Home / Welding technique

Back

Reading time: 3 min

0

604

Welding joints are a very common welding technology; it is used almost everywhere, since metal structures are often made up of elements that need to be connected.

For this purpose, many types of welding were invented using different equipment such as automatic, semi-automatic, manual welding, as well as many imported and domestic consumables.

This method is simple and does not require large expenditures, but it demonstrates good results.

Of course, it is difficult to conform to a standard, since each metal is individual, has its own thickness and properties, and the quality of the connection depends on this.

To work with welding, of course, you need to have basic knowledge of physics and chemistry; first of all, this will affect your safety, and in a business like welding this is quite important.

But as we have already said, each metal is special in its chemical and physical properties. For this purpose, a method was developed to individually calculate the quality of the connection for different cases.

Such parameters will orient you to the level of quality of the seam that is in front of you.

- General information

- How to determine the strength of a weld? Seams at the joints

- Seams on the corner

How to calculate the strength of a weld

In the production of metal structures, the most reliable method of connecting individual parts together is welding. The adhesion strength is ensured by intermolecular interaction that occurs under the influence of high temperature. In order for the joints (paths, seams) of the finished product to be of high quality, the calculations of the weld must be correctly performed before starting work. Accurate calculations are needed to select basic and consumable materials, to understand how reliable and monolithic the structure will be.

Calculation of a weld seam for shear is carried out according to generally accepted standard formulas.

Determining the quality of a welded joint

How correctly and efficiently the seam is made can be determined even by a simple external inspection. The following characteristics and parameters are taken into account:

- A welded joint of excellent quality appears smooth, slightly convex, with a wavy surface.

- The seam should not have any visible defects: depressions, cavities, porosity. And even more so - uncooked areas or, conversely, burnt holes.

- The area surrounding the weld joints must be free of cracks and depressions. All metal must have a uniform and identical structure.

But this is only external data. The welding process is also accompanied by chemical changes that occur in the structure of the metal. To check the quality of the product from this perspective, tests are carried out for various loads, as well as calculations of the parameters of the welded joint.

What parameters are used in the calculation

When calculating the strength of welded joints, a number of indicators are required.

The following main parameters are taken into account:

The process of tension and compression of metal is calculated using the formula:

.

If during the manufacture of a product parts from different metals are welded, then the formulas use Ry and Ru for the material with the lowest strength. Proceed similarly when enabling parameters in the calculation of a shear seam.

When calculating strength, a number of indicators are required.

In addition to the above numerical indicators, the reliability of the connection is affected by:

Such characteristics must be taken into account; the accuracy of calculating the clutch quality depends on each of them.

General information

As already noted, welds are among the strongest among existing permanent connections. They arise as a result of the action of molecular adhesion forces, which is the result of strong heating until the parts melt at the point of their adhesion or the parts are heated to a plastic state through mechanical force.

Despite the strength and reliability of the weld, such a connection also has a number of shortcomings: due to the fact that the connection is heated and cooled unevenly, residual stress may be observed. In addition, some defects may form during the welding process, such as cracks or lack of fusion. All this negatively affects the strength of welded joints.

The initial strength calculation of welds is carried out at the design stage. This point should be given special attention, since it is important to choose materials that are reliable and durable and can withstand certain loads.

If you make a correct calculation of the strength of the resulting seam, you can determine the required amount of material consumed.

Seam strength coefficient

This is the φ indicator, which is the ratio between the strengths of the welded track and the base material. Its value is standardized and determined by the welding method and the design of the joint. It is adopted on the basis of the Gosgortekhnadzor Rules and is reflected in the appendices of GOSTs R52857.1-2007, 14249-89 and 34233.1-2017.

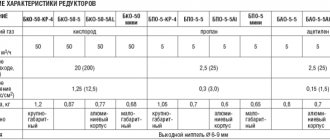

Table 1. Strength coefficients of welding seams

| Type of welded joint | φ value | |

| Controlled area of the total length of the seam: | ||

| 100% | 10-50 % | |

| Butt one-sided, made by manual welding | 0,9 | 0,65 |

| T-shaped, with a structurally provided gap between parts | 0,8 | 0,65 |

| One-sided butt joint, produced with a flux or ceramic lining, automatic or semi-automatic welding | 0,9 | 0,8 |

| V-joint or butt joint with continuous double-sided penetration, performed automatically or semi-automatically | 1,0 | 0,9 |

| Butt welding with root welding or T-weld welding with continuous welding on both sides, made by manual welding | 1,0 | 0,9 |

| One-sided butt joint, during welding it has a metal lining on the root side of the seam, adjacent to the base material along the entire length of the seam | 0,9 | 0,8 |

The strength factor for tracks soldered with soft and hard solders using devices made of non-ferrous metals is 0.7 for composite soldering, 1 for homogeneous soldering.

