Cylinder arrangement

A carbon dioxide cylinder is a container made of metal in the shape of a cylinder, which has a thread with a screwed-in shut-off valve at the top of the device. It is important to note that the type of shut-off valve will depend on the gas it is filled with. Separate high requirements are placed on the tightness and reliability of gas cylinders, especially with substances such as carbon dioxide.

You can also add that the design of the valve for a carbon dioxide cylinder has not one, but three threads. The lower one is intended to secure it in the container itself. The valve stem is attached to the top thread, and the side thread is intended for the plug.

Types of cylinders

It is important to understand that one of the features of these containers is their diversity. There are metal and composite cylinders, as well as gas cartridges. Of course, the most common type is the metal cylinder. Its advantage is its cost-effectiveness. The body of this cylinder consists of either low-carbon or alloy steel. Also attractive is the large selection of gas storage volumes. The volume of a carbon dioxide cylinder can be 5, 10, 12, 20, 27, 40, 50 liters.

It is important to note that storing a fifty-liter cylinder is allowed only outside in a special cabinet, as well as with special markings. Since the containers are made of metal, their mass is quite large, even if they are empty. The weight of one empty cylinder ranges from 4 to 22 kg and depends on the displacement.

One important point is that metal tanks are most often intended to store or transport large volumes of carbon dioxide. If the amount of substance is small, then it is better to choose a composite cylinder as storage. The main advantage of this type of tank is the lighter weight of the tank itself. The weight of a composite carbon dioxide cylinder will be approximately 70% less than a metal one.

What should the carbon dioxide pressure be on a semi-automatic machine?

The working pressure of carbon dioxide during semi-automatic welding is 0.02 kPa. But this indicator is not absolute; the presence of a draft or wind slightly increases the consumption of material. Accordingly, the pressure to create a normal seam will increase. The burner angle should be between 65-75°.

Interesting materials:

What should you do to be happy? What should you do to find the first factor? What should you do to avoid falling asleep while driving? What should you do if the shadows are scattered? What should you do with daffodils after flowering? What do you need for a shawarma business? What is needed to make bows? What is needed for a red certificate in 11th grade? What do you need to open a sewing studio? What do you need to send a parcel by cash on delivery?

Containers according to GOST

According to GOST 949-73, the volumes for CO2 cylinders are 5, 10 and 40 liters. They are used for storing, transporting and distributing gas to consumers. These devices must include the following parts:

- oxygen valve VK with a mass of 0.5 kg;

- 2 rubber transport rings;

- support shoe weighing 5.2 kg;

- a steel or re-certified cap, weighing 1.8 kg, or the same part, but made of fiberglass weighing 0.5 kg;

- a ring that fits onto the neck weighing 0.3 kg.

The production of metal cylinders with carbon dioxide should be carried out only from steel grade 45 D or from steel grade 40 X GSA, if it is a container with a volume of 40 liters.

Calculation of oxygen in cylinders

The parameters and dimensions of oxygen cylinders can be viewed according to GOST 949-73 “Small and medium steel cylinders for gases at Рр ≤ 19.7 MPa”. The most popular are cylinders with volumes of 5, 10 and 40 liters.

According to GOST 5583-78 “Gaseous technical and medical oxygen” (Appendix 2), the volume of gaseous oxygen in a cylinder (V) in cubic meters under normal conditions is calculated by the formula:

V = K1•Vb,

Vb — cylinder capacity, dm3;

K1 - coefficient for determining the volume of oxygen in the cylinder under normal conditions, calculated by the formula

K1 = (0.968P + 1) * *

P - gas pressure in the cylinder, measured by a pressure gauge, kgf/cm2;

0.968 — coefficient for converting technical atmospheres (kgf/cm2) into physical ones;

t is the gas temperature in the cylinder, °C;

Z is the oxygen combustion coefficient at temperature t.

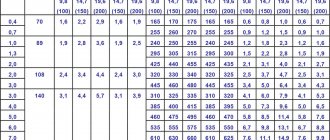

The values of the K1 coefficient are given in Table 4, GOST 5583-78.

