKYUDSHYU KHREEL RYU X NAPUANRYNI DYUBKEMKHEL. RYUHE YAOKYUBSH LYUPYKHPSCHR ASYBNI "yu" KH MYUVYUKEMSHLH ASYBYULH BUNDYKHU B MKHU SHKELEMRNB: yu09-2, yu06-1, yum-2.5, yuyalr. b OEPBSHE DBYU YAOKYUBYU BUNDIR B SYUGYUMMNE YNKKHVEYARBN NKNBU H LEDH (OEPBYU ZHTPYU-NKNBN, BRNPYU-LEDE B%), B RPERKHI 2.7-3.3% Ni X B VERBEPRSHY LEDE YASPELYU H REKKSP.

3. rHRYUM X ETSN YAOKYUBSH.

rKHRUM - RSTSNOKYUBYKHI LERYUKK I MEBSHYANYNI OKNRMNYARECH. sDEKEMYU OPNVMNYARE RKHRYUMYU BSHYE, VELS WITH LMNTSKHU KETSKHPNBYUMMSHU YNMYARPSYZHNMMSHU YARYUKEY, ONSHRNLS OPH GULEM YARUKEY RKHRYUMNBSHLH YAOKYUBYULH LNFMN OPH PYUBMNI OPN VMNYARKH SLEMEHRE LYUYAYAS DERYUKH MU 40%. rKHRYUM UNPNN NAPYUAYURSHBUERYA DYUBKEMKHEL, YABUPHBUERYA, HG METSN LNFMN KHCTSNRNBKHRE YAKNFMSHE NRKKHBYKH, MN NAPUANRYU PEGYUMHEL GYURPSDMHREKEMYU. dK ONKSVEMH YAOKYUBNB I SKSVIEMMSHLH YABNIYARBYULH ETSN KETSKHPSCHR YUKCHLHMHEL, UPNLNL, LNKHADEMNL. rKHRYUM KH ETSN YAOKYUBSH LYUPYHPSCHR ASYBYULH "br" KH ONP'DYNBSHL MNLEPNL:

br1-00, brg-1, br4, br8, br14.

oRE RKHRYUMNBSHU YAOKYUBNB NANGMYUVEMSH KHMYUVE:

0r4-0, 0r4, 0r4-1, or-7l, or-3b.

4. LYUTSMKHI KH ETSN YAOKYUBSH.

yaPEDH OPNLSHKEMMSHU LERYUKKNB LYUTSMKHI NAKYUDUER MUHLEMEYEI OKNRMNYARECH (1700 YC/L3). LYUTSMKHI KH ETSN YAOKYUBSH MESYARNIVKHBSH OPNRKHB YNPPNGKHKH, OPH ONBSHYEMKHKH RELOEPYURSPSH LYUTSMKHI KHMREMYAKHBMN NYHYAKERYAKH DUFE YYULNBNYAOKYULEMERYA. nM NAKYUDUER LUKNI OPNVMNYARECH H OKYUYARKHVMNYARECH, ONSHRNLS YUY YNMYARPSYZHNMMMSHI LUREPHYUK VKHYARSHI LYUTSMKHI ME HYAONKEGSERYA. dK ONBSHYEMKH UHLKHYN-LEUUMKHVEYAYKH YABNIYARB B LYUTSMKHEBSHE YAOKYUBSH BBNDYR YUKCHLKHMKHI, ZHHMY, LYUPTSUMEZH KH DPSTSKHE KETSKHPSCHYHE DNAYUBYKH.