Formulas used

There are many formulas by which calculations are made to create high-quality welded paths. They use indicators determined not only by the type of seam, but also by the type and thickness of the base material, the area and location of the joined parts, maximum loads, operating temperature of the product, etc. The equations for individual types of welds differ.

There are many formulas by which calculations are made.

Calculation of the strength of seams on convex surfaces

In the production of vessels - pipes of various capacities - butt welded joints are used. This includes seams on convex bottoms (meridional and chordal) and on shells (longitudinal). Accepted standards and methods for calculating the strength of such products are reflected in GOST 34233.11-2017. The calculation of a welded joint on a convex surface depends on a number of indicators - the grade and thickness of the steel from which the vessel is made, internal and external pressure on the walls, type of load, etc.

The equation for calculating the permissible stress (measured in MPa) using the example of a cylindrical shell for a vessel operating under single static loads and made of low-alloy or carbon steel:

This formula is applicable only for vessels made of plastic materials when metals are used.

Dependence on weld type

There are several options for coupling metal elements into a single structure. Based on the location of the parts to be connected, the following types of welds are distinguished:

For each of these types, the calculation is made using an individual formula.

Before you begin calculating the strength of the future adhesion, you need to calculate its cross-sectional area. To do this, the length of the welded joint is multiplied by its thickness.

Overlapping sheets

To calculate the shear stress, use the formula:

,

It is clear from the expression that the resulting shear stress should be less than the maximum permissible.

The load value P is:

.

When calculating, the minimum cross-sectional area of the welded track in diameter is taken into account. This is due to the fact that welding materials can exceed the base metal in strength.

A little about welding. Part three. Myths and facts.

I sincerely apologize to my readers who were interested in the topic “A little about welding”

and who were waiting for my new text about welding and related issues.

— Ambushes in work and personal life prevented (yes, and will always interfere) from making a new post. When I put something off until tomorrow, I understand that I am putting it off forever... This is impossible. Today I will try to rehabilitate myself. Well, at least somehow))

So, let's talk about myths about welding.

Well, for sure, each of us has heard some stories about welding work, about welders, about seams, about iron and about how mysterious it all is)) - There is nothing mysterious here! Complete physics and psychology. Or rather, a mixture of physics and psychology. Oddly enough, in general.

I’ll tell you about “milk from being harmful” later, in the next post)) About safety precautions.

Myth four

- Anyone can cook. Yes, in general, everyone can cook. But some people will be good at cooking pasta and dumplings, while others will be good at welding metal. Moreover, for both groups, the result will depend only on practice. “The more we try to cook, the better we will get.” Direct dependency ))

Myth fifth

— the apotheosis of a welder’s skill is welding two razor blades. I tried it and it turned out kind of a mess. I guess I'm a lousy welder. I welded the blades themselves to the piece of iron (3mm), but I couldn’t weld them together.

Myth seventh

— buying a welding machine automatically makes you a welder. - No. Just like buying a moonshine still does not make you a bootlegger, buying a rabbit does not make you a farmer, buying a wedding ring does not make you a groom, buying a gun does not make you a hunter, and buying a stethoscope does not make you a doctor.

If you have your own myths about welding, write in the comments. Let's discuss.

Source

What affects the strength of the connection?

The strength of the connection is determined not only by the seam itself and adherence to welding technologies; other factors also influence.

- The quality of the material itself used to assemble the product. The weld may be correctly executed, but the surrounding metal does not always meet the required characteristics.

- Consumables used in welding operations are as important as compliance with other requirements. Electrodes or additives of poor quality will not form the correct connection with sufficient strength parameters (changes in the structure of the metal itself: fragility, brittleness, etc.).

- The equipment used for welding must meet the required technology (for example, argon arc welding) and power.

- Welding modes (polarity, current) determine the quality of penetration and the reliability of the connection of parts.