Let's calculate the volume of oxygen in the most common cylinder in construction: a volume of 40 liters with a working pressure of 14.7 MPa (150 kgf/cm2). Coefficient K1 is determined according to Table 4, GOST 5583-78 at a temperature of 15°C:

V = 0.159 • 40 = 6.36m3

Conclusion (for the case under consideration): 1 oxygen cylinder = 40l = 6.36m3

Table 4. GOST 5583-78.

| Gas temperature in the cylinder, °C | The value of the Ki coefficient at excess pressure, MPa (kgf/cm2) | ||||||||||||||

| 13,7 (140) | 14,2 (145) | 14,7 (150) | 15,2 (155) | 15,7 (160) | 16,2 (165) | 16,7 (170) | 17,2 (175) | 17,7 (180) | 18,1 (185) | 18,6 (190) | 19,1 (195) | 19,6 (200) | 20,1 (205) | 20,6 (210) | |

| -50 | 0,232 | 0,242 | 0,251 | 0,260 | 0,269 | 0,278 | 0,286 | 0,296 | 0,303 | 0,311 | 0,319 | 0,327 | 0,335 | 0,342 | 0,349 |

| -40 | 0,212 | 0,221 | 0,229 | 0,236 | 0,245 | 0,253 | 0,260 | 0,269 | 0,275 | 0,284 | 0,290 | 0,298 | 0,305 | 0,312 | 0,319 |

| -35 | 0,203 | 0,211 | 0,219 | 0,226 | 0,234 | 0,242 | 0,249 | 0,257 | 0,264 | 0,272 | 0,278 | 0,286 | 0,293 | 0,299 | 0,306 |

| -30 | 0,195 | 0,202 | 0,211 | 0,217 | 0,225 | 0,232 | 0,239 | 0,248 | 0,253 | 0,261 | 0,267 | 0,274 | 0,281 | 0,288 | 0,294 |

| -25 | 0,188 | 0,195 | 0,202 | 0,209 | 0,217 | 0,223 | 0,230 | 0,238 | 0,243 | 0,251 | 0,257 | 0,264 | 0,270 | 0,277 | 0,283 |

| -20 | 0,182 | 0,188 | 0,195 | 0,202 | 0,209 | 0,215 | 0,222 | 0,229 | 0,235 | 0,242 | 0,248 | 0,255 | 0,261 | 0,267 | 0,273 |

| -15 | 0,176 | 0,182 | 0,189 | 0,196 | 0,202 | 0,208 | 0,215 | 0,221 | 0,227 | 0,234 | 0,240 | 0,246 | 0,252 | 0,258 | 0,263 |

| -10 | 0,171 | 0,177 | 0,183 | 0,189 | 0,195 | 0,202 | 0,208 | 0,214 | 0,220 | 0,226 | 0,232 | 0,238 | 0,244 | 0,250 | 0,255 |

| -5 | 0,165 | 0,172 | 0,178 | 0,184 | 0,190 | 0,195 | 0,202 | 0,207 | 0,213 | 0,219 | 0,225 | 0,231 | 0,236 | 0,242 | 0,247 |

| 0 | 0,161 | 0,167 | 0,172 | 0,179 | 0,184 | 0,190 | 0,196 | 0,201 | 0,207 | 0,213 | 0,219 | 0,224 | 0,229 | 0,235 | 0,240 |

| +5 | 0,157 | 0,162 | 0,168 | 0,174 | 0,179 | 0,185 | 0,190 | 0,196 | 0,201 | 0,207 | 0,212 | 0,217 | 0,223 | 0,228 | 0,233 |

| +10 | 0,153 | 0,158 | 0,163 | 0,169 | 0,174 | 0,180 | 0,185 | 0,191 | 0,196 | 0,201 | 0,206 | 0,211 | 0,217 | 0,222 | 0,227 |

| +15 | 0,149 | 0,154 | 0,159 | 0,165 | 0,170 | 0,175 | 0,180 | 0,186 | 0,191 | 0,196 | 0,201 | 0,206 | 0,211 | 0,216 | 0,221 |

| +20 | 0,145 | 0,150 | 0,156 | 0,160 | 0,166 | 0,171 | 0,176 | 0,181 | 0,186 | 0,191 | 0,196 | 0,201 | 0,206 | 0,211 | 0,215 |

