What is the pressure in a 10 liter carbon dioxide cylinder?

Carbon dioxide cylinders 10 liters GOST 949-73

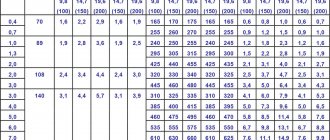

| Volume, l. | 10 | |

| Working pressure , MPa (kgf/cm2) | 9,8 (100) | 14,7 (150) |

| Diameter of the cylindrical part, mm. | 140 | |

| Cylinder body length , mm. | 830 | 865 |

| Cylinder weight , kg. | 10 ,2 | 15,0 |

Purchase: selection and rejection criteria

Purchasing high-pressure (HP) equipment for long-term use, new or used, is not difficult. Difficulties will arise when refilling carbon dioxide cylinders if the buyer does not take into account the restrictions on operation and refilling:

- Refilling cylinders with carbon dioxide is difficult if the filling station equipment is designed for a larger displacement - fire extinguisher refillers will help out;

- Filling small-capacity containers in a garage is possible using a donor cylinder with a high-pressure hose, subject to safety conditions;

- If the certification period is missed, the HP vessel is subject to inspection and certification testing;

It is advisable to purchase gas equipment from reliable suppliers. Used – from manufacturers. They monitor the equipment, document flow is at the level: they will provide the original certificate of conformity, test reports.

Reasons for rejection of gas cylinder equipment relating to all filling categories based on the results of an external inspection:

- shut-off valve malfunction;

- neck thread wear;

- incomplete application of passport data, the next inspection is overdue: the absence or incompleteness of passport information transfers the cylinder to the status of unfit for use;

- the lifespan of the cylinder from the moment of first certification by the manufacturer is 20 years, exceeding the service life is impossible in practice;

- large area and depth of external corrosion;

- dents or bulges;

- cracks;

- risks and sinks with a depth of 1/10 of the thickness of the metal;

- the shoe is damaged or set askew;

- mismatch between color and lettering.

Mandatory requirements for the user of high pressure equipment:

- the vehicle for transportation must ensure transportation in a horizontal position;

- the rest period, regardless of the season, before starting work is 0.5 hours;

- used and storage HP vessels are not exposed to direct sunlight and are not stored near heating devices.

Why is a carbon dioxide cylinder dangerous?

Balloon

gas with carbon dioxide does not pose any particular danger if it is completely sealed.

Carbon dioxide

does not burn or explode; on the contrary, it prevents combustion.

It is no coincidence that it is used when extinguishing fires. ... If the containers are damaged, carbon dioxide

can spread into the air.

Interesting materials:

Who should come first? Who delivers housing and communal services receipts? Who is going to Eurovision from Moldova? Who is Agatha Christie? Who is Laysan Utyasheva? Who is Feduk by nationality? Who said: Dreaming is not harmful, but not dreaming is harmful? Who speaks Turkic? Who is SpongeBob's orientation? Who invented gaskets and when?

Application: gas treatment

Long-term and intermediate storage of cylinders is allowed on ramps equipped with roofs and protective partitions that prevent the ingress of precipitation, in cold and heated rooms with natural ventilation.

Liquid carbon dioxide supplied for welding work is purchased in the highest and first grades . Refilling cylinders with carbon dioxide for food producers is expensive, but desirable: The gas humidity is zero.

The use of second grade gas is allowed if drying is possible: an unregulated amount of liquid vapor is added to 1% of the aqueous sediment. A gas dryer extracts water vapor from a gas flow.

This is a sealed container filled with hygroscopic materials. Low pressure dryers are installed after the reducer, high pressure dryers take gas from a cylinder in front of the reducer. Desiccants are aluminum gel, silica gel, and copper sulfate .

Adiabatic cooling of a gas provokes a sharp volumetric expansion. Gas consumption in the range of 15–20 l/min leads to freezing of moisture vapor, which can lead to clogging of the gearbox. A high-volume gas intake requires the installation of a 24/36 V coil-type gas heater. The thermoelement neutralizes the freezing of water vapor and is designed to pass large volumes.

Active gas protection of welds during semi-automatic arc welding with a consumable wire electrode is carried out with carbon dioxide in pure form or mixed with argon.

The use of cylinders implies a limited daily consumption by welding stations . A 40-liter cylinder with an internal pressure of 6 MPa holds 25 kg of liquefied substance. In gaseous form, after evaporation, the liquid is transformed into 12.5 thousand liters of gas.