- Preparing the workpieces for welding is no less important. Even the shape of the edges at the joints will affect the shape and quality of the seam.

All these factors are taken into account when planning work, especially with important and critical structures.

Carrying out calculations for the strength of welded seams - rules and standards for evaluation

Home / Welding technique

Reading time: 3 min

Welding joints are a very common welding technology; it is used almost everywhere, since metal structures are often made up of elements that need to be connected.

For this purpose, many types of welding were invented using different equipment such as automatic, semi-automatic, manual welding, as well as many imported and domestic consumables.

This method is simple and does not require large expenditures, but it demonstrates good results.

Of course, it is difficult to conform to a standard, since each metal is individual, has its own thickness and properties, and the quality of the connection depends on this.

To work with welding, of course, you need to have basic knowledge of physics and chemistry; first of all, this will affect your safety, and in a business like welding this is quite important.

But as we have already said, each metal is special in its chemical and physical properties. For this purpose, a method was developed to individually calculate the quality of the connection for different cases.

Such parameters will orient you to the level of quality of the seam that is in front of you.

How to properly make tacks when welding?

You have decided that you need potholders, you know how many there will be and how long they will be. Now the only thing left to do is make the connection. But even here everything is not as simple as we would like. If you don’t follow a certain algorithm, you can make a lot of mistakes, and in the future all the work will have to be redone.

The sequence of tack welding directly depends on what seam you are currently working with:

- Short or medium. The first tack is made strictly in the center. The next one is to her left, then to her right. All subsequent tacks are located at the same distance from each other, while the alternation continues in the specified manner. Thus, it is necessary to reach the edges of the workpieces.

- Long. Here everything must be done exactly the opposite way than in the previous version. First, grab the edges, and then gradually move towards the middle.

- Annular. In this case, the method of welding tacks is slightly different. The first point is placed arbitrarily. The second one is opposite her. Then from each point you need to turn at an angle of 45 degrees and make tacks there. As a result, you will get elements welded to each other crosswise. Then, between each two points, one more is added to increase reliability, especially if we are talking about pipes with a large diameter.

General information

Welding provides the highest quality and unbreakable connections, as mentioned above.

The essence of this process is this: molecular bonding occurs when we heat two metals to such an extent that they begin to melt in the places where we need to connect them. We can make them pliable using mechanical force.

Everything has its drawbacks, for example the welding seams are not ideal either. Of course, with certain methods they turn out almost ideal if the welding is in the hands of a professional, but with some welding methods they are completely imperfect.

Sometimes this is due to rapid and uneven heating and cooling and may leave some stress in the parts.

Assembling products for tack welding: basic recommendations

When making tacks, you must understand that although they are needed for temporary fixation, you must approach this matter with all responsibility. That is why we recommend not to forget about several basic recommendations:

- The quality of the tacks should be no worse than that of the main seam. If you made a mistake and defects appeared on them, it is better to redo everything in a new way.

- Tacks are made with the same electrode as the main seam.

- When making tacks, set the current higher than when welding by 20%. That is, if you plan to cook with a current of 100 A, then for tacks set the indicator to 120 A.

- Be sure to clean the tacks of slag. To ensure that there are no defects in the main seam, they must be smooth and clean.

As a rule, assembly takes up to a third of the time it takes to completely manufacture the structure. This is an important and time-consuming process, non-compliance with the basic rules of which can most likely lead to a defect.

How are products assembled? As a rule, according to the general algorithm:

- All parts included in the structure are assembled in the place where welding work is planned to be carried out.

- Assembly is carried out gradually, moving from one part to another.

- First, individual components are assembled, and only then they are combined into a complete structure.

During work, you can use special support wedges, magnetic clamps, special stands and welding tables.

When the structure is connected, you can start making tacks. But it is important to remember that they cannot be placed at the intersection of the weld. You can order everything you need for electric arc welding: equipment, materials and accessories in our online store Welder Buy. We offer reasonable prices, delivery throughout Belarus, and assistance with the selection of necessary goods. Contact us!

Dependence on weld type

There are several options for coupling metal elements into a single structure. Based on the location of the parts to be connected, the following types of welds are distinguished:

For each of these types, the calculation is made using an individual formula.

Before you begin calculating the strength of the future adhesion, you need to calculate its cross-sectional area. To do this, the length of the welded joint is multiplied by its thickness.

