Characteristics of the site

A modern forge shop is a combination of several sections. This includes production and auxiliary departments, warehouses, as well as service and household areas.

If we talk about each individually, then production departments are areas where they prepare parts, as well as rooms where forging hammers and presses, stamping hammers and other main equipment for work are located. Auxiliary areas include workshops that repair main equipment. This also includes power plants, heating plants, laboratories, technical control of finished parts, etc.

The warehouses of the forge shop usually store metal, blanks, forgings, burrs, spare parts, etc.

Functions of the forge shop

Each object poses new and non-trivial tasks for designers. Architects must understand both the complexities of shaping residential architecture and industrial buildings. The design assignment is always created by the customer, in which he lists the basic requirements for the future object and its purpose. A forge shop is a workshop in which metal is forged; it is usually part of mechanical engineering production and consists of several zones or sections:

- warehouse area;

- work production area;

- auxiliary premises;

- office premises.

Figure 1. Forge shop. Author24 - online exchange of student work

Are you an expert in this subject area? We invite you to become the author of the Directory Working Conditions

The main equipment, for example forging hammers and presses, is located in the production department; workshops can be located in auxiliary areas where equipment is repaired in case of breakdown or malfunction. Warehouses are necessary for the temporary storage of metal, blanks, and spare parts.

In production, technology is of particular importance, which must be described in the technical specifications. The technological process is closely related to the cost of production and the cost of one ton of forgings.

Typically the process consists of four stages, first the parts are sorted into blanks of the required length, then the blanks are heated, the metal is machined under high pressure to give the desired shape, and the finished part undergoes final machining.

The most complex and responsible part is the central part of the process; it is important to create conditions for heating the workpiece based on its thermal conductivity.

There are several types of forge shops, the main ones are:

- forging and pressing shop, it is designed for processing heated workpieces;

- the forging and stamping shop operates at machine-building plants; the necessary parts are produced there;

- an auxiliary forge shop, which is used for repairing factory equipment and making tools.

Finished works on a similar topic

Course work Forge shop 430 ₽ Abstract Forge shop 250 ₽ Test paper Forge shop 220 ₽

Receive completed work or specialist advice on your educational project Find out the cost

The production volume of a forge shop can be large, medium or small, and the nature of production can be specialized or general-purpose.

Definition 1

A forging is a metal blank that is an intermediate product. It is processed by forging or hot stamping and can have various shapes, such as a shaft, a ring, a circle or a rectangle.

Figure 2. Forge shop. Author24 - online exchange of student work

Technological process

Today, the forge shop, like any other area of production, needs to develop a technological process for efficient operation. For workshops of this type, there is one main criterion by which the production process is selected. This criterion is the lowest cost per ton of forgings, which will fully comply with the required quality. In second place when choosing the main production technology is the required volume of parts, as well as possible special requirements for the elements.

Most often in a forge shop, the technological process is divided into the following stages:

- dividing the required material into pieces of the required length;

- This is followed by heating the workpiece and its heat treatment;

- processing the material with high pressure to give it the desired shape;

- this is always followed by separation-type processes, after which finishing work is usually required to remove possible burrs and so on.

General characteristics of forging and stamping production

The main technological operations in forging and stamping production are divided into procurement, forging and stamping, finishing and finishing.

To the procurement

This includes the preparation of ingots and rolled products for forging or die stamping (cutting into piece blanks and heating).

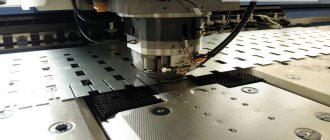

Forging and stamping

are all operations leading to a significant change in the shape of the processed ingot or primary workpiece from the profile. All forging and die forging operations are performed using hammers, presses and specialized equipment, such as forging rollers, rotary crimping and horizontal forging machines.

To the final ones

These include the operations of trimming the burr formed on forgings during open stamping, piercing and punching holes in forgings, and heat treatment.

Finishing

operations include straightening and calibrating forgings, and cleaning them from scale.

Ingots, rolled products of various sections, extruded rods and cast blanks are used as initial blanks for forging and stamping production.

Steel ingots weighing 1.2…50 tons are used for forging. Smaller workpieces are made from high-alloy steels, but not less than 200 kg. For forging, a section profile of a simple geometric shape is also used after cutting it into blanks of the required size. All types of rolled products of normal and high precision are suitable for volumetric stamping. Stamping of cast blanks (autoforge process) is carried out only in cases where it is necessary to improve the tightness of products, for example, elements of the fuel system of a car.

The resistance to deformation of the workpiece during hot deformation is lower than during cold stamping, and the ductility is higher; therefore, by cold deformation, as a rule, forgings of parts weighing less than 40 kg are produced. Metals that, under normal conditions, have a tensile strength < 600 MPa and a relative elongation of at least 12% are used as the initial workpiece for cold die forging.

Almost all grades of steel, aluminum and copper alloys are used to obtain workpieces by pressure treatment. When deforming magnesium alloys, it is necessary to withstand the main deformation modes more accurately, compared to other alloys. Processing of workpieces made of deformable magnesium alloys is carried out at a temperature of 300...400 °C. In the case of hot deformation of titanium alloy workpieces, conditions of protection from interaction with air during heating are of particular importance due to the high chemical activity of titanium at elevated temperatures.

An assessment of the feasibility of using forging or one of the die stamping methods should be carried out taking into account the structural and technological characteristics of the part, the technical and economic indicators of the methods for producing forgings, the equipment available at the enterprise and the requirements for workpieces that ensure their manufacturability during machining.

At the initial stage of solving this problem, it is advisable to take into account the most important criteria that influence the choice of the optimal option for obtaining a forging. Among these criteria we highlight the following:

• batch size of manufactured parts;

• shape and size of forging;

• technological properties of the initial workpiece material;

• accuracy of geometric shapes, forging dimensions and quality of the surface layer.

Heating the material

When working in a forge, increased attention is paid to the process of heating the workpiece. To successfully complete this stage, it is necessary to very accurately determine the thermal conductivity of the material. Thermal conduction refers to the process during which heat passes from the outer walls of the workpiece inward. This parameter depends on the heat capacity and density of the metal. Therefore, the higher this indicator, the faster the heat will penetrate inside, which means the less time it takes to warm up. In addition, thermal conductivity is also affected by the type of metal, its chemical composition and the temperature at which the workpiece is exposed. It is worth noting that most often at temperatures of 700–800 degrees Celsius, the thermal conductivity coefficients of different steels become equal.

Type of workshop

Today there is a forging and pressing shop, which is designed to process already heated workpieces. There are two methods of influence - dynamic or static. If a dynamic processing option is used, then forging or stamping of the material is usually used; for static work, pressing is used.

Work in the forging and pressing shop is carried out using only three types of equipment - hammers, stampings and presses. Heating of the material is usually carried out in either combustion or electric furnaces. It is worth noting that work in such a workshop is quite complicated by the fact that in such rooms there is a heating microclimate. For example, in the warm season, the temperature at a blacksmith’s workplace can be approximately 8–10 degrees Celsius higher than the air temperature. All this should be taken into account when placing furnaces and hammers that create high thermal radiation.

The largest manufacturers in the forgings and stampings market

In Russia there are currently a significant number of factories producing forgings of various weights. This section provides brief information on the main enterprises, with the main focus being on those factories that position themselves as forging and mechanical plants, that is, producing blanks for enterprises from other sectors of the economy. Below are the financial results of activities for 2015, because tax reporting for 2016 has not yet been processed by the tax authorities of the Russian Federation.