| +25 | 0.142 | 0,147 | 0,152 | 0,157 | 0,162 | 0,167 | 0,172 | 0,177 | 0,182 | 0,186 | 0,191 | 0,196 | 0,201 | 0,206 | 0,210 |

| +30 | 0,139 | 0,143 | 0,148 | 0,153 | 0,158 | 0,163 | 0,168 | 0,173 | 0,177 | 0,182 | 0,187 | 0,192 | 0,196 | 0,201 | 0,206 |

| +35 | 0,136 | 0,140 | 0,145 | 0,150 | 0,154 | 0,159 | 0,164 | 0,169 | 0,173 | 0,178 | 0,182 | 0,187 | 0,192 | 0,196 | 0,201 |

| +40 | 0,133 | 0,137 | 0,142 | 0,147 | 0,151 | 0,156 | 0,160 | 0,165 | 0,170 | 0,174 | 0,178 | 0,183 | 0,188 | 0,192 | 0,196 |

| +50 | 0,127 | 0,132 | 0,136 | 0,141 | 0,145 | 0,149 | 0,154 | 0,158 | 0,163 | 0,167 | 0,171 | 0,175 | 0,180 | 0,184 | 0,188 |

Features of a CO2 cylinder

The carbon dioxide cylinder must be completely painted black and also have the inscription “CARBON ACID” made of yellow enamel. It is worth noting that the weight of the container is established without taking into account such parts as valves, rings, caps, shoes. In addition to the coloring and inscription, the tank must contain passport information about it.

This data is applied using the impact method. It is important to know that information is applied at the top of the cylinder, and its location is completely cleaned to a metallic shine and has a highlighting line 20-25 mm wide in yellow. Here is a list of information that a passport should contain:

- date of container production and year of subsequent inspection;

- what is the pressure of carbon dioxide in the cylinder (indicated in MPa (kgf/cm2);

- tank capacity (indicated in liters);

- empty container weight (indicated in kilograms);

- serial number of the tank and the brand of the company that manufactured it;

- the brand of the company that carried out the technical examination;

- the last stamp from the technical control department of the company that manufactured the tank.

l

Technical carbon dioxide 40 l

Description:

Information on accepting carbon dioxide cylinders:

Technical or food carbon dioxide , unlike Argon, Oxygen, Welding mixture, has a peculiarity: it is pumped (poured) into cylinders in liquid form in kilograms, the rest of the gases (except Acetylene) are pumped into cylinders from a liquid to a gaseous state!!!

Operating pressure in carbon dioxide cylinders filled with gas is from 30 atm. up to 80 atm. (oxygen, argon, nitrogen, welding mixture, helium 140-150 atm in gaseous form, depending on the ambient temperature), so the difference between the cylinders currently stored outside and indoors may be different, low pressure of carbon dioxide (according to the pressure gauge on the reducer) does not mean that the cylinder is not fully filled. The technical characteristics of the cylinders indicate the working pressure of the vessel itself ( 147 atm. as a rule, and it has nothing to do with the pressure of the gas itself - carbon dioxide!!! All high-pressure cylinders, except Acetylene, are the same and are intended for different types of gas, the difference can only be valve and painting. And of course, you cannot refill cylinders that were originally prepared and already filled with oxygen or argon, other gases, for example nitrogen or helium, since different gases may be incompatible and the cylinder always contains remnants of the previous gas and its residual pressure) .

Acceptance of a filled carbon dioxide cylinder must be by weight!!!

The construction site has run out of carbon dioxide, call 8-925-123-33-99.

Carbon dioxide cylinders 40 l steel can be rented or purchased with delivery for exchange or pickup in Moscow . Purpose: transportation and storage of carbon dioxide (carbon dioxide) in cylinders with a volume of 40 liters. GOST 949-73 Carbon dioxide in cylinders is the well-known carbon dioxide, carbon dioxide (or carbon dioxide). Carbon dioxide is a non-toxic, colorless gas that has a sour odor and corresponding taste. Carbon dioxide cylinders are one of the most used technical gases in the national economy. Gas carbon dioxide cylinders are used in the food industry (food storage and production), medicine, gas welding industry and in production when carrying out welding work. Household gas cylinders containing carbon dioxide are used for carbonating drinks, as well as for feeding flower, fruit and vegetable crops in greenhouses.