Overlapping sheets

To calculate the shear stress, use the formula:

When joining with an overlap, cutting the edges is not required.

It is clear from the expression that the resulting shear stress should be less than the maximum permissible.

The load value P is:

When calculating, the minimum cross-sectional area of the welded track in diameter is taken into account. This is due to the fact that welding materials can exceed the base metal in strength.

Corner designs

Such connections are calculated based on their cross-section, the smallest, i.e., in the most dangerous place of the track. The bending stability index of a simple fillet weld, when it is loaded only with moment M, is calculated as follows:

Corner structures are calculated based on their cross section.

And the shear stress of a simple corner joint will be written as follows:

When calculating fillet welds for shear, the generally accepted expression is used:

When determining the pull-off length of the welding bond, the force directed towards the center of gravity must be taken into account. In this case, the cross-sectional area is chosen in the most dangerous place of the track, i.e. the smallest.

T-seams

The condition for the adhesion strength of T-joints made end-to-end and subjected to tension P and moment M looks like this:

The formula for the same, but not butt, but fillet weld:

T-seams can be one-sided or two-sided.

If the T-joint will be subject to bending and torque, then the equation applies:

The torsional and bending force are respectively determined by the following formulas:

Welding at the joint

The calculation of a butt seam, which will work in compression or tension, is performed according to the equation:

The permissible effective load P will be:

Butt coupling working in bending is calculated using the formula:

If the weld stress arises from both bending M and compression or tension P, then it is determined by the equation:

We calculate how long a weld seam can withstand

Maximum seam load after electrode welding

As you know, great hopes are placed on the welding seam.

When welding various structures and products, the load on the seam is calculated and tests are carried out before serial production. They test for fracture, compression, tension and fatigue of metal in various temperature conditions. They create conditions in which the operation of structural parts will take place. As for repairs in various weather conditions, it is quite difficult to conduct various experiments due to the lack of special equipment. In such cases, our hope rests on the ability to weld and certain knowledge in the field of electrodes and the metals being welded. You can find information about welds in various welding reference books. There is also GOST 5264-80 where we can find the joint we need. This applies to simple structures made of steel, iron-nickel and nickel alloys. Pipes are welded with a seam completely different from GOST 16037-80.

Let's look at an example of structural steel. We will cook with an MP-3 Arsenal electrode.

The maximum permissible load value is 430 MPa. Provided we cook it correctly. Let's take the metal from the St3 passport. Its characteristics.

As we can see, the maximum load value is 490 MPa. Let's take the thickness 3mm and weld the seam as in the picture.

Now let's look at the T6 connection itself.

We see that the leg exceeds the thickness of the metal by about one third. Thus, we equalize the maximum load on the seam. In this example, 490 MPa. The video shows a test of such a connection.

Practice shows that welding can withstand much stronger loads than steel itself. It happens that the welded area overheats and the structure weakens, which leads to fracture. Since the plasticity of the weld takes on part of the internal stress, try to weld with a tear on thin metal. I personally burned through it more than once. Especially when there is nothing other than the diameter of the three. And we had to weld steel 1.5 mm thick, and then in hard-to-reach places.

As for the pipeline, the most important thing is the absence of defects in the deposited metal. Otherwise, the slightest crack will eventually lead to an accident. The weld welding technique is carried out continuously, with the exception of changing electrodes. There are joints that are not rotatable and you have to work with a mirror. If the pipes are under pressure, then the load extends to the walls of the pipeline. Since the structure of the metal in the weld zone is not uniform. Such places are stretched (swollen). For example, in winter, accidents often occur in the water supply and heating pipelines.

Therefore, we answered the question of how long a weld seam can withstand after welding with electrodes using one example. If we want to achieve good results and are not afraid that the welding will burst along the seam, then use GOST standards. I mentioned a few of them earlier. As for the quality of welding in winter, this is a separate issue and more complex requirements for the technical process.

And if you want to calculate for yourself how much a seam can really withstand, I’ll give you links to good literature.

Welder's Handbook p. 353 strength calculation of welding joints.

Source

How to determine the strength of a weld?

Of course, making such a calculation is not at all easy, you need to use several formulas and spend an hour of your time, but in order to know that your welds will have a high strength coefficient, you still need to take into account how the metal is located, its shape, dimensions, features.