PJSC "Ural Forge"

| Name | "URAL FORGE", PUBLIC JOINT STOCK COMPANY |

| Short title | PJSC URALKUZ |

| Date of the latest changes in the Unified State Register of Pools | 29.12.2016 |

| Status according to the Unified State Register of Legal Entities | Current (as of 04/03/2017) |

| Status according to Rosstat | Current (as of 03/01/2017) |

| Date of initial registration | 19.04.1993 |

| Address | 456440, CHELYABINSK REGION, CHEBARKUL G, DZERZHINSKOGO STREET, 7 |

| Telephone | (35168) 9-23-49 |

| Fax | (35168) 9-22-20 |

| [email protected] | |

| OKOPF | Public joint stock companies (12247) |

| OKFS | Private property (16) |

| OKOGU | Privatized enterprises (4210008) |

| Industry | Production of blanks |

| Type of activity (classifier 2001) | Forging, pressing, stamping and profiling; manufacturing of products using powder metallurgy (28.40) |

| Type of activity (classifier 2007) | Forging, pressing, stamping and profiling; manufacturing of products using powder metallurgy (28.40) |

| Type of activity (classifier 2014) | FORGING, PRESSING, STAMPING AND PROFILING; MANUFACTURING PRODUCTS USING POWDER METALLURGY (25.5) |

| Region | Chelyabinsk region |

| OKATO | 75458000000 |

| OGRN | 1027401141240 |

| TIN | 7420000133 |

| OKPO | 07509310 |

| OKONH | 14291 |

| Disclosure Address | www.mechel.ru/investors/enclosure/kuznica/index.wbp |

| Authorized capital | 547 761,00 |

| Number of employees (persons) | from 2501 to 5000 |

Financial indicators

| 2013 | 2014 | 2015 | ||

| year | year | year | ||

| Fixed assets | thousand roubles | 1 307 732 | 1 593 199 | 3 887 576 |

| Current assets, total | thousand roubles | 11 150 062 | 10 112 280 | 14 824 986 |

| Balance currency (asset) | thousand roubles | 14 949 326 | 19 032 191 | 24 210 750 |

| Capital and reserves, total | thousand roubles | 11 567 376 | 14 417 196 | 17 094 184 |

| Long-term liabilities, total | thousand roubles | 1 851 148 | 1 704 579 | 541 444 |

| Current liabilities, total | thousand roubles | 1 530 802 | 2 910 416 | 6 575 122 |

| Revenue (net) from sales | thousand roubles | 13 179 666 | 12 709 275 | 12 509 167 |

| Profit (loss) from sales | thousand roubles | 1 986 418 | 1 916 343 | 1 479 832 |

| Profit (loss) before tax (KSP, SMP) | thousand roubles | 2 282 857 | 2 852 381 | 2 771 683 |

| Net income (loss) | thousand roubles | 2 256 993 | 1 681 150 | 2 676 988 |

Financial ratios

| 2013 | 2014 | 2015 | ||

| year | year | year | ||

| Return on sales | percent | 15,1 | 15,1 | 11,8 |

| Profit margin before tax (profit of the reporting period) | percent | 15,7 | 19,2 | 18,2 |

| Average receivables turnover period | day days | 41 | 63 | 88 |

| Average payables turnover period | day days | 45 | 39 | 44 |

| Provision of own working capital | percent | 86,8 | 71,8 | 56,0 |

| Share of loans and borrowings in short-term liabilities | percent | 0 | 56,6 | 77,9 |

| Current liquidity (total coverage) | once | 7,60 | 3,54 | 2,28 |

| Debt to equity ratio | once | 0,292 | 0,320 | 0,416 |

| Ebit | thousand roubles | 2 386 602 | 3 130 016 | 3 377 889 |

| Ratio of borrowed funds to earnings before interest and taxes (Total debt / EBIT) | once | 0,776 | 1,07 | 1,68 |

OJSC "Ural Forge" is a manufacturer of stamped products from special steels and alloys. It has forging and stamping production based on heavy and super-heavy units, the basis of which is stamping hammers with a mass of falling parts from 2 to 25 tons, and a large bevelless hammer with an impact energy of 150 ton-force, which allows the production of stampings weighing up to 2.5 tons and length up to 4 meters.

The company's product line includes several thousand products weighing from 1 to 2500 kg.

In 2013-2015 stable sales revenue was observed, with a simultaneous increase in net profit.

OJSC Chelyabinsk Forging and Press Plant

| Name | "CHELYABINSK FORGING AND PRESS PLANT", PUBLIC JOINT STOCK COMPANY |

| Short title | PJSC "ChKPZ" |

| Date of the latest changes in the Unified State Register of Pools | 22.02.2017 |

| Status according to the Unified State Register of Legal Entities | Current (as of 04/03/2017) |

| Status according to Rosstat | Current (as of 03/01/2017) |

| Date of initial registration | 16.12.1992 |

| Address | 454012, CHELYABINSK REGION, CHELYABINSK, GORELOVA STREET, 12 |

| Date of foundation | December 1992 |

| Telephone | (351)* 259-45-01 |

| [email protected] | |

| Website | www.chkpz.ru |

| OKOPF | Public joint stock companies (12247) |

| OKFS | Private property (16) |

| OKOGU | Privatized enterprises (4210008) |

| Industry | Production of cars, buses, trolleybuses and trailers for cars and tractors |

| Type of activity (classifier 2001) | Manufacture of parts and accessories for motor vehicles and their engines (34.30) |

| Type of activity (classifier 2007) | Manufacture of parts and accessories for motor vehicles and their engines (34.30) |

| Type of activity (classifier 2014) | PRODUCTION OF SPECIAL PURPOSE VEHICLES (29.10.5) |

| Region | Chelyabinsk region |

| OKATO | 75401368000 (Leninsky) |

| OGRN | 1027402696023 |

| TIN | 7449006184 |

| OKPO | 00231550 |

| OKONH | 14341 |

| Disclosure Address | www.chkpz.ru |

| Authorized capital | 160 057 600,00 |

| Number of employees (persons) | from 1001 to 2500 |

Financial indicators

| 2013 | 2014 | 2015 | ||

| year | year | year | ||

| Fixed assets | thousand roubles | 1 170 182 | 1 071 911 | 1 167 213 |

| Current assets, total | thousand roubles | 3 449 586 | 4 519 641 | 4 492 738 |

| Balance currency (asset) | thousand roubles | 4 863 449 | 5 641 458 | 5 694 786 |

| Capital and reserves, total | thousand roubles | 1 317 214 | 1 459 875 | 1 587 299 |

| Long-term liabilities, total | thousand roubles | 2 315 598 | 2 365 581 | 2 236 375 |

| Current liabilities, total | thousand roubles | 1 230 637 | 1 816 002 | 1 871 112 |

| Revenue (net) from sales | thousand roubles | 4 422 340 | 4 800 304 | 4 867 642 |

| Profit (loss) from sales | thousand roubles | 446 853 | 465 181 | 497 420 |

| Profit (loss) before tax (KSP, SMP) | thousand roubles | 195 986 | 169 407 | 176 883 |

| Net income (loss) | thousand roubles | 140 705 | 141 686 | 126 458 |

Financial ratios

| 2013 | 2014 | 2015 | ||

| year | year | year | ||

| Return on sales | percent | 10,1 | 9,7 | 10,2 |

| Profit margin before tax (profit of the reporting period) | percent | 4,1 | 3,1 | 3,3 |

| Average receivables turnover period | day days | 116 | 140 | 114 |

| Average payables turnover period | day days | 59 | 101 | 99 |

| Provision of own working capital | percent | 64,3 | 59,8 | 58,4 |

| Share of loans and borrowings in short-term liabilities | percent | 38,5 | 29,3 | 33,4 |

| Current liquidity (total coverage) | once | 2,80 | 2,49 | 2,40 |

| Debt to equity ratio | once | 2,69 | 2,86 | 2,59 |

| Ebit | thousand roubles | 427 901 | 447 259 | 560 325 |

| Ratio of borrowed funds to earnings before interest and taxes (Total debt / EBIT) | once | 6,52 | 6,48 | 5,11 |

The company has a significant fleet of forging and pressing equipment:

16 lines of presses with force from 1000 t to 6300 t

All presses are equipped with induction units, as well as pre-forming equipment (rollers), allowing for stamping parts weighing up to 40 kg/piece. and diameter 375 mm.