Carbon dioxide refilling carried out in our company meets all necessary safety standards. In addition to refilling with carbon dioxide, you can order new carbon dioxide cylinders with delivery at reasonable prices in Moscow.

Refilling cylinders of 10 and 40 liters with carbon dioxide (carbon dioxide) in our company is carried out only after the cylinder has been checked at a special stand for its technical serviceability and the period of certification (inspection) of the cylinder (visual inspection of the body, valve threads, presence of depressurization of threaded connections), this ensures safety when refueling and further operation of any 10 or 40 liter gas cylinder. You can buy carbon dioxide by leaving a request on our website or by contacting us by phone at 8-495-664-65-83.

Characteristics:

| Cylinder volume, l | 40 |

| Working pressure, MPa | 14,7 |

| Height, mm | 1400 |

| Diameter, mm | 219 |

| Material | Steel 45, D |

| Cylinder weight, kg | 65 |

| Locking device type | valve |

| Gas volume m3 | 6,0 |

| Gas weight | 19-24 kg |

| GOST | 949-73 |

Technical specifications

Depending on the capacity of the container, various technical requirements are imposed on it. If the tank is produced with a volume of 5 liters, then the grade of steel that should be used for its production is 45 D. The pressure of carbon dioxide in a cylinder with such a displacement should be 14.7 MPa (kgf/cm2). The diameter of such a cylindrical container is 140 mm, length is 475 mm, and weight is 8.5 kg.

Cylinders with a capacity of 10 liters are manufactured from the same grade of steel as 5-liter ones. The pressure in such tanks, as well as their diameter, also corresponds to the previous type. The length of such a cylinder should be 865 mm, and the weight should be 8.5 kg.

A 40-liter carbon dioxide cylinder can be made of 45 D steel or 40 X GSA steel. If production is carried out from the first grade of steel, then the pressure in it also remains at the level of 14.7 MPa (kgf/cm2), and if from steel 40 X GSA, then the working pressure increases to 19.5 MPa (kgf/cm2). The diameter of both gas tanks will be 219 mm. The length of a cylinder made from steel 45 D will be equal to 1370 mm, and from steel 40 X GSA 1350 mm. The weight of the container made from the first grade of steel is 58.5 kg, and from the second - 51.5 kg.

How much carbon dioxide does the cylinder hold?

The use of carbon dioxide has recently been actively expanding into new areas. If initially the material was used exclusively in production and industrial sites due to the fact that the welding seam is as correct as possible and free of excess burning, then recently the cylinders have found their use in medicine, as a freezing agent in operating units; in perfume factories to obtain a pure, chemical-free, odor-free and uniform consistency; in the food segment, in cafes and restaurants.

Each of the potential clients, before buying carbon dioxide, chooses their own volume that suits them.

Typical volume options

- For industrial facilities, cylinders of 40 to 50 liters are used due to the fact that they do not need to be refilled frequently; plus there is a technical base for transporting them to hard-to-reach places;

- Owners of bars and restaurants use cylinders with a volume of 10–15 liters on average to pour drinks from kegs, which lasts for a month to a month and a half.

- For operating rooms and beauty salons (removal of warts with frozen acid), small forms of 5 liters or more are used, since this is not a very frequent procedure.

| Cylinder volume | Volume of gas in the cylinder | Weight of gas in cylinder | |

| Carbon dioxide GOST 8050-85 | 40 l | 6.0 cubic meters | 20-24 kg |

| 10 l | 1.6 cubic meters | 6 kg | |

| 7 l | 1.1 cubic meters | 4.2 kg |

Rules for calculating weight for transportation

By purchasing products from, you will receive valuable information that gas is sold not in liters, but in kilograms, and its ratio in the container is in the range of 50–60% of the entire capacity. That is, if a cylinder with a volume of 10 liters, then the maximum, taking into account the permissible operating pressure, can be pumped into it 5-6 kg.

On average, the density of the material approaches 1, so the weight of the cylinder increases noticeably. During the process of refueling and further transportation, it is necessary to apply physical force to load and then unload the gas container.