Formulas will help

For oxygen

V = K coefficient × V b

K=((0.968× D + 1) × 293×10 -3)/((273+ T) × Z)

V b in dm 3 ─ capacity, D in kgf/cm 2 ─ pressure gauge data, Z ─ oxygen combustion coefficient. The parameter 0.968 kgf/cm2 recalculates the technical indicators of atmospheres.

For propane and butane

Gas mass = V cylinder m3 × (0.4× Flat prop. + 0.6 × Flat bottle)

Under normal conditions, the density of liquid propane is 510 kg/m3, and butane is 580 kg/m3. The numbers 0.4 and 0.6 indicate the percentage of chemical elements.

Gearbox

Stabilization, reduction of gas protection supply pressure, optimal consumption of carbon dioxide during semi-automatic welding, and blocking of the supply of carbon dioxide when welding is stopped are carried out by the gearbox.

Single-chamber and two-chamber (two-stage) pressure regulators with a sequential arrangement of pressure reduction cavities are adjusted by turning the manual regulator for changing the CO2 supply flow.

The inlet pressure gauge records the pressure of carbon dioxide in the cylinder. The second is in the regulation chamber, the carbon anhydride distribution network . Not limited to the function of a change recorder, the reducer works as an outlet pressure stabilizer.

The consumption of carbon dioxide in the cylinder should not affect what pressure of carbon dioxide should be when welding with a semi-automatic machine. The reducer membrane takes the position of allowing gas into the cavity of the chamber to reduce the operating pressure during the initial setting. Changing the voltage settings of the control spring activates the opposite control spring.

The open cross-sectional area of the intake valve gradually changes upward, but the consumption of carbon dioxide during semi-automatic welding remains the same. The constancy or change in the output pressure is adjusted according to the current reading of the pressure gauge using an adjusting screw.

Manipulations of the ball valve included in the package are used to clarify the amount of gas flow . The flow washer with nozzle adjusts the outlet according to the pressure value in the working chamber.

The pneumatic reducer is protected by a built-in safety valve. A pressure surge will cause the membrane to rupture. Loss of tightness at the inlet fitting with an increase in gas flow leads to preventive locking of the system.

Pneumatic reducers are classified by the number of pressure equalization stages (chambers) . A two-stage reducer with a consistent reduction in pressure in an unheated room in winter is indispensable.

Separation of pneumatic regulators according to conditions of use:

- network – work in a stationary network of a carbon dioxide station;

- ramp – servicing multi-post areas.

Important! Using the gearbox on an inclined, lying cylinder is unacceptable![/stextbpx]

Interchangeability of oxygen and carbon dioxide

Structurally they are similar, and their replaceability is partial .

The oxygen reducer is designed for a pressure 2.5 times higher, and the operating requirements are more stringent. Carbon dioxide is chemically neutral and does not damage the membrane. But carbon dioxide on an oxygen cylinder will not last long precisely because of the destruction of the membrane. But using it for other purposes would be a mistake. When welding with carbon dioxide, the oxygen reducer freezes . The expansion coefficient of carbon dioxide leads to a decrease in the temperature at the reducing valve to –600 C. Crystallization of moisture will lead to failure of the device.

Explosion safety requirements dictate that a gearbox with union nuts be installed on oxygen. The carbon dioxide cylinder can be secured with a clamp - a leak will not lead to a fire.

UR 6-6

Among the variety of gearboxes, the compact universal pointer UR 6-6 with a calibrated jet is distinguished. Suitable for regulating the supply of argon, other gases and mixtures with a maximum oxygen content of up to 23% on gas cylinder equipment of 20–50 l . The impact-resistant body is made of brass. It is recommended to connect an electric heater.

Specifications:

- a cleaning filter is built into the inlet valve, preventing backflow into the cylinder;

- inlet pressure – up to 20 MPa;

- throughput – up to 1.8 m3/hour. (30 l/min.);

- working pressure – 0.35 MPa;

- operating pressure unevenness limit – 4%

- weight – 0.7 kg;

- considered the most economical model.

With rotameter

The convenience of a flow meter while maintaining the functionality of a conventional regulator in displaying carbon dioxide consumption during semi-automatic welding in the current mode. The rotametric regulator is equipped with a calibrated throttle valve at the output. The accuracy of control and gas flow readings is guaranteed .

The pressure gauge indicates the units of flow. The device is configured and further adjustments are not recommended. Two-rotameter gearboxes are designed to protect the seam of chemically active metals on both sides.

Additional elements of the gas tank structure

There are several design details that increase ease of use. These include:

- Shoe. It has a rectangular shape to stabilize the container. This is important because falls, strong mechanical pressure and other similar hazards must not be avoided.