10 gas condensate compressor lines with capacity from 630 t to 3510 t

All presses are equipped with an induction unit/furnaces for continuous heating and are designed for stamping axle shafts with a diameter of up to 400 mm.

2 hydraulic presses

Hydraulic presses with phosphating line. Currently this line is under construction. After commissioning, it is planned to perform cold extrusion on shafts weighing up to 20 kg.

10 lines of hammers with force 2 - 16 t

All hammers are equipped with pre-forming equipment and induction/gas oven. The 16 t hammer is equipped with a manipulator. The lines can produce forgings up to 450 kg.

Free forging

There is a line with a 5t hammer for free forging. Gas furnaces are used to heat metal. It is possible to produce parts up to 500 kg.

The company produces a wide range of products (forgings) for almost all Russian railway engineering enterprises, the production of tractors and special equipment, buses, as well as for manufacturers of pipeline fittings and drilling equipment.

The company's revenue is stable in 2013-2015.

CJSC "Forging and Mechanical

| Name | "PA" FORGING AND MECHANICAL PA "KMZ IZHORA-METAL" |

| Date of the latest changes in the Unified State Register of Pools | 25.01.2017 |

| Status according to the Unified State Register of Legal Entities | Current (as of 04/03/2017) |

| Status according to Rosstat | Current (as of 03/01/2017) |

| Date of initial registration | 27.05.2008 |

| Address | 192029, SAINT PETERSBURG, NEVSKY DISTRICT, NEVSKAYA ZASTAVA MUNICIPAL DISTRICT, OBUKHOVSKOY OBORONY AVENUE, 86 LITERA K POM 24-N |

| Website | https://kmz-9.ru/ |

| Telephone | (812) 322-82-32 |

| Fax | (812)* 461-11-90 |

| [email protected] | |

| OKOPF | Non-public joint stock companies (12267) |

| OKFS | Private property (16) |

| OKOGU | Organizations established by legal entities or citizens, or legal entities and citizens jointly (4210014) |

| Type of activity (classifier 2001) | Manufacture of other fabricated metal products (28.75) |

| Type of activity (classifier 2007) | Manufacture of other fabricated metal products (28.75) |

| Type of activity (classifier 2014) | PROVISION OF SERVICES FOR FORGING, PRESSING, 3D AND SHEET STAMPING AND PROFILING OF SHEET METAL (25.50.1) |

| Region | Saint Petersburg |

| OKATO | 40285561000 (Nevskaya Zastava) |

| OGRN | 1089847216832 |

| TIN | 7817313733 |

| OKPO | 85579680 |

Financial indicators

| 2013 | 2014 | 2015 | ||

| year | year | year | ||

| Fixed assets | thousand roubles | 28 | 22 | 15 |

| Current assets, total | thousand roubles | 8 427 | 7 108 | 13 732 |

| Balance currency (asset) | thousand roubles | 8 465 | 7 140 | 13 757 |

| Capital and reserves, total | thousand roubles | 1 024 | 1 035 | 4 417 |

| Long-term liabilities, total | thousand roubles | 0 | 0 | 0 |

| Current liabilities, total | thousand roubles | 7 441 | 6 105 | 9 340 |

| Revenue (net) from sales | thousand roubles | 40 481 | 15 295 | 156 586 |

| Profit (loss) from sales | thousand roubles | 898 | 41 | 3 935 |

| Profit (loss) before tax (KSP, SMP) | thousand roubles | 873 | 14 | 4 227 |

| Net income (loss) | thousand roubles | 675 | 11 | 3 382 |

Financial ratios

| 2013 | 2014 | 2015 | ||

| year | year | year | ||

| Return on sales | percent | 2,2 | 0,268 | 2,5 |

| Profit margin before tax (profit of the reporting period) | percent | 2,2 | 0,092 | 2,7 |

| Average receivables turnover period | day days | 26 | 66 | 18 |

| Average payables turnover period | day days | 63 | 146 | 19 |

| Provision of own working capital | percent | 11,7 | 14,1 | 32,0 |

| Share of loans and borrowings in short-term liabilities | percent | 0 | 0 | 0 |

| Current liquidity (total coverage) | once | 1,13 | 1,16 | 1,47 |

| Debt to equity ratio | once | 7,27 | 5,90 | 2,11 |

| Ebit | thousand roubles | 873 | 14 | 4 227 |

CJSC “Forging Mechanical” specializes in the production of press forgings (weight up to 3.0 tons), the production of hammer forgings (weight from 1 kg to 2 tons) from carbon, alloy, stainless steel grades and malleable non-ferrous metals, as well as stampings (weight up to 30 kg), manufactured by hot stamping.

The company's machine park includes the following forging and pressing equipment:

- Hydraulic forging press 1,250 t.p. with manipulator MKRM - 5 with a lifting capacity of 5 tons;

- Forging hammer 3 t.p. with a manipulator with a lifting capacity of 2.0 tons;

- Forging hammer 1.8 t.p. with a manipulator with a lifting capacity of 2.5 tons;

- Forging hammer 2.0 t.s. - 1 pc.; 1.3 t.s. - 2 pcs.; 0.75 t.s. - 1 PC.;

- Hammer stamps. 3 t.s. - 1 PC.; 2 t.s. - 1 PC.; 1 t.s. - 1 PC.;

- Screw arc presses with a force of 250 tons and 630 tons;

- Crank presses with a locking force of 400 t, 160 t and 100 t;

- Friction press with a locking force of 250 tons..

- Thermal heating furnaces.

In 2015, the company significantly increased its revenue by attracting orders for its products.

OJSC "Forging and Press Production"

| Name | "FORGING AND PRESSING PRODUCTION", OPEN JOINT STOCK COMPANY |

| Short title | OJSC "KPP" |

| Date of the latest changes in the Unified State Register of Pools | 19.08.2016 |

| Status according to the Unified State Register of Legal Entities | Current (as of 04/03/2017) |

| Status according to Rosstat | Current (as of 03/01/2017) |

| Date of initial registration | 07.12.1992 |

| Address | 170020, TVER REGION, TVER, ZAVOLZHSKY DISTRICT, PETERSBURG HIGHWAY, D 45 B |

| Website | https://www.aokpp.ru/about.html |

| Telephone | 55-91-61//55-66-43//55-01-00 |

| Fax | 55-09-78 |

| OKOPF | Public joint stock companies (12247) |

| OKFS | Private property (16) |

| OKOGU | Privatized enterprises (4210008) |

| Industry | Production of blanks |

| Type of activity (classifier 2001) | Providing services for forging, pressing, volumetric and sheet stamping and sheet metal profiling (28.40.1) |

| Type of activity (classifier 2007) | Providing services for forging, pressing, volumetric and sheet stamping and sheet metal profiling (28.40.1) |

| Type of activity (classifier 2014) | PROVISION OF SERVICES FOR FORGING, PRESSING, 3D AND SHEET STAMPING AND PROFILING OF SHEET METAL (25.50.1) |