Taking into account the different heights from 100 to 140 cm, the cylinders are stored in special boxes. The manufacturer is relying on increasing the overall volume, rather than the height indicator.

Comparative technical specifications table

| Operating pressure | 14.7 MPa (150 kgf/cm2) | 19.6 MPa (200 kgf/cm2) |

| Capacity | 40 liters | 40 liters |

| Diameter of cylindrical part | 219 mm | 219 mm |

| Cylinder body length | 1400 mm | 1460 mm |

| Cylinder weight | 65 kg | 90 kg |

When transporting a filled cylinder, it is necessary to check the fixation of the protective cap, and only then move. Carbon dioxide is transported horizontally with additional rubber gaskets, while a new filled cylinder cannot be thrown, crushed, or left exposed to direct sunlight. Mobile cylinders must also be transported and stored vertically, and it is recommended that, for example, there are no electrical communications or fires under the bar counter. Even though the gas is safe, safety regulations must be followed due to the compressed pressure.

Carbon dioxide is also known to many in the form of fire extinguishers in buses, trains and electric vehicles - cylinders with a volume of no more than 2 liters, and wholesale quantities are transported along roads and railways in a closed carriage or no more than 20 units in a passenger car. The company also refills fire extinguishers for businesses and individuals.

Carbon dioxide is stored for a long time, and by refilling the cylinder at Cryogenservice, you don’t have to worry about the accuracy of the calculation and receive an additional 15% discount.

cryogenservis.ru

Application of cylinders

Below are some applications of these CO2 tanks.

- In medicine, they are used during freezing in the operating room.

- In the food industry they are used in the production of carbonated drinks, as well as some cocktails.

- They are also used in the perfume industry to produce perfumes with a rich aroma and without an unpleasant, specific odor.

- Of course, they are used when carrying out construction or repair work during welding of a structure, where the formation of additional carbon deposits cannot be allowed.

It is also worth noting that all carbon dioxide cylinders are conventionally divided into three categories. The first includes small containers - 2, 5, 10 liters. The second includes medium tanks from 20 to 40 liters, and the third large - from 40 liters and more. The demand for each category depends on the scope of their use. For example, in industrial sectors medium and large cylinders are used because they do not need to be refilled very often. It is important to note that each tank must be certified every 5 years.

How much does nitrogen weigh?

Under normal conditions, nitrogen is a colorless gas, odorless, slightly soluble in water (2.3 ml/100 g at 0 °C, 1.5 ml/100 g at 20 °C, 1.1 ml/100 g at 40 °C, 0.5 ml/100 g at 80 °C), density 1.2506 kg/m³ (at ambient).

Interesting materials:

What is the cube of the sum and difference? What is the volume of a regular triangular prism with base side a and? What is one newton equal to in grams? What is 1 Aeroflot mile equal to? What is the electric field strength? What is the total surface area of a regular quadrangular pyramid? What is the length of the borders of Kyrgyzstan? What is the standard AC frequency? What is the standard frequency of an industrial generator? What is the side of a regular polygon?

Pressure parameters

When using these containers, it is important to know that they have two pressure indicators. The first indicator includes the operating pressure, which, subject to all the rules for operating and transporting the tank, should not go beyond 150 Atm. The second type of pressure is test pressure, which becomes more important during the stage of connecting the main system. This parameter should not be higher than 225 Atm. It is also worth noting that when ordering these containers, you must make sure that there is a protective cap.

It can be added that after some chemical research, as well as laboratory observations, it was found that CO2 in the tank is the safest gas among all, and therefore it can be used in open areas.

Characteristics of gas in the cylinder

You can start with the fact that the cost of this substance is quite low. This product does not have any color and is also non-toxic. Carbon dioxide is obtained during the combustion of coal fuel, gaseous waste from the alcohol and sugar industries. At a temperature of carbon dioxide in a cylinder of +31 degrees Celsius and a pressure of 75.3 atm, this substance is liquefied. As the temperature decreases, the liquefaction pressure will also decrease.

