What are metal scissors

From the name it becomes clear for what purposes the devices in question are intended. Like regular scissors, metal cutting devices are designed only for working with sheet materials. It is impossible to cut pipes, angles and profiles with metal cutting devices, since they are not designed for this, and simply will not cope with this task.

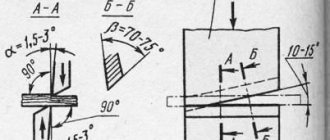

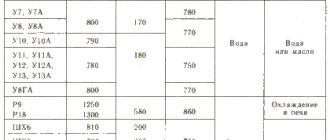

Structurally, hand-held metal scissors consist of handles and cutting knives. The mobility of the knives is ensured by the mounting bracket. The sharpening angle of cutting knives is 60-75 degrees. This sharpening angle ensures high performance with minimal effort. The large sharpening angle means that the tool can be used for cutting hard metal sheets. The knives in relation to the handle are located at an angle of 7 to 12 degrees.

The knives of the tools in question are made of alloy (chrome-vanadium) or tool steel, which has a positive effect not only on the quality of the cut, but also on the service life. When the blades on knives become dull, they can be sharpened. The tool handles are covered with plastic, rubber or silicone material for ease of work.

This is interesting!

Many people use hand-held metal shears to cut thin sheet metal, such as galvanized sheets or corrugated sheets, and do not know that there are different types of such tools. Depending on the task at hand, it is necessary to select the appropriate type of tool.

"Penknife"

Working on the abdominal muscles in the “Penknife” exercise affects all muscle groups: abdominals, rectus and oblique muscles.

To begin the exercise, you need to lie on your stomach, keeping your legs extended as far as you can, while keeping your arms straight and extended above your head. Next, lift your chest and legs, trying to support your legs on your hands. After this, carefully return to the starting position, and then repeat this exercise ten times.

If you find it difficult to perform the exercise, lift your legs one at a time, alternating them.

Types of tools

Before you buy hand scissors for cutting thin sheet material, you need to understand their types. To carry out the relevant work on processing sheet steel, you need to take the appropriate tool, which will allow you to achieve the necessary results. What are the devices in question or their types, we will find out further.

- A straight cutting tool is the simplest type of device, which is designed for cutting large circles and straight cutting of material

- Mechanical with curved blades - used for cutting holes, as well as for obtaining cuts of different shapes

- Finger blades with thin blades - used to produce cuts of various shapes. The blades on finger scissors have different positions relative to each other. It follows that tools are divided into left and right, and depending on the task at hand, it is necessary to use the appropriate type of device

- Chair saws - used for cutting thick sheet steel. They cope with steel thicknesses up to 2-3 mm. When cutting thick sheet steel, effort must be made, so the design of the devices has a special bend. This bend is necessary in order to hook the tool to the workbench, thereby ensuring that the upper handle is pressed with high force, increasing the cutting force

- Power - another type of device for cutting sheet metal with a thickness of 2.5 mm. Power mechanical scissors consist of two levers, which are fixed using a hinged bracket. Power tool models come with replaceable discs and blades that can be used to cut metal rods up to 8 mm thick

- Lever scissors are professional models of scissors that are attached to a workbench. The design of such devices is such that one blade is movable and the other is fixed. The movable blade is driven by a handle on the tool. They are used for cutting aluminum, steel, copper, brass, etc. The maximum thickness of steel reaches 4 mm, and brass, copper and aluminum up to 8 mm

All types of scissors are divided into professional and amateur. They differ not only in price, but also in quality. Professional models are made from high-quality materials, so they are intended for constant use. They have a long service life and are 2 times cheaper than amateur ones. Amateur ones are intended for infrequent use, since low-grade types of steel are used for their manufacture.

“Reverse” press

When working in this exercise, you will improve the abdominal muscles, rectus abdominis, and oblique abdominal muscles. To perform the exercise correctly, you should lie on your stomach and keep your arms extended along your body. Bend your knees until you form a 90° angle. Raise your torso so that you bring your legs bent at the knees towards your head. Then return to the starting position. Keep your knees bent at all times.

Manual models of metal scissors and their manufacture

The manufacturing process of hand scissors involves the use of two options:

- Forging

- Casting

Models differ in price. Forged devices are much more expensive than cast ones, but they are much more reliable and durable. To make the blade durable, it is subjected to additional heat treatment. Hardening the cutting part prevents dulling of the cutting part, so it is extremely rare to sharpen this type of tool. After sharpening, the blades will dull much faster.

Cast scissors are suitable for farming, they are inexpensive and do an excellent job. With frequent use of scissors, the blade quickly becomes dull, so they need periodic sharpening. This tool can only cut thin sheet steel up to 2 mm.