| Region | Tver region |

| OKATO | 28401365000 (Zavolzhsky) |

| OGRN | 1026900507644 |

| TIN | 6902006971 |

| OKPO | 10785930 |

| OKONH | 14291 |

| Disclosure Address | www.tvz.ru |

| Authorized capital | 3 048 900,00 |

| Number of employees (persons) | from 251 to 500 |

Financial statements

| 2013 | 2014 | 2015 | ||

| year | year | year | ||

| Fixed assets | thousand roubles | 62 623 | 56 139 | 63 703 |

| Current assets, total | thousand roubles | 244 496 | 297 228 | 189 623 |

| Balance currency (asset) | thousand roubles | 318 667 | 366 750 | 276 337 |

| Capital and reserves, total | thousand roubles | 255 600 | 259 615 | 219 178 |

| Long-term liabilities, total | thousand roubles | 1 582 | 1 568 | 1 555 |

| Current liabilities, total | thousand roubles | 61 485 | 105 567 | 55 604 |

| Revenue (net) from sales | thousand roubles | 610 091 | 522 701 | 368 640 |

| Profit (loss) from sales | thousand roubles | 25 376 | 8 756 | -49 443 |

| Profit (loss) before tax (KSP, SMP) | thousand roubles | 23 817 | 6 279 | -49 771 |

| Net income (loss) | thousand roubles | 18 016 | 4 015 | -40 437 |

Financial ratios

| 2013 | 2014 | 2015 | ||

| year | year | year | ||

| Return on sales | percent | 4,2 | 1,7 | -13,4 |

| Profit margin before tax (profit of the reporting period) | percent | 3,8 | 1,2 | -13,3 |

| Average receivables turnover period | day days | 91 | 136 | 92 |

| Average payables turnover period | day days | 34 | 66 | 43 |

| Provision of own working capital | percent | 75,4 | 65,3 | 71,3 |

| Share of loans and borrowings in short-term liabilities | percent | 0 | 0 | 0 |

| Current liquidity (total coverage) | once | 4,06 | 2,88 | 3,49 |

| Debt to equity ratio | once | 0,247 | 0,413 | 0,261 |

| Ebit | thousand roubles | 23 817 | 6 279 | -49 771 |

| Ratio of borrowed funds to earnings before interest and taxes (Total debt / EBIT) | once | 0,066 | 0,250 | -0,031 |

The company is engaged in the certified production of forgings, stampings and springs for undercar bogies of passenger cars, as well as production for other types of mechanical engineering (agriculture, tractor building, locomotive building). We specialize in the production of products from carbon and alloy steels.

In 2015, there was a decline in sales and, therefore, a negative profitability of the enterprise.

LLC "Ural Metallurgical Plant"

| Name | "URAL METALLURGICAL PLANT", LIMITED LIABILITY COMPANY |

| Short title | LLC "UMZ", LLC "URAL METALLURGICAL PLANT" |

| Date of the latest changes in the Unified State Register of Pools | 21.11.2016 |

| Status according to the Unified State Register of Legal Entities | Current (as of 04/03/2017) |

| Status according to Rosstat | Current (as of 03/01/2017) |

| Date of initial registration | 16.03.2005 |

| Address | 620010, SVERDLOVSK REGION, EKATERINBURG, KHIBINOGORSKY LINE, 33 |

| Website | https://www.uralmz.ru/ |

| Telephone | (343) 217-48-40 |

| Fax | (343) 217-48-40 |

| OKOPF | Limited liability companies (code OKOPF introduced by Order of Rosstandart dated December 12, 2014 N 2011-st) (12300) |

| OKFS | Private property (16) |

| OKOGU | Organizations established by legal entities or citizens, or legal entities and citizens jointly (4210014) |

| Type of activity (classifier 2001) | Providing services for forging, pressing, volumetric and sheet stamping and sheet metal profiling (28.40.1) |

| Type of activity (classifier 2007) | Providing services for forging, pressing, volumetric and sheet stamping and sheet metal profiling (28.40.1) |

| Type of activity (classifier 2014) | PRODUCTION OF OTHER METAL TANKS, TANKS AND CONTAINERS (25.29) |

| Region | Sverdlovsk region |

| OKATO | 65401390000 (Chkalovsky) |

| OGRN | 1056605199595 |

| TIN | 6674153011 |

| OKPO | 76509568 |

| Authorized capital | 26 000 000,00 |

| Number of employees (persons) | from 251 to 500 |

Financial indicators:

| 2013 | 2014 | 2015 | ||

| year | year | year | ||

| Fixed assets | thousand roubles | 21 178 | 433 334 | 418 360 |

| Current assets, total | thousand roubles | 270 458 | 325 164 | 373 737 |

| Balance currency (asset) | thousand roubles | 338 646 | 791 243 | 833 559 |

| Capital and reserves, total | thousand roubles | 205 868 | 101 565 | 53 466 |

| Long-term liabilities, total | thousand roubles | 18 236 | 462 460 | 466 781 |

| Current liabilities, total | thousand roubles | 114 542 | 227 218 | 313 312 |

| Revenue (net) from sales | thousand roubles | 570 295 | 542 726 | 748 628 |

| Profit (loss) from sales | thousand roubles | 37 592 | -36 511 | 6 393 |

| Profit (loss) before tax (KSP, SMP) | thousand roubles | 38 314 | -124 748 | -63 867 |

| Net income (loss) | thousand roubles | 29 029 | -99 753 | -53 119 |

Financial ratios

| 2013 | 2014 | 2015 | ||

| year | year | year | ||

| Return on sales | percent | 6,6 | -6,7 | 0,854 |

| Profit margin before tax (profit of the reporting period) | percent | 6,5 | -20,6 | -7,0 |

| Average receivables turnover period | day days | 19 | 38 | 36 |

| Average payables turnover period | day days | 75 | 114 | 127 |

| Provision of own working capital | percent | 60,7 | 33,3 | 20,3 |

| Share of loans and borrowings in short-term liabilities | percent | 0 | 15,9 | 11,0 |

| Current liquidity (total coverage) | once | 2,54 | 1,50 | 1,26 |

| Debt to equity ratio | once | 0,645 | 6,79 | 14,59 |

| Ebit | thousand roubles | 38 314 | -120 503 | -45 061 |

| Ratio of borrowed funds to earnings before interest and taxes (Total debt / EBIT) | once | 0,476 | -4,14 | -11,12 |

The company's machine park consists of the following forging and pressing equipment:

- Hydraulic forging press with a force of 20MN. Weight of forgings: from carbon steel grades - up to 6000 kg, from stainless steel grades - up to 2800 kg.

- Hammer with MFC - 0.75 t. Weight of forgings: from carbon steel grades - up to 20 kg, from stainless steel grades - up to 15 kg.

- Open-die forging hammer with MFC - 3.15 tons. Weight of forgings: from carbon steel grades - up to 120 kg, from stainless steel grades - up to 100 kg.

- Hammer with MFC - 5.0 tons. Weight of forgings: from carbon steel grades - up to 350 kg, from stainless steel grades - up to 300 kg.

In this segment, the company has the ability to produce hammer forgings of smooth shafts, bars, plates, cylinders, bushings, disks, nuts, rolling rings, flanges with and without holes and other products.

The company increased sales in 2016, revenue increased by 40% compared to 2014.