It is important to note that at a temperature of -78.5 degrees Celsius, this substance will begin to transition from a gaseous to a liquid state. During the evaporation of 1 kg of liquid, 505 liters of gas will be obtained. It is also important to note that during storage and transportation this product is in a liquid state under a pressure of 60-70 atm. Another important fact is that a 40-liter cylinder holds only 25 kg of liquid carbon dioxide. When the entire volume of liquid evaporates, 12,600 liters of gas will be obtained.

How many cubes are there in a carbon dioxide cylinder? How much do oxygen cylinders weigh?

Oxygen is widely used in construction, industry and medicine. It is transported and stored in oxygen cylinders. The weight of an oxygen cylinder is one of its main parameters. The weight of an empty oxygen cylinder consists of several components: the gas container itself, the valve, the cap and the ring for screwing on the cap. This kit may include a shoe to give the product stability. In the manufacture of containers for compressed gases, seamless pipes made of carbon or high-alloy steel are used, with a wall thickness of 7 mm. A piece of pipe of the required length, using the crimping method, is given a spherical shape at one end, and at the other, a neck is formed to attach the shut-off valve. A ring is pressed onto the neck intended for fastening the gearbox. The cap is designed to protect the gearbox from external mechanical influences. The included accessories have a significant mass that must be taken into account.

Average set weight:

- ring – 0.3 kg

- metal cap – 1.8 kg

- shoe – 5.2 kg

The weight of a 40 l oxygen cylinder is indicated in the table:

Weight is indicated without balloon valve (0.5 kg), ring (0.3 kg), metal cap (1.8 kg), shoe (5.2 kg).

The weight is indicated taking into account the balloon valve (0.5 kg), ring (0.3 kg), metal cap (1.8 kg), shoe (5.2 kg). The data in the tables corresponds to GOST 949 – 73. The weight of a full oxygen cylinder for 150 atmospheres is 73 kg, and for 200 atmospheres – 88 kg.

At a nominal pressure of 150 kgf/cm2, a vessel of such capacity holds 6 m3 of oxygen or 6000 liters. Due to the gas, the difference in weight of a full and empty oxygen cylinder is:

- for 200 - atmospheric: about 11.5 kg

- for 150 – atmospheric: about 8 kg

The weight of a 50 l oxygen cylinder is indicated in the table:

Weight is indicated without balloon valve (0.5 kg), ring (0.3 kg), metal cap (1.8 kg), shoe (5.2 kg). The weight of an oxygen cylinder of this volume filled with gas:

- for 200 – atmospheric: 117 kg

- for 150 – atmospheric: 72 kg

The weight of the new oxygen cylinder is 40 liters, which our company offers is 47 kg. You can find out more information by calling the numbers listed at the top of the site.

Oxygen is a colorless and odorless gas that actively supports combustion. The density of oxygen gas is 1.43 kg/m3 (at a temperature of 0 degrees Celsius and a pressure of 760 mm Hg), which is 1.11 times heavier than air, therefore gaseous oxygen released from the cylinder accumulates in the lower part of the room, filling all pits and trenches and lingers there for a long time, forming an oxygenated zone. The maximum permissible oxygen content is 23%. According to its chemical properties, oxygen is a strong oxidizing agent. Oil explodes in an oxygen environment, so all parts operating in an oxygen environment must be clean of oil.

Note: in order to avoid overfilling the cylinders, in accordance with the “Rules for the design and safety of operation of pressure vessels”, it is allowed to fill the cylinder at 1-2 atm. below the values indicated in the table.

Oxygen accounts for about 47% of the mass of the solid crust. Sea and fresh waters contain a huge amount of bound oxygen - 88%, in the atmosphere the content of free oxygen is 20% by volume, or 23% by mass. The element is part of more than 1,500 compounds.

Gaseous oxygen is produced by gasification from liquid oxygen. The raw material for gasification - liquid oxygen - is obtained from atmospheric air using air liquefaction devices - turboexpanders. Next, liquid oxygen is transported to the place of its use in cryogenic containers such as thermos tanks. The station for pumping oxygen into cylinders is a filling point consisting of reserve and working tanks, a cryogenic pump, an evaporator and a device for direct distribution of gas into cylinders - a filling ramp. Oxygen is pumped into a cylinder under a pressure of 150 atm at a temperature of 20 degrees Celsius. Oxygen is used in industry and medicine. Technical oxygen GOST 5583-78 is used in autogenous cutting and gas welding, metallurgy, chemical industry, metalworking, and as a fuel component in liquid rocket engines.

