Cutting sheet metal is not an easy task. The material is hard, the sheet format is quite large. Some types of materials (corrugated sheets or metal tiles) cannot be cut with conventional tools - a grinder or a cutting disc mounted on an electric drill. You need a specialized tool that preserves the polymer protective coating and does not form burrs.

To obtain a clean, straight cut without destroying the finish, roller shears are used. This is a tool that has been known for a long time, but is relatively rare in home workshops, since additional devices are required to pull it along a sheet of metal. Let’s take a closer look at the features and types of roller shears.

What it is

Roller or disk shears are a specialized tool for cutting sheet metal into strips of any length and width. In addition, a curved cut is possible (if the design of the tool and the relief of the sheets allow).

Externally, this is a compact device in the form of double rollers, placed one above the other with a slight axial displacement. The edges of the rollers touch each other, ensuring cutting of the material that falls under the influence of the cutting edges.

Cutting metal (or plastic) occurs when the rollers rotate in different directions. Various forms of drive mechanisms are used, both internal motors and external drive mechanisms.

Most hand-held circular shears are available as attachments for an electric drill or screwdriver.

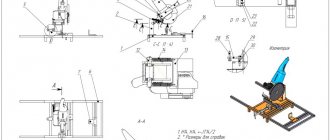

There are also stationary industrial installations that operate on the same principle. As a rule, they are part of production lines and ensure the execution of certain work operations.

Exploitation

When producing a large batch of parts, the sheet is mounted on a workbench. Guides for scissors are installed on it or a template is set. The cutting process begins from the edge of the sheet. A hole is made in solid metal into which the lower disk is inserted. By pressing the scissors down and against the template, the device is moved forward by the handle.

Before starting work, the integrity of the cutting edge is checked and a gap is set, depending on the thickness of the material being processed.

Cutting sheet metal with regular scissors is tedious. It is irrational to use a grinder to cut thin sheets. To do this, you should use metal circular knives.

Purpose and areas of use

Disc shears are used for cutting sheet metal. They are used in home workshops for cutting roofing materials, as well as other types of sheet metal or plastic. They are distinguished by high cutting speed without physical effort. The result is a smooth and clean cut without sharp jagged edges or burrs.

Expert opinion

Torsunov Pavel Maksimovich

Most types of roller shears are designed to cut metal with a maximum thickness of 2 mm. However, the work moves most easily if the thickness of the sheet does not exceed 1 mm (for example, roofing material, corrugated sheets or other types of galvanized rolled metal 0.5-0.8 mm thick).

You can cut different types of material:

steel (regular or stainless, annealed)

copper

aluminum

The tool specifications indicate the maximum thickness of the metal being processed relative to carbon steel. The values declared by manufacturers do not always correspond to practical results. For example, when cutting steel of extreme thickness (2 mm), malfunctions are possible. As a rule, they are caused by excessive hardness of the metal.

Roller shears are used in various fields of technology and industry.

Main Applications:

- production and cutting of roofing materials (for example, seam roofing, corrugated sheets, etc.);

- production and installation of air ducts, elements of ventilation systems;

- auto repair shops, service stations;

- production of housings for household and industrial installations, devices, household appliances.

This list is far from complete, but there is no need to present it in its entirety. The use of roller shears is found in almost all areas of technology and industry, in repair and installation work.

Purpose

In a home workshop, hand-held roller shears are used to cut thin steel sheets, galvanized sheets, and corrugated sheets. Depending on the design, the device allows you to quickly cut strips with smooth edges and cut out shaped parts with smooth contour lines.

In production, roller shears are used for additional processing of edged parts, cutting corrugated sheets during roofing work, and cutting other types of materials. The compact device does not require a special place for operation. Metal roofing material is cut according to markings in any position.

Design

Roller shears operate on the principle of a conventional tool, but their cutting elements are modified and have the shape of two rollers.

They are equipped with sharp cutting edges located in the same plane. Along the axis of rotation, the rollers are directed in different directions. When a sheet of metal is placed between the cutting edges, the material is compressed simultaneously from above and below the sheet, separating the parts that are on both sides of the cut line.

There are roller shears with electric drive and with manual rotation. The first designs are preferable because they do not require the application of physical force. This allows the worker to focus on precise mark cutting, or increase productivity when cutting strips.

Best lever shears

Lever metal shears have a rigid and movable blade. The latter is driven by a long lever that transmits pressure through a gear mechanism. Due to this design, small operator pressure is converted into enormous force. A tool from this rating category can cut sheet iron, rods, squares, corners and strips of metal. But due to their large weight and dimensions, they are only suitable for stationary placement in workshops and factories.