VolgaStalProject LLC

| Name | "VOLGASTALPROEKT", LIMITED LIABILITY COMPANY |

| Short title | LLC "VOLGASTALPROEKT" |

| Date of the latest changes in the Unified State Register of Pools | 21.02.2017 |

| Status according to the Unified State Register of Legal Entities | Current (as of 04/03/2017) |

| Status according to Rosstat | Current (as of 03/01/2017) |

| Date of initial registration | 09.09.2005 |

| Address | 603035, NIZHNY NOVGOROD REGION, NIZHNY NOVGOROD, MOSKOVSKY, CHAADAEVA STREET, 1 |

| Telephone | (831) 274-57-41 |

| Website | https://www.vspnn.ru/ |

| [email protected] | |

| OKOPF | Limited liability companies (code OKOPF introduced by Order of Rosstandart dated December 12, 2014 N 2011-st) (12300) |

| OKFS | Private property (16) |

| OKOGU | Organizations established by legal entities or citizens, or legal entities and citizens jointly (4210014) |

| Type of activity (classifier 2001) | Forging, pressing, stamping and profiling; manufacturing of products using powder metallurgy (28.40) |

| Type of activity (classifier 2007) | Forging, pressing, stamping and profiling; manufacturing of products using powder metallurgy (28.40) |

| Type of activity (classifier 2014) | WHOLESALE TRADE OF METALS AND METAL ORES (46.72) |

| Region | Nizhny Novgorod Region |

| OKATO | 22401370000 (Moscow) |

| OGRN | 1055238116218 |

| TIN | 5260156231 |

| OKPO | 78708237 |

| Authorized capital | 1 000 000,00 |

Financial indicators

| 2013 | 2014 | 2015 | ||

| year | year | year | ||

| Fixed assets | thousand roubles | 23 581 | 30 044 | 166 573 |

| Current assets, total | thousand roubles | 395 826 | 547 798 | 574 431 |

| Balance currency (asset) | thousand roubles | 419 407 | 577 841 | 741 201 |

| Capital and reserves, total | thousand roubles | 135 235 | 173 509 | 200 895 |

| Long-term liabilities, total | thousand roubles | 0 | 0 | 992 |

| Current liabilities, total | thousand roubles | 284 172 | 404 333 | 539 314 |

| Revenue (net) from sales | thousand roubles | 560 633 | 688 269 | 638 861 |

| Profit (loss) from sales | thousand roubles | 39 231 | 46 159 | 51 261 |

| Profit (loss) before tax (KSP, SMP) | thousand roubles | 42 352 | 58 813 | 57 689 |

| Net income (loss) | thousand roubles | 31 855 | 38 273 | 27 386 |

Financial ratios

| 2013 | 2014 | 2015 | ||

| year | year | year | ||

| Return on sales | percent | 7,0 | 6,7 | 8,0 |

| Profit margin before tax (profit of the reporting period) | percent | 7,5 | 7,3 | 6,7 |

| Average receivables turnover period | day days | 79 | 35 | 43 |

| Average payables turnover period | day days | 180 | 207 | 312 |

| Provision of own working capital | percent | 28,2 | 26,2 | 16,6 |

| Share of loans and borrowings in short-term liabilities | percent | 0 | 0 | 0 |

| Current liquidity (total coverage) | once | 1,39 | 1,35 | 1,20 |

| Debt to equity ratio | once | 2,10 | 2,33 | 2,69 |

| Ebit | thousand roubles | 42 352 | 58 813 | 57 689 |

The company produces a wide range of products (forgings and stampings):

- Press forgings (hydraulic presses with force 600t.s., 800t.s., 1000t.s., 1200t.s., 2500t.s.) Forgings of round and rectangular cross-section, smooth and with steps, collars and flanges. Diameter (section side) up to 800mm, length up to 10000mm, maximum weight – 8000kg.

- Forgings such as discs and discs with a hole. Outer diameter up to 2000mm, minimum height 150mm, maximum weight – 5500kg.

- Forgings such as rolling rings. Outer diameter up to 2000mm, minimum height 120mm, minimum wall thickness 100mm, maximum weight – 5500kg.

- Forgings such as cylinders with a hole. Outer diameter up to 500mm, length up to 1500mm, minimum wall thickness – 100mm, maximum weight – 3000kg.

- Forgings such as cubes, bars, plates. Maximum weight – 5500kg.

- Forgings produced by hot heading in backing rings. Outer diameter up to 800mm, height up to 800mm, diameter of the stitched hole up to 200mm, maximum weight – 3000kg.

- Forgings of round and rectangular cross-section, smooth and with shoulders, shoulders and flanges. Diameter (section side) up to 250mm, length up to 4000mm, maximum weight – 1000kg.

- Stampings are round in plan (blanks for wheels, gears, counter flanges, shells, pipes). Maximum outer diameter – 400mm, maximum weight – 80kg.

The company shows stable sales in 2013-2015.

LLC "Russian Forging Plants"

| Name | "RUSSIAN FORGING RUSSIAN FORGING IKMZ" includes a forging and press shop, a shop for mechanical and heat treatment of forgings. The workshops are equipped with modern equipment, which includes:

The main types of forgings are: cube, shaft, spindle, plate, solid and holed disks, rings, etc. OJSC "Tyazhstankogidropress"

Financial indicators

Financial ratios

The forging and pressing shop is equipped with hydraulic open-forging presses with a force of 600 tf and 2000 tf and pneumatic hammers with a weight of falling parts of 400 kg and 1000 kg. Presses and hammers produce forgings of various sizes and configurations from steel ingots of grades 10, 15, 20, 25, 35, 45, 20Х, 40Х, 45ХН, 50ХН, 20ХН3А, 30ХН3А:

Heating of ingots, heat treatment of forgings - normalization, annealing, high tempering - in chamber furnaces with a sliding hearth. The company significantly increased sales in 2015 (by 58%). CJSC "Penza Forging and Press Plant"

Financial indicators

Financial ratios

The company produces elliptical bottoms by forging in the range from 3.4 to 575 kg by order of Penzkompressormash OJSC, Penzkhimmash OJSC and other chemical engineering enterprises in the country. In view of this, the company's sales are stable, at the level of 200-250 million rubles per year. Voronezh Forge LLC

Financial indicators

Financial ratios

VKZ "Faber" produces the following products:

|

Mechanical engineering workshops

The forge shop of a machine-building plant can be divided into three types, depending on its purpose.

There are forging and stamping departments at machine-building plants. In this case, the nature of the parts produced will correspond to the selected types of mechanical engineering. This could be automotive, engine manufacturing and other types.

If we talk only about those types of workshops that can be located on the territory of a larger enterprise engaged in mechanical engineering, then there is another type - auxiliary ones. They are mainly used to produce small forgings for main production. They can be used to repair factory equipment in a forge shop and to produce the necessary tools.

Large machine-building plants set up forging and stamping shops on their territory, since they can produce the necessary parts on a large scale. Ancillary species are usually found on the territory of medium or small factories.

Tool and stamping shop of a machine-building plant

2 Master plan

The designed area measures 300x300m. The master plan is made according to the type of in-depth planning, taking into account the location of the site, technological processes, traffic flows and terrain.

The production area of the industrial enterprise is divided into four zones:

- Prezavodskaya, includes auxiliary buildings designed to house administration, medical institutions, laboratories, household buildings, passages, and parking for vehicles.

- Production, in which production workshops for the main and auxiliary purposes are concentrated.

- A utility room in which energy facilities, underground and surface utilities are located.

- A warehouse in which buildings for storing materials, blanks, finished products, transport buildings and structures are located.

On the designed master plan, the connection between individual zones corresponds to the technological process, and the production flow has the shortest extent.

The following buildings and structures are designed in the pre-factory area: a checkpoint, a canteen, a medical facility, an administrative building, a parking lot with a capacity of 120 cars and a railway station. control room The production area houses a tool and stamping shop, repair vehicles and technical equipment. The utility area houses a combined heat and power plant and a power plant.

The plan shows the layout of roads and highways and designs pedestrian and passenger paths that do not intersect with freight paths.

According to the vertical layout, all structures are located in the ground and above-ground zones.

The distances between buildings and structures comply with fire safety standards SNiPa II-A.5-70 and sanitary standards of industrial enterprises (SN 245-71); auxiliary workshops, warehouses and power structures are located near the main workshops served. The production flow of raw materials and finished products is forward and shortest, without counter or return directions; railway tracks and roads were located on the territory according to the nature of the movement of freight flows.

For a clear architectural composition, the correct forms of industrial buildings, the straightness of highways and driveways are observed, the parallelism and perpendicularity of the axes of buildings and structures are maintained, and individual landscaping elements are rationally placed.

The building area is located outside the swampy area, which is not flooded during the spring flood, and does not have large slopes. To drain rain and melt water, a site slope of 0.001-0.003 m is provided. The groundwater level is below the depth of underground devices.