Oxygen cylinders GOST 949-73 are accepted for filling in volumes of 40, 10 and 5 liters. Cylinders are made of steel by hot rolling. Typically, cylinder bodies for all technical gases with a volume of 40 liters are produced in two types - with a working pressure of 150 or 125 atm. Oxygen cylinders must be painted blue and have the inscription “oxygen” in black. The cylinders are equipped with valves of the VK-86 or VK-94 brand. Cylinders with a working pressure of less than 150 atmospheres, without shoes, oily, previously filled with other gases, or with traces of mechanical damage or corrosion are not accepted for filling with oxygen. The cylinder is certified once every five years.

Pressure in a full oxygen cylinder depending on the ambient temperature:

| Ambient temperature environment C | -30 | -20 | -10 | 0 | 10 | 20 | 30 |

| The pressure in the cylinder is no more than P kg/cm | 110 | 120 | 130 | 135 | 140 | 145 | 150 |

Oxygen cylinder (volume 40 liters)

Main technical characteristics: Cylinder diameter: 219 mm Weight: from 65 to 75 kg Capacity: 40 l Height: 1430 mm Operating pressure: 14.7 MPa

People have long known the life-giving power of the most common element on our planet - oxygen. In addition to the natural life support of most living organisms, oxygen is widely used in medicine, metallurgy, chemical and food production, as well as in agriculture. It began to be used on an industrial scale from the middle of the last century, when a device was invented for liquefying and separating liquid air into components with the subsequent release of oxygen. Oxygen for widespread use is produced and stored in special cylinders. They come in two types - technical and medical. Currently, the leading supplier of technical and medical gases in Ukraine and Europe and the CIS countries is.

Medical cylinders

Medical institutions use oxygen contained in cylinders for breathing procedures that restore the body. This gas is used in medicine to treat asthma, angina pectoris, pneumonia, heart failure, restore the respiratory, nervous and cardiovascular systems and improve metabolic processes in the body. In addition, oxygen relieves symptoms and speeds up treatment in a number of other complex diseases. Recently, the popularity of oxygen cocktails – drinks saturated with this gas that improves health and well-being – has been gaining momentum. Lack of oxygen - hypoxia - can often cause negative and irreversible changes in the body's systems. Visiting oxygen bars and drinking cocktails enriched with oxygen will help restore immunity, metabolism, get rid of stress and reduce accumulated fatigue.

Technical cylinders

Currently it is also engaged in the supply of technical oxygen, being one of the confident leaders in the field of sales of industrial gases. Gaseous and liquid technical oxygen is used in many industrial fields - construction, production of military equipment, oil production and chemical industries, as well as metallurgy and agriculture. The use of liquid technical oxygen is typical for the rocket industry - it is used as a fuel oxidizer. In the chemical industry it is used to create explosives, sulfuric and nitric acids, ammonia and methyl alcohol. In addition, much larger gaseous oxygen is produced from liquid oxygen, which is convenient for storage and transportation. In the metallurgical industry, oxygen for welding and metal processing is also supplied in liquid form. Gaseous oxygen in cylinders is used in a much larger number of areas: for the enrichment of water bodies with oxygen, the production of explosives, acetylene, ammonia, methane, methyl alcohol, acids, steel, for flame cutting and welding of metals. In addition, oxygen gas is used in the food industry (as a propellant, packaging gas and food additive) and in agriculture. Enterprises operating in the metallurgical industry, as a rule, prefer to purchase oxygen gas, using it for melting and processing non-ferrous metals and in steelmaking units for the production of high-strength alloys. When purchasing significant volumes of this gas and there is a high probability of further cooperation, the company may be provided with significant discounts. offers customers technical oxygen of excellent quality at the most affordable prices, and also provides its customers with timely delivery of cylinders and refilling them with oxygen.