Advantages and disadvantages

The advantages of roller shears include:

- high efficiency, ease of cutting sheet metal and plastic;

- the tool provides a fast and clean cut without burrs or notches;

- work safety;

- small size, light weight;

- ease of setup and operation;

- can cut steel and non-ferrous metals;

- it is possible to choose the appropriate model.

Disadvantages of roller shears:

- the thickness of the sheets is limited, and as the thickness increases, productivity sharply decreases;

- scissors with one cutting element can only perform straight cuts;

- when performing figured cutting, you cannot make contours with a small radius of curvature;

- if processing is done along the internal contour, you have to make a starting hole for insertion.

Despite some disadvantages, roller shears are highly valued by specialists and home craftsmen. The cleanliness of the cut, ease of operation and precision of work far exceed the quality of alternative tools. At the same time, the worker does not have to exert physical effort, which ensures stable quality and high productivity.

The best rebar shears (bolt cutters)

Rebar shears are designed for cutting bolts, rods and reinforcement due to large levers that convert forces from manual squeezing by the operator. The longer the lever, the more powerful the pressure.

KNIPEX KN-7182950

Rating: 4.8

In first place in this rating category is a product from the German company Knipex. The bolt cutter comes in a red color that is easily distinguishable among building materials, so it is easy to find on site. Experts in reviews praise it for its thick handles, which soften the pressure from the levers during operation. The metal part is made of chrome-vanadium alloy and has a rod thickness of 11 mm. The material was additionally oil-hardened to increase strength. The hardness of the cutter is 62 HRC, which not all competitors demonstrate. The cutting part can be set according to the opening width in 12 different positions, which increases productivity during the same type of manipulation.

Our experts included the model in the rating due to the special shape of the headband. Unlike other metal scissors, these cutting jaws are designed for lateral insertion of the part. This makes it easier to use in narrow places, since the master needs to position them not perpendicular to the plane, but parallel. This option is great for working with rolled meshes.

Advantages

- powerful handles, diameter 11 mm;

- flat design of jaws and hinge;

- the metal body is powder coated;

- thick two-component handles.

Flaws

- high price;

- inconvenient to carry around the construction site due to its size;

- weight 4.11 kg tires your hands faster;

- The coating of the handles allows electric current to pass through.

STAYER 2330-090 900 mm

Rating: 4.7

In second place in the ranking are products from the Stayer brand, owned by the German corporation Kraftool. The tool is capable of cutting through non-hardened steel (HRC 20) with a cross-section of up to 1.6 cm in one click. In the case of hardened rods (with a strength of HRC 30), the scissors will cut through a cross-section of up to 1.1 cm. To ensure such strength of the blades, the tool steel was hardened with high-frequency currents. Great force is possible due to the long arms of 90 cm.

We highlighted this model in the rating as the most powerful and suitable for harsh construction conditions. The bolt cutter will cope with thick reinforcement without damaging the jaws. Craftsmen, judging by the reviews, like their reinforced connector, which extends the life of the product despite regular loads. The headband is phosphated, so you can use it in the rain or in damp weather without fear of ruining the expensive device.

Advantages

- there are holes in the handles for tying the lace;

- stop-limiter so as not to crush your fingers;

- adjustment of the degree of closure of the jaws;

- additional coating against corrosion.

Flaws

- weight 5 kg;

- large dimensions;

- high price;

- a perpendicular approach to the part is required (enough space is required).

How to choose the right tool

Choosing roller shears is a task for trained people. It is necessary to take into account your own needs and the specifics of the upcoming work. In addition, it is necessary to analyze the characteristics of models available for sale.

The following factors need to be taken into account:

maximum sheet thickness for this model;

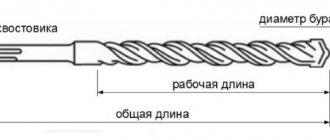

roller diameter;

mobility of knives, type of drive;

number of drive rollers (only the top one or both);

body material.

One of the important points is the possibility and ease of removing the rollers for replacement or sharpening. In addition, you need to pay attention to the method of adjusting the disks and the specifics of setting the gap between them.

The design features of the tool should also be taken into account. There are right and left models (with the top knife positioned on the right or left). They differ only in the location of the cutting elements; all other indicators remain the same.