Utility networks, sewers, power cables, and heating lines were installed outside the roadway and not under buildings, taking into account the depth of freezing of the ground. The distance from buildings and structures to the water supply network is at least 5 m, for sewerage at least 3 m.

The master plan was completed in accordance with all requirements in accordance with SNiP II-89-80* “Master plans of industrial enterprises” and GOST 21.508-93 “Rules for the implementation of working documentation for master plans of enterprises, structures and housing and civil facilities”

What is cold forging

This technology is also used in blacksmithing. The main difference from the conventional process is that there is no preliminary stage in which the workpiece is heated to the desired temperature. In this case, only local heating of those areas where the bend needs to be made is allowed. This method is based on the plasticity of the metal.

Any metal has parameters such as bending, tensile and tearing strength. Using these features, it is possible to process metal without preheating it. It is worth mentioning here that due to the absence of exposure to high temperatures on the workpiece, the chemical composition of the steel does not change, and therefore tempering, annealing and hardening may not be carried out.

V.V. Kadannikov expressed serious concern about the future of Russia, about the ways of its further development as an industrial Power, about the strategy for this development. He writes: “It is worthy of special regret that our scientific and technical intelligentsia, with its glorious traditions laid down in the creation of the defense shield of the USSR, the conquest of space, as well as the implementation of many large-scale national economic projects, turned out to be, by and large, on the sidelines of what is happening in country of processes." “The lack of demand for scientific, engineering and technical personnel in the domestic market is partly to blame for both the state and industry leaders” [1]. “Currently, there is almost a unanimous opinion that the positions occupied by Russian industry in the markets for raw materials and low-value products are not strong enough for the necessary economic growth. It is necessary to develop an innovative economy and use scientific and technical potential” [1]. Very significant is his statement that “the era of consumer society, which gave birth to the market economy of the 20th century, is coming to an end. The new century requires new approaches” [2]. It is pleasant to realize that, finally, insight and understanding is beginning that the market economy itself cannot solve the socio-economic, scientific and technical problems of the state with its own hands and for its benefit. V.V. Kadannikov raised a number of problems and posed a number of rhetorical questions that, of course, require their own understanding and resolution: the significance of the “virtual” world, mechanical engineering of the “new” economy, “science and industry: together or separately?” and others. His statement [3] that “mechanical engineering is essentially a branch of industries” is absolutely true. Very important is his appeal to the problem of “increasing the role and status of the engineering corps, reviving and enhancing the country’s intellectual potential”, “increasing the efficiency of our public organizations” [2]. Being an outstanding engineer, industrialist and politician, V.V. Kadannikov competently says that “In the global economy, an increasingly important role is played by those people who are generators and bearers of knowledge - specialists, scientists, designers, i.e. that social group that we usually call the scientific and technical intelligentsia.” “Despite all the losses suffered by the Russian intelligentsia over the past decade, there is no other social group in the country with which one could begin to “Collect Russia” - a new Russia, and not the Russia of the “new Russians.” [1]. “If we want the country to maintain its unity and develop a national competitive advantage in global markets, integration processes at the national level must advance.” “... world experience shows that global competitiveness in any sector, including science, cannot be ensured without having a strong position at the national level” [1]. V.V. Kadannikov invited industry experts to continue discussing the issues raised. Realizing the enormity and exceptional importance of the formulated problems and posed questions [1÷3], we dare to join the discussion and once again express our point of view on this issue. In our opinion, the solution to all the problems and questions raised in articles [1-3] depends on the answer to one single question: what kind of Russia do we want to see in the 21st century: a colony or a Great scientific and technological power? Having taken the first path, onto which Russia’s ill-wishers have been purposefully and deliberately directing all the years of “perestroikas” and “reforms,” we are putting an end to science, technology, industry, mechanical engineering, and education. , and for higher education, and for the engineering corps, and for the intellectual potential of the country. But this is not the Russian way. Therefore, we do not consider the issues raised in this vein. It is necessary to preserve and restore Russia as a Great Scientific and Technical Power, and it is in this spirit that all its problems and ways to achieve this should be considered. Since this discussion arises within the framework of the KShP, KPM and OMD, the problems of this industry should be the main ones. Thesis by V.V. Kadannikov: “mechanical engineering is essentially a branch of industries” [3] needs to be developed and strengthened: the basis of mechanical engineering is the branch of forging and stamping production, forging and press engineering and material processing by pressure [4 - 6]. Indeed, it is known that 50-95% of the parts from which aerospace equipment and weapons are assembled, engines and turbines, surface and underwater vessels, cars, agricultural and road equipment, railway transport facilities, working technological machines, aggregators and complexes, instruments and automation equipment, objects of the construction, oil and gas industry, instruments, household machines and devices, etc., are manufactured in forging and stamping industries of all industries on forging and pressing machines using pressure processing methods of materials [4 -6]. Moreover, the level of mechanical and physical properties, the level of technical and operational characteristics of the mentioned parts, the level of their reliability and durability depend on the level of science, technology, technology of KSHP, KPM and OMD. Finally, which is very important for aerospace engineering objects, it is necessary to obtain maximum service, strength, and operational characteristics in parts of minimal weight. This, as a rule, can only be achieved by pressure treatment of materials. Therefore, to preserve Russia as an industrial Power, we need state and political will and attention to the core - the basis of all mechanical engineering - KShP, KPM, OMD. We are pleased to note that numerous appeals from the Kuznets Union, the Stankoinstrument Association, and many factories and enterprises to the country's leadership about the catastrophic state in the industry of forging and press engineering (KPM), forging and stamping production (KSHP) and metal processing pressure (OMD) with specific proposals for the preservation, restoration and strategy for further development of the industry, apparently, had an effect. I would like to believe that the turning point in the fate of the KShP, KPM and OMD industry will be the conversation that took place at a meeting of the Security Council chaired by Russian President V.V. Putin in June 2006 V.V. Putin said that “the level of military security directly depends on the rate of economic growth and technological development.” “The key to the success of any country in the world market is constant updates, continuous innovative activity in all spheres of the economy.” “Today the share of participation of Russian enterprises in the development of the scientific and design base is only 6%; in the USA, EU countries, Japan and China this figure is close to 60%.” “We now have every opportunity to look into tomorrow and formulate a long-term strategy for the country’s development in all critical areas” [7]. The President is echoed by the Chairman of the Government of Russia M.E. Fradkov: “I have no doubt, as the Chairman of the Government, that we are simply doomed to solve these problems” [7]. The rich scientific, technical, intellectual and spiritual potential of the industry of KPM, KShP, OMD, based on the finally demonstrated political will of the Russian leadership, can also confirm the doom of our country to restore and develop this industry as a priority, fundamental, foundation-forming and ensuring the national security of Russia. Today Russia needs precisely a strategy for the development of the industry. It is in this context that it is necessary to consider this problem. Otherwise, our actions will remain fruitless. Today there are few tactical steps. In the 70s and early 80s of the last century, the USSR firmly entered the top five countries of the largest producers of engineering products. The production of KPM was increased to 50-55 thousand units per year [8-9]. However, the “perestroika” and “reforms” that began in 1985, which continue to this day, have largely destroyed the scientific and technical potential of the KPM industry and significantly destroyed forging and stamping production in all traditional industries. In order to objectively outline strategic ways for the restoration and development of the KPM, KShP and OMD industry in Russia, it is necessary to once again, at least briefly, characterize the current state of the industry. Figure 1 shows the picture of the production of CPM in Russia - the USSR for 100 years (data from the Ministry of Stankoinprom and the Stankoin-Tool Association) [8-22]. The collapse of KPM production, which was organized by “perestroika” and “reforms” in 1985-1995, led to the fact that over the next 12 years, the production of KPM in Russia is at the level of 1917 without any visible growth trends ( Fig. 1). (A similar, close to this picture occurs in almost all major branches of mechanical engineering) [10]. At the same time, it is known that the depreciation of fixed assets in all branches of mechanical engineering reaches 70% only according to official data. Correcting this situation requires hard work by the KShP and KPM. It is known that the wear of the forging equipment itself also significantly exceeds the level of 60-70%. This requires a serious update of the entire fleet of KPM in KShP, which requires hard work from the KPM industry itself. The USSR KPM fleet contained about 900 thousand KPM units. As a result of the collapse of the USSR, part of this Park ended up abroad or was destroyed. However, in Russia the KPM fleet now apparently amounts to at least 500 thousand KPM units. And this Park has physical wear and tear of at least 60-70% and requires updating. We must admit that with today's production of 1200-2000 units. KPM (Fig. 1) per year it will take hundreds of years to update the KPM Park [8, 9, 11, 16, 17]. Russia does not have this time. The current state of the KPM and KShP industry without a fundamental change predetermines its complete destruction over the next 10-15 years. Therefore, strategically, Russia should now sharply, tenfold, increase the production of KPM and restore the production of KPM from the 80s and even exceed it.