There are many methods of welding, using a variety of equipment and consumables, of course, each type of welding gives a different result, some were invented for working in difficult areas, and some are suitable for beginners, but in our time the following types of welding remain the most popular:

We also cannot skip welding manually and using a semi-automatic machine, but these are no longer types, but methods of operation and a type of equipment.

It also often depends on the type of metal that we will weld; for non-ferrous metals, some types of welding are effective, and for ferrous metals, others are effective, and there are also a huge number of other properties and factors.

The most common are tee and butt, corner and overlapping corners. For each type of seam, their quality is calculated separately since they have completely different quality characteristics.

Tack welding before welding: what is it?

Tack welds are small welds made by manual arc welding machines using a coated electrode.

They are carried out in strict accordance with existing standards. That is, there are certain rules by which the sizes of seams and the step between them are selected. Tacks perform several functions during welding. They help maintain the required gap between the elements and prevent their displacement, and also increase the rigidity of the assembly, which is no less important. Small seams are considered part of the preparatory work. It largely depends on them how strong and high-quality the main connection will be, and how comfortable the process of its implementation will be. In some situations, working without tacks is impossible, since not all structures can be assembled on stands, and without fixing it will not be possible to maintain the configuration.

Connection calculation method

Calculation of the weld for shear and strength is carried out individually for each type of connection.

Butt seams. When working with butt welds, one of the main parameters for calculations is the nominal cross-section. At the same time, metal deposits that form during welding are not taken into account. The calculation is based on the relationships that arise in solid beams known from material strength data. When the simultaneous impact of tangential and normal stresses begins, which are concentrated at the most loaded point on the section, the equivalent stress can be calculated using the fourth theory of strength using the following formula:

In this case, the strength condition looks like: σE ≤ [σ']P

The data for this value is determined from the table below:

| Welding method | Allowable stresses | ||

| When stretched | |||

| Automatic, manual electrodes E42A and E50A | [σ]р | [σ]р | 0.65 [σ]р |

| Manual with standard quality electrodes | 0.9 [σ]р | [σ]р | 0.6 [σ]р |

| Contact point | 0.5 [σ]р | ||

How to calculate the strength of welding seams

Depending on how the connecting elements are placed during welding, different types of seams are distinguished: corner, butt, T, and overlap. In the photo below you can see different ways of connecting welded parts together.

For each type of connection, the strength calculation of welds is carried out individually and taking into account different parameters. The strength values of butt welds are determined by the nominal cross-section of the welded area, where there are no sagging. For corner joints, the strength indicators are determined by the leg.

In any case, before calculating the strength of the weld, it is necessary to calculate its cross-sectional area. The cross section can be determined by multiplying the length and thickness of the welding joint.

The permissible tensile force in a joint can be determined using the formula: P = σp × S × I

When compressed, the formula is slightly different: P = σcompression × S × I

The symbols in the formulas are as follows:

You can calculate what strength the lap seam will have using the formula: P = τav × 0.7K × I , in which:

When calculating the load-bearing capabilities of a butt weld, it is necessary to focus on the stress that is permissible in the most dangerous section (s), as well as on the stress depending on the yield strength (HSE). Maintaining the ratios of these two indicators is mandatory, and only if they fully comply will the metal structure element satisfy all the requirements for strength characteristics.

Online calculation of joint strength

Carrying out preliminary strength calculations before welding metal products allows you to prevent inaccuracies and defects that lead to the destruction of structures. In order to accurately calculate the strength of welds, examples of ready-made calculations can serve as instructions for the correct execution of all actions. The best way to calculate strength properties is online, using special “Strength Calculator” programs.

Using the program, it is not difficult to calculate without errors the load-bearing capacity of seams along the length and leg, select the diameter of the reinforcement according to the required tensile load, set the cross-sectional area and calculate other values on which the strength and reliability of welded structures depends.

Example analysis

When our welding takes place in manual, semi-automatic or automatic mode, the indicator will be equal to 0.7. If everything is calculated correctly, then the seam has the shape of an isosceles triangle.

If you cook using the most common semi-automatic machine, but you did everything robotically in several stages, then it will be equal to 0.8.

In the same situation, but when using an automatic machine, this indicator will be 0.9, and if our automatic machine has single-wire welding, then the indicator will still be 1.1.