LYUTSMKHEBSHE YAOKYUBSH ONDPYUGDEKCHR MY DETNPLHPSELSHE (tsnyar 14957-76) KH KHREIMSHE (tsnyar 2856-79). oEPBSHE LYUPYKHPSCHRYA ASYBYULH "lyu", BRNPSHE "lk". ONYAKE ASYB SYUGSHBUERYA ONP'DYNBSHI MNLEP YAOKYUBYU B YANNRBERYARBSCHYEL Tsnyare. mYOOPHLEP:

lyu1-DETNPLHPSELSHI LYUTSMHEBSHI YAOKYUB ╧1;

lk19-KHREMSHI LYUTSMHEBSHI YAOKYUB ╧19

mHFE OPHBEDEMSH KHMDHBKHDSYUKEMSHE GYUDYUMKH ON PYYYAHTPNBYE LYUPNY YNMYARPSYZHNMMSHU LUREPHYUKNB.

| |lupykh ynmyarpsyzhhnmmshu lurephuknb. | |1|ayaR3YO, 08u20m14ya2, p9, yav25, l006, yuLV3, br1-00, lkg | |2|11у11м2б2лт, ьу30, с11, bv45, аПу9лж2к, юк19, br1-0, лк4 | |3|25utsya yu, p6l5t2y8, 50, yv50, aPyu7lZh15fgm2zh2, y6, nr4-0, lyu1 | |4|45umgltyu, yu9, 20ОЯ, yuvya-4, aP04zh7ya5, yud0e, nr4-1, lyu2 | |5|10u17m13l2r, yu20, yaR6, yuvy-1, aPnt4-0, 25; yukgg, nr-4, lk19 | |6|yaR5tsOYag, 25u13m2, 15YO, yubv-1, kya63-2, yLZh, br5, lk15 | |7|16u11m2blt, yu40ts, yu15, yav10, kyu77-2, d16, br9, lyu18 | |8|45u22m4lg, s 13, byaR2OYA2, bv1yan, l2P, yuk25, br14, lyu15 | |9|31u19m9lbar, p9, 45, yv45, aPyaSgmgzhgya20t, yu8, br16, lk5 | |1|12u18m9r, yu15tsia, yu20, yuvya-5, kzh40lZhgyu, yuk21, br20, lyu17 | |0| | |1|byaR3OYA, 20u, p12, yuvb-2, kflZh59-1-1, yuy4l4, br22, lk6 | |1| | |1|15u60ch, p6l5, s13yu, yuvy-2, kya59-1, d12, or-7l, lk10 | |2| | |1|38u2lchyu, byaR4OYA2, 50ts, yuvya-3, k68, yu5e, or-gb, lyu-12 | |3| | |1|36u18m25ya2, yu30, byaR2YAO, iv60, aPyufmch-4-4, yuk2, br9, lyu11 | |4| | |1|40ultyu, pnlgt2, yug0, bv80,aPyu7lZh15fgm2zh2, yuy9, br5, lk8 | |5| | |1|yaR0, 30u13, p6l5t2y8, yaV15, aPyu9f4m4lZh1, yuLC6, br1-0, lyu21 | |6| | |1|09u16m4a, byaR3ts, yu6, yav18, kzh23yuAfglZh2, d16, br16, lk19 | |7| | |1|45umglt-j, s11, All, bv70, kyul77-2-0.05, yuk23, br5.lyu18 | |8| | |1|14ts2yut, pnl2tg, byaR5YAO, yav24, aP0tA, 5-0, 15; d18, br1-00, lyu19 | |9| | |2|15у7м2р-ь, р6л5т2й8, ьу9, йв63, кй80-3, yuj4л4.br22, лк8 | |0| | |2|byaR1, 50uts, pnlgt2, yuvya-6, aPylZhg-1, yuy7, br20, lk12 | |1| | |2|08u18r1, s10yu, 30ОЯ, bv40, aP06zh6yag, yuk9, or-3b, lyu2 | |2| | |2|p12, 13u14mb2tp, yaR5OYa3, yav20, kzh38lZh2ya2, yLC2, brg, lk4 | |3| | |2|s9, 07u25m13, yu15, yv35, aPyufmlZh9-4-4-1, yud0, br14, lyu20 | |4| | |2|yu11, 20u12bmlt, 25YAO, bv80, kyumylZh75-2-2, 5-0.5-0.5; yu7, br9, lk9 | |5| |