The foregoing indicates a very difficult state of the KPM, KShP industry, but its condition is not hopeless. Today, Russia has preserved a unique scientific, technical, spiritual and personnel potential that must be preserved and realized. In our opinion, the strategy of the problem under consideration of the restoration and development of the industry requires official recognition at the state level of the fact that the industry of KPM, KShP and OMD is a strategic, priority, fundamental, fund-forming industry of modern and promising mechanical engineering and all equipment and requires an appropriate relationship. This strategic position presupposes appropriate practical steps in relation to the preservation and improvement of engineering education in Russia and the re-equipment of the KSHP and KPM industry. It is necessary to be clear that the transfer of higher engineering education to the two-level Bologna system will lead to the destruction of the entire system of classical engineering education in Russia, of which it was rightfully proud and superior to foreign systems of higher education. This will lead to the destruction of the Russian engineering corps and the loss of its intellectual level, which rightly worries V.V. Kadannikov [1-3]. The destruction of the engineering education system will lead to the destruction of high technical culture in Russia, to the loss of personnel, to the destruction of scientific and technical schools, to the loss of invaluable scientific and technical experience and traditions of veterans, to the loss of continuity of generations in the technical and engineering field , to the impossibility of restoration and development of the KPM, KShP and OMD industry and mechanical engineering in general. Therefore, preserving the classical system of engineering education in Russia is an urgent state task. The above will allow us to successfully solve the following practical problems of the industry:

1. Preservation, restoration and updating of all types of CPMs in operation. 2. Modernization of all types of CPMs in operation; 3. Restoration in Russia of the production of slab and slab hammers, screw and hydraulic screw hammers and press hammers, stamping hydraulic presses, the production of which was lost in Russia as a result of “reforms” [8, 9, 17]; 4. Development and creation of qualitatively new promising CPMs for upgrading the CSA of all industries.

The proposed program for the restoration and development of the domestic fleet of CPMs involves practical steps to restore production, modernize equipment and develop qualitatively new CPMs according to the scheme of parallel-sequential actions as the tasks are understood and the customer and manufacturing plants are ready to solve them in practice. In this sense, the Kuznetsov Union, the Moscow State Evening Metallurgical Institute (MGVMI), the Stankoinstrument association and the Ryazan OJSC Tyazhpressmash have outlined a long-term cooperation program in all mentioned sections [22]. 1. Preservation and restoration of CPMs in operation in KShP workshops. It is necessary to organize the production of units and parts of steam-air hammers, hydraulic and crank presses, screw hammers: frames, cylinders, working cylinders, columns, screw pairs, control units and drives, vibration isolation systems. Everyone and the KShP factories should be involved in solving this problem. 2. Modernization of KPM, which are in operation in the KShP workshops. KPO's long-term work has revealed numerous components and parts that require significant modernization and updating: hammer heads, frames, working cylinders, working screw pairs, control systems, drives, vibration isolation systems, etc. In order to increase efficiency and production standards, it is necessary conversion of hammers and screw forging machines to hydraulic drive. The Kuznetsov Union, together with Ryazansky, is developing a qualitatively new design of hydraulically driven stamping hammers, which combines a working cylinder and a hydropneumatic accumulator in one unit. This solution makes it possible to increase the effective efficiency of the hammer from 3% to 40-50%, to create a hammer with a widely adjustable drive and program control, to ensure stamping of products with a CMM of more than 0.5, to increase productivity, culture and environmental friendliness of production. In practice, this problem can be successfully solved by Tyazhpressmash (Ryazan), Tyazhmekhpress (Voronezh), Azov KPO and KPA plants, Nelidovsky hydraulic drive plant, plants in the Urals and other regions of Russia. 3. Restoring the production of lost CPM (hydraulic screw press hammers, hydraulic stamping and forging presses, stamping and forging hammers). This problem must be solved by expanding the range of such plants as CJSC (Ryazan), Uralmash, Tyazh-Stankogidropress (Novosibirsk), KPO plant (Voronezh) and other plants. 4. Development and creation of qualitatively new promising CPMs. It is known that, despite the importance of the operated CPMs, they are largely characterized by low efficiency, low accuracy of stamped forgings, vibrations, and low environmental friendliness. Below are just a few directions for the creation of such new forging and pressing machines: - hydraulic presses for stamping with rolling (GPSH) of axisymmetric parts (flanges, disks, wheels, rollers, etc.) [18]; — hydraulic presses for stamping and rolling (GPSH) of long products (mega-project, a fundamentally new class of KPM); — hydraulic screw universal press hammers and hammers [19]; — specialized hydraulic screw press hammers and hammers for double-action stamping in split dies and other operations [19]; — hydraulic screw slideless press hammers and hammers; — hammerless hammers with air and hydraulic drive [20]. It is known that classical stamping with complete simultaneous covering of the entire surface of the workpiece with dies predetermines the appearance of stagnant zones and zones of difficult deformation, high specific deformation forces and contact frictions in a plastically deformable workpiece, which in turn leads to the need to create high integral forces when stamping forgings [18]. The above leads to the fact that, for example, stamping of aircraft disks from heat-resistant alloys with a diameter of up to 900 mm is carried out using a steam-air stamping hammer with an MPH. 16 tons for 5-7 offsets with a total number of impacts up to 200. In this case, the CMM of stamped disks does not exceed 0.4. However, the industry requires osymmetrical products with a diameter of up to 1500-2000 mm. Even more complex is the problem of stamping long, complexly ribbed products such as panels, beams, monorails, etc. The longest (within 4-4.2 m) products of this type in Russia can currently be stamped only on a rollless hammer with an impact energy of 1500 KJ (150 tm) and on a hydraulic press with a force of 750 MN (75,000 tf) - the most powerful in the world. However, the industry requires purpose-stamped products up to 12-20 m long. Such problems can be successfully solved on the basis of a qualitatively new stamping process, combining the advantages of classical stamping and rolling schemes, on qualitatively new forging and pressing machines. The Kuznetsov Union, the Moscow State Evening Metallurgical Institute (MGVMI) and the Ryazan OJSC Tyazhpressmash are currently developing hydraulic presses for stamping and rolling (GPSHO) of the mentioned products [18]. The proposed presses are highly adjustable and controllable in terms of basic technological parameters and allow for stamping products from a wide range of alloys and composite materials with the greatest accuracy, with CMM up to 0.6-0.8 and higher. The mentioned products with a length of up to 12-20 m can be stamped using the proposed method at a GPSH with a force of 100-200 MN. A very promising type of CPM are hydraulic screw press hammers (HSPM) [19]. In the 60-80s. of the last century by the efforts of the Moscow Higher Technical University named after. N.E. Bauman, VNII-METMASH, ChPO KPO (Chimkent), ENIKMASH, TMP plant (Voronezh) complex research, development and mastering of industrial production of CVPM with force 1.6 were carried out; 6.3; 10; 25 MN for precision stamping of a wide range of parts. Research and industrial operation of these CVPMs have shown their wide technological capabilities for precision stamping, high energy performance (efficiency up to 39%), and wide possibilities for regulating the main machine and technological parameters. Unfortunately, as a result of “restructuring”, the ChPO KPO plant (Chimkent) ended up abroad and all work towards the creation of a gas-fired machine was stopped. However, the capabilities of the GVPM were not fully realized even at that time. Currently, the Kuznetsov Union, together with the Ryazan OJSC Tyazh-pressmash, is developing new GVPM schemes for precision stamping of disk-type parts, for precision stamping of complex forgings in split dies with CMM up to 0.8 and higher. Ryazan OJSC "Tyazhpressmash" is a leader among KPM factories and is technically ready to implement many projects to create the indicated promising types of KPM (GPShO, GVPM), to modernize existing equipment, to restore forging equipment in use. Creative organized cooperation with Ryazan, with Voronezh "Tyazhmekhpress", with Azov plants KPO and KPA, etc. will allow us to successfully solve the problem of creating fundamentally new KPM, significantly update the KPO fleet of Russia and raise the scientific and technical level of KSP. To successfully solve the problem under consideration, it is also necessary: - to create, within the framework of the Kuznetsov Union and the Stankoinstrument association, a scientific, technical, analytical, information and training Center for the KPM and KShP industry; — to restore research laboratories and scientific-experimental departments at KPM factories to test new promising KPM designs and mechanical engineering processes; — develop and implement measures to consolidate human resources at enterprises in the KPM industry; — restore the vocational school system and the distribution system for graduates of the departments of general education of technical colleges; — create in the Park of the Kuznetsov Union and the Museum of Forging Science and Technology of the Kuznetsov Union an exhibition of achievements in the field of forging steel, mechanical engineering and mechanical engineering; — establish Russian Blacksmith Day on November 14; — take part in the II All-Russian competition of scientific and technical projects announced by the Kuznets Union. prof. A.I. Zimin “Forging and stamping production in Russia in the 3rd millennium”, the results of which will be summed up in 2008 (the terms of the competition were published in the magazine “KSHP.OMD” No. 7, 2005). The posed state strategic problem can be successfully solved if 1. The forging and stamping production of the plants will send the necessary applications-orders for the supply of the required KPMs and complexes based on them to the Stankoinstrument association and to the KPM manufacturing plants; 2. supplier factories and customers will provide conditions for mutual assistance and mutual most favorable conditions for each other; 3. factories, suppliers and customers will ensure mutual work at the first stages with a minimum reasonable profit and maximum benefit for the industry and national security of Russia. The current situation in the industry and in Russia requires organization, as in the years of previous hard times. With a kind, reasonable, trusting and honest approach, the industry of KPM, KShP and OMD will be restored and developed, which will ensure the national security of Russia.