It is necessary to take into account PLEASE NOTE! When calculating the strength of a weld at an angle, it is necessary to calculate the tangential stresses.

But in order to maintain this condition, you need to know this is the total shear stress. In order to find out this indicator, you need to determine the point at which the most voltage drops.

What do you need to know?

During welding, the tack is completely welded or removed mechanically. Based on this feature, they can be divided into two types:

Tack on corner joint

The sequence of making seams of various lengths:

Length

The length depends on the length of the connection of the parts. It is considered common to consider tacks with a length of 10-50 mm, or generally point ones on short connections.

A connection length of less than 10 mm is used for fastening parts made of thin steel, the thickness of which does not exceed 3 mm, and during the assembly of small parts, as well as for preliminary and temporary fastening of the structure. When welding pipes, the length is equal to 2-5 metal thicknesses.

Quantity

The number of tacks determines the step or otherwise the interval through which the points are located. It is influenced by the thickness and rigidity of the parts, as well as the dimensions and configuration of the product being welded.

The connection failed due to lack of tack

Different materials have their own standards. For example, for parts made of sheet metal 0.5-4 mm, the step is 30-60 mm (fusion welding) or 50-150 mm (spot welding).

The quantity depends on the size of the product. A pipe with a diameter of 100 - 400 mm should have 3-4 tacks 30-40 mm long, while for a diameter less than 50 mm one or two about 10 mm long are sufficient.

How long does it last?

As with a weld, strength is affected by:

Therefore, it is impossible to accurately answer the question of what load the welding tack will withstand.

It is worth considering that initially the tack is designed only to tack the seam, and not to carry the load. However, despite this, it must support sufficient weight so as not to burst during basic welding work.

Notes from a novice welder, part 1 - Page 62 - Manual arc welding - MMA

WelderHandler, good evening, here is my continuous stink on the pipe, the story is this, I am correcting a jamb of steps, on this stand

A little further you can see a certain “assistant in assembling the steps” ala a wooden conductor, upon completion of the corrections, it was already getting dark, let me think about the pipe without interruption, but why am I rushing with enthusiasm, my eyes are burning... well, it turned out to be a pipe... Then the idea was formed to grab 2 pieces of pipe on potholders and grab it to the stand, then lift the stand vertically to depict a non-rotating joint with elements of convenience, and you get a kind of cartridge holder (what, then cut off the gusset and you’re done, and when necessary, grab it in place). MP3 grabbed the pipe

, burned a hole, the metal is rusty, the plate is about 2 mm thick, but it’s all in craters, my hand trembled for a split second, I held it in one place - this is the “technological hole”. And so the first step is laziness, let me remind you it was getting dark, I didn’t clean the scraps to be welded. Universal stupidity one - I took it because of the rust Uoni. Action two - I took a corner to burn a little of the electrode, dry it, hold the arc and check the current setting (set it to 100A) Universal stupidity two - I got out of the habit of using the electrode, or rather you expect slag (rutile), and this is the metal floating, there is a seam on the horizontal passed without sticking or fading

Step three - put the stand in a vertical position, so that when starting to cook you could lean on your knee, making a seam, starting at 6:30, smoothly bringing the electrode out to 12 and continuing (I decided, why in cool videos can you scald from top to bottom) Universal stupidity three - excessive self-confidence and poor preparation for welding...

and if you urgently needed to weld a pipe in order to provide water to a couple of houses, or at least yourself. Step four, the stucco molding went around 4x. For fear of burning, I tear off the electrode, it goes out, out of habit of easily igniting rutile, I poke in the hope of catching the arc, but... again unsuccessful ignition.

Universal stupidity four - no comments, it happens in Africa and in camboge and in welding. Action five, as soon as I reached 11:30, I turned the electrode like rutile at an angle of 20 degrees to the surface. and for coating, 12 hours passed, accelerated.

Universal stupidity five - there is no need to rush, the pipe process is not understood, theory is ahead of practice, there is no sense of the process, I know how, but I can’t do it. Conclusion - the play is short and not productive, a fixed joint is not given, there are no smells, there is a lot of current and( or) sluggish movements. UONI Direct polarity, current 100A, later reduced by 95A, MP3 pipe tack current 105, direct polarity, initially welding MP3 reverse polarity, but switching to direct I liked it more (subjectively) electrode diameters three, victim (pipes) 32nd. websvarka.ru