- Shut-off valve. Typically a brass product is used. It has a right-hand thread. This measure is important for tightness, to prevent leaks and to ensure a tight connection.

- Steel cap. Used as an additional means of protection.

- Rubber rings. Installed along the entire cylindrical part of the cylinder. They help control its condition as pressure increases.

All technical elements of the container may wear out due to prolonged use. In order to notice signs of breakdowns in time, you need to regularly perform inspection and maintenance. The inspection is carried out every five years. A special inscription indicates that a correct examination was carried out. It can be found on the neck in a yellow circle.

An unscheduled inspection may be required. This is triggered if there are potential external signs of a leak, loss of integrity, or problems with shut-off valves.

The difference between reinforced CO2 cartridges

Reinforced gas cylinders can be used for regular air pistols (which are sold in every gun store). Their main difference is the higher shot power.

A special gas composition (inert gas is used) makes it possible to accelerate a steel ball or lead bullet to the initial speed of a bullet from pistols such as PM and TT. Moreover, the bullet becomes able to pierce through a metal sheet 0.5-0.7 mm thick.

Reinforced cylinders have a standard shape (the same as simple cylinders). The number of shots on one cylinder is at least 100. The standard initial speed of a bullet is 70-120 m/s. If a reinforced balloon is used, the initial speed can be approximately 230 m/s. For comparison, the flight speed of a combat PM cartridge is approximately 245 m/s.

Hypercapnia and hypoxemia: signs, occurrence, diagnosis, how to treat

Today, arterial hypertension is considered the “plague of the 21st century.” A third of the world's population suffers from it. Mortality from the development of cardiovascular complications due to arterial hypertension accounts for more than 56% of total mortality in Russia. The number of people getting sick is steadily growing, and high blood pressure is becoming a vice of younger and younger people.

The fact that all this is happening against the backdrop of the existence of hundreds of drugs on the market to lower blood pressure and the extremely high development of the pharmaceutical industry cannot but cause deep thought. For several decades now, the pharmaceutical industry has been steadily developing in the production of antihypertensive drugs, but the morbidity and mortality from hypertension not only does not decrease, but also exceeds all possible limits, turning into a pandemic...

A person suffering from high blood pressure for many years is accustomed to believing that this disease appeared on its own; in some individual cases, people refer to heredity. Few people know the fact that high blood pressure is a forced protective reaction of the body, designed to preserve the life support of your organs when there is a lack of oxygen in the tissues - oxygen starvation.

Use of carbon dioxide

The physical and chemical properties of the product explain its wide distribution. Under standard conditions of use, the gas is colorless. It has its own scent. It has a slightly sour taste, so it is often possible to immediately recognize the presence of a leak.

The substance can also be pumped into the cylinder in a liquid state. In this case, it is necessary to maintain a constant pressure of 5850 kPa.

Another property of the product is the ability to change its state when cooled. If the pressure in the container is 519 kPa and the temperature drops to −56 degrees, the substance hardens.

Uniform cooling with parallel pressure control produces dry ice. It has also found application in many industrial fields.

Carbon dioxide supply options

The product is pumped into cylinders. It arrives on site in a fully ready-to-use condition. There are three delivery options:

- In the form of liquefied gas. The delivery pressure should be 50 kg/cm2. In storage areas, as well as directly during operation, the temperature level should not exceed +31 degrees.

- Liquid. During transportation and storage, specially designed, tested and sealed thermoses are used.

- Dry ice. For production, it is necessary to comply with requirements for both pressure and temperature.

Special black tanks are used to store the substance. They are marked with yellow inscriptions, special markings that give a complete picture of the characteristics of the goods.

Cylinder mass and parameters influencing it

The weight of the cylinder, the volume of substance pumped inside, the mass of carbon dioxide itself - these are three parameters related to each other. In production, when pumping gas inside, the mass is strictly controlled.

We have special scales installed that help determine the weight of the cylinder. The mass of the vessel itself, all additional accessories, and shut-off valves is subtracted.

The weight of additional elements depends on what they are made of. Determining the mass is no less important than answering the question of what pressure should be in the carbon dioxide cylinder.

Types of capacity of carbon dioxide containers

To obtain carbon dioxide of a high level of quality, you need to work with a manufacturing company that also supplies containers and carries out inspections. Cylinders are delivered to the site and connected to the operating units.

| Cylinder capacity, l | Gas quantity, kg | Diameter, cm | Height, cm |

| 40 | 24 | 21,9 | 140 |

| 20 | 12 | 21,9 | 85 |

| 10 | 6 | 14 | 86,5 |

This is the most common container. The choice depends on the purpose of use and other factors.