In addition, sometimes strong rollers are mounted on an unreliable frame, and the strength and power of the support units is insufficient. For an untrained person, it is difficult to determine by eye the degree of reliability of a tool, but any doubts should be interpreted as an important argument against purchasing this model.

Varieties

The cutting tool can be manual or electrically driven. The first cutting tools were used in home workshops, teams of roofers, and car mechanics. Electric models are installed in production.

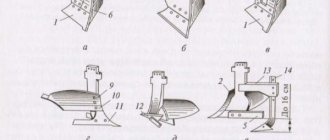

According to the location of the cutting rollers and their mobility, scissors are distinguished:

- with fixed rollers;

- with one movable roller;

- with two rotating knives.

Models with fixed rollers are used for cutting strips in a straight line. The device moves along the ruler, or is fixed motionless and the sheet is pulled through it. Cutting is limited to sheet thickness up to 0.7 mm.

Using tools for cutting sheets with an upper rotating roller, the worker spends 20–30% less effort. The metal slides along the lower support under the rotating round knife. In addition to straight strips, scissors can cut sheets in an arc with a radius of more than 1 m.

Two rotating knives with bevels along the planes forming the cutting edge are capable of cutting complex shaped parts and cutting profiled sheets. The minimum turning radius of models is from 50 mm. Scissors with movable rollers glide easily over metal, cutting it. By running rollers along the markings, complex-shaped workpieces are obtained. For the production of large batches, a template is used.

Scissors with one movable roller

The best manufacturers and models

Roller shears are a specific tool used primarily in small-scale production or professional repair work. Therefore, few manufacturers are engaged in the manufacture of such instruments.

Among them are the following companies:

Makita

This is a well-known Japanese concern that produces a huge range of tools and equipment. Makita roller shears are a whole group of items, including hand tools for cutting metal 0.5 mm thick and stationary machines for cutting sheets up to 4 mm thick;

Bosch

A German company known for the quality and durability of its products. Manufactures universal electric scissors capable of cutting various materials (the main purpose is cutting PVC when installing plastic windows);

Machine ToolSupply

A Russian company that produces mechanical and electrically driven disc shears marked SMR;

Van Mark

A company from the USA produces various types of tools and equipment. Roller shears from this company are reliable and easy to use.

Of the most popular models, it should be noted:

Makita CP100DZ

Universal disc shears for cutting polymer materials, linoleum, PVC or thin metal (up to 0.5 mm). Powered by battery, shaft rotation speed - up to 300 rpm;

BOSCH 0.601.9B2.904

Universal electric shears designed for cutting thin sheet materials (mainly polymer). Working shaft rotation speed - up to 700 rpm;

Holzmann-Maschinen RBS15

Mechanical disc shears with manual drive. The tool is designed for cutting sheet metal up to 1.5 mm thick. The feeding of the sheet to the cutting edges is ensured by a lever with a ratcheting mechanism, which simultaneously ensures rotation of the disks;

NS-1600

Self-propelled disc shears, made in the form of an attachment for an electric drill or screwdriver. Capable of cutting sheet metal up to 1 mm (steel) or 1.5 mm (aluminum) thick. They have the ability to adjust the cutting speed in the range from 0.1 to 25 m/min.

This review deliberately did not consider stationary industrial models, since they have a narrow specialization and can only be used to solve production problems.

The best metal nibblers

Nibblers differ from other types in their ability to cut not a thin line, but a wide strip in one pass. The device cuts material along two lines at once, forming a passage with a width of 1 to 3 mm. In addition, the knives have equipment for breaking chips and removing them, which immediately forms a ready-made hole for installation. Such models from the rating are useful for creating various grooves and cutouts in metal used when installing slopes, ebbs or electrical panels.

KNIPEX KN-9055280

Rating: 4.9

In this rating category, we have identified only one high-quality model from a German manufacturer. The Knipex company has equipped the scissors with double knives that allow you to cut metal with a thickness of 1.2 mm. It will be possible to cut a groove in plastic even with a workpiece thickness of 2 mm. The drive and working part are made of chrome-vanadium alloy, which is not subject to corrosion. On the nose, the manufacturer placed a chipbreaker in the form of a bracket with a protrusion, which ensures a clean cut without additional processing of the edges. The maximum grip width for the model is 2.7 mm. The tool steel was oil-hardened to maintain its edge longer.

Our experts liked the nibblers for their quality and long service life, for which they were included in the rating of the best. With this model, cutting through metal and breaking chips is carried out in one click, which reduces the number of manipulations with the workpiece and does not require further processing. The blades in the model are replaceable, so after their service life is exhausted, you will not have to buy a new tool, but only accessories for it.