References: 1. Kadannikov V.V. Competitiveness of national industry and the role of scientific and technical intelligentsia in the era of globalization. “Forging and stamping production. Processing of materials by pressure", No. 11, 2005. 2.V.V. Kadannikov. Solving current problems of socio-economic development of regions and the role of the engineering corps. “Forging and stamping production. Metal forming", No. 1, 2006, 3-9 p. 3. V.V. Kadannikov. Some results of Russia's integration into the world economy and an assessment of the role of domestic mechanical engineering. “Forging and stamping production. Metal forming", No. 2 and 3, 2006, 3-9 p. 4.Zimin A.I. Criteria for evaluating machines and technology for metal forming / Sat. MVTU "Automation and mechanization of production processes in mechanical engineering", M. "Machine Building", 1967, p. 120-127. 5.Zimin A.I. Higher school and the introduction of research into production, “Forging and stamping production,” No. 2, 1969, p. 2-7. 6.Zimin A.I. Periodic system of energy types of forging and pressing machines, “Forging and stamping production”, No. 10, 1965, p. 25-28. 7. Artes A.E. On the issue of the development of domestic mechanical engineering, “Preparatory production in mechanical engineering”, No. 12, 2006 8. Zimin Yu.A. Forging science, culture and production in the aspect of national security of Russia, Heavy Engineering, No. 2, 1998, M., pp. 3-11. 9. Zimin Yu.A. State and problems of forging and press engineering and forging and stamping production in Russia, Proceedings of the VI International Congress “Kuznets 2002”, Sat. “Status, problems and prospects for the development of forging and stamping production, forging and press engineering and material processing by pressure”, M., 2002, pp. 4-6. 10. Barankevich A. and Usmanov I. Setting to defeat, “Soviet Russia”, 1998. 11. Zakharov B.F. State and prospects of forging and pressing production in Russia, “Heavy Engineering”, 1998, No. 2, p. 14-16. 12. Zimin Yu.A. Ecology of forging and stamping production, M., Intermet Engineering, 2002, 200 p. 13. Glazyev S.Yu. Russian genocide. Russia and the new world order, M., 1997, 188 p. 14. Portnov AM “Novorussky” paradox, “Russian House”, No. 7, 1998, pp. 20-21. 15. Press-forging mechanical engineering in the USSR, NIIMASH, M., 1967, p. 196. 16. Zimin Yu.A. State of the press-forging equipment fleet and the problem of national security of Russia, Sat. MGVMI and the Kuznetsov Union “Status, problems and prospects for the development of metallurgy and metal forming,” vol. No. 4, M., 2004. 17. Zimin Yu.A. Strategy for the development and improvement of powerful forging and pressing equipment, "KShP OMD", No. 2, 2002. 18. Zimin Yu.A., Burman P.N., Nagovitsyn V.V. and others. Hydraulic presses for stamping with rolling of axisymmetric workpieces, TsNIITEItyazhmash, M. 1991, 30. 19. Zimin Yu.A., Kondratenko V.G., Mansurov I.Z. Stamping on screw press hammers and hammers, NIIMASH, M. 1978, 96 p. 20. Zimin Yu.A. Prospects for the creation of powerful hammer-free hammers, “Heavy Engineering”, No. 5, 1990. 21. Russian mechanical engineers set a course for effective development, “Industrial Regions of Russia”, No. 1, 2007. 22. Recommendations of the Board of Directors of the Russian Association “Stankoin-tool” ", "KShP. OMD", No. 11, 2006.

How is forging done using this method?

To carry out cold forging, three types of operations are usually used:

- pressing the workpiece using manual or mechanized equipment;

- embossing is one of several processes that relate to forging without preheating, but most often it is possible to apply an ornament only to copper, since the metal is quite soft and pliable;

- The third processing option is bending, which is one of the main ones.

Pros and cons of using this method

The obvious advantages include the following:

- firstly, there is no need for preheating, which significantly reduces the cost of products, since there is no need to purchase and use heating devices;

- secondly, the products are characterized by greater strength;

- thirdly, it is possible to fit the part to the template with high accuracy;

- the need for additional finishing of the finished part is completely eliminated or minimized;

- the finished product does not have soot residues or other combustion products on the surface.

However, cold forging is not without its disadvantages:

- it is necessary to put in much more effort to achieve results than with hot pressing;

- it is impossible to work with durable metal, which is presented in the form of sheets or blanks;

- in some processing options, a huge amount of force will be required, which requires special equipment;

- Before work, you need to thoroughly clean the surface.

As a result, we can say the following. Firstly, the equipment for a forge is hammers, presses and stampings. In addition, depending on the operation being performed, various additional devices may be used. Secondly, the forge shop today is an integral part of a larger-scale production, and not a separate structure.