Technical oxygen is sold in blue cylinders with a black inscription and without stripes. Oxygen cylinders are sold in full compliance with GOST requirements. The offered oxygen includes: - gaseous technical (first grade), purity 99.7%. A 40 liter cylinder contains 6.2 cubic meters. m of gas at a pressure of 150 kgf/sq. see Regulatory document: DSTU GOST 5583-09; — medical gas, 99.5% purity. A 40 liter cylinder contains 6.2 cubic meters. m of gas at a pressure of 150 kgf/sq. see Regulatory document: DSTU GOST 5583-09.

Gas cylinders are used in everyday life and in industrial production: heating a home, cooking, welding, refueling a car. The cylinders store oxygen, propane, hydrogen, argon, nitrogen, and helium. It is sealed and opaque. How to find out the amount of content?

Causes

The homeowner expects to have enough fuel for the winter. The welder uses it for work. The engineer tries to correctly estimate the volume of the estimate. And you just don’t want to throw away a useful thing if there is content.

Define roughly

Rock the balloon slightly. You will hear a slight splash at the level where the substance is located. A ball is placed inside. If it rattles at the bottom, the vessel is empty. Otherwise the sound will be muffled.

Let's weigh it

You will need three things: durable floor scales, a full cylinder, and a conditionally empty one. On factory products, the mass is stamped. Use complete cylinders with footrest and valve. After weighing, determine the arithmetic difference in kilograms.

Pressure

A full vessel with propane has a pressure of 1.6 MPa, and an empty vessel has a pressure of 0.005 MPa. If the cylinder is rusty and the pressure gauge does not show residual pressure, it will have to be thrown away. This indicator guarantees the integrity of the container and the ability to check for safety. No one will undertake refueling with zero parameters.

Volume and weight of gases

Compressed and dissolved

Technical oxygen and acetylene are produced in cylinders: 40, 10 and 5 liters. Propane-butane is stored in containers: 50, 27, 12, 5 liters. Under standard conditions in a volume of 40 liters, technical gases have the following mass:

- Nitrogen 7.5 kg (5.7 m3)

- Argon 7.5 kg (6.3 m3)

- Helium 1 kg (5.7 m3)

- Oxygen 8.3 kg (6.3 m3)

- Carbon dioxide from 20 to 24 kg (6.0 m 3)

- Dissolved acetylene 6.0 kg (5.5 m 3)

Propane has a mass of 21.5 kg (9.5 m 3) in a volume of 50 liters.

Liquefied

Based on capacity, cylinders are divided into groups:

Transparent walls

The gaseous substance in a vessel made of transparent material is easy to control. Availability is determined by weighing, pressure readings on the pressure gauge and visually. Transparency does not change depending on the service life and type of gas. The vessels are made of composite polymers (fiberglass).

Formulas will help

For oxygen

V = K coefficient × V b

K=((0.968× D + 1) × 293×10 -3)/((273+ T) × Z)

V b in dm 3 ─ capacity, D in kgf/cm 2 ─ pressure gauge data, Z ─ oxygen combustion coefficient. The parameter 0.968 kgf/cm2 recalculates the technical indicators of atmospheres.

For propane and butane

Gas mass = V cylinder m3 × (0.4× Flat prop. + 0.6 × Flat bottle)

Under normal conditions, the density of liquid propane is 510 kg/m3, and butane is 580 kg/m3. The numbers 0.4 and 0.6 indicate the percentage of chemical elements.

Refilling cylinders with carbon dioxide

Several methods can be used to fill a tank with gas. The first method is to transfer the substance from one cylinder to another. In order to carry out this process, it is necessary to use specialized equipment, as well as adapters. The most important point when refilling is weighing the container, since this is the only way to determine how much of the substance is inside after refilling.

It is possible to use specialized installations for pumping gas using a compressor to fill a cylinder with carbon dioxide. This method is considered more relevant, since it provides more accurate filling of the gas cylinder, and also minimizes the loss of substance during this operation. In order to understand how full the cylinder is, it is also necessary to use container weighing.

It is worth noting that to carry out the refueling process, it is necessary to turn the container, which is the donor, down with the valve so that it is as close to the floor as possible. After this, a high-pressure hose is screwed to it, which will serve as a conductor of the substance from one reservoir to another.