This is interesting!

The hinge mechanism on hand scissors consists of two parts, which is done specifically to double the applied physical force.

Manufacturers also produce lever products that are made from two different materials. The cutting part is made of high-quality material, which increases their service life. The handles of such devices are made of ordinary steel, which has a positive effect on the cost of the tool. Using lever shears allows you to cut metal without much effort.

When purchasing hand scissors, you need to consider the placement of the knives. They are straight, as well as left and right. Straight ones are designed for smooth cutting, as well as cutting out large round shapes. As for the left and right shapes of the blades, here you need to know the following:

- Left - used to make cuts in the left direction. The left scissors should be used primarily while holding them in the right hand. When working with a tool with left-handed blades, the left side of the blades enters from below

- Right - used when it is necessary to bend to the right side. When working, you should hold such a tool in your left hand. When cutting with scissors, the right side goes under the sheet from below, which allows you to make an even cut

To make it easier to distinguish them, manufacturers paint the handles in different colors. The right scissors are painted green, and the left scissors are painted red. When using hand-held cutting devices, everyone has encountered the fact that when cutting a long sheet, the plane becomes bent and bent. This usually happens when using scissors with a symmetrical arrangement of knives. To prevent creases from forming, when cutting a long sheet of steel, you need to use a tool with asymmetrical knives.

This is interesting!

Instruments with asymmetrical knives are extremely rare on sale.

The reason for such low popularity is their high cost. However, in order to make an even and neat cut, it is recommended to buy just such metal scissors with asymmetrical blades. What can be cut with hand metal scissors:

- Galvanized steel

- Corrugated sheet

- Metal tiles

- Sheet metal

- Steel mesh

- Linoleum

- Rubber

- Ruberoid

The advantage of hand-held metal shears is that they cost 10 times less than power tools.

We pump up the press while lying on a ball

Choose a ball large enough to allow your feet to form a 90-degree angle. Next, sit on the ball and move your legs forward so that your lower back rests on the top of the ball. Place your hands around the back of your head. Raise your body until you feel your abdominal muscles tense and contracted. Return to the starting position. Repeat 10-12 times. It is important not to use your arms to help your upper body complete the exercise. Otherwise, the back muscles will work, not the abdominal muscles!

Imaginary threats: why getting close to another person is stressful

Disinfecting wipes are easy to make at home. They are economical and no less effective

Makeup artist in a hijab: popular bloggers of the East with a huge audience of subscribers

Electric scissors for fast and precise cutting of sheet material

Accuracy and accuracy of cutting with hand scissors is ensured only by choosing the right tool. In addition to manual scissors, manufacturers also produce electric scissors. The power tool does not require any physical effort to cut sheet material, since the electric motor is responsible for this action. There are two types of electric metal shears:

- Punching or die-cutting - structurally they have no resemblance to manual ones

- Knife - similar to hand tools, and their work is ensured by the mobility of one blade

Die-cut

received this name due to their operating principle. They are used for cutting sheets of corrugated sheets and metal tiles. The advantage of such devices is their ease of use and operational efficiency. When cutting through a steel sheet, sparks do not occur, and the roof covering does not deform. That is why it is recommended to abandon the use of an angle grinder when cutting thin-sheet material, replacing it with manual or electric scissors, or even better, buy an attachment for a drill for cutting metal.

Electric cutting scissors can not only cut straight, but also cut out various curly patterns. If you plan to cut a shape in the center of the sheet, then first you need to drill a hole and then install the cutting edge of the scissors into it. They work on the principle of a hole punch, and a movable mechanism—a punch—is responsible for punching through steel. When piercing steel, the knife moves very quickly, so the possibility of deformation and bending of the sheet is excluded.

In addition to cutting (or mortise) scissors, there are also knife scissors

. They are also called sheet or spline. They are very similar to manual ones, only they consist of movable and stationary knives. The movable blade moves due to an electric drive, making reciprocating movements. They are suitable not only for making straight cuts, but also for curved ones.

During operation, such scissors do not create waste, but they have a drawback - they jam the corrugated sheets. It is recommended to use them exclusively for cutting smooth sheet materials such as galvanized sheets, tin, etc. During operation, only the movable cutting knife becomes dull, which must be sharpened and replaced when worn.

Sheet shears have one fixed blade and the other a movable one. Slotted ones differ from them in that they have two fixed knives at the bottom and one movable one at the top. When using spline tools, chips are formed, the size of which does not exceed a few millimeters. The shavings are rounded when working with scissors and go to the side. You can work with a spline tool not only on the smooth surface of sheet materials, but also on corrugated sheets and metal tiles.