Advantages

- trusted manufacturer;

- two-component handle;

- high stops that prevent the hand from slipping;

- built-in chipbreaker.

Flaws

- high price;

- you need to practice a lot on rough blanks to master the work;

- low performance.

Questions and answers

It is normal for questions to arise at the initial stage of getting to know a new tool. At the same time, different people often have the same questions that should be answered immediately.

Let's consider a few of the most common points that will help remove misunderstandings when choosing or using roller scissors:

What to choose, mechanical or electric? What to choose, mechanical or electric driven tools? driven tools?

The hand tool does not require power supply. This allows you to use it in the field without saving battery power. However, using hand tools requires muscular effort, and the quality of cutting is directly related to the physical condition of the worker. The electric drive eliminates these problems and allows you to focus on cutting accuracy, but requires a power supply.

What size rollers do you prefer?

The larger the diameter of the rollers, the easier and cleaner the metal is cut. Therefore, you should choose a tool with a maximum diameter of cutting edges. This choice will increase the operating time without the need for sharpening, reduce the load on the electric drive, and improve the quality of the cut.

Which is better, a hand tool or a stationary machine?

Manual roller shears are mobile and can be used in the field, on a construction site or at any other site. However, a stationary machine has greater productivity and adjustment accuracy. Therefore, it is impossible to say unequivocally which design option is better. Here they choose based on working conditions and quality requirements.

What is the durability of roller shears?

Most manufacturers make cutting edges from hard tool steel. A resource of 25 km for a straight cut with a metal thickness of 0.5 mm is considered the norm. Based on this indicator, you can approximately calculate the durability of the tool for a certain type of material. At the same time, it is necessary to take into account possible additional loads - a curved cut with a complex configuration, heterogeneity and variety of materials.

If you plan to cut curved parts with small radii, which tools are best to choose?

In this case, the best option would be a tool with small diameter rollers. They turn easier at small radii and are not too resistant to changing the direction of the cut. There are few such devices on sale, so it will not be easy to find a tool for this task.

The best hydraulic shears

Hydraulic shears are equipped with a rod inside that is driven by oil pressure. A blade is attached to the end of the piston. The response side is stationary. The working part is made in the form of a C-shape or with long parallel knives. The operator pumps up the pressure manually by operating the handles.

KVT BRG-12

Rating: 4.9

A tool in this category is specific and is useful only under certain conditions, so we have singled out only one model from a Russian manufacturer in the ranking of the best. Hydraulic shears produce a force of 5 tons, so they can easily cut rebar, square or rod with a diameter of 12 mm. To do this, they have an inflating handle and a cylinder with a piston. The entire body is metal (except for the second handle), which reduces the likelihood of damage if dropped. To quickly relieve pressure, there is a valve with labeled arrows. It is convenient to transport the scissors from site to site in the plastic case included in the kit.

The experts in the reviews like that the product is not subject to mandatory certification according to technical regulations (an official letter from the manufacturer on the sellers’ website), so its use is not limited in any way at facilities subject to state control. And our experts liked the product because it is easy to cut reinforcement with a cross-section of up to 12 mm, which is practical when tying armored belts during construction work. This will not require stringing power lines to the top of the building, and hydraulics will protect your hands from overwork.

Advantages

- valve for quick pressure release;

- durable body;

- cutting force 5 tons;

- practical transport case.

Flaws

- uncomfortable handle;

- the work proceeds slowly (pressure needs to be pumped up);

- The hand gets tired faster from the weight of 2.3 kg.

Electrical appliance

Electric tools make metal cutting easier and faster. There are two types of electric scissors: nibblers and knife scissors. Nibblers or nibblers are used when cutting profiled metal and are used as shears for metal tiles. They do not jam the material being cut and do not spark during operation.

The punching tool can also make cuts in the center of the sheet. To do this, a hole is first made in the workpiece, and from there the cutting edges begin cutting. This tool is called poisson shears because the cutting is done with a moving poisson. Nibblers for cutting metal tiles can also be used as an attachment for an electric drill.

Knife tools are divided into two types: slotted and sheet. Both of them have fixed lower knives and movable upper ones. The upper knives are driven by an electric motor. The only difference is the profile of the lower blades.

Sheet ones have two cutting edges, while slotted ones have three. The two lower ones are installed motionless at a certain distance from each other, and the upper one fits between them when cutting.