Ball exercise

An exercise for the sides of the abdomen using a ball as an exercise machine is very effective. This will strengthen both the internal and external obliques, as the instability of this “machine” forces the muscles to work at maximum levels while we strive to balance our body position. Lie sideways on the right side of your thigh on the ball. Place your left foot on top of your right. Use a wall if you need additional support.

Place your hands behind your head as if you were covering the back of your head, but try not to use them to support your head during the workout. Lift your upper body, “breaking” your side muscles. Slowly return your body to the starting position. Repeat this twelve times. If you find it difficult, limit yourself to nine repetitions. Switch sides and repeat the exercise.

Why do you need guillotine shears?

There is another type of scissors, which also belongs to the group of hand tools. They're called

guillotine, which consist of a frame, as well as a fixed knife and a movable blade. Due to their design, they are also called tabletop or stationary. To cut sheet material, it is necessary to place the sheet on the knife according to preliminary markings. The sheet is cut by lowering the cutting blade.

This type of tool is suitable exclusively for cutting in a straight direction. They are not suitable for circular cutting, so you should choose a tool depending on its purpose. Guillotine shears are used in industry when large volumes of work are performed. Manufacturers also produce hydraulic guillotine tools for cutting pipes, profiles and other compact non-sheet materials.

"Scissors"

This is a great exercise for the abdominal muscles. Lie on your stomach, keeping your arms extended along your body. Smoothly bend your knees and lift them up. Next, bend one leg to a 45° angle. The other leg should be 5 cm above the floor. This is an important note, because if it is not followed, the leg muscles will work, not the abs! Then simply change legs and repeat the exercise.

An interactive “map of undiscovered life” on Earth has been created: 80% remains to be found

How to understand that the soul is tired, not the body. Vacation plan for the soul

“When my mother wakes me up in the morning, but not for school”: children were asked what happiness is

How to choose scissors for cutting metal

Choosing a tool is the most important undertaking, since the purchase determines the ability not only to do the job, but also to do it efficiently. Every craftsman should have a pair of metal scissors in his arsenal. The prices for these devices vary, so you should choose depending on the tasks at hand. If you need to cut reinforcement, it is better to choose hydraulic guillotine shears, and for cutting galvanized sheets, ordinary ones with straight blades are suitable.

Which scissors to choose for the job depends on the technological tasks, so you need to focus on the following parameters:

- The location of the blades is left and right. Depends on what types of cuts you plan to make

- The shape of the blades is straight and curved. Scissors with straight blades are convenient for cutting in a straight direction, and curved blades can be used to make curved and shaped cuts.

- The capabilities of the tool depend on the material from which the device is made. They are cast, forged, and mixed

This is interesting!

Often, a decrease in the performance of scissors occurs not due to dulling of the blades, but due to a violation of the distance between the knives. The distance increases due to the loosening of the hinge joint under heavy loads. To improve the quality of metal cutting, the tool must be periodically adjusted.

Working with hand scissors is not difficult if you choose them correctly for certain jobs. Once you try a power tool in action, you probably won’t want to go back to hand tools. The only advantage of manual devices is that they are not expensive, so it is worth buying them so that you can use them at any time to cut thin-sheet materials. The video below explains in detail how to use the tool in question correctly.

To summarize, it should be noted that the devices in question are manufactured according to the relevant standards GOST 7210-75. To choose the best scissors, you don’t need to look for a rating of the best, since price is an indicator of quality. However, if you do not choose the right tool for the appropriate type of work, then even high quality and high price will not help.

Abdominal muscles

The core of our body only has 3 major muscle groups, and each of them plays an important role when it comes to the appearance of the abdomen and torso. When a person's abdominal muscles are not toned and strong enough, the stomach appears bulging and “loose.” There are straight muscle fibers in the abdominal cavity, which, with good training, will guarantee that you will have a flat stomach.

The oblique external and internal muscles are responsible for the shape of the waist, helping to create the desired silhouette that you would like to have. If you want to get a thin waist and stomach, keep your attention and focus on these three abdominal muscle groups. To do this, you need to perform a combination of static and dynamic training with weights and stretching exercises.

Rospotrebnadzor assessed the possibility of re-vaccination with Sputnik V

We make effective fertilizing for seedlings: waste is put to use

Seedlings will grow by leaps and bounds, literally and figuratively: effective feeding

Stretching the rectus abdominis muscles

Abdominal stretching is a fairly well-known technique among yoga practitioners. This position is called “cobra pose”. It stretches the rectus abdominis muscles very effectively. Lie on your stomach with your hands shoulder-width apart. Use arm strength to lift your upper body while keeping your hips and pelvis on the floor.

Hold this position for 10-15 seconds. Perform it in 